📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Definitive Guide to Pallet Racking OSHA Requirements: Engineering a Safer, Compliant Warehouse frothe Ground Up

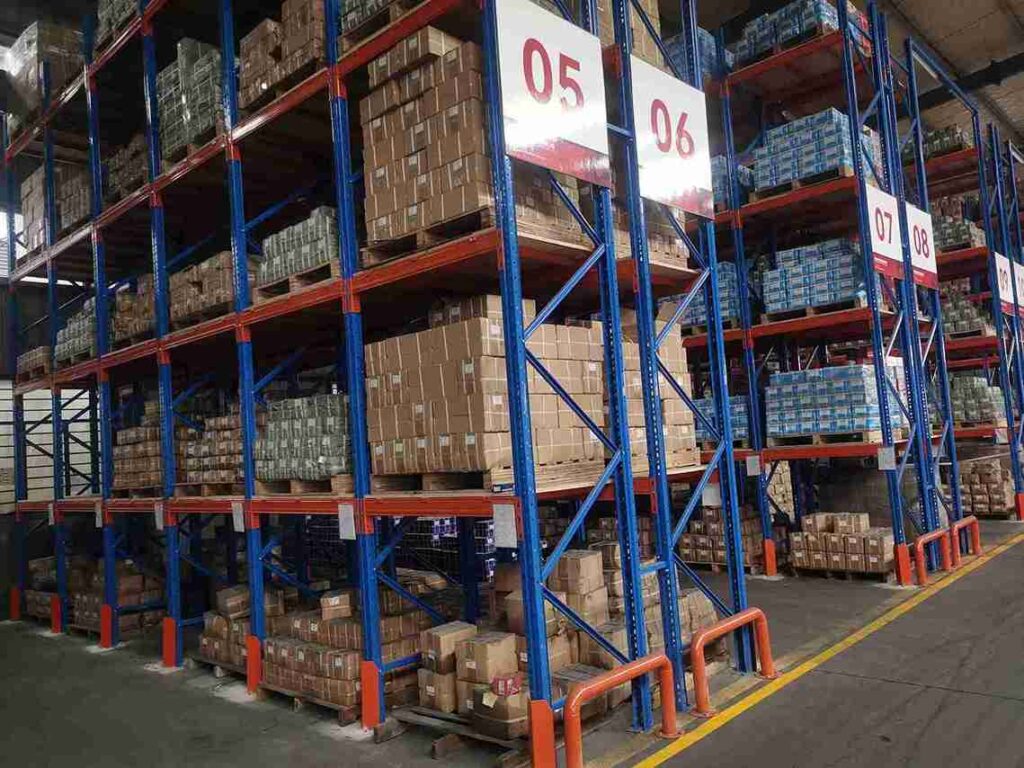

In the dynamic landscapes of emerging markets—from the bustling ports of Vietnam and the sprawling logistics parks in the UAE to the growing industrial hubs of Nigeria and Brazil—warehouse operators face a universal challenge: balancing relentless pressure for storage density and throughput with the non-negotiable imperative of worker and asset safety. At the heart of this balance lies the steel skeleton of modern logistics: the pallet racking system. Its failure is not an operational incident; it is a catastrophic event.

While the specific letter of U.S. Occupational Safety and Health Administration (OSHA) law may not jurisdictionally apply in Manila or Mombasa, the rigorous framework of pallet racking OSHA requirements has become the global gold standard for operational integrity. This guide transcends basic compliance checklists. It delves into the engineering principles, management systems, and cultural shifts necessary to transform pallet racking OSHA requirements from a perceived bureaucratic burden into the foundational strategy for a resilient, efficient, and legally defensible warehouse operation.

For any manager overseeing storage assets, understanding and implementing these pallet racking OSHA requirements is the most critical investment in business continuity they can make.

Why Global Operators Treat OSHA Standards as the Universal Safety Code

A common misconception in regions like Southeast Asia or West Africa is that pallet racking OSHA requirements are irrelevant to local operations. This is a dangerous and costly assumption. Local regulations, where they exist, often provide broad, performance-based mandates similar to OSHA’s General Duty Clause, requiring a workplace free from recognized hazards. However, they frequently lack the detailed, prescriptive guidance on how to achieve that safety. This is where the comprehensive body of pallet racking OSHA requirements, and the industry standards they reference, becomes indispensable.

They provide the “how.” Multinational corporations, international insurance underwriters, and global auditing firms increasingly use this framework as their benchmark. Therefore, adherence to pallet racking OSHA requirements is not about American law; it’s about demonstrating world-class due diligence, mitigating transnational liability, and building a facility that can attract and retain blue-chip clients. It is, in essence, the professional language of warehouse safety spoken worldwide.

Deconstructing the Regulatory Foundation: From OSHA’s Rule to Actionable Engineering

The core of pallet racking OSHA requirements is found in 29 CFR 1910.176(b), which states: “Storage of material shall not create a hazard…” This simple, powerful statement places the entire responsibility for safe storage on the employer. For pallet racking, OSHA enforcement interprets this through the lens of recognized industry consensus standards, primarily the ANSI MH16.1 standard developed by the Rack Manufacturers Institute (RMI). In practical terms, an inspector—whether from OSHA, a local authority, or a corporate safety team—will assess whether the racking system presents a hazard.

If beams are overloaded, uprights are damaged, or installations are unanchored, they constitute a hazard. The accepted method to abate that hazard is to comply with RMI/ANSI standards. Thus, pallet racking OSHA requirements effectively mandate compliance with these engineering specifications. The cycle of compliance is built on four interdependent pillars: Design & Installation, Inspection, Training, and Repair & Modification. A weakness in any single pillar compromises the entire structure’s safety.

Pillar 1: Design, Specification, and Installation – Where Compliance is Engineered

Compliance cannot be inspected into an inherently unsafe system. The first and most critical set of pallet racking OSHA requirements pertains to the system’s initial conception and physical realization.

Load Capacity and the Sacred LARC Plaque: Every component of a rack system has a rated capacity. The fundamental pallet racking OSHA requirements dictate that loads must not exceed these ratings. This is operationalized through the Load Application and Rack Configuration (LARC) plaque, a metal tag affixed to every rack bay. This plaque, an RMI mandate, is the system’s birth certificate and operational bible. It specifies the maximum permissible load per beam level, the overall bay capacity, and the configuration used in the engineering calculations. Ignoring the LARC plaque violates the most basic of pallet racking OSHA requirements. Operators must ensure that their storage plans, including the weight and dimensions of all palletized goods, are cross-referenced against this plaque.

Environmental and Seismic Design Considerations: The pallet racking OSHA requirements framework emphasizes that design must account for the operating environment. In Southeast Asia, this may mean designing for high humidity and corrosion resistance. In the Middle East, ambient temperature extremes can affect steel properties. In seismically active zones like parts of Latin America and the Philippines, design to local seismic codes (often based on IBC or similar standards) is a non-negotiable aspect of pallet racking OSHA requirements. A rack designed for a static warehouse in Germany is not inherently suitable for a facility in Chile without rigorous engineering review.

The Critical Role of Professional Installation: Even a perfectly engineered rack can fail if poorly installed. Pallet racking OSHA requirements, through referenced standards, demand installation per the manufacturer’s specifications and engineered drawings. This includes proper alignment and plumb (typically within 1/4 inch in 10 feet), correct sequencing of assembly, and the use of calibrated torque wrenches on all structural bolts. Floor flatness and anchor integrity are part of this equation. A professional, certified installation team is the best assurance that the design’s safety factor is preserved in the field.

Pillar 2: The Inspection Regime – The Continuous Pulse Check

Proactive, documented inspection is the cornerstone of ongoing compliance with pallet racking OSHA requirements. OSHA expects a formal inspection program, and RMI/ANSI provides the methodology. A best-practice program involves three escalating tiers:

Operator Visual Checks: Forklift and AGV operators should be trained to conduct a brief visual scan of aisles before and during operations, reporting any obvious, fresh impacts immediately. This is the first line of defense.

Scheduled Internal Inspections: Conducted quarterly or semi-annually by a designated, trained employee (e.g., a warehouse supervisor or safety officer). This person uses a detailed checklist based on RMI guidelines to assess every rack component for damage, wear, and misuse. Documentation of each inspection is crucial evidence of due diligence under pallet racking OSHA requirements.

Annual Professional Third-Party Audit: This is the gold standard and a critical component of robust pallet racking OSHA requirements compliance. An independent, certified rack inspector brings specialized tools (e.g., dial indicators, laser levels, ultrasonic thickness gauges) and an unbiased eye. They identify subtle fatigue, measure precise deflection, and assess cumulative damage that may be missed internally. Their formal report provides a technical snapshot of the system’s health and a prioritized repair agenda, serving as a powerful legal document.

Understanding Damage Criteria: The Science Behind the “Red Tag”

A key aspect of inspection is knowing what constitutes critical damage. Pallet racking OSHA requirements rely on RMI’s empirical research, which defines precise damage thresholds. For example:

Upright Frame Damage: A dent deeper than 3/4 inch in a critical column location, or any visible tear, can reduce load capacity by up to 50%. Brace members are equally critical. Inspectors measure dent depth and location against strict charts.

Beam Deflection and Connection Integrity: Beams showing permanent downward sag (set) under no load, or with damaged/ missing beam locks, pose imminent collapse risks. Connector hooks must be fully seated and undamaged.

Anchorage and Alignment: Loose, missing, or corroded anchors violate the fundamental pallet racking OSHA requirements for stability. Racks leaning out of plumb create dangerous eccentric loads.

Pillar 3: Training and Operational Discipline – The Human Factor

Technology fails only when human systems allow it. Pallet racking OSHA requirements explicitly place the responsibility for worker training on the employer (OSHA 1910.178, Powered Industrial Trucks). This goes beyond basic forklift licensing.

Rack-Aware Forklift Operator Training: Operators must be trained on the specific physical limits of the racking in their facility. This includes understanding the LARC plaque, recognizing the fragility of uprights (often compared to aluminum cans in compression), and mastering maneuvering to avoid impacts. Training should include consequences: a 5 mph impact can generate tens of thousands of pounds of force, easily exceeding the design capacity of an upright.

Load Placement and Handling Protocols: Compliance with pallet racking OSHA requirements demands disciplined load management. Pallets must be centered on beams, not overhanging. Damaged or unstable pallets must not be racked. The use of pallet support bars or wire decking may be required for small or unstable loads, as per the original design.

Integrating Automation (AGV, Unmanned Forklifts): Automated guided vehicles and robotic forklifts introduce new variables. Their paths must be meticulously programmed and physically protected (e.g., with column guards) to prevent repetitive micro-impacts. Their load placement accuracy must be flawless and regularly validated. The pallet racking OSHA requirements for load stability and placement apply with even greater rigor to automated systems, as human oversight is less immediate.

Pillar 4: Repair, Modification, and Documentation – The Protocol for Integrity

When damage occurs or changes are needed, a formal protocol aligned with pallet racking OSHA requirements is essential to maintain system certification and safety.

The Absolute Prohibition of Field Welding: Welding on rack components without controlled procedures anneals the high-strength steel, creating localized brittle zones that can fail catastrophically without warning. Pallet racking OSHA requirements and RMI standards explicitly forbid unauthorized welding. All repairs must use manufacturer-approved, engineered repair kits (e.g., sleeve reinforcements for dented uprights) installed by qualified personnel.

Engineering Review for Any Modification: Changing beam elevations, adding cross-bracing, tying into a building column, or increasing the number of tiers is a modification. Each modification changes the load dynamics and requires a professional engineering review to recalculate capacities and update the LARC plaque. Proceeding without this review voids all prior certifications and blatantly violates core pallet racking OSHA requirements.

The Lockout-Tagout-Unload Process: Any rack component identified with “red tag” damage must be immediately unloaded, cordoned off, and tagged out of service until a certified repair is completed. This formal process, analogous to equipment lockout/tagout, must be part of the written safety program addressing pallet racking OSHA requirements.

The Tangible Cost of Ignoring Pallet Racking OSHA Requirements

The rationale for investing in a program based on pallet racking OSHA requirements is starkly economic and ethical. Non-compliance carries a multi-faceted cost:

Direct Catastrophe: A progressive collapse can destroy millions in inventory, halt operations for months, and cause fatalities.

Financial and Legal Liability: Costs include business interruption, insurance deductibles and premium hikes, massive regulatory fines (even in local jurisdictions), and devastating civil litigation from injured parties.

Reputational Capital: A company known for a warehouse collapse or serious safety violations will struggle to attract quality employees, retain customers, and secure financing.

Buocalized nuance.

Southeast Asia: High humidity and frequent rain demand a focus on corrosion protection (hot-dip galvanized finishes) and concrete floor integrity. Seismic design is crucial in the Philippines and Indonesia.

Middle East: Extreme heat and sand abrasion require specific material considerations. Supply chain volatility can lead to the use of non-OEM parts; a strict procurement policy mandating certified components is vital.

Africa: Challenges may include voltage fluctuations affecting warehouse lighting for inspections, and a scarcity of local certified inspectors, underscoring the need to develop internal audit competency or partner with international firms.

Latin America: Robust seismic codes exist, but enforcement can be variable. A proactive approach based on pallet racking OSHA requirements provides a clear, defensible standard that exceeds local minimums.

Selecting a Partner Who Embodies the Spirit of OSHA Requirements

The choice of supplier for racking, automated guided vehicles (AGVs), or conveyor systems is a choice in a safety partner. Key vetting questions must center on pallet racking OSHA requirements:

Can you provide full seismic calculations for our specific site?

Do you maintain an inventory of OEM-certified repair parts and offer certified repair services in our region?

Will your installation crew provide post-installation alignment and torque reports?

Do you offer training modules for our staff specifically on the inspection and operation of the system you provide?

Conclusion: From Compliance to Competitive Advantage

Ultimately, a deep, operational commitment to pallet racking OSHA requirements represents a paradigm shift. It moves safety from a cost center to a core component of operational excellence and risk management. In the high-growth, competitive markets of the world, a warehouse known for its impeccable safety standards is a more valuable asset, enjoys lower insurance costs, attracts a more stable workforce, and presents a lower risk profile to investors and partners. The detailed, systematic approach demanded by pallet racking OSHA requirements is the blueprint for building that asset. It is not merely about avoiding collapse; it is about constructing a legacy of reliability and responsibility.

Advanced FAQs on Pallet Racking OSHA Requirements

How do pallet racking OSHA requirements apply to rack-supported mezzanines or semi-automated systems like carton-flow lanes?

The principles are identical but more complex. A rack-supported mezzanine is a structure governed by building codes and rack standards. It requires a professional engineer’s stamp for both the building authority and the rack safety program. Carton-flow lanes add dynamic live loads. The pallet racking OSHA requirements mandate that the entire integrated system, including the live load of moving cartons and the point loads of pickers, is engineered, documented on a LARC plaque, and inspected accordingly.

We are planning a warehouse expansion. What specific documentation should we demand from our rack supplier to ensure we meet pallet racking OSHA requirements from day one?

Demand a complete engineering package: signed and sealed design calculations, detailed erection drawings, manufacturer-specific LARC plaques, and a certificate of compliance stating the rack meets ANSI MH16.1. Also, require documentation that the installers are trained/certified by the manufacturer.

Is there a recognized certification for individuals who conduct professional rack inspections per pallet racking OSHA requirements?

Yes. The RMI offers a Certified Storage Rack Inspector (CSRI) program. SEMA in the UK offers a similar credential. Hiring an inspector with such a certification is strong evidence of your commitment to meeting pallet racking OSHA requirements.

How frequently should we replace our racking system? Is there a service life mandated by pallet racking OSHA requirements?

There is no fixed service life in the pallet racking OSHA requirements. Service life is determined by the condition found during inspections. A well-maintained, rarely impacted rack in a controlled environment can last decades. A rack in a high-traffic, high-impact environment may require component replacement much sooner. The inspection cycle dictates the replacement schedule, not a calendar.

With the rise of IoT sensors, can technology help us achieve continuous compliance with pallet racking OSHA requirements?

Absolutely. While not a replacement for physical inspections, IoT solutions (impact sensors on uprights, load monitoring sensors on beams, tilt sensors) provide real-time data and alerts. This allows for immediate response to impacts and creates a valuable data log proving proactive monitoring, aligning perfectly with the performance-based goals of pallet racking OSHA requirements.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com