📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

System Installation Cost: A Strategic Guide to Budgeting Your AGV & AS/RS Project

For any logistics manager or business leader contemplating automation, the question of system installation cost is paramount. However, a truly accurate understanding of this figure extends far beyond a simple equipment price list. The final system installation cost for an Automated Guided Vehicle (AGV) or Automated Storage and Retrieval System (AS/RS) project is a complex variable, shaped by engineering choices, software depth, and regional logistics.

This definitive guide provides a granular, transparent look into the components that define this investment. It empowers decision-makers in markets like Southeast Asia, the Middle East, and Latin America to move beyond vendor price tags and understand the value equation, enabling them to secure a transparent quote for a solution that delivers a robust and rapid return on investment.

Deconstructing the Total Investment: What “System Installation Cost” Really Means

In the realm of warehouse automation, the term system installation cost is frequently misunderstood. It is not a single line item but a comprehensive capital outlay that merges tangible assets with intellectual capital and transformative labor. A superficial focus on the lowest initial bid often leads to a higher Total Cost of Ownership (TCO). A meticulously planned system installation cost, while potentially higher upfront, is engineered for longevity, scalability, and operational thrift. The true system installation cost is the price of achieving a future-state operation that is fundamentally more efficient, accurate, and competitive.

This holistic investment encompasses several critical pillars:

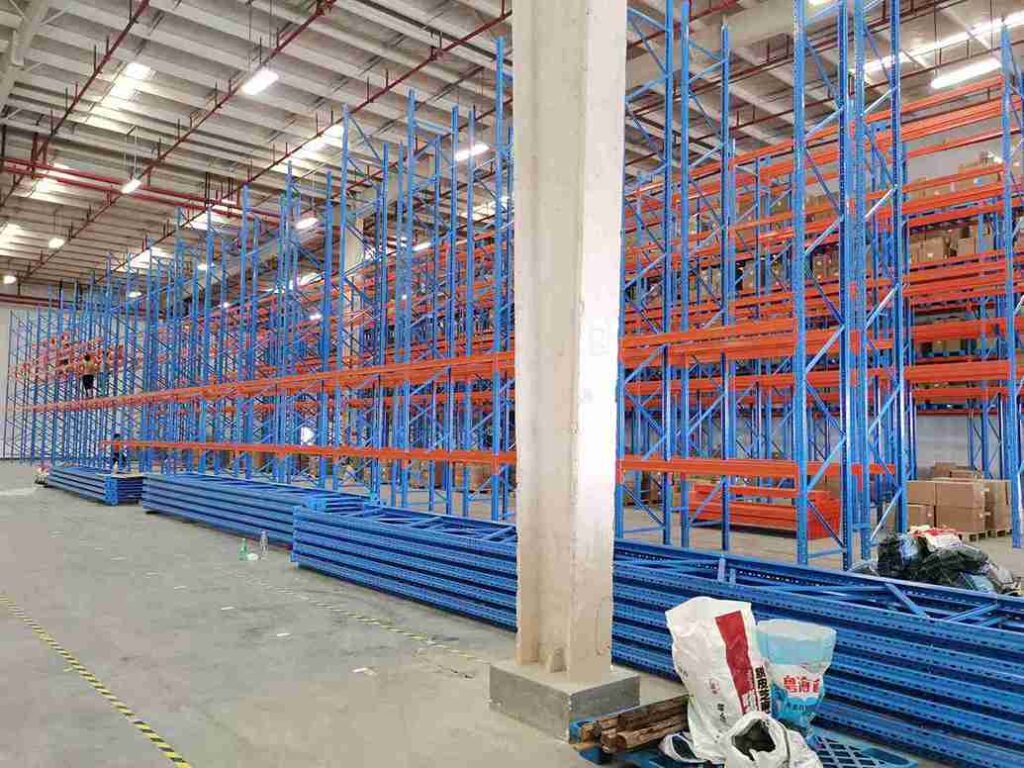

Capital Hardware Expenditure: This includes the physical components—the AGV fleet, the structural steel of the AS/RS, the stacker cranes, and conveyance systems.

The Software Nervous System: The intelligence layer, including the Warehouse Management System (WMS), the real-time Warehouse Control System (WCS), and fleet management software, constitutes a significant portion of the modern system installation cost.

Site Readiness and Civil Works: This is a frequently underestimated variable in the system installation cost equation, covering essential groundwork like floor flattening, structural reinforcement, and power upgrades.

Professional Integration Services: The cost of expertise—system design, project management, and commissioning—ensures all components operate in synchrony, a non-negotiable element of a successful system installation cost.

Future-Proofing Provisions: Allocation for comprehensive operator training, initial spare parts kits, and a clear post-installation support model are integral to a realistic system installation cost projection.

The Primary Levers Controlling Your AGV & AS/RS Installation Budget

Project Scale and Operational Complexity: The Core Determinants

The physical and operational scope of a project is the most influential factor governing the final system installation cost. A compact system with five AGVs for line-side delivery is fundamentally different from a high-bay, fully automated distribution center. Therefore, the system installation cost is directly proportional to the operational ambition.

Key determinants that suppliers analyze to calculate the system installation cost include:

Storage Density and Dynamic Throughput: The number of pallet or tote locations and the required movements per hour (lines picked, pallets stored/retrieved) directly dictate the scale of hardware and the sophistication of software needed, thereby scaling the system installation cost.

Degree of Automation Integration: The choice between a goods-to-person automated system and a more modular, assisted-picking solution creates a substantial variance in the system installation cost. A fully automated “lights-out” facility commands a higher system installation cost but offers the greatest labor savings.

System Interfacing Requirements: The depth of integration required with existing Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), or legacy material handling equipment adds layers of software complexity, influencing the overall system installation cost.

Hardware Configuration: A Major Variable in the Cost Equation

The selection of specific technologies creates significant divergence in the projected system installation cost.

AGV Technology and Navigation Philosophy: The choice of AGV guidance—from cost-effective magnetic tape to flexible vision-based navigation—carries different price points and implications for future reconfiguration, impacting the long-term agility factored into the system installation cost. Load capacity, battery systems, and safety sensor packages further differentiate the system installation cost per vehicle.

AS/RS Typology and Performance Specs: A unit-load AS/RS for pallets has a different system installation cost profile per location compared to a high-speed mini-load system for totes. The specification of the stacker crane—its vertical and horizontal travel speeds, acceleration/deceleration rates, and duty cycle—is a critical driver of the system installation cost for the storage system.

The Cognitive Layer: Software’s Role in the Total System Installation Cost

Underestimating the software component is a common pitfall in budgeting for automation. The hardware provides the muscle, but the software provides the brains. An underpowered software suite can cripple the performance of a high-end hardware investment, negating the value of the entire system installation cost.

Warehouse Management System (WMS) Licensing: This top-level system manages inventory, orders, and billing. Whether licensed perpetually or as a Software-as-a-Service (SaaS) model, its cost is a fixed element of the system installation cost.

Warehouse Control System (WCS) and Custom Code: The WCS is the real-time nerve center, issuing commands to every automated device. Its development, licensing, and integration represent a substantial, and vital, portion of the intelligent system installation cost.

Data Integration and API Fabric: Creating robust Application Programming Interfaces (APIs) to seamlessly connect new automation with legacy systems requires specialized development effort, adding a layer to the technical system installation cost.

Unmasking the Hidden Contributors to the Final System Installation Cost

Site Preparation: The Foundational Investment

The condition of the existing facility is a wild card that can dramatically alter the final system installation cost. A comprehensive site survey is essential to uncover these potential costs.

Floor Flatness and Structural Integrity: AGVs require exceptionally flat floors (specified by F<sub>F</sub>/F<sub>L</sub> ratios) for stable operation. AS/RS racks demand a perfectly level and load-bearing foundation. Remediating an inadequate slab is a major civil works project that can escalate the system installation cost.

Building Envelope and Clear Height: Installing a high-bay AS/RS may require raising the roof or reinforcing support columns. These structural modifications are among the most significant potential adders to the baseline system installation cost.

Utilities and Network Infrastructure: Automated systems are power-intensive and data-dependent. Upgrading electrical supplies, installing charging infrastructure, and deploying a resilient, facility-wide industrial WiFi network are necessary investments that contribute to the foundational system installation cost.

The Price of Expertise: Professional Services and Project Management

The system installation cost is not merely for products; it is for proven expertise. The cost of experienced professionals is embedded in a reliable project quote.

Detailed Engineering and System Simulation: Prior to installation, hundreds of hours are invested in 3D modeling and discrete-event simulation. This digital twin validates system performance and optimizes workflows, an upfront cost that prevents expensive field modifications and is a wise component of the system installation cost.

Dedicated Project Governance: A seasoned project manager acts as the client’s single point of accountability, orchestrating the entire process from factory acceptance tests to final commissioning. This oversight is a critical line item in a professional system installation cost proposal.

Commissioning and Site Acceptance Testing (SAT): The process of bringing the system live, fine-tuning software parameters, and rigorously testing against performance metrics requires a team of engineers on-site for an extended period. This final phase is a definitive part of the system installation cost that ensures operational readiness.

A Framework for Clarity: How to Secure a Truly Transparent Quote

A transparent quote is an educational document that demystifies the system installation cost. It should empower the client, not confuse them. When evaluating proposals, leaders should insist on the following:

A Granular, Itemized Breakdown: The system installation cost should be dissected into clear categories: hardware, software, professional services, and potential site works. Ambiguity is a red flag.

A Referenced Assumptions Document: The quoted system installation cost must be tethered to a detailed System Requirements Specification (SRS). This ensures all vendors are pricing against the same operational benchmarks.

A Phased Project Timeline with Milestones: A credible partner provides a realistic schedule, linking the system installation cost to a timeline for design, manufacturing, installation, and commissioning.

A Total Cost of Ownership (TCO) Analysis: Beyond the initial system installation cost, a valuable proposal projects operational savings, maintenance costs, and the anticipated ROI period, contextualizing the investment.

Explicit Post-Installation Support Terms: The quote must clearly outline warranty coverage, service level agreements (SLAs), and the cost structure for ongoing support, completing the picture of the long-term system installation cost.

The Geographic Variable: How Location Influences System Installation Cost

The system installation cost for an identical system will vary between Singapore, Dubai, and Mexico City. A provider with deep regional experience is essential to navigate these variables.

Logistics, Tariffs, and Local Compliance: Shipping heavy racking and sophisticated robots involves complex logistics. Freight costs, insurance, and import duties can significantly impact the landed system installation cost. Furthermore, compliance with local building codes and electrical standards may necessitate specific adaptations.

Labor Markets and Climatic Adaptations: The cost and availability of skilled local installation teams differ by region. Additionally, systems in the Middle East may require enhanced cooling, while coastal facilities in Southeast Asia need specific anti-corrosion treatments, both affecting the final system installation cost.

The Justification: Calculating ROI to Contextualize the System Installation Cost

The ultimate metric is not the system installation cost itself, but the value it unlocks. A rigorous ROI analysis transforms the system installation cost from an expense into an investment.

Direct Labor Optimization: Automation significantly reduces reliance on manual forklift operators, pickers, and stock-takers. In regions with rising wages and labor shortages, this saving powerfully offsets the system installation cost.

Radical Space Optimization: An AS/RS can increase storage density by over 100%, effectively doubling the capacity of a existing footprint. The value of this saved real estate is a direct financial benefit that amortizes the system installation cost.

Unprecedented Accuracy and Damage Elimination: Automated systems achieve near-perfect inventory accuracy and virtually eliminate product damage from mishandling. The savings from reduced shrinkage and claims directly improve the payback period on the system installation cost.

Predictable, Scalable Throughput: An automated facility operates with consistent, predictable performance, enabling higher service levels and business growth without a linear increase in operational overhead, thereby justifying the initial system installation cost.

A Phased Implementation Strategy: Mitigating Risk and Managing Cash Flow

For organizations cautious of a single, large capital outlay, a phased approach to automation provides a strategic path forward. This methodology distributes the system installation cost over multiple budget cycles, building confidence with each successful phase.

Phase 1: Pilot an AGV Fleet: Deploy a small fleet of AGVs for a specific, high-volume task, such as moving raw materials from receiving to production lines. This allows the organization to validate the technology and its benefits with a contained initial system installation cost.

Phase 2: Integrate a Mini-Load AS/RS: Automate the storage and retrieval of fast-moving small parts. This demonstrates the power of high-density storage and goods-to-person ergonomics, adding a second, justifiable segment to the overall system installation cost.

Phase 3: Scale and Integrate: Expand the AGV fleet and integrate a unit-load AS/RS for pallet handling, weaving the automated components into a seamless, facility-wide ecosystem. The total system installation cost is thus achieved through a series of managed, value-proven investments.

Selecting the Right Partner: The Ultimate Factor in System Installation Cost Control

The choice of automation partner is the most critical decision in the process. A supplier selected solely on the lowest initial system installation cost represents a profound risk. The right partner delivers value, reliability, and long-term operational stability.

Single-Source Accountability and Integration: A provider that delivers the racking, AGVs, software, and integration as a unified solution eliminates vendor finger-pointing and ensures accountability for the entire system installation cost and system performance.

Demonstrable Regional Experience: A partner with a proven track record in the specific challenges of a client’s region—be it the supply chain nuances in Vietnam or the climate extremes of the Gulf—brings invaluable insight that de-risks the system installation cost and project execution.

In-House Software and Control Expertise: Suppliers that develop their own WCS possess a deeper ability to customize, troubleshoot, and optimize the system, protecting the intelligence value embedded in the system installation cost.

A TCO-Centric Design Philosophy: A reputable partner designs for low lifetime maintenance and high uptime. Using premium components and structured engineering, they focus on minimizing the operational costs that follow the initial system installation cost, safeguarding the client’s long-term ROI.

Conclusion

Navigating the intricacies of the system installation cost for an AGV or AS/RS project is a strategic exercise in financial and operational planning. It requires a shift in perspective from viewing this as a mere capital expense to understanding it as a transformative investment in competitive capability. A deep, granular comprehension of all cost components—from the foundational civil works to the cognitive software layer—empowers businesses to engage with suppliers from a position of strength. The objective is to commission a system that delivers relentless, measurable value for years, making the initial system installation cost one of the most astute strategic investments a modern logistics-dependent enterprise can make.

Frequently Asked Questions (FAQs)

1. Beyond equipment, what is the single most often overlooked factor that increases the final system installation cost?

The most frequently underestimated factor is site preparation, specifically floor flatness and structural reinforcement. Many facilities require significant civil works to meet the stringent tolerances of automated systems, and this cost is often only confirmed after a detailed site survey, leading to unplanned additions to the initial system installation cost projection.

2. How does the software licensing model (SaaS vs. Perpetual) impact the long-term financial profile of the system installation cost?

A perpetual license typically front-loads the system installation cost, while a SaaS model operationalizes it as an ongoing annual fee. The SaaS model lowers the initial capital outlay but results in a higher Total Cost of Ownership over a 10-year period. The choice affects both the project’s CAPEX and long-term OPEX, changing the financial profile of the system installation cost.

3. For a business with seasonal peaks, how can the system installation cost be justified?

The system installation cost is justified by designing a system that handles peak volumes efficiently without requiring seasonal labor, which is often costly and difficult to train. The automation provides a fixed, predictable operational cost during peaks, preventing revenue loss due to capacity constraints and protecting service levels, thereby justifying the system installation cost through peak-season performance and brand protection.

4. What are the typical ongoing maintenance costs as a percentage of the original system installation cost?

As a general rule, businesses should budget 3-5% of the original system installation cost annually for a comprehensive preventive maintenance program and support agreement. This cost ensures high system availability and protects the health of the asset, safeguarding the value of the initial system installation cost investment.

5. Can a modular approach to automation help manage the initial system installation cost?

Absolutely. A modular approach allows a company to address its most pressing pain point first with a contained system installation cost. The ROI generated from this first module can then help fund subsequent phases. This step-by-step strategy makes the overall system installation cost more manageable and lessens the perceived financial risk, building internal buy-in for a full-scale automation journey.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com