📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Optimizing Warehouse Economics: A Strategic Deep Dive into Push Back Pallet Racking

The modern warehouse is no longer a static repository; it is a dynamic, pulsating center of capital, labor, and space efficiency. In this high-stakes environment, storage methodology transitions from an operational afterthought to a core strategic lever. Among the spectrum of high-density solutions, push back pallet racking has emerged as a uniquely balanced and compelling choice for a vast array of industries.

This system represents a sophisticated fusion of mechanical engineering and logistical principle, designed to confront the universal challenge of maximizing storage footprint without sacrificing selectivity. For operations managers, logistics directors, and business owners across emerging markets—from the bustling ports of Vietnam to the industrial zones of Saudi Arabia and the growing distribution networks of Nigeria—understanding the nuanced application and tangible return on investment of push back racking is critical.

A comprehensive evaluation, culminating in a detailed warehouse-specific cost analysis, is not merely a procurement step; it is an essential business planning exercise.

The Operational Anatomy and Mechanical Philosophy of Push Back Pallet Racking

At its foundation, push back pallet racking is a gravity-assisted, last-in, first-out (LIFO) live storage system. Its design philosophy rejects the trade-off between depth and accessibility that plagues many storage approaches. The system’s intelligence lies in its elegantly simple mechanics: a series of inclined, nested cartridges or carriages mounted on rails within a robust steel frame.

Each pallet is loaded onto the front carriage at the aisle. The act of loading the subsequent pallet gently pushes the preceding one backward, utilizing the inclined plane. This process allows for the storage of multiple pallets—typically two to five deep—in a single lane. Retrieval is intuitively reversed; removing the front pallet allows the next one to roll smoothly into the accessible pick position.

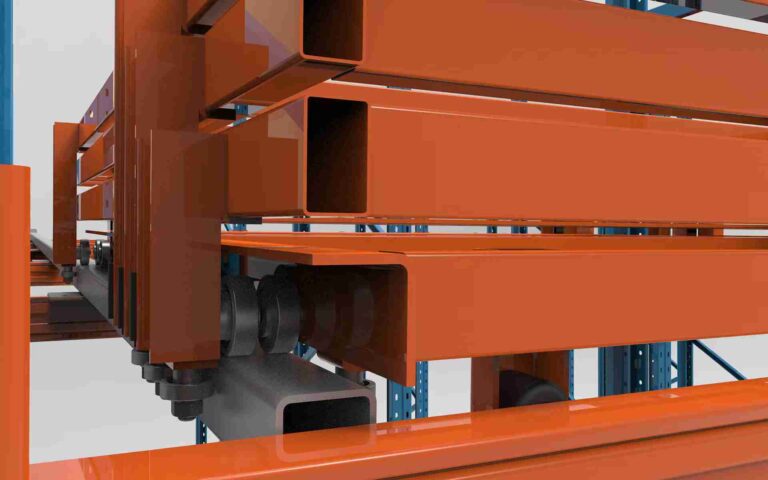

This fundamental operation belies a significant depth of engineering. A high-quality push back racking system is characterized by several non-negotiable components. The structural backbone consists of heavy-duty, roll-formed upright frames and beams, often manufactured from high-yield-strength steel and protected by advanced coating technologies to withstand diverse climatic conditions, from coastal salt air to arid desert dust. The heart of the system is the carriage assembly.

These are not simple carts; they are precision-engineered units featuring robust wheels, sealed bearings for minimal maintenance, and a calibrated incline that ensures reliable movement without excessive force, protecting both product and equipment. The integrated rail system and final stop mechanisms complete the assembly, ensuring safety, alignment, and predictable pallet positioning every time.

The choice to implement push back pallet racking is, therefore, a decision to inject dynamic movement into the storage process. It transforms a static rack bay into a “live” lane, where inventory is constantly poised for action. This inherent dynamism is what unlocks its most significant benefits, making push back racking a cornerstone for efficient warehouse design.

Quantifying the Multifaceted Advantages: Beyond Simple Density

The value proposition of push back pallet racking extends far beyond a mere increase in pallet positions. Its advantages are interconnected, creating a compound effect on warehouse productivity and profitability.

1. Transformative Space Utilization and Storage Density Gains: The most cited and compelling benefit is the dramatic reduction in aisle space. Compared to traditional selective pallet racking, a well-designed push back racking system can reduce aisle requirements by 50% to 75%. This directly translates to a 30% to 60% increase in storage capacity within the same building envelope. For facilities facing physical expansion constraints or exorbitant real estate costs—a common scenario in rapidly developing urban centers across Southeast Asia and Latin America—this density gain is revolutionary. It allows businesses to scale operations vertically and in-depth, deferring or eliminating the need for costly new construction.

2. Maintaining High Selectivity and Throughput Velocity: Unlike drive-in or drive-through systems where any pallet can be behind any other, push back pallet racking maintains lane-level selectivity. Each lane is dedicated to a single SKU, and the most recently stored unit of that SKU is always immediately accessible at the aisle face. This eliminates the “digging” or “cherry-picking” inefficiencies of other deep storage methods. Forklift operators enjoy direct, unimpeded access to the target load, significantly reducing travel and search time per transaction. The result is a measurable increase in picks and puts per hour, a crucial metric for warehouses serving fast-paced retail or e-commerce sectors.

3. Enhanced Safety and Inventory Integrity: Safety is an intrinsic design feature of proper push back racking. Pallets rest securely on sturdy carriages, not on the beams themselves, distributing weight evenly and minimizing the risk of beam deflection or collapse. The controlled, guided movement of pallets prevents the swaying, tipping, or sudden shifts common when placing loads on traditional rails. Furthermore, forklifts never need to enter the rack structure, drastically reducing the incidence of costly impacts and damage to both the racking and the MHE (Material Handling Equipment). This engineered safety directly protects the workforce, minimizes product damage and inventory shrink, and can lead to favorable insurance premiums.

4. Operational Flexibility and Future-Proofing: The modular nature of push back pallet racking offers significant adaptability. Lane depths can be specified differently within the same system to accommodate varying SKU velocities or batch sizes. As inventory profiles evolve, the system can often be reconfigured or expanded with relative ease compared to more monolithic alternatives. Furthermore, push back racking integrates seamlessly into broader automation strategies. Its predictable lane dimensions and fixed access points make it an ideal target for guided vehicles like AGVs (Automated Guided Vehicles) or unmanned forklifts, creating a high-density, automated buffer zone within a hybrid warehouse environment.

Strategic Application: Identifying the Ideal Inventory Profile

The superior performance of push back pallet racking is contingent upon its alignment with specific inventory characteristics. Its application is strategic, not universal.

An ideal candidate for push back racking exhibits a profile of high-volume, medium-to-low SKU count storage. It thrives in environments with large quantities of a limited number of products. Common examples include beverage distribution (storing pallets of water or soft drinks), packaged food warehousing, building materials, and certain chemical or pharmaceutical products with stable, non-perishable qualities. Since the system operates on a LIFO principle, it is perfectly suited for non-date-sensitive goods or products with very long shelf lives. Where First-In, First-Out (FIFO) is mandatory, alternative systems like pallet flow racking would be prescribed.

Critical to success is pallet consistency. The carriage and rail mechanism is designed for uniformity. Optimal performance is achieved with standardized, in-spec pallets of consistent dimensions, weight, and bottom deck condition (preferably four-way entry block pallets). Operations with a highly fragmented or inconsistent pallet pool may face challenges with jamming or uneven movement, underscoring the need for a disciplined warehouse management foundation alongside the physical push back racking investment.

The Imperative of a Holistic Warehouse Cost Analysis

The decision to invest in push back pallet racking must be grounded in rigorous financial analysis. Requesting a “Cost Analysis for Your Warehouse” should yield a comprehensive business case, not a simple quotation. A professional analysis dissects both the visible and hidden financial facets of the project, moving the conversation from price to value and from cost to investment.

Deconstructing the Capital Expenditure (CapEx):

The initial investment encompasses more than rack components. It includes:

System Hardware: All structural steel (uprights, beams, bracing), carriage sets, rail systems, and safety accessories specific to the push back pallet racking design.

Professional Services: Fees for detailed warehouse layout engineering, load calculations, seismic assessments (where applicable), and integration planning with existing MHE or automation.

Installation & Commissioning: Costs for skilled, certified installation crews, project management, and post-installation safety certification and load testing.

Ancillary Site Costs: Potential flooring upgrades, lighting adjustments, signage, and any building modifications required to accommodate the new system’s height or weight.

Quantifying the Operational Impact and Savings (OpEx):

This is the true engine of ROI. A superior analysis will model:

Real Estate Savings / Avoidance: The financial value of the reclaimed floor space. Can a planned expansion be canceled? Can more revenue-generating activities be housed in the existing facility? This is calculated by applying local square meter lease or ownership costs to the space saved.

Labor Productivity Gains: Reduced travel time for forklifts, faster load/unload cycles due to direct access, and simplified operation lead to higher throughput per operator. This can be translated into labor cost savings or increased handling capacity without adding staff.

Reduced Operational Risks: Projected savings from lower product damage rates, decreased racking and forklift repair costs, and potential reductions in workplace incident rates and associated insurance costs.

Energy and Indirect Savings: In climate-controlled warehouses, reducing the cubic volume requiring cooling or heating by storing more in less space can yield significant energy savings.

Synthesizing the Financial Return:

The culmination of the analysis is a clear set of financial metrics:

Net Present Value (NPV): Assessing the project’s value in today’s currency, factoring in all cash inflows (savings) and outflows (costs).

Internal Rate of Return (IRR): The projected annual return on the invested capital. For a well-planned push back racking project, IRRs often exceed a company’s hurdle rate, signaling a strong investment.

Payback Period: The time required for the cumulative operational savings to equal the initial CapEx. Many organizations witness a payback on their push back racking investment within 2 to 4 years, after which the savings flow directly to the bottom line.

A Framework for Implementation and Long-Term Performance

Adopting push back pallet racking is a managed project. Following the cost analysis and project approval, a phased implementation ensures success. The process begins with final, meticulous design and custom manufacturing of components. This is followed by coordinated site preparation and delivery. Installation by certified technicians is critical, as the precise alignment of rails and carriages is paramount for smooth operation. The project concludes with comprehensive operator training—ensuring staff understand the LIFO dynamics and proper handling techniques—and a formal commissioning with load testing.

Long-term performance hinges on a minimal but consistent maintenance regimen. This typically involves periodic visual inspections of carriage wheels and rails for debris, checking for structural integrity, and ensuring safety locks are functional. Partnering with a supplier that offers a reliable spare parts supply chain is essential for maximizing uptime over the system’s 20+ year lifespan.

Conclusion: A Strategic Investment in Logistic Resilience

In the global marketplace, where supply chain agility and cost containment are paramount, warehouse infrastructure is a strategic asset. Push back pallet racking stands out as a profoundly effective solution for businesses seeking to optimize their storage density while preserving operational speed and safety. It represents not just a storage method, but a strategic tool for capitalizing on existing space, boosting productivity, and building a more resilient, cost-effective logistics operation.

The journey to this optimization begins with knowledge and is validated by data. A detailed, transparent Cost Analysis for Your Warehouse is the essential bridge between recognizing a potential solution and executing a profitable investment. It transforms the concept of push back pallet racking from a technical specification into a validated financial opportunity, empowering decision-makers to act with confidence and precision. For operations ready to elevate their storage strategy, the first step is a collaborative, in-depth evaluation of their unique landscape—an exercise that invariably reveals the significant, quantifiable value embedded in a well-engineered push back racking system.

FAQs About Push Back Pallet Racking

1. Can push back pallet racking be used for FIFO inventory?

No, push back pallet racking operates on a LIFO system. For FIFO, consider pallet flow racking.

2. What is the maximum depth for push back pallet racking?

Most systems support 2-6 pallets deep, depending on design.

3. Does push back pallet racking require special forklifts?

No, standard counterbalance or reach forklifts work, but proper training is essential.

4. How long does installation take?

Typically 2-4 weeks, depending on warehouse size.

5. Can push back pallet racking be reconfigured later?

Yes, beams and carts can be adjusted for changing needs.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com