📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

H1: Maximize Your Cold Storage ROI: How High-Density Racking Systems Can Boost Your Capacity by 40% or More

The relentless pursuit of efficiency in cold storage logistics is a battle fought in cubic feet and kilowatt-hours. For distribution center managers, logistics directors, and facility planners, the soaring costs of energy, real estate, and labor are converging into a perfect storm. The solution, however, may not lie in expansive new construction but in a radical re-imagination of existing space through the strategic deployment of advanced racking for cold storage.

This article serves as a definitive guide for industry professionals seeking to transform their cold chain operations. It delves into the engineering principles, system selection criteria, and financial mechanics behind achieving a documented 40% or greater increase in storage capacity. The focus is not on mere storage, but on building a resilient, high-throughput, and profoundly profitable material handling ecosystem where the right racking for cold storage acts as the foundational backbone.

H2: The High Cost of Wasted Air: Inefficiency in the Cold Chain

In ambient warehouses, inefficient layout primarily wastes space. In cold storage facilities, it incurs a continuous and compounding penalty. The true cost of outdated racking for cold storage extends far beyond mere footprint, creating a cascade of operational and financial drains.

H3: The Energy and Real Estate Double Bind

Every aisle that is wider than necessary, every gap between pallets, and every under-utilized vertical meter represents a volume of air that is being expensively conditioned for no return. Traditional wide-aisle racking for cold storage designs, necessitated by the turning radius of counterbalance forklifts, create massive volumes of wasted cooled space. This translates directly to higher electricity consumption for refrigeration systems, which are among the most power-intensive components of any facility. Simultaneously, the real estate cost—whether mortgage, lease, or opportunity cost—of this inefficiently used space is a fixed and burdensome overhead. Optimizing racking for cold storage density is, therefore, a direct attack on two of the largest line items in a cold storage operator’s budget.

H3: The Operational Drag of an Outdated Layout

The inefficiencies of a suboptimal racking for cold storage system manifest in daily operational friction. Extended travel distances for order pickers and forklifts lead to longer cycle times for put-away and retrieval. This not only reduces overall throughput but also increases the duration that freezer doors are open, allowing costly cold air to escape and warm, moist air to infiltrate. This infiltration leads to ice buildup, creating safety hazards and demanding frequent, energy-intensive defrost cycles. The very layout of the racking for cold storage can be the root cause of slowed operations, higher labor costs, and increased energy consumption.

H2: The High-Density Arsenal: A Deep Dive into Advanced Racking for Cold Storage

The term “high-density” encompasses a spectrum of engineered solutions, each designed to maximize pallet positions within a given footprint. Selecting the correct type of racking for cold storage is a strategic decision based on SKU profile, throughput, and inventory rotation requirements.

H3: Drive-In and Drive-Through Racking: The Dense Storage Workhorse

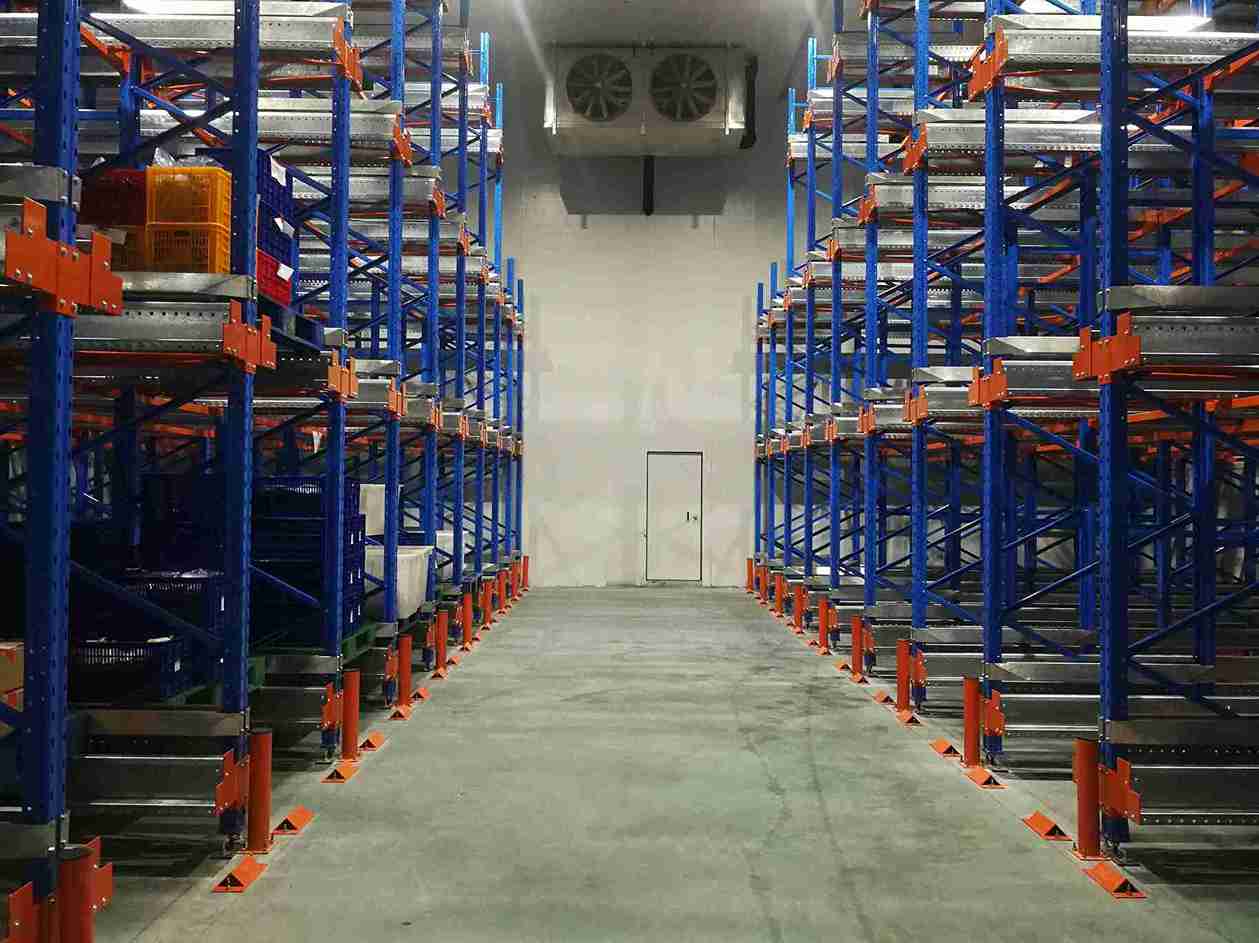

As a foundational high-density solution, Drive-In and Drive-Through racking for cold storage configurations function as multi-level storage lanes. Forklifts drive directly into the rack structure to deposit and retrieve pallets from deep lanes.

Capacity Mechanism: This design eliminates multiple access aisles, consolidating storage into continuous blocks. This approach to racking for cold storage can increase storage density by 60% to 75% compared to selective pallet racking.

Cold Storage Application: This form of racking for cold storage is highly effective for bulk storage of products with low SKU variety and high volume, such as seasonal frozen goods. It typically operates on a LIFO (Last-In, First-Out) basis, though a Drive-Through configuration can allow for FIFO (First-In, First-Out) flow from one end to the other. A critical consideration is the increased heat and humidity introduced by frequent forklift entry deep into the rack structure, a factor that must be mitigated with high-speed doors and optimized operational protocols.

Ideal Use Case: Large-scale food producers and distributors storing homogeneous products in large quantities.

H3: Push-Back Racking: Dynamic Storage with Enhanced Selectivity

Push-back racking for cold storage offers a compelling balance between density and selectivity. It features nested carts on inclined rails within each pallet position, allowing pallets to be stored multiple deep.

Capacity Mechanism: By storing pallets 2 to 6 deep, this racking for cold storage system significantly reduces the aisle footprint while providing better access to multiple SKUs than Drive-In systems. The inclined design uses gravity to bring the next pallet forward automatically after retrieval.

Cold Storage Application: This system is superb for batch storage where managing product expiration dates or lot codes is critical. It enables faster restocking and picking than Drive-In systems, minimizing the time doors are open and reducing the forklift’s travel distance within the cooled environment. The mechanical components of this racking for cold storage must be specified with low-temperature-tolerant metals and lubricants to prevent failure.

Ideal Use Case: Dairy, beverage, and packaged food distributors requiring better product rotation across a moderate number of SKUs.

H3: Pallet Shuttle Systems: The Semi-Automated Density Multiplier

This technology represents a significant leap in racking for cold storage capability. A battery-powered, remotely controlled shuttle cart operates within the racking lanes, moving pallets to and from the front access point.

Capacity Mechanism: This racking for cold storage solution enables extremely deep lanes (10+ pallets) without any need for a forklift to enter. It creates an ultra-high-density block, often increasing capacity by over 80% while requiring only a single, minimal-width access aisle per bay.

Cold Storage Application: This is a transformative racking for cold storage solution for cold environments. The forklift operator remains outside the racking lane, dramatically cutting heat ingress, energy loss, and operational noise. The system provides unparalleled inventory control and seamless integration with Warehouse Management Systems (WMS). The shuttles themselves are engineered as dedicated racking for cold storage components, built with cold-rated batteries, electronics, and materials.

Ideal Use Case: High-volume cold storage facilities seeking a bridge to automation, ideal for fast-moving goods with high SKU counts.

H3: Mobile Pallet Racking: The Ultimate Space Optimizer

For the absolute maximum storage density, Mobile racking for cold storage is the pinnacle solution. The entire rack structure is mounted on electrically driven carriages that move laterally on rails, creating a single, temporary access aisle only where and when needed.

Capacity Mechanism: By eliminating all permanent aisles, this racking for cold storage system can achieve near-total volumetric density, often doubling or tripling storage capacity within the same footprint.

Cold Storage Application: The energy savings are profound. Operators are only cooling a single aisle at any given moment, drastically reducing the refrigeration load. This racking for cold storage system requires a robust floor slab and integrated safety systems, including floor sensors, safety sweeps, and warning lights. The higher initial investment is frequently justified by the monumental savings in energy and real estate costs in cold storage applications.

Ideal Use Case: High-value product storage, archives, and facilities in markets with exorbitant real estate costs where maximizing every square foot is paramount.

H2: The Non-Negotiable Engineering: What Makes Racking for Cold Storage Unique

Specifying standard industrial racking for cold storage for a sub-zero environment is a critical error. The physics of extreme cold demand a specialized, engineered approach to racking for cold storage that prioritizes safety and longevity.

H3: Metallurgy and the Battle Against Brittle Fracture

Standard structural steel undergoes a ductile-to-brittle transition as temperatures drop. An impact from a forklift truck that would cause a minor dent at ambient temperature can result in a sudden, catastrophic crack in a -30°C freezer. Therefore, all racking for cold storage must be fabricated from impact-tested, low-temperature-grade steel. This specialized steel is alloyed and processed to maintain its toughness and ability to absorb energy without fracturing. Reputable providers of racking for cold storage will supply material certifications, including Charpy V-Notch test results, verifying performance at the facility’s specific operating temperatures.

H3: Structural Design for a Hostile Environment

The cold storage environment presents unique challenges that influence the design of racking for cold storage. Engineers must account for:

Thermal Contraction: Steel contracts significantly in the cold. The design of the racking for cold storage must allow for this movement without compromising structural integrity or connection strength.

Ice Load: The potential accumulation of ice on beams and uprights adds a dead load that must be factored into the structural calculations for the racking for cold storage.

Corrosion Protection: A standard powder coat is insufficient. High-performance racking for cold storage utilizes an Epoxy Electrocoat (E-Coat) process. This electrophoretic application creates a uniform, resilient, and impenetrable layer on every surface, including the interior of hollow tubes, providing superior resistance to corrosion from constant humidity and freeze-thaw cycles.

H2: The Automation Synergy: Integrating Racking for Cold Storage with Robotic Systems

A high-density racking for cold storage system is a powerful asset on its own. When integrated with automation, it becomes the core of a lights-out, high-throughput logistics hub. This synergy is where the 40% capacity gain is frequently coupled with a 30-50% reduction in labor costs.

H3: AGVs: The Unmanned Workhorses for Cold Storage Racking

Automated Guided Vehicles (AGVs) are the ideal partners for high-density racking for cold storage, particularly shuttle and mobile systems. Their integration offers distinct advantages:

Uninterrupted Operation: AGVs are impervious to the cold, enabling 24/7 operation in environments that are challenging for human workers, thus maximizing asset utilization.

Precision Handling: AGVs interface with the racking for cold storage with millimeter accuracy, which is essential for the tight tolerances of automated systems and prevents costly damage.

Systemic Integration: Modern AGV fleets are managed by a central control system that is fully integrated with both the WMS and the software governing the racking for cold storage shuttle systems. This creates a seamless, paperless flow of goods from receiving to storage.

H3: ASRS: The Pinnacle of Automated Racking for Cold Storage

For the ultimate in density, speed, and accuracy, an Automated Storage and Retrieval System (ASRS) using stacker cranes within very-narrow-aisle (VNA) racking for cold storage represents the state of the art. This configuration completely removes personnel from the storage area, allowing for the building’s full height to be utilized and aisles to be minimized. The decision to invest in an ASRS-based racking for cold storage solution is a major capital expenditure, but for high-volume, high-throughput distribution centers, the long-term operational savings are unparalleled.

H2: The Financial Model: Deconstructing the ROI of Advanced Racking for Cold Storage

Translating the technical advantages of high-density racking for cold storage into a compelling financial business case is crucial. The return on investment is calculated through a combination of hard cost savings and avoided capital expenditure.

H3: Quantifying the Capacity and Operational Gains

Direct Capacity Increase: The most straightforward metric. By comparing the pallet positions in a proposed high-density racking for cold storage layout against the current setup, the gain is clear. A 40% increase is a conservative and achievable target.

Energy Savings Modeling: Advanced modeling software can calculate the reduced volume of cooled space, especially with mobile racking for cold storage. This is combined with the reduced heat load from minimizing forklift traffic. These cubic meter reductions are translated into kWh savings based on local utility rates.

Labor Efficiency Calculations: The reduced travel times and automated retrieval processes of advanced racking for cold storage systems directly reduce the number of forklift operators required. This labor can be reallocated to value-added tasks like quality control or order customization.

H4: Illustrative ROI Comparison: Traditional vs. Advanced Racking for Cold Storage

| Financial Metric | Standard Selective Racking | High-Density Push-Back Racking | Semi-Automated Pallet Shuttle System |

|---|---|---|---|

| Total Pallet Positions | 6,000 | 9,000 (+50%) | 12,600 (+110%) |

| Estimated Annual Energy Cost | $300,000 | $285,000 (-5%) | $250,000 (-17%) |

| Forklift Operators (in freezer) | 6 | 4 (-33%) | 2 (-67%) |

| Projected Annual Damage & Maintenance | $18,000 | $9,000 | <$3,000 |

| Estimated Payback Period | Baseline | 2 – 3 Years | 3 – 4 Years |

Note: Table values are illustrative. A precise financial analysis is required for each unique operation.

H2: Implementation Without Interruption: A Phased Strategy for Racking for Cold Storage Retrofit

A core concern for any operational cold storage facility is how to implement a new racking for cold storage system without halting business. A phased, methodical approach is the industry best practice.

H3: Phase 1: Discovery and Digital Replication

This initial phase involves a comprehensive audit of inventory, workflows, and peak season demands. Using this data, engineers create a digital twin of the new racking for cold storage layout. This model allows for simulation and optimization before installation, de-risking the entire project.

H3: Phase 2: Surgical Staging and Commissioning

The installation of the new racking for cold storage is conducted in designated zones or phases. Operations continue in non-active zones while the new system is built. Inventory is then migrated in a controlled, sequential manner. This meticulous planning ensures that daily throughput and order fulfillment are maintained throughout the transition to the new racking for cold storage.

H2: Case Study: Transforming a Latin American Frozen Food Hub

A major frozen food distributor in Brazil was facing a capacity crisis, with its existing selective racking for cold storage system maxed out at 10,000 pallets. Expansion was geographically constrained.

The Solution: A tailored pallet shuttle system for cold storage was designed and installed in their -28°C facility. The solution included:

High-density racking for cold storage built from certified -30°C rated steel.

A fleet of 15 pallet shuttles engineered for cold storage operation.

Full WMS integration for real-time inventory management.

Two unmanned fork AGVs for transporting pallets to the racking interface.

The Results:

Pallet positions surged from 10,000 to 14,500 (a 45% increase).

Labor costs within the freezer were reduced by 70%.

Order accuracy improved to 99.98%.

The investment in the new racking for cold storage system achieved a full ROI in 2.8 years through avoided construction costs and operational savings.

H2: The Future-Proof Facility: Racking for Cold Storage as a Strategic Asset

Investing in advanced racking for cold storage is not merely a tactical upgrade; it is a strategic move to future-proof a cold chain operation. The data-rich, physically optimized infrastructure laid down by a modern racking for cold storage system seamlessly enables the adoption of next-generation technologies.

IoT and Predictive Analytics: Sensors embedded within the racking for cold storage can monitor structural health, track load weights in real-time, and even provide zone-specific temperature mapping, feeding data into a predictive maintenance platform.

The Lights-Out Cold Storage Facility: The combination of high-density racking for cold storage, AGVs, and robotic picking stations creates a pathway toward fully automated, 24/7 operations that minimize human intervention and maximize efficiency and accuracy.

Conclusion

In the high-stakes world of cold chain logistics, stagnation is not an option. The imperative to maximize ROI is driving a fundamental shift from passive storage to active, intelligent space optimization. The journey begins with a critical assessment of the current racking for cold storage and a vision for what is possible.

By embracing the engineering principles, technological integrations, and strategic planning outlined herein, cold storage operators can confidently embark on a transformation that yields not just a 40% capacity increase, but a fundamental and lasting improvement in resilience, agility, and profitability. The most valuable space in your facility is the space you already own; the right racking for cold storage is the key to unlocking it.

Frequently Asked Questions (FAQs)

1. How does the structural weight capacity of high-density racking for cold storage compare to traditional selective racking?

While individual beam capacities in high-density racking for cold storage might be similar or slightly lower, the total weight stored per square foot is dramatically higher. The engineering focus shifts from individual point loads to the total distributed load and the dynamic forces at play. Every project includes a full structural analysis to ensure the racking for cold storage and the building slab can safely support the intended load in the specific cold environment.

2. Can a pallet shuttle-based racking for cold storage system handle our wide variety of pallet types and conditions?

A shuttle system requires a high degree of pallet uniformity for reliable operation. Inconsistent pallet dimensions or damaged pallets can cause jams and system failures. A successful implementation of this type of racking for cold storage often involves a complementary investment in a pallet quality management program. For facilities with highly inconsistent pallets, a push-back racking for cold storage system may offer a more flexible and robust solution.

3. What is the true total cost of ownership for advanced racking for cold storage, including maintenance?

Beyond the initial capital outlay, the TCO includes preventive maintenance for moving parts (shuttles, mobile base drives), periodic inspections, and potential software licensing. However, this must be weighed against the TCO of a traditional system, which includes higher energy bills, more frequent damage repairs from forklift impacts, and significantly higher labor costs. The TCO for advanced racking for cold storage is often lower over a 5-7 year period.

4. How does order picking work efficiently from a high-density racking for cold storage block?

High-density racking for cold storage is primarily designed for reserve storage. The most efficient model is “goods-to-person” picking. The automated system retrieves a full pallet from the high-density racking for cold storage block and delivers it to a dedicated, climate-controlled pick station on the periphery. There, operators efficiently break down the pallet into mixed-SKU orders without ever entering the harsh storage environment, combining the benefits of ultra-dense storage with ergonomic order fulfillment.

5. We have a low-ceiling facility. Are high-density racking for cold storage solutions still viable?

Absolutely. While high-bay facilities achieve their massive gains by leveraging height and depth, low-ceiling facilities can achieve tremendous density gains by minimizing aisle space. Mobile racking for cold storage is exceptionally effective in these scenarios, as it can eliminate all but one aisle. The principles of selecting the right racking for cold storage are the same: analyze SKU profile, turnover, and operational workflows to choose the optimal system.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com