📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Strategic Warehouse Racking Design: The Ultimate Blueprint for Maximizing Density & Efficiency

For any growth-focused enterprise, the warehouse is more than a storage facility; it is the dynamic, logistical heart of the operation. Yet, this heart often faces a critical challenge: the palpable strain of expansion within a confined space. The conventional response—seeking more square footage—is a capital-intensive solution that often merely postpones the underlying problem. The truly transformative solution lies not in acquiring more space, but in radically re-engineering the space already owned.

This is the precise domain of expert warehouse racking design. It is a sophisticated discipline that transcends simple shelving layout, representing a holistic, data-driven engineering process aimed at transforming static storage into a dynamic, profit-driving asset. This definitive guide delves into the advanced methodologies and intelligent systems that empower businesses to achieve unprecedented levels of storage density and operational throughput. A superior warehouse racking design is the cornerstone of a scalable, resilient, and cost-effective supply chain, directly impacting the bottom line by slashing operational costs and enhancing customer satisfaction through faster, more accurate order fulfillment.

The High Cost of Inefficiency: Why Standard Storage Solutions Fail Growing Businesses

Many organizations begin their journey with basic pallet racking or simple shelving units—a pragmatic starting point that quickly becomes a strategic liability. The limitations of a non-optimized storage layout are insidious, creating a cascade of operational inefficiencies that directly stifle growth and erode profitability. An inadequate warehouse racking design manifests in wasted vertical airspace, excessively long travel paths for order pickers, chronic aisle congestion that slows material handling equipment, and an environment ripe for inventory errors and safety incidents.

This “storage sprawl” is a silent profit killer, leading to inflated labor costs, diminished order accuracy, and a hard ceiling on scalability. For a business on an upward trajectory, the transition from a reactive storage model to a proactively engineered warehouse racking design is not merely an operational upgrade; it is a critical strategic imperative for sustainable expansion.

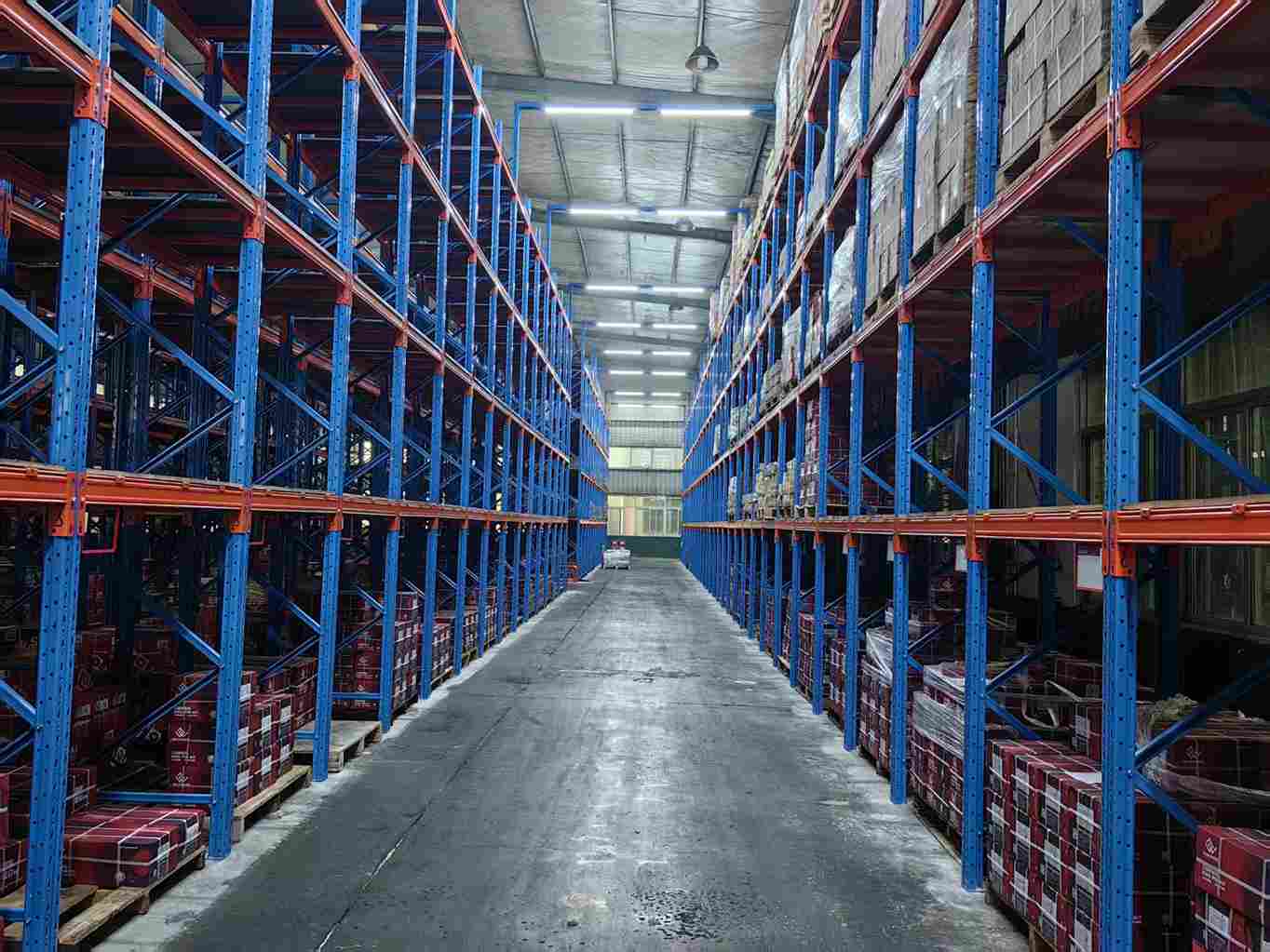

Wide aisle spacing around pallet beam racking systems for safer warehouse design

The Three Foundational Pillars of a World-Class Warehouse Racking Design

Constructing a storage system that genuinely scales with a business requires a steadfast commitment to three interdependent pillars. A failure in any one of these areas will compromise the integrity, efficiency, and return on investment of the entire storage infrastructure.

Pillar 1: Mastering Cubic Space Through Intelligent Storage Density

The most frequently squandered asset in any storage facility is the unused cubic volume above the first rack level. A strategic warehouse racking design is fundamentally concerned with the mastery of this three-dimensional space.

Aggressive Vertical Utilization: Standard selective racking often leaves a gaping void between the top beam and the ceiling structure. A professional warehouse racking design involves engineering solutions to safely extend storage upward, capturing thousands of cubic feet of lost space. This process demands a rigorous analysis of floor load capacity, seismic considerations, and the precise capabilities of the material handling equipment (MHE) fleet.

Precision Aisle Width Optimization: Traditional wide aisles, designed for counterbalance forklifts, can devour over 50% of a facility’s total floor area. By integrating a warehouse racking design based on narrow-aisle (NA) or very-narrow-aisle (VNA) principles, aisle widths can be reduced from 12 feet to 6 feet or less. This single intervention instantly reclaims vast tracts of floor space for productive storage positions.

The “Stored Cube” Philosophy: Ultimate density is achieved when the warehouse racking design moves beyond the generic pallet position to accommodate the specific dimensions and handling characteristics of the actual products. This philosophy dictates that the storage solution—whether for pallets, cases, or totes—is dictated by the product profile, not the other way around.

Pillar 2: Engineering Operational Workflow into the Physical Design

A storage system can achieve remarkable density while being profoundly inefficient if it disrupts the natural flow of goods. The second pillar of a superior warehouse racking design is the seamless integration of operational workflow into the physical layout.

Dynamic, Velocity-Based Slotting: This is a non-negotiable best practice in modern warehouse racking design. The fastest-moving products (A-items) must be positioned in the “Gold Zone”—the ergonomic area between the knees and shoulders of an order picker. A sophisticated warehouse racking design incorporates dynamic slotting strategies that automatically adapt to fluctuating sales velocity, ensuring the layout is always optimized for minimal travel and maximum pick speed.

Flow-Through and Cross-Docking Integration: For businesses handling high volumes of time-sensitive goods, the warehouse racking design must facilitate rapid movement. This involves creating dedicated zones where inbound goods are immediately sorted and transferred to outbound shipping docks, bypassing storage entirely. This flow-through warehouse racking design drastically reduces touch points and handling times.

Picking Path Geometry: The very geometry of the aisles—whether parallel, across-the-dock, or in a U-shape—has a direct and measurable impact on the total distance traveled per order. A data-driven warehouse racking design will model typical order profiles to engineer a layout that creates the most efficient picking paths, thereby significantly reducing labor hours and operator fatigue.

Pillar 3: Creating a “Smart” Warehouse Through Technology Integration

The term “smart warehouse racking design” refers to systems that are deeply integrated with and enhanced by digital technologies. This integration is what separates a modern, agile operation from an outdated, static one.

Deep Warehouse Management System (WMS) Integration: In a smart warehouse racking design, the physical racking is the hardware, and the WMS is the operating system. A proper design ensures that every single storage location has a unique, scannable address. This enables directed put-away and picking, real-time inventory accuracy exceeding 99.9%, and optimized space utilization based on live data analytics.

Automation and Robotics Readiness: The future of logistics is inextricably linked to automation. A forward-thinking warehouse racking design is, therefore, built with future integration in mind. This means ensuring structural compatibility for robotic arms, providing clear navigation paths for Autonomous Mobile Robots (AMRs), or designing the racking interface to work with automated storage and retrieval systems (AS/RS). A truly resilient warehouse racking design is inherently automation-ready.

A Technical Deep Dive into Advanced Racking Systems for Maximum Density

Moving from theoretical pillars to practical application, the following systems represent the core toolkit for any consultant specializing in high-performance warehouse racking design.

Narrow-Aisle & Very-Narrow-Aisle Racking: The Foundation of Modern Warehouse Racking Design

This system is often the first major upgrade for businesses outgrowing their conventional selective racking. It represents a fundamental shift in warehouse racking design philosophy.

Operational Mechanics: A narrow-aisle warehouse racking design functions with aisles typically between 6 to 8 feet wide. It necessitates specialized narrow-aisle reach trucks or order pickers. These machines can “reach” into the racking to access pallets, eliminating the need for the forklift to turn within the aisle, which is the primary reason for wide aisles in traditional designs.

Tangible Benefits of this Warehouse Racking Design:

Substantial Capacity Increase: This approach to warehouse racking design typically yields a 40-50% increase in storage positions compared to conventional wide-aisle layouts.

Enhanced Operational Efficiency: NA trucks are highly maneuverable and efficient within their designed environment, leading to faster cycle times.

Uncompromised Selectivity: Every pallet remains 100% accessible, a key advantage over deeper storage systems.

For the ultimate in space savings, a Very-Narrow-Aisle (VNA) warehouse racking design pushes the boundaries further, with aisles as narrow as 5 feet. VNA systems rely on turret trucks or swing-mast trucks, where the forks rotate to store/retrieve loads while the truck travels straight down the aisle. The most advanced VNA warehouse racking design incorporates wire or rail guidance for pinpoint accuracy and enhanced safety.

Drive-In & Drive-Thru Racking: The High-Density Champion for Bulk Storage

When the application involves storing large quantities of a limited number of SKUs, a Drive-In or Drive-Thru warehouse racking design offers the highest possible pallet density.

Core Functionality: This warehouse racking design resembles a multi-level parking garage for pallets. Instead of aisles, it features deep lanes with rails. A forklift drives directly into these lanes to place or retrieve a pallet, operating on a Last-In, First-Out (LIFO) or First-In, First-Out (FIFO) basis.

Drive-In Racking: A warehouse racking design with a single entry/exit point, ideal for LIFO inventory like seasonal goods or raw materials.

Drive-Thru Racking: A warehouse racking design with access from both ends, enabling true FIFO flow for perishables or items with strict lot control.

The Compelling Value Proposition:

Maximum Cube Utilization: By eliminating most aisles, this form of warehouse racking design can increase storage capacity by up to 75% versus selective racking.

Perfect for Bulk Storage: The ideal warehouse racking design for homogenous product runs.

Push-Back Racking: Dynamic LIFO Storage with Superior Throughput

Push-Back Racking is an ingenious system that masterfully blends high density with excellent selectivity. It is a popular choice in a modern warehouse racking design for its balance of performance and accessibility.

How it Works in a Warehouse Racking Design: Pallets are stored on wheeled carts that nest on inclined rails within a structural frame. Each lane can typically hold 2 to 6 pallets deep. The act of loading a new pallet pushes the existing pallets backward. Upon retrieval, the next pallet rolls gently to the front position by gravity. This LIFO mechanism is a hallmark of this specific warehouse racking design.

Key Advantages in a Warehouse Racking Design:

Significant Density Gains: Multiple-deep storage drastically reduces the aisle footprint in the overall warehouse racking design.

Improved Selectivity & Speed: Every lane is accessible from a single aisle, and the next pallet is always presented at the front, making this warehouse racking design faster than drive-in systems.

Enhanced Inventory Control: It allows for multiple SKUs per bay, offering more flexibility than other deep-lane warehouse racking design options.

Pallet Flow & Carton Flow Systems: The Pinnacle of FIFO Warehouse Racking Design

For high-velocity, high-SKU environments, particularly in piece-pick or case-pick operations, a flow-based warehouse racking design is unparalleled. It uses gravity to automate product movement, creating a highly efficient “product-to-person” system.

The Mechanics of a Flow Warehouse Racking Design: The system consists of skatewheel or roller tracks set on a calculated decline. Product is loaded into the rear and moves gently to the front for picking. This creates a perfect, high-throughput FIFO system, a critical feature of this warehouse racking design for perishable goods or items with expiration dates.

Why this Warehouse Racking Design Boosts Efficiency:

Unbeatable FIFO Control: Essential for compliance and product quality in many industries.

Dramatically Reduced Picking Times: Pickers remain in a single zone, and product comes to them, a core benefit of this warehouse racking design that eliminates travel within the aisle.

High-Density Potential: These systems can be built very tall and deep, making excellent use of cubic space in the overall warehouse racking design.

Mobile Pallet Racking: The Transformative Solution for Ultimate Density

For operations with vast inventory but low to medium SKU counts, a Mobile Pallet Racking design is the ultimate space-saving solution. It is, quite simply, the densest form of storage possible while maintaining 100% selectivity.

The Core Concept of this Warehouse Racking Design: Imagine a storage footprint with no permanent aisles. The racking is mounted on motorized bases that move on embedded rails. An operator creates a temporary “access aisle” only where and when it is needed. This is the fundamental principle of a mobile warehouse racking design.

The Unmatched Benefits:

Revolutionary Density Gains: By eliminating all but one or two access aisles, this warehouse racking design can double or even triple storage capacity within the same footprint.

Total Selectivity: Every single pallet location is accessible.

Enhanced Security and Climate Control: The system can be closed up, securing inventory and reducing the volume of space that requires lighting or climate control.

The Critical Synergy: Matching Material Handling Equipment to the Warehouse Racking Design

A world-class warehouse racking design is functionally inert without the correct equipment to interface with it. The MHE and the racking are a single, integrated system. A proper warehouse racking design consultancy always includes an MHE analysis to ensure perfect synergy.

For Narrow-Aisle Warehouse Racking Design: Reach Trucks and Order Pickers are the standard. The warehouse racking design must specify the required lift height, load capacity, and mast type to ensure compatibility.

For VNA Warehouse Racking Design: Turret Trucks are the specialized solution. The warehouse racking design must account for the truck’s dimensions, lift height, and the integration of the guidance system.

The Role of Specialized Attachments: Often, the key to unlocking efficiency in a warehouse racking design is not a new truck, but the right attachment—fork positioners, carton clamps, or rotating heads—that can dramatically improve handling for non-standard loads.

The Implementation Blueprint: A Phased Approach to Warehouse Racking Design Excellence

A successful warehouse racking design project is not a product but a process. It requires a meticulous, phased approach to ensure operational success and a strong return on investment.

Phase 1: In-Depth Discovery and Data-Driven Analysis

The foundation of any successful warehouse racking design is deep immersion into the client’s business. This phase involves a rigorous analysis of SKU profiles, order histories, peak season data, and growth projections. Time-motion studies and workflow analysis are conducted to pinpoint current bottlenecks. This data-driven approach ensures the resulting warehouse racking design is not a generic template but a custom-tailored solution.

Phase 2: 3D Modeling, Simulation, and Virtual Validation

Before any installation begins, the proposed warehouse racking design is brought to life through advanced 3D modeling and simulation software. This allows stakeholders to “walk through” their future warehouse. Simulations can stress-test the warehouse racking design under peak load scenarios, validating its robustness and identifying potential issues before capital is committed.

Phase 3: Phased Installation with Zero Operational Disruption

Understanding that business cannot stop, a professional warehouse racking design rollout is executed in carefully planned phases. Expert installation teams work around existing operations—often during nights or weekends—to ensure a seamless transition with minimal impact on daily throughput and customer fulfillment.

Phase 4: Comprehensive Training, WMS Integration, and Ongoing Support

The final, critical phase is ensuring the new warehouse racking design is fully operationalized. This includes comprehensive training for operators, seamless integration with the client’s WMS to ensure perfect inventory sync, and a structured handover. The relationship continues with ongoing support and periodic operational audits to ensure the warehouse racking design continues to perform at its peak for years to come.

Conclusion: Transforming Your Storage Infrastructure into a Competitive Weapon

In the modern economy, the warehouse is a critical determinant of competitive advantage. A strategically engineered warehouse racking design is the catalyst that transforms this logistical hub from a cost center into a powerful engine for growth. It is the foundational element that drives down operational costs, accelerates order fulfillment, unlocks latent capacity, and provides the scalable agility required for sustainable, profitable expansion. By embracing the principles of high-density, workflow-integrated, and technology-enabled warehouse racking design, business leaders are making a strategic investment in the future-proof resilience of their entire operation. The journey toward a smarter, denser, and more efficient warehouse begins with a commitment to a world-class warehouse racking design.

Frequently Asked Questions (FAQs)

1. How is the potential Return on Investment (ROI) calculated for a new high-density warehouse racking design?

A professional warehouse racking design consultancy builds the ROI case by quantifying both hard and soft costs. Key metrics include: the capital cost of avoided expansion or relocation, the value of reclaimed cubic space (calculated as a percentage of total facility overhead), labor savings from reduced travel and picking times, and the reduction in inventory shrinkage and product damage. A detailed financial model projecting a typically short payback period is a standard deliverable in a professional warehouse racking design proposal.

2. What are the critical structural and safety considerations for a high-bay warehouse racking design?

Safety and structural integrity are paramount in any warehouse racking design. A non-negotiable engineering assessment is conducted, including seismic analysis, verification of the concrete slab’s load-bearing capacity, ensuring adequate clearances for MHE and sprinkler systems, and designing for proper load distribution and impact protection. All designs must comply with or exceed RMI (Rack Manufacturers Institute) standards and local building codes.

3. Can advanced warehouse racking design systems be integrated into an existing facility without a complete overhaul?

Absolutely. Hybrid approaches are often the most practical and cost-effective warehouse racking design strategy. A common solution is to deploy a high-density system like push-back or pallet flow for bulk storage, while retaining or upgrading a selective or narrow-aisle system for slower-moving items or active picking. A phased implementation of the new warehouse racking design can be planned to align with budgetary and operational constraints.

4. How does a Warehouse Management System (WMS) truly interact with a smart warehouse racking design in practice?

In a technology-integrated warehouse racking design, the WMS acts as the central nervous system. It knows the exact dimensions, weight, and velocity of every SKU. Upon receipt, the WMS directs the forklift to the optimal empty location within the warehouse racking design. For picking, it creates optimized batch orders and sequences them into the most efficient path through the racking aisles. This symbiosis is what creates a truly “smart” operation.

5. What is the typical lead time from the initial warehouse racking design phase to full operational deployment?

Lead times are project-dependent, varying with scale, complexity, and supply chain conditions. A straightforward narrow-aisle warehouse racking design conversion might take 8-12 weeks. A large-scale, automated project with mobile racking and AGV integration could span 6-9 months. A detailed, phase-gated project plan is provided at the outset of any warehouse racking design engagement to facilitate precise business planning.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com