📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Introduction to Zero-Waste Warehousing

Zero-waste warehousing is no longer a niche concept—it’s a business imperative. By redefining how warehouses manage resources, energy, and waste, companies can slash costs, comply with tightening regulations, and meet consumer demand for eco-friendly logistics. This guide unpacks actionable strategies, from lean inventory management to cutting-edge green technologies, helping businesses transition from linear “take-make-dispose” models to circular, waste-free ecosystems.

The Environmental and Economic Impact of Waste in Warehousing

The logistics sector generates 23% of U.S. landfill waste annually (EPA), with warehouses contributing significantly through packaging, energy overuse, and obsolete stock. Financially, waste disposal and inefficiencies drain 8–12% of operational budgets. However, pioneers like Patagonia and Unilever prove that zero-waste warehousing isn’t just eco-friendly—it’s profitable. For example, Unilever’s reusable crate system reduced packaging costs by 15%, while Patagonia’s Reno center achieved 97% landfill diversion through closed-loop recycling.

Key Principles of Zero-Waste Warehousing

1. Reduce, Reuse, Recycle: The Core Triad

- Reduce: Opt for digital documentation and minimalist packaging.

- Reuse: Implement returnable containers (e.g., Walmart’s shared pallet program saves 200,000+ trees yearly).

- Recycle: Partner with facilities like TerraCycle to process complex materials like mixed plastics.

2. Lean Inventory Management

Adopt Just-In-Time (JIT) systems supported by AI tools like Locus Robotics, which cut overstock by 30% through real-time demand forecasting.

3. Energy Efficiency

Upgrade to motion-sensor LEDs (saving 60% energy) and solar-powered HVAC systems (e.g., IKEA’s warehouses offset 100% energy via solar panels).

How to Design a Zero-Waste Warehouse Layout

Space Optimization

Use modular shelving (e.g., Kardex Remstar’s Shuttle XP systems) and cross-docking to minimize handling steps.

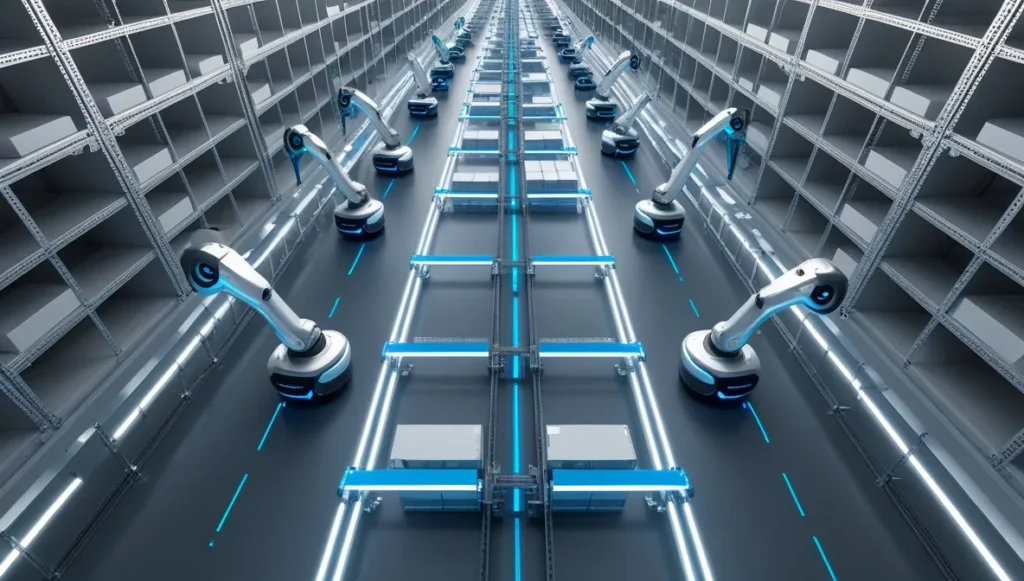

Vertical Storage Solutions

Deploy Automated Storage and Retrieval Systems (AS/RS), like Amazon’s Kiva robots, which boost storage density by 400% and reduce energy use by 50%.

Implementing Sustainable Packaging Solutions

Sustainable packaging cuts waste and appeals to 68% of eco-conscious consumers (Nielsen, 2023). Strategies include:

- Biodegradable materials: Dell uses mushroom-based foam, reducing packaging waste by 40%.

- Right-sizing: FedEx’s box reduction program eliminated 200 million pounds of packaging since 2020.

- Supplier collaboration: Partner with **FSC-certified** vendors for recyclable cardboard.

Adopting Green Technologies in Warehousing

Solar Power

Solar panels can slash energy bills by 70%, as seen in **Walmart’s Project Gigaton** warehouses.

IoT and Automation

Sensors from **Honeywell** or **Siemens** monitor energy use, predicting equipment failures and reducing downtime waste by 25%.

Waste Auditing and Continuous Improvement

Conduct quarterly waste audits tracking:

- Waste-to-landfill ratios (aim for <5%).

- Energy use per square foot (benchmark: 0.15 kWh/sq. ft).

Use **Kaizen** methodologies to refine processes iteratively.

Employee Training for Zero-Waste Success

Empower teams with:

- Workshops on how to reduce warehouse waste through daily actions (e.g., turning off idle equipment).

- Incentive programs: DHL rewards staff who propose waste-cutting ideas, saving $1.2 million annually.

Case Studies: Zero-Waste Warehouses in Action

1. Patagonia’s TRUE Zero Waste Certification

By repurposing 97% of waste (e.g., fabric scraps into new products), Patagonia’s Reno hub became a global benchmark (Patagonia Sustainability Report).

2. Amazon’s Climate Pledge

Amazon’s 10,000+ robots optimize inventory paths, cutting energy waste by 30% while transitioning to 100% biodegradable packaging by 2025 (Amazon Sustainability Report).

3. Walmart’s Project Gigaton

Solar-powered warehouses and shared pallets reduced emissions by 20% and saved $2.3 billion in 2023 (Walmart ESG Report).

Navigating Regulatory Compliance for Zero-Waste Warehouses

EU Regulations

- **European Green Deal**: Mandates <10% landfill waste by 2030. Non-compliance risks fines up to 5% of revenue.

- **EPR Laws**: Germany’s VerpackG requires firms to fund packaging recycling.

U.S. Regulations

- **California SB 1383**: Requires 100% organic waste recycling by 2025.

- **Federal Tax Credits**: 30% credit for solar installations (IRS Form 3468).

Future Trends in Zero-Waste Warehousing

- Circular Economy: Adidas’ Futurecraft.Loop shoes, made from 100% recyclable materials, exemplify waste-to-resource models.

- Blockchain: IBM’s Food Trust tracks waste reduction in real time.

Conclusion

Zero-waste warehousing is a win-win: slashing costs while future-proofing operations against regulatory and consumer pressures. Start with a **waste audit template** (EPA), scale with technologies like AS/RS and solar, and foster a culture of sustainability.

FAQs

1. How can small warehouses afford zero-waste upgrades?

Prioritize low-cost wins like **LED lighting** and digital workflows. Apply for grants like the **USDA’s REAP program**.

2. What’s the ROI timeline for solar panels?

Most warehouses recoup costs in 3–5 years via energy savings and tax credits.

3. How do we handle non-recyclable materials?

Partner with **waste-to-energy plants** or innovators like **Brightmark** (plastic-to-fuel conversion).

4. Does zero-waste improve customer loyalty?

Yes—73% of consumers pay premium for sustainable brands (IBM, 2023).

5. How to start a zero-waste program?

Begin with a **waste audit template from the EPA**.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com