📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Maximize Storage Efficiency: The Ultimate Guide to Turnaround Points in Industrial Racking

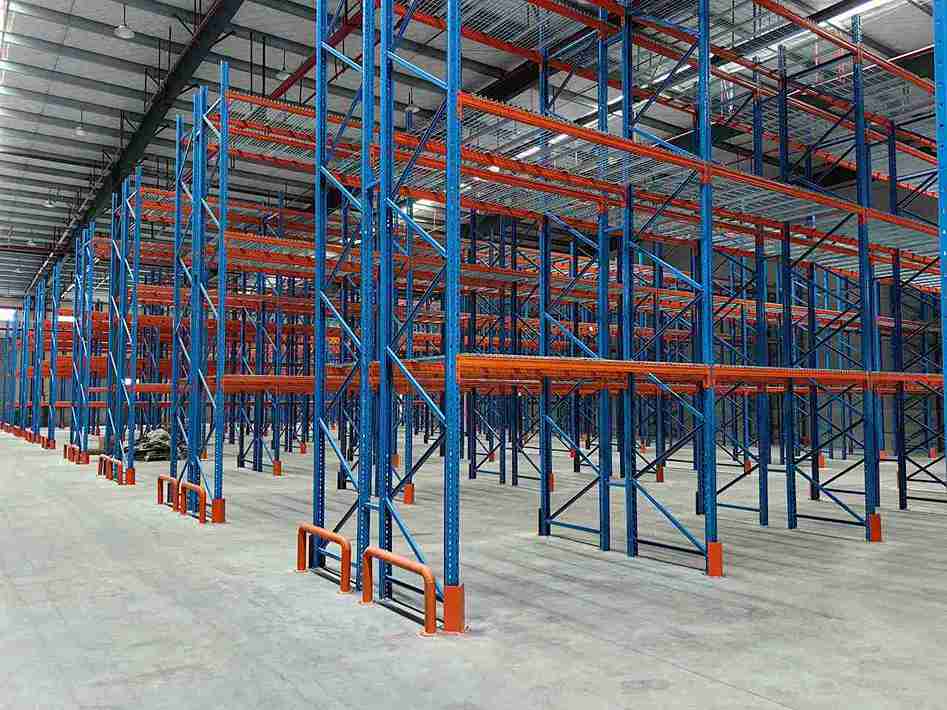

For logistics directors and warehouse managers from Jakarta to Johannesburg, São Paulo to Dubai, the pursuit of storage efficiency is a relentless challenge. In an era defined by e-commerce velocity and razor-thin margins, the traditional approach of simply adding more steel is a bankrupt strategy. The true differentiator, the key to unlocking dramatic gains in density and throughput, lies in mastering the critical, dynamic spaces within a facility: the turnaround points in industrial racking.

This comprehensive guide delves deep into why these pivotal zones are the epicenter of modern warehouse optimization. It moves beyond basic definitions to provide a strategic framework for analyzing, designing, and perfecting these areas, offering a clear path to a more profitable and productive operation. For any business leveraging selective pallet racking, narrow aisle systems, or advanced automated storage and retrieval systems (ASRS), a command of turnaround points in industrial racking is not just an advantage—it is an operational necessity.

Deconstructing Turnaround Points: The Heartbeat of Warehouse Flow

At its core, a turnaround point in industrial racking is the designated zone where material handling equipment executes the maneuvers necessary to access a storage location. However, to view it as merely an empty space is to miss the entire point. In reality, these points are the heartbeat of a warehouse’s circulatory system. They are high-activity, high-stakes areas where efficiency is won or lost with every single transaction.

A poorly conceived turnaround point in industrial racking acts as a constant, low-grade bottleneck, sapping productivity, increasing cycle times, and elevating the risk of costly accidents and damage. Conversely, a well-engineered turnaround point in industrial racking creates a rhythm of seamless, fluid motion, allowing personnel and automated systems to perform at their peak.

The Three-Zone Anatomy of a High-Performance Turnaround

Every effective turnaround point in industrial racking can be broken down into three distinct yet interconnected operational zones:

The Approach Zone: This is the entry corridor leading into the racking bay. It must provide a clear, unobstructed path long enough for equipment—whether a manned forklift or an AGV—to approach at a safe and operational speed without requiring premature deceleration or complex steering adjustments.

The Core Maneuvering Zone: This is the critical hotspot directly in front of the racking face. It is in this zone that the essential work happens: the forklift’s final turn to square up with the load, the lateral shift of a reach truck’s forks, or the precise docking of an unmanned forklift. The dimensions of this zone are non-negotiable and are dictated by the hard physics of the equipment’s turning radius and the load’s dimensions.

The Egress Zone: This is the exit path that allows the now-laden equipment to merge back into the main traffic flow smoothly and safely. An inadequate egress zone forces operators into risky reverse maneuvers or creates conflict points with cross-traffic, undermining the efficiency gained in the core maneuvering zone.

Understanding this anatomy is the foundational first step. The strategic implementation, however, requires a nuanced understanding of how these turnaround points in industrial racking interact with different storage modalities and technologies.

The Direct Correlation: Turnaround Points and Bottom-Line Profitability

The connection between optimized turnaround points in industrial racking and a company’s financial health is direct, measurable, and often underestimated. This is not an abstract concept of “better flow”; it is a concrete driver of cost savings and revenue enhancement. The impact is felt across several key performance indicators.

Quantifying the Density Dividend

The most immediate benefit of optimizing turnaround points in industrial racking is a dramatic increase in storage density without expanding the building’s footprint. The logic is simple: by refining the spaces between the racks, you can fit more racks into the same area.

The Aisle Width Revolution: Traditional warehouses designed for counterbalance forklifts require aisles of 3.5 meters or more. However, by focusing on the precision of the turnaround points in industrial racking, companies can deploy narrow aisle (NA) or very narrow aisle (VNA) trucks that operate in aisles as slim as 1.6 meters. This single change can increase storage capacity by over 25%, a transformative figure for operations in high-rent urban centers in Southeast Asia or land-constrained facilities in the Middle East.

Eliminating the “Just-in-Case” Buffer: In poorly planned layouts, managers often leave extra space “just in case,” leading to significant wasted floor space. A data-driven approach to turnaround points in industrial racking replaces this guesswork with engineering precision, reclaiming every square meter for productive use.

Throughput Velocity and Order Fulfillment Speed

In logistics, time is the ultimate currency. Every second shaved off a pick-and-putaway cycle compounds over thousands of transactions daily. The design of turnaround points in industrial racking has a profound impact on this velocity.

Elimination of Maneuvering Friction: A well-designed core maneuvering zone allows an operator to position the forklift perfectly on the first attempt. This eliminates the time-consuming, fuel-wasting “jockeying”—the back-and-forth shuffling that plagues inefficient layouts. When this friction is removed from hundreds of daily interactions with the industrial racking, the cumulative time savings are staggering.

Congestion Mitigation: Strategic design of turnaround points in industrial racking prevents the formation of queues at high-frequency picking locations. When one piece of equipment can complete its maneuver without impeding the next, the entire workflow from receiving to shipping maintains its momentum, directly translating into faster order fulfillment and happier customers.

The High Cost of Ignorance: Consequences of Poor Turnaround Design

Overlooking the critical importance of turnaround points in industrial racking is a decision with severe and tangible financial consequences. The costs are not always immediately apparent on a balance sheet, but they relentlessly erode profitability through a series of direct and indirect channels.

The Triad of Loss: Damage, Downtime, and Danger

Asset and Inventory Damage: This is the most visible cost. Tight, ill-conceived turnaround points in industrial racking are the primary cause of collisions between forklifts and racking uprights. A single impact can compromise the structural integrity of an entire bay, requiring immediate repair or replacement. The resulting product damage from falling loads leads to direct inventory write-offs. The cumulative cost of these incidents can run into tens of thousands of dollars annually.

Accelerated Equipment Degradation: Forcing forklifts to perform sharp, strained turns in confined turnaround points in industrial racking places excessive stress on tires, steering mechanisms, and mast components. This leads to more frequent breakdowns, higher maintenance costs, and a shorter operational lifespan for expensive capital equipment.

Compromised Safety: Congested and confusing layouts around turnaround points in industrial racking are a breeding ground for accidents. From minor scrapes to serious collisions involving pedestrians, the human and financial costs—including insurance premiums, workers’ compensation, and potential litigation—can be catastrophic.

A Case in Point: The Manila Distribution Bottleneck

A concrete example illustrates this cost. A major distribution center in the Philippines was experiencing chronic shipment delays. Their facility was modern, and their team was diligent, yet a persistent bottleneck was strangling productivity. A forensic analysis revealed that the turnaround points in industrial racking at the ends of their selective pallet racking aisles were under-designed. This created a daily peak-time queue of forklifts, each waiting its turn to navigate the tight space.

This single flaw was costing them over 60 productive minutes each day. By re-engineering these specific turnaround points in industrial racking, the facility increased its peak throughput by 22% without a single new equipment purchase. The ROI was calculated in weeks, proving that the strategic management of turnaround points in industrial racking is one of the highest-yield investments a warehouse can make.

A System-Specific Blueprint: Tailoring Turnaround Points to Racking Type

A universal solution does not exist for optimizing turnaround points in industrial racking. The approach must be meticulously tailored to the specific storage system in use, as each presents unique challenges and opportunities for these critical zones.

Selective Pallet Racking: The Art of the Balance

As the workhorse of the industry, selective racking offers flexibility. The key to optimizing turnaround points in industrial racking in this context is balancing easy accessibility with storage density. The calculation revolves around the Minimum Aisle Width formula, which factors in the forklift’s turning radius and load length. For a genuinely cost-effective warehouse solution, transitioning from a counterbalance forklift to a narrow aisle reach truck can redefine the turnaround points in industrial racking, shrinking aisles and boosting capacity dramatically.

Narrow Aisle & VNA Racking: Where Precision is Paramount

Very Narrow Aisle (VNA) systems represent the frontier of high-density static storage. Here, the aisles are so tight that the forklift itself must be guided, often by a rail or wire. In this environment, the turnaround points in industrial racking are consolidated almost entirely at the aisle ends. The design of these end-of-aisle zones is absolutely critical; they must be perfectly square and clear to allow the truck to enter the aisle in flawless alignment. The margin for error is virtually zero, making the planning of these turnaround points in industrial racking a specialized task requiring expert knowledge.

Drive-In/Drive-Through Racking: Navigating the Deep Lane

These high-density systems for homogeneous products present a unique challenge. The “aisle” is itself a deep storage lane. The turnaround point in industrial racking here is the entry and exit vector. The forklift must reverse into a deep channel, a maneuver requiring significant skill and spatial awareness. The design of the entrance turnaround point in industrial racking must be perfectly aligned and protected to prevent devastating side-impact collisions deep within the racking structure, where repair is most difficult and dangerous.

Mobile Pallet Racking: The Dynamic Dance

In a mobile system, the entire floorplan is fluid. Racking rows move on rails to create a temporary access aisle. In this scenario, the concept of a turnaround point in industrial racking expands to encompass the entire open aisle. Safety systems are paramount to ensure no personnel are trapped in a moving aisle. The efficiency gain is phenomenal—storage density can exceed 80%—but it is wholly dependent on a perfectly level floor and a meticulously managed system for controlling access to these dynamic turnaround points in industrial racking.

The Automation Imperative: Turnaround Points in the Age of Robotics

The strategic importance of turnaround points in industrial racking is magnified exponentially in an automated warehouse. While AGVs (Automated Guided Vehicles) and unmanned forklifts bring unparalleled consistency and labor savings, they operate with machine-like rigidity. They cannot adapt to poorly defined spaces. Therefore, the environment for these systems must be engineered to perfection, and this starts with the turnaround points in industrial racking.

Coding Efficiency: How AGVs Depend on Perfect Turnaround Points

For an autonomous system, a turnaround point in industrial racking is not a suggestion; it is a hard-coded coordinate in its digital map and a pre-programmed maneuver in its software. Any deviation from the expected layout can cause a system fault, halting the vehicle and requiring human intervention.

Dimensional Rigidity: Every single turnaround point in industrial racking used by an AGV fleet must be identical. The vehicle is programmed to expect a precise amount of space to execute its lift, turn, and dock sequence. Variation is the enemy of automation.

Sensor-Friendly Environment: Automated systems rely on LiDAR, cameras, or reflectors for navigation. The areas around turnaround points in industrial racking must be free of visual clutter, stray pallets, or overhead obstructions that could “blind” the vehicle’s sensors and cause a navigation failure.

Millimeter-Accurate Installation: The industrial racking itself must be installed with a degree of precision that was once reserved for machine shops. The racking faces must be perfectly planar and aligned to match the AGV’s programmed approach paths. The tolerance for error in the turnaround points in industrial racking for automation is measured in millimeters, not inches.

Case Study: The Dubai Cold Storage Transformation

A flagship project for a frozen food leader in Dubai exemplifies this principle. The sub-zero environment made manual labor inefficient and hazardous. The solution was a fleet of unmanned forklifts integrated with a high-density mobile racking system. The project’s success hinged on the flawless execution of the turnaround points in industrial racking. The floor was laser-leveled, and the racking was installed with millimeter precision.

The predefined open aisles served as the automated vehicles’ meticulously calibrated maneuvering zones. Because these turnaround points in industrial racking were designed in lockstep with the vehicles’ capabilities, the system achieves a phenomenal 99.8% operational uptime and has slashed energy costs due to the incredible density of the mobile racks. This is a testament to how turnaround points in industrial racking form the foundational logic of a world-class automated facility.

From Audit to Action: A Manager’s Guide to Turnaround Point Optimization

Improvement begins with assessment. Warehouse managers can take immediate, proactive steps to evaluate and enhance the turnaround points in industrial racking within their own facilities using this systematic approach.

Conduct a Process Flow Mapping Exercise: Create a detailed map of all material flows, from receiving to storage to picking to shipping. Identify all intersections and interaction points with the industrial racking.

Pinpoint High-Friction Zones: Spend time on the floor observing the operation. Where do queues naturally form? Where do you see operators performing multi-point turns or engaging in visible frustration? These are your critical turnaround points in industrial racking that require immediate attention.

Execute a Detailed Physical Audit: For each identified turnaround point in industrial racking, take precise measurements: actual aisle width, depth of the core maneuvering zone, and headroom. Compare these against the specifications of your material handling equipment.

Document with Video Analysis: Use time-lapse photography or video recording to capture activity at these points over a full shift. The visual evidence often reveals inefficiencies and conflict patterns that are invisible to the naked eye during a walk-through.

Engage in Operator Ethnography: The forklift drivers are the true experts on the state of your turnaround points in industrial racking. Conduct structured interviews. Ask them: “Where does the layout fight you?” and “What one change would make your job safer and faster?” Their insights are invaluable.

Tactical Interventions for Immediate Efficiency Gains

A full-scale warehouse redesign is not always feasible. However, numerous high-impact, low-cost interventions can significantly improve the performance of turnaround points in industrial racking.

Implement Comprehensive Floor Marking: Use high-visibility, durable floor tape to physically outline the three zones of each critical turnaround point in industrial racking. Define approach paths, core maneuvering boxes, and egress lanes. This simple visual management tool dramatically improves traffic flow and safety awareness.

Deploy Proactive Racking Protection: Install structural column guards, end-of-aisle protectors, and post protectors on any upright that forms part of a high-traffic turnaround point in industrial racking. This is a low-cost insurance policy against the immense cost of racking repair and product damage.

Optimize Warehouse Management System (WMS) Logic: Work with IT or WMS vendors to optimize task interleaving and pick path sequencing. The goal is to algorithmically minimize travel distance and, crucially, to reduce congestion at the busiest turnaround points in industrial racking during peak operational windows.

Right-Size the Material Handling Fleet: Conduct an audit of equipment usage. Is a large, cumbersome forklift being used for tasks that a more agile, compact pallet stacker or walkie-reach truck could handle? Using appropriately sized equipment is one of the fastest ways to alleviate pressure on cramped turnaround points in industrial racking.

The Intelligent Future: AI, IoT, and Self-Optimizing Warehouses

The evolution of turnaround points in industrial racking is transitioning from static architecture to dynamic, intelligent systems. The next frontier involves leveraging data and artificial intelligence to create warehouses that continuously self-optimize.

AI-Powered Dynamic Traffic Management: The future involves mixed-fleet environments where AGVs, unmanned forklifts, and manned equipment coexist. Advanced AI software will manage this ecosystem in real-time, treating the entire network of turnaround points in industrial racking as a dynamic graph. The AI will assign right-of-way, reroute vehicles around congestion, and predictively sequence tasks to maximize throughput across all these critical nodes.

Predictive Simulation and Digital Twins: Before a single rack is bolted down, warehouse designers can use advanced simulation software to create a “digital twin” of the entire operation. This model can run through millions of scenarios to identify potential bottlenecks in the turnaround points in industrial racking, allowing for perfect optimization in the virtual world before committing to a physical layout.

The IoT-Enabled, Self-Learning Warehouse: With Internet of Things (IoT) sensors installed on racking uprights and forklifts, the warehouse itself becomes a data-generating organism. These sensors will monitor vibration from impacts, track traffic density, and measure cycle times at specific turnaround points in industrial racking. Machine learning algorithms will analyze this data to recommend micro-adjustments to storage layouts and workflows, ensuring that the efficiency of every turnaround point in industrial racking is continuously refined.

Conclusion: The Strategic Inflection Point for Your Warehouse

The journey toward a truly world-class warehouse is a journey of precision. It demands a shift in perspective from viewing storage as a static arrangement of steel to understanding it as a dynamic, interactive system. Within this system, the turnaround points in industrial racking emerge as the most critical leverage points for driving performance. They are the interface where investment in infrastructure meets the reality of daily operation.

Mastering these zones delivers an unbeatable combination: higher storage density, faster inventory turnover, a safer working environment, and a stronger bottom line. For businesses competing in the fast-moving markets of Southeast Asia, Africa, the Middle East, and Latin America, this mastery is no longer a strategic option—it is the key to durable competitive advantage. The question for leadership is not whether to address this, but how soon to begin. The moment for strategic action is now.

Frequently Asked Questions (FAQs)

1. We are planning a new warehouse. At what stage should we consider turnaround point design?

The design of turnaround points in industrial racking must be integrated into the earliest conceptual phases of a new warehouse project. It is a foundational element that will directly influence your choice of material handling equipment, your overall storage density calculations, and even the building’s column spacing and clear height. Treating turnaround points in industrial racking as an afterthought is a guaranteed path to costly redesigns and permanent operational constraints.

2. Can we optimize our existing turnaround points without a major capital investment in new forklifts or racking?

Yes, significant improvements are often achievable through operational changes. Conducting a thorough audit, re-sequencing workflows in your WMS, implementing clear floor marking, and providing targeted operator training can yield substantial gains in the efficiency and safety of your turnaround points in industrial racking. These “soft” interventions typically offer a very fast return on investment and can defer the need for major capital expenditure.

3. How do turnaround points directly affect the structural integrity of the racking system?

Repeated low-impact collisions from equipment in tight turnaround points in industrial racking are a primary cause of racking degradation. A bent upright may seem like a minor issue, but it compromises the load-bearing capacity of an entire vertical section, creating a significant safety hazard and potential liability. Properly designed turnaround points in industrial racking, complemented by protective devices, are a direct investment in the long-term structural health and safety of your storage asset.

4. What is the single most important measurement for a safe and efficient turnaround point?

The most critical dimension is the clear width and depth of the core maneuvering zone. This space must be calculated based on the specific turning radius of your forklift model while carrying the longest pallet or load you handle. Failure to provide this tailored space turns every interaction with the industrial racking into a high-risk, inefficient maneuver.

5. How does the integration of a mezzanine floor change turnaround point planning?

Mezzanines introduce vertical material flow via lifts or conveyors, creating super-critical turnaround points in industrial racking at the base of these vertical transfers. These zones must be designed as spacious staging and queuing areas to prevent the lift from becoming a system-wide bottleneck. The turnaround points in industrial racking serving mezzanine access typically require more generous dimensions than a standard racking bay to accommodate the constant loading and unloading cycle.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com