📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

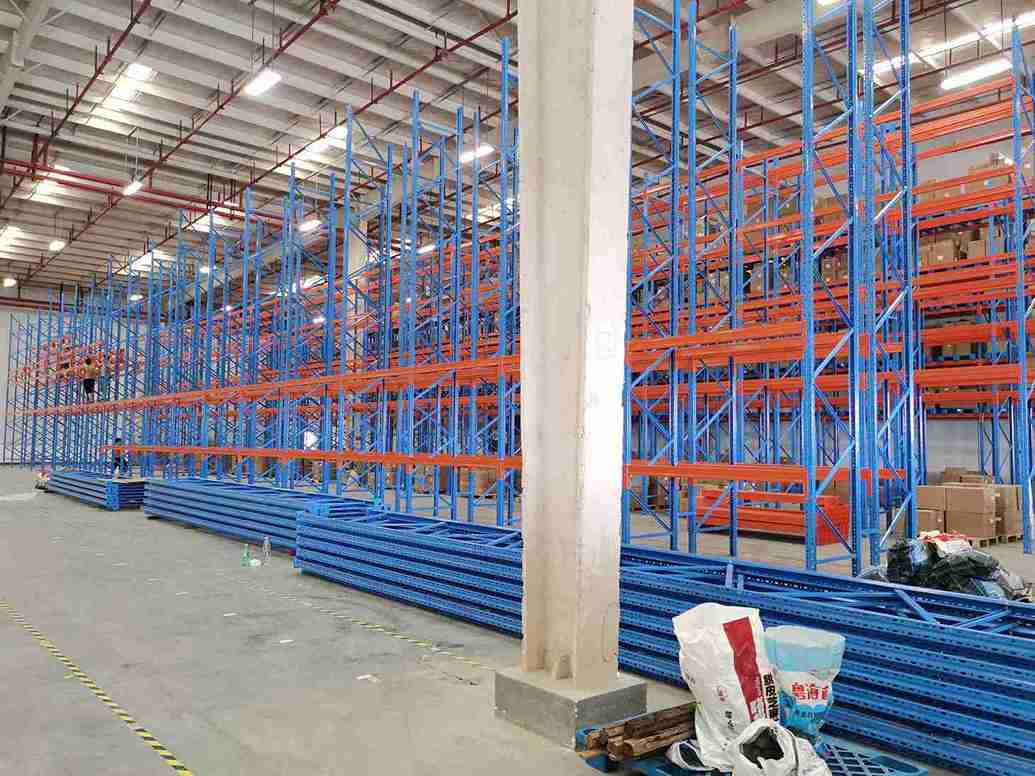

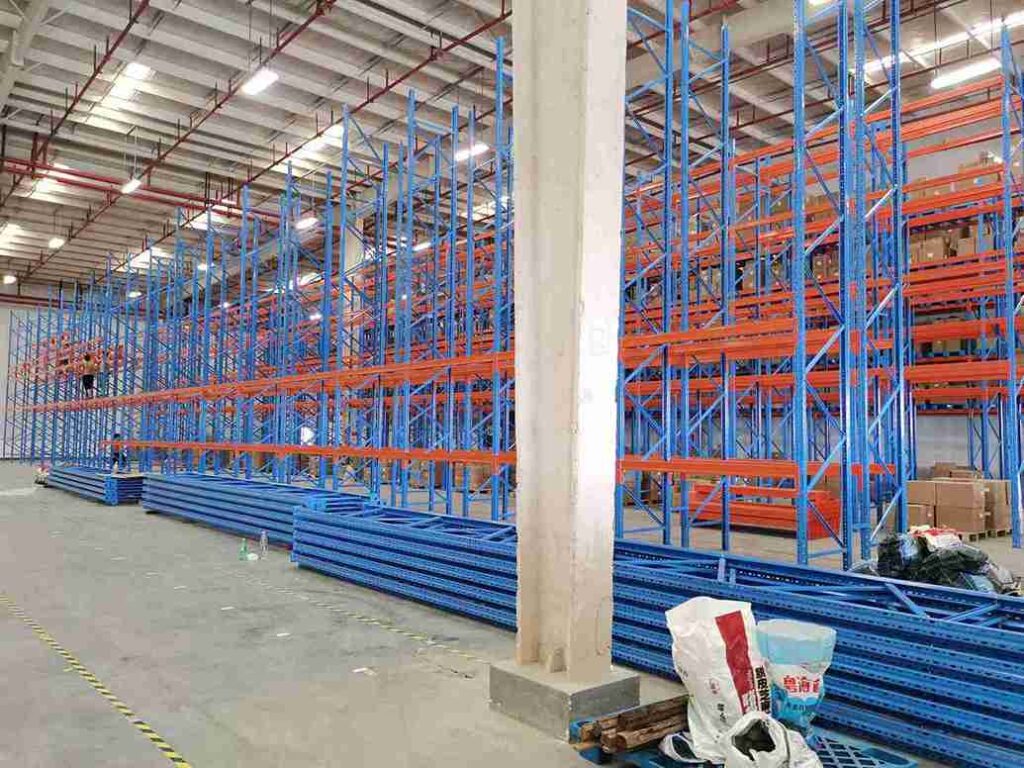

As global supply chains become more intricate and competitive, businesses must rely on intelligent infrastructure to support their warehouse operations. One of the most critical components of an efficient logistics environment is the pallet racking installation. Properly designed and expertly installed systems don’t just store pallets—they optimize workflows, maximize space utilization, reduce labor costs, and ensure safety and scalability for years to come. This article delves into how professional pallet racking installation from a trusted China-based manufacturer can save time, cut costs, and support long-term growth across industries. With extensive experience and a commitment to quality, our solutions meet the highest standards in warehouse engineering and global logistics performance.

H1: Understanding the Importance of Pallet Racking Installation

Every warehouse operation depends on seamless inventory movement, reliable storage solutions, and a layout that supports productivity. At the core of this system lies the pallet racking installation process. While the steel components might appear uniform, the planning, customization, and professional setup are critical for optimal performance.

Improper implementation can cause alignment issues, safety hazards, reduced load capacity, and workflow disruptions. In contrast, expert pallet racking installation ensures structural integrity, precise fitment, and compliance with seismic or local regulations. It also forms the basis for future upgrades, whether adding mezzanines, integrating AGVs, or automating picking systems.

In today’s data-driven logistics environments, where every second of downtime impacts fulfillment KPIs, cutting corners on pallet racking installation is no longer an option.

H2: Why Professional Installation is So Important for Your Warehouse

A warehouse is not just a storage facility—it’s a strategic asset. Maximizing its value means ensuring every square meter works harder. This is where skilled pallet racking installation adds measurable value. By working with trained technicians and industry-specific engineers, businesses gain access to:

- Optimized Load Distribution: Proper weight dispersion reduces frame stress and extends equipment lifespan.

- Precision Alignment: Even minor deviations can lead to pallet jams or compromise structural safety.

- Faster Project Completion: Professional crews complete systems efficiently, even in large-scale setups.

- Compliance Assurance: Work is performed in accordance with OSHA, FEM, and ISO standards.

- Future-Proofing: A properly installed system enables easy expansion without the need for dismantling.

Choosing professional support for pallet racking installation is a strategic investment that safeguards operations and protects assets.

H3: End-to-End Installation Workflow

Delivering a robust and compliant system requires much more than basic assembly. It demands an orchestrated process, driven by logistics insight and engineering precision:

- Warehouse Audit and Consultation: Our team evaluates the client’s operation—product mix, throughput goals, SKU velocity, and access methods (manual, forklift, AGV). This lays the foundation for a customized pallet racking installation plan.

- CAD-Based Layout Design: Engineers draft detailed layouts that optimize space and factor in seismic zones, safety clearances, and forklift movement. Every aspect is tailored for productivity and safety.

- In-House Manufacturing and Quality Assurance: All components are manufactured in our ISO-certified facility. Strict quality checks ensure consistency, on-time delivery, and scalability.

- Pre-Installation Site Prep: Technicians prepare the environment by leveling the floor, verifying lighting, dust control, and drainage.

- Rack Assembly and Anchoring: Crews use laser-guided tools for precision placement. Anchor bolts and bracing ensure system integrity throughout the pallet racking installation.

- Final Inspection and Commissioning: We conduct dimensional checks, load tests, and issue compliance certifications. Optional IoT and RFID solutions are added here.

- Post-Installation Training and Support: Clients receive user training, inspection guidelines, and maintenance schedules to maximize the longevity of their pallet racking installation.

H4: Customized Solutions for Every Warehouse

Every facility is unique. That’s why each system we deliver is adapted to industry-specific needs and workflows:

- Food & Beverage: Corrosion-resistant frames suitable for cold storage and easy-to-clean surfaces.

- E-commerce Fulfillment: High-density configurations for fast-moving SKUs, integrated with smart conveyors.

- Automotive & Manufacturing: Heavy-duty options for storing parts, tires, and component assemblies.

- Retail Distribution: Adjustable systems for seasonal demand shifts and varied inventory profiles.

Our pallet racking installation service accommodates cross-docking setups, hybrid picking systems, and future expansion planning.

H5: The Cost of Poor Execution

Improper setup is one of the hidden costs in warehouse operations. The initial savings from using unqualified labor are quickly negated by:

- Downtime: Misaligned systems slow operations.

- Risk of Collapse: Inadequate anchoring increases the chances of failure.

- Legal Issues: Unsafe environments expose businesses to lawsuits and compensation claims.

- Insurance Complications: Non-compliance can void policies or raise premiums.

- Retrofitting Expenses: Fixing errors often requires complete reinstallation of the pallet racking installation.

Investing in professional pallet racking installation services early prevents long-term losses.

H6: The Role of Accurate Site Assessment

A successful pallet racking installation project starts with a thorough site evaluation. This ensures technical soundness and practical feasibility. We assess:

- Floor Load Capacity: Verifying the slab can support the system plus inventory weight.

- Environmental Conditions: Evaluating humidity, temperature, and corrosion potential.

- Traffic Patterns: Mapping forklift, AGV, and worker movement to avoid congestion.

- Regulatory Requirements: Ensuring fire spacing and seismic standards are met.

These insights are essential for designing a durable and safe pallet racking installation solution.

H7: Safety Protocols That Set Us Apart

Safety is embedded in every phase of our work. Our team maintains a zero-incident mindset and adheres to global standards:

- Compliance with FEM and SEMA guidelines

- ISO-certified processes and quality control

- PPE enforcement and hazard marking

- Load certification upon completion

- In-person training for inspection and safe usage

Anti-collapse mesh, locking pins, and reinforced bases are used where necessary to enhance the safety of your pallet racking installation.

H8: Technology Integration

Modern warehouses require more than static infrastructure. That’s why our pallet racking installation integrates smart solutions:

- Shuttle Systems for automated storage

- AGV-Compatible Aisles

- IoT Load Monitoring

- WMS and ERP Compatibility

These features make your pallet racking installation a stepping stone to future automation.

H9: Global Reach, Local Expertise

As a China-based producer, we combine cost efficiency with global accessibility. Our partners benefit from:

- Factory-Direct Rates

- Short Manufacturing Timelines

- Multilingual Project Managers

- Certified Local Installation Teams

From Southeast Asia to Europe and North America, our crews collaborate with engineers, contractors, and managers to deliver fast, compliant pallet racking installation results.

H10: Real-World Success Stories

Case Study 1: Netherlands Retail Center A 14,000 sqm facility adopted a hybrid storage system. The project was completed in just 18 days, improving pick efficiency by 45% thanks to strategic pallet racking installation.

Case Study 2: Korean Cold Chain Operation Faced with low temperatures and tight spaces, we installed corrosion-resistant racks and doubled storage utilization with efficient pallet racking installation.

Case Study 3: U.S. Automotive Parts Supplier Heavy-duty structures were installed two weeks early, delivering $80,000 in operational savings through seamless pallet racking installation.

Conclusion

Professional pallet racking installation is among the best investments in warehouse infrastructure. It improves safety, reduces costs, and increases throughput. Our globally supported services ensure rapid delivery and tailored design.

If you’re planning an upgrade or new project, our experienced team is ready to design, manufacture, and implement a future-ready pallet racking installation solution that fits your every operational and strategic requirement.

Q1: How long does pallet racking installation usually take? A: From 3 days to 4 weeks, depending on scale and complexity.

Q2: What’s included in your pallet racking installation service? A: Design, delivery, professional assembly, testing, and ongoing support.

Q3: Can automation be added after pallet racking installation? A: Yes, systems are compatible with AGVs, shuttles, and conveyors.

Q4: How is pallet racking installation quality guaranteed? A: Compliance with international standards and detailed inspections.

Q5: Do you operate pallet racking installation outside China? A: Yes, we serve over 60 countries with certified local partners.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com