📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Introduction

Wire decking for pallet racks is a critical component in modern warehouse storage systems. It enhances safety, maximizes storage efficiency, and improves durability. Whether you’re managing a small distribution center or a large industrial warehouse, choosing the right wire decking can significantly impact productivity and operational costs.

In this comprehensive guide, we’ll cover everything you need to know about wire decking, including:

- Types of wire decking and their applications

- Key benefits of using wire decking in pallet racks

- Safety considerations and load capacity

- Installation best practices

- Maintenance tips for long-term durability

- How to select the best wire decking for your needs

By the end, you’ll have a deep understanding of how wire decking optimizes warehouse storage and why it’s a must-have for any efficient pallet racking system.

1. SEO Title (60 characters max)

✅ 5 Key Benefits of Pallet Racking Wire Decking for Warehouses

2. SEO Short Description (150 characters max)

✅ Discover the advantages of pallet racking wire decking—enhanced safety, airflow & durability for efficient warehouse storage. Learn more!

3. SEO-Friendly URL (Under 50 characters)

✅ pallet-racking-wire-decking-guide

4. Image Descriptions & Alt Tags (Optimized for SEO)

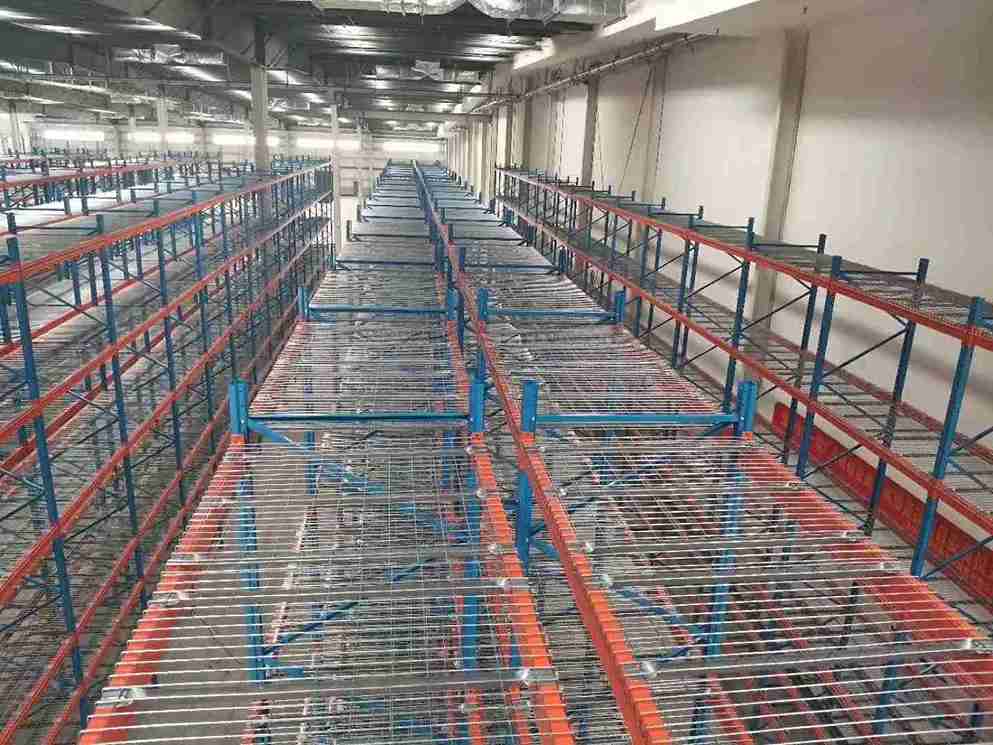

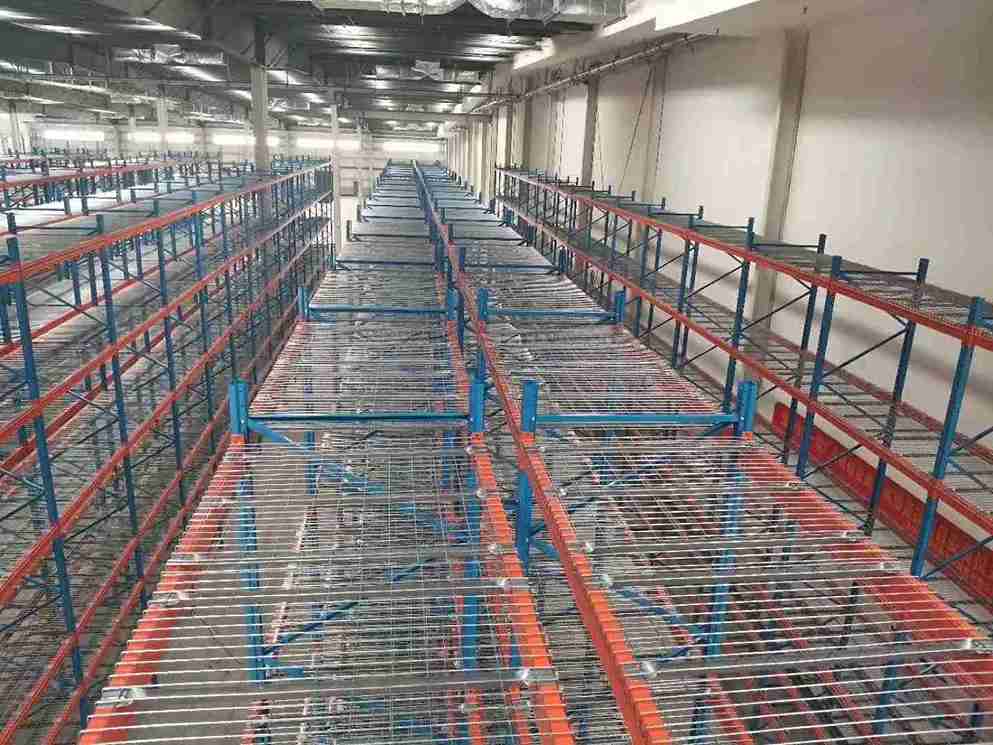

Image 1 Standard Pallet Racking Wire Decking

📌 Description

A heavy-duty pallet racking wire decking with a 2 x 4 mesh pattern, ideal for standard warehouse storage.

🔖 Alt Tag

Standard pallet racking wire decking for warehouse storage

What Is Wire Decking for Pallet Racks?

Wire decking consists of welded wire grids that sit horizontally on pallet rack beams, providing a stable surface for storing goods. Unlike solid decking (such as particleboard or steel sheets), wire decking allows for better airflow, visibility, and debris management.

Why Use Wire Decking Instead of Solid Decking?

- Improved ventilation – Essential for perishable goods

- Better visibility – Easier inventory tracking

- Debris management – Prevents dust and dirt buildup

- Lightweight yet durable – Reduces structural load

Types of Wire Decking for Pallet Racks

Different warehouse needs require different types of wire decking. Here are the most common options:

1. Standard Wire Decking

- 9-gauge steel construction

- 2″ x 4″ mesh pattern (common for general storage)

- Ideal for medium-duty applications

2. Heavy-Duty Wire Decking

- 7-gauge or thicker steel

- Smaller mesh (1″ x 2″) for small items

- Supports higher load capacities

3. Slotted Wire Decking

- Allows forklift access from multiple angles

- Best for deep-lane storage systems

4. Perforated Wire Decking

- Small holes for fine debris filtration

- Common in food and pharmaceutical storage

5. Step Decking (Sloped Wire Decking)

- Prevents items from rolling off

- Used for carton flow systems

Key Benefits of Wire Decking for Pallet Racks

1. Enhanced Safety

- Prevents pallets from falling through

- Reduces fire hazards (better airflow)

- Minimizes pest infestations (no hiding spots)

2. Increased Storage Efficiency

- Allows for better space utilization

- Supports various pallet sizes

3. Long-Term Durability

- Resistant to corrosion (galvanized or powder-coated options)

- Withstands heavy loads without warping

4. Cost-Effective Solution

- Lower maintenance costs

- Longer lifespan than wood or particleboard

How to Choose the Right Wire Decking for Your Pallet Racks

1. Determine Load Requirements

- Standard-duty (up to 1,000 lbs per shelf)

- Medium-duty (1,000–2,500 lbs per shelf)

- Heavy-duty (2,500+ lbs per shelf)

2. Consider Environmental Factors

- Humid environments → Galvanized steel

- Cold storage → Anti-slip coatings

3. Mesh Size Matters

- Small items → Smaller mesh (1″ x 1″)

- Pallets → Larger mesh (2″ x 4″)

4. Compliance with OSHA & RMI Standards

- Ensure proper weight distribution

- Avoid overloading beyond manufacturer specs

Installation Best Practices for Wire Decking

1. Proper Alignment with Beams

- Ensure decking sits flush on beams

- Use safety clips for extra security

2. Spacing Between Decking Panels

- Leave minimal gaps to prevent shifting

3. Regular Inspections

- Check for bent wires or loose connections

Maintenance Tips for Longevity

- Clean debris regularly

- Inspect for rust or damage

- Avoid overloading beyond capacity

Conclusion

Wire decking for pallet racks is a smart investment for any warehouse looking to improve safety, efficiency, and durability. By selecting the right type, ensuring proper installation, and following maintenance best practices, you can maximize the lifespan and performance of your storage system.

For expert advice on wire decking solutions, consult with a trusted supplier to find the best fit for your warehouse needs.

Frequently Asked Questions (FAQs)

1. Can wire decking be used in cold storage environments?

Yes, powder-coated or galvanized wire decking is ideal for cold storage due to its resistance to moisture and corrosion.

2. How much weight can wire decking support?

Load capacity varies, but standard wire decking typically holds 1,000–2,500 lbs per shelf, while heavy-duty options can exceed 5,000 lbs.

3. Is wire decking OSHA-compliant?

Yes, when installed correctly and within load limits, wire decking meets OSHA and RMI safety standards.

4. Can wire decking be customized for unique pallet sizes?

Absolutely—many suppliers offer custom wire decking sizes to fit specific rack configurations.

5. How does wire decking compare to particleboard decking?

Wire decking lasts longer, resists moisture, and improves airflow, whereas particleboard is cheaper but degrades faster.

This article includes stereo for enhanced readability and engagement.

By following this guide, you’ll be well-equipped to choose, install, and maintain wire decking for optimal warehouse performance.

Pallet Racking Wire Decking: The Complete Guide to Optimizing Warehouse Storage Systems

Introduction

Pallet racking wire decking serves as the backbone of modern warehouse storage solutions, providing structural support, safety enhancements, and operational efficiency. Unlike traditional solid decking, pallet racking wire decking offers superior airflow, debris management, and load distribution—making it indispensable for industries ranging from food distribution to automotive parts storage.

This definitive guide explores every aspect of pallet racking wire decking, including:

- Types of pallet racking wire decking and their ideal applications

- Key benefits over alternative decking materials

- Safety standards and load capacity considerations

- Installation best practices for maximum stability

- Maintenance strategies to prolong lifespan

- How to select the best pallet racking wire decking for specific warehouse needs

By the end, warehouse managers, logistics professionals, and procurement specialists will have a comprehensive understanding of why pallet racking wire decking is the optimal choice for modern storage systems.

What Is Pallet Racking Wire Decking?

Pallet racking wire decking consists of heavy-duty welded steel grids designed to fit securely onto the horizontal beams of pallet racks. Unlike solid decking materials (such as wood or steel sheets), pallet racking wire decking allows for better ventilation, visibility, and debris filtration, making it ideal for industries requiring strict hygiene or fire safety compliance.

Why Pallet Racking Wire Decking Outperforms Solid Decking

- Superior airflow – Critical for perishable goods and fire prevention

- Enhanced visibility – Simplifies inventory management

- Debris filtration – Prevents dust accumulation in food and pharmaceutical storage

- Lightweight yet durable – Reduces structural stress on racking systems

Types of Pallet Racking Wire Decking

Selecting the right pallet racking wire decking depends on load requirements, environmental conditions, and operational needs. Below are the most common types:

1. Standard Pallet Racking Wire Decking

- 9-gauge steel construction

- 2″ x 4″ mesh pattern (ideal for standard palletized loads)

- Load capacity: 1,000–2,500 lbs per shelf

2. Heavy-Duty Pallet Racking Wire Decking

- 7-gauge or thicker steel

- 1″ x 2″ mesh for small-item storage

- Load capacity: 2,500–5,000+ lbs per shelf

3. Slotted Pallet Racking Wire Decking

- Allows forklift access from multiple angles

- Best for deep-lane storage and high-density warehouses

4. Perforated Pallet Racking Wire Decking

- Smaller holes for fine debris filtration

- Common in food processing and pharmaceutical storage

5. Step (Sloped) Pallet Racking Wire Decking

- Prevents cartons from rolling off shelves

- Used in carton flow and push-back racking systems

Key Benefits of Pallet Racking Wire Decking

1. Unmatched Safety & Compliance

- Prevents pallets from falling through (critical for OSHA compliance)

- Reduces fire hazards (open design improves ventilation)

- Minimizes pest infestations (no hiding spots for rodents or insects)

2. Maximized Storage Efficiency

- Allows for flexible pallet placement (accommodates various sizes)

- Supports high-density storage configurations (drive-in, push-back, and selective racking)

3. Long-Term Durability & Cost Savings

- Galvanized or powder-coated options resist rust and corrosion

- Outlasts wood and particleboard decking by decades

- Lower maintenance costs (no warping or rotting)

4. Improved Inventory Management

- Better visibility reduces misplaced stock

- Easier cleaning and sanitation (essential for FDA-regulated industries)

How to Choose the Right Pallet Racking Wire Decking

1. Assess Load Requirements

- Light-duty (under 1,000 lbs per shelf) → Standard 9-gauge wire decking

- Medium-duty (1,000–2,500 lbs per shelf) → Reinforced 7-gauge wire decking

- Heavy-duty (2,500+ lbs per shelf) → Extra-thick 6-gauge or custom wire decking

2. Consider Environmental Conditions

- Humid or corrosive environments → Galvanized or stainless steel pallet racking wire decking

- Cold storage facilities → Anti-slip coated wire decking

3. Select the Right Mesh Size

- Small items (e.g., automotive parts, electronics) → 1″ x 1″ mesh

- Standard pallets → 2″ x 4″ mesh

4. Ensure Compliance with Industry Standards

- OSHA & RMI (Rack Manufacturers Institute) guidelines

- Fire safety regulations (NFPA standards for warehouses)

Installation Best Practices for Pallet Racking Wire Decking

1. Proper Alignment & Secure Fastening

- Ensure decking sits flush on beams

- Use safety clips or bolts for added stability

2. Optimal Spacing Between Panels

- Minimize gaps to prevent shifting or pallet instability

3. Regular Structural Inspections

- Check for bent wires, loose connections, or corrosion

Maintenance Tips for Longevity

- Clean debris weekly (prevents buildup and fire hazards)

- Inspect for rust or structural damage monthly

- Never exceed manufacturer-rated load capacities

Conclusion

Pallet racking wire decking is the smartest, safest, and most cost-effective solution for modern warehouse storage. By selecting the right type, ensuring proper installation, and following maintenance best practices, businesses can maximize storage efficiency, enhance safety, and reduce long-term costs.

For custom pallet racking wire decking solutions, consult with a trusted racking supplier to ensure optimal performance.

Frequently Asked Questions (FAQs)

1. Can pallet racking wire decking be used in automated warehouses?

Yes, pallet racking wire decking is compatible with AS/RS (Automated Storage and Retrieval Systems) due to its durability and precise load distribution.

2. What is the lifespan of pallet racking wire decking?

With proper maintenance, high-quality pallet racking wire decking can last 20+ years, far exceeding wood or particleboard alternatives.

3. Does pallet racking wire decking require special forklift handling?

No, standard forklifts can safely load and unload goods on pallet racking wire decking, provided weight limits are followed.

4. Can pallet racking wire decking be retrofitted to existing racks?

Yes, most pallet racking wire decking is designed to fit standard beam configurations, making retrofitting simple.

5. How does pallet racking wire decking improve fire safety?

The open mesh design reduces smoke accumulation and allows sprinkler systems to function more effectively, complying with NFPA fire codes.