📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

A Strategic Blueprint: Mastering True Pallet Racking Cost Per Square Foot for Global Supply Chains

For logistics managers, warehouse operators, and business owners across Southeast Asia, the Middle East, Africa, and Latin America, the search for a definitive pallet racking cost per square foot is a common starting point. However, industry veterans understand this figure is a gateway to a far more complex and consequential conversation. The quoted cost per square foot is merely a static snapshot in a dynamic operational landscape. True investment intelligence lies in dissecting the total cost of ownership (TCO) and understanding how strategic design and technological integration can radically redefine this metric, transforming storage infrastructure from a capital expense into a scalable competitive asset.

This comprehensive analysis moves beyond simplistic pricing. It delves into the engineering, economic, and operational variables that determine the real pallet racking cost per square foot over a system’s lifetime. Crucially, it demonstrates how innovative racking configurations and the integration of automation—such as Automated Guided Vehicles (AGVs) and Automated Storage and Retrieval Systems (AS/RS)—do not merely represent an added cost but are powerful levers to optimize the long-term storage cost per square foot by maximizing volumetric efficiency, accelerating throughput, and building operational resilience. In the high-growth, fast-evolving markets that define today’s global logistics hubs, this perspective is indispensable.

Deconstructing the Real Metrics Behind Pallet Racking Cost Per Square Foot

In 2024, focusing solely on the initial purchase price for pallet racking cost per square foot is a strategic misstep. Volatile raw material markets, fluctuating logistics corridors, and the imperative for supply chain agility demand a holistic view. The professional benchmark shifts from a simple spatial cost to the dynamic cost per pallet position retrieved per hour. A superficially cheaper, low-density system that consumes excessive floor space and demands high labor input invariably carries a heavier long-term operational burden than a smarter, denser solution with a higher initial ticket.

For a 3PL in Thailand scaling for e-commerce peaks, a freezer storage operation in the UAE, or a manufacturing hub in Mexico, the calculation must encompass scalability. Therefore, astute analysis evaluates three intertwined cost spheres: the Capital Expenditure (CapEx) of the physical system, the recurring Operational Expenditure (OpEx) of running it, and the often-overlooked Opportunity Cost of inefficiency and inflexibility. Advanced storage solutions are engineered to compress all three, delivering a net-present value that fundamentally alters the traditional understanding of pallet racking cost per square foot.

The Anatomy of Investment: A Granular Breakdown of System Costs

To command the economics of a warehouse fit-out, one must dissect the invoice beyond the bottom line. A racking system is a precision-engineered asset, not a bulk commodity.

Core Material Science and Fabrication Integrity

The foundation lies in the metallurgy and fabrication quality. High-tensile, roll-formed steel provides a superior strength-to-weight ratio, directly impacting load capacities and long-term structural integrity. The protective finish—typically a multi-stage electrostatic powder coating—is not cosmetic; it is a vital shield against corrosion in the humid climates of Vietnam or the saline coastal air of Mombasa. Opting for a lower-grade material to reduce the upfront pallet racking cost per square foot is a Faustian bargain.

The inevitable consequences—premature fatigue, higher maintenance frequency, and a shortened system lifespan—will inflate the true lifetime cost per square foot substantially. Expert suppliers specify materials calibrated to both the local environmental stressors and the dynamic load profiles of the client’s inventory.

Strategic Design and Engineering: The Blueprint for Efficiency

This phase is where genuine optimization is authored. A generic, copy-paste layout inherently wastes space; a custom-engineered design creates capacity. The process involves a forensic analysis of SKU profiles, turnover velocity (critical for FIFO or LIFO flows), material handling equipment (MHE) specifications, and ambitious growth projections. Utilizing advanced 3D simulation tools, engineers model traffic patterns and pick paths to pre-empt bottlenecks.

This investment in professional design, though a line item in CapEx, is the most potent tool for reducing the effective operational cost per square foot. It ensures every cubic meter of the warehouse—from floor to ceiling—is a productive asset. In contrast, poor design manifests as wasted aisle space, unreachable storage positions, and the urgent, costly need for premature expansion.

Logistics, Installation, and Commissioning: The On-Ground Reality

A racking system’s safety and performance are inextricably linked to its installation. Project budgeting must account for certified installation crews, their specialized equipment, and realistic timelines. In regions like Central Asia or certain African nations where specialized labor may be scarce, this may involve mobilizing a regional expert team.

Logistics—the journey from manufacturing plant to final site—constitute a significant and volatile variable. Managing ocean freight, customs clearance, local trucking, and on-site storage requires precision to avoid delays that balloon the project’s overall pallet racking cost per square foot. Established suppliers mitigate this through regional hub-and-spoke models and meticulous logistics planning.

Certification and Compliance: The Non-Negotiable Foundation

Any credible supplier must provide structural load certifications and documentation proving compliance with international standards (e.g., FEM, RMI) and, pivotally, local building and safety codes. In seismic zones like Indonesia or Chile, this engineering is non-negotiable and complex. Overlooking stringent certification for a marginally lower quote is an existential risk, potentially leading to structural failure, voided insurance, and severe liability. This component of the pallet racking cost per square foot is an investment in risk mitigation and uninterrupted business continuity.

The Hidden Cost Drivers Eroding Warehouse Profitability

The most significant expense of a storage system is often not its price tag, but the operational inefficiencies it perpetuates.

The High Price of Poor Space Utilization

The most common and costly error is the underutilization of the vertical cube. Conservative design and manual handling limitations often leave meters of unused air space above inventory—space that is already paid for through rent or capital depreciation. In markets like Manila or Bogotá where industrial real estate costs are surging, failing to maximize storage density directly erodes profitability. The effective storage cost per square foot becomes exorbitant when only 60-70% of the available building volume is leveraged.

Operational Friction: Labor, Time, and Error Amplification

A layout that forces forklifts into long, congested travel paths directly increases cycle times, energy consumption, and labor hours. Each extra minute of travel is a recurring cost compounded across shifts and years. Furthermore, a disorganized storage scheme leads to mis-picks, lost inventory, and shipment delays—eroding customer trust and margins. These relentless operational expenditures are direct derivatives of storage design and have a far more profound impact on the true pallet racking cost per square foot over a decade than any initial purchase price differential.

The Future-Proofing Deficit: Cost of Obsolescence and Modification

A static system that cannot adapt to evolving inventory or business needs becomes a liability. The need to accommodate taller pallets, heavier products, or a different picking strategy should not necessitate a complete overhaul. If the system lacks inherent modularity, the cost of modification—including production downtime, new components, and re-installation—can be prohibitive. A visionary design embeds adaptability, protecting the long-term value of the pallet racking investment per square foot against inevitable change.

Strategic Optimization: Levers to Redefine Cost Per Square Foot

True optimization is the deliberate application of engineering and technology to convert storage infrastructure from a cost center into a performance engine.

Advanced Storage Configurations: Engineering Density and Flow

Transcending basic selective racking is the first strategic leap toward mastering pallet racking cost per square foot.

The Push Back Racking Analysis: Aisles vs. Density

While selective racking offers universal access, it demands wide aisles (often 3+ meters). Push back racking, storing pallets 2-5 deep on dynamically nested carts, dramatically increases density by eliminating entire aisles. The immediate pallet racking cost per square foot of floor space improves because more pallets occupy the same footprint. Ideal for medium-to-high-turnover products with multiple pallets per SKU—common in FMCG distribution across Southeast Asia—the incremental cost of the pushback mechanism is typically offset within 18-24 months by the savings in valuable building space, thereby reducing the long-term operational cost per square foot.

Drive-In/Drive-Thru Systems: Maximum Density for Specific Applications

For cold storage or bulk storage of homogeneous products (e.g., bottled beverages, raw materials), drive-in racking offers unparalleled density. Forklifts drive directly into the rack structure, utilizing every cubic inch. This design can boost storage density by up to 80% compared to selective racking, drastically lowering the storage cost per square foot for suitable inventory. The critical cost factors are the need for exceptionally robust uprights to withstand frequent contact, specialized operator training, and a disciplined LIFO inventory management approach. For large-scale agricultural exporters in Africa or Latin America, the savings in required building volume are transformative.

Pallet Flow Racking: Automated FIFO as an Operational Advantage

Pallet flow systems utilize gravity on inclined tracks to create a continuous, first-in-first-out (FIFO) flow. This is paramount for perishables, pharmaceuticals, or dated products. It merges high storage density with automated stock rotation, eliminating manual labor for rotation and drastically minimizing spoilage risk. While the capital cost per pallet position is higher, the dramatic reduction in product waste and labor for stock management delivers a compelling ROI. For the food processing sector in the GCC or pharmaceutical distributors in Brazil, this system optimizes both the pallet racking cost per square foot and the cost of goods sold (COGS).

The Automation Integration Imperative: AGVs and AS/RS

This is the frontier where warehouse economics are being rewritten. Automation is a scalable strategy for modernizing facilities in Jakarta, Riyadh, Lagos, and Santiago.

Case Study Deep Dive: AGV Integration in a Manila 3PL

The Operational Challenge: A third-party logistics provider in the Philippines, serving global e-commerce brands, contended with severe labor turnover, rising wage pressures, and a 40% seasonal demand spike. Their manual, selective racking system was slow, error-prone during peaks, and physically demanding.

The Engineered Solution: A hybrid, phased approach was deployed. The warehouse core was reconfigured into a high-density push back racking block for bulk storage. A fleet of pallet-handling AGVs was integrated to autonomously service this block, handling all pallet movements from receiving to storage and from storage to forward picking zones. Manual pickers were concentrated in optimized, ergonomic pick modules.

The Quantifiable Outcome:

Labor Productivity: Forklift operator requirements dropped by over 60%, allowing staff reallocation to value-added tasks.

Throughput & Scalability: 24/7 operational capability was achieved. Peak season throughput surged by 130% without additional hiring, directly addressing the core business challenge.

Spatial Efficiency: The dense push back block, enabled by AGV precision, increased storage capacity by 45% within the existing envelope.

Accuracy & Safety: Pallet misplacement errors fell to near-zero, and forklift incidents in the automated zone were eliminated.

Cost Transformation Analysis: The CapEx encompassed both racking reconfiguration and AGV investment. However, the OpEx savings and new revenue capacity from increased throughput yielded a payback period of under 30 months. The effective, all-in cost per square foot for storage and handling was reduced by more than half, fundamentally altering the company’s service offering and profitability.

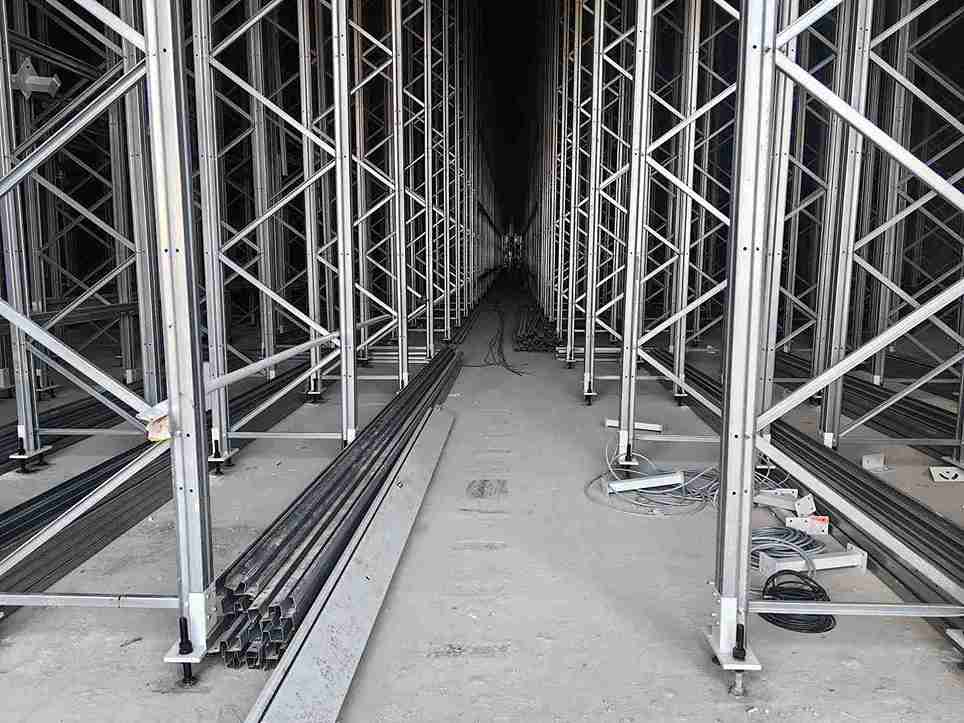

The AS/RS Equation: Vertical Growth as a Strategic Alternative

For new greenfield sites or facilities facing extreme land cost premiums, the most powerful solution is vertical. Automated Storage and Retrieval Systems (AS/RS), with cranes operating within the rack structure itself, represent the apex of density and speed. An AS/RS can triple the storage capacity within the same building footprint compared to conventional high-bay racking. In this scenario, the traditional pallet racking cost per square foot of floor area becomes almost moot, as the investment is in creating multiple vertical storage tiers.

The decision model suits high-volume, high-SKU environments with rapid turnover. Interest is robust from pharmaceutical distributors in the Middle East and advanced manufacturers in Southeast Asia. When integrated with a WMS and AGVs for horizontal transport, it creates a “lights-out” logistics nucleus, setting a new benchmark for low operational cost per cubic foot stored.

Engineering for Legacy: Climate and Seismic Factors in Emerging Markets

A racking system in the desert climate of Dubai faces different existential threats than one in the tropical humidity of Bangkok or an industrial zone in Lagos. Professional engineering is inherently localized.

Seismic and Wind Load Engineering: Non-Negotiable Safety

The Pacific Ring of Fire makes seismic design mandatory for countries like the Philippines and Chile. Systems require engineering with specific seismic coefficients, involving additional bracing, heavier gauge uprights, and specialized anchor bolts. Similarly, in regions prone to cyclones or high winds, wind load calculations govern design. Sacrificing this engineering integrity for a lower initial pallet racking cost per square foot is unconscionable. Reputable engineering teams commence with a geotechnical and climatic risk assessment for the precise site.

Corrosion Defense for Harsh Environments

High humidity, saline air, and industrial pollution aggressively attack steel. A standard powder coat is insufficient for a port-side warehouse in Haiphong or a chemical storage facility in Panama. For harsh environments, a multi-stage defense is specified: phosphating for adhesion, a high-build epoxy primer, and a durable polyester top-coat. In extreme cases, hot-dip galvanizing the structural members prior to painting offers supreme protection. This increases the initial material cost per square foot but is the definitive factor in achieving a 25+ year service life, representing the most economically sound choice for the total pallet racking cost per square foot over the asset’s lifetime.

Regional Strategic Playbooks: Optimizing for Localized ROI

Southeast Asia: Mastering Density in Constrained Urban Landscapes

The primary challenge is the premium on urban and peri-urban space, exacerbated by the e-commerce boom in Indonesia, Vietnam, and Thailand. The strategic response is vertical density and automation-readiness. Recommendations frequently center on narrow aisle racking systems, supported by wire-guided reach trucks or turret trucks, as an intermediate automation step. For large-scale fulfillment centers, multi-tier mezzanine structures integrated with conveyor or AGV systems on different levels maximize cube utilization. The philosophy emphasizes phased, scalable investment—racking infrastructure first, with automation layers added as volume justifies—to align with capital flow and business growth, thereby managing the phased pallet racking cost per square foot investment.

The Middle East: Scale, Technology, and Climate Control

Characterized by visionary mega-projects and economic diversification drives, markets like Saudi Arabia and the UAE demand future-proof solutions. Conversations begin with high-bay racking and swiftly progress to fully automated AS/RS and integrated AGV fleets. A critical, specialized consideration is temperature-controlled storage for pharmaceuticals, fine chemicals, and electronics. Racking designs must facilitate consistent air circulation, and automation provides the added benefit of minimizing ambient air exchange, reducing the energy cost per square foot for climate control. The calculation here is on a grand scale, where automation drives down the long-term operational cost per square foot of mega-facilities.

Africa: Balancing Durability, Simplicity, and Total Cost

The African market requires solutions that prioritize robustness and ease of maintenance, given varied supply chains for spare parts. Engineering emphasizes over-specification for durability—superior steel grades, enhanced protective finishes—to withstand demanding operational environments and extend service intervals. Systems are designed for straightforward repair using locally available skills. While selective racking remains a versatile workhorse, pallet flow systems are gaining traction in the FMCG sector for expiry date management. The business case for automation is built on reliability, consistency, and mitigating challenges in sourcing skilled forklift operators, all factors that influence the real pallet racking cost per square foot.

Latin America: Adapting to Diverse Industrial Ecosystems

From the manufacturing corridors of Mexico to the agricultural export zones of Chile and Brazil, requirements are diverse. In industrial hubs, integration of racking with production line feeding via conveyors or AGVs is paramount. In agro-export, drive-in racking for seasonal buffer stock and pallet flow for processing lines are prevalent. Seismic engineering is critical for the Pacific coast. The strategic approach involves aligning the storage system not just with the warehouse, but with the entire end-to-end supply chain, ensuring the pallet racking cost per square foot investment amplifies efficiency across the production and export lifecycle.

Conclusion: Reframing Cost as a Measure of Strategic Value

The pursuit of an optimized pallet racking cost per square foot is, in essence, a strategic exercise in total lifecycle asset management. It begins by rejecting the commoditization of storage infrastructure and embracing it as the foundational framework for operational excellence. By investing in professional design, environmentally-calibrated fabrication, and a vision that integrates scalability and automation readiness, businesses transform a capital outlay into a long-term engine for growth, resilience, and competitive differentiation.

For enterprises competing in the dynamic markets of Southeast Asia, the Middle East, Africa, and Latin America, victory belongs to those who extract maximum productivity from every asset. Warehouse space is a prime asset. Whether through advanced, density-optimized racking designs, the seamless integration of AGVs to augment labor and throughput, or the strategic deployment of AS/RS for volumetric supremacy, the ultimate goal is singular: to systematically drive down the true, total cost of storage and handling per square foot while constructing an agile platform for sustainable expansion. This is the engineering philosophy that turns a line-item cost into a cornerstone of market leadership.

Frequently Asked Questions (FAQs)

1. How does warehouse clear height significantly impact the calculation of pallet racking cost per square foot?

Warehouse clear height is the single greatest multiplier of potential storage density. A building with a 10-meter eave height versus one with 6 meters offers exponentially greater volumetric capacity for a similar footprint. The effective pallet racking cost per square foot plummets as you build upward, as the fixed costs of land, roofing, and floor space are amortized over vastly more pallet positions. Investing in a higher building or maximizing height usage in an existing facility is often the most impactful decision for reducing long-term spatial costs. Any meaningful analysis of cost per square foot must begin with a measurement of available cubic meters.

2. What role does a Warehouse Management System (WMS) play in optimizing the return on a pallet racking investment?

A WMS is the operational intelligence layer that brings a physical racking system to life. It optimizes put-away and picking paths, directs operators, manages inventory in real-time, and enforces FIFO/LIFO rules. Without a WMS, even the best-designed racking system operates below its potential, leading to wasted travel time, inefficient space use, and errors. The ROI on a sophisticated racking system is severely diminished without the digital brain to control it. Therefore, the WMS is not an ancillary cost but a core component of achieving the lowest possible operational cost per square foot.

3. For businesses with highly seasonal demand, what racking strategies help manage fluctuating inventory without inflating average cost?

Seasonal businesses require flexible, scalable solutions. A core strategy is implementing a base layer of selective racking for year-round inventory, complemented by a scalable zone of portable, stackable racking or drive-in racking for peak season overflow. Another approach is designing aisles to be easily reconfigured between wide (for counterbalance forklifts during high-volume peak putaway/retrieval) and narrow (for dense storage during the off-season). This flexibility prevents paying for permanent, high-density infrastructure that lies underutilized for part of the year, thus controlling the annualized average pallet racking cost per square foot.

4. How does the choice between bolt-together and clip-in (teardrop) racking systems affect long-term cost and flexibility?

Bolt-together systems offer superior rigidity and strength, often required for drive-in racks, high-bay applications, or in seismic zones. They are more labor-intensive to assemble and reconfigure. Clip-in (teardrop) systems allow for faster, tool-less beam adjustment, offering exceptional flexibility for frequently changing inventory profiles. While potentially having a slightly lower initial material cost per square foot, the lifetime value depends on operational needs. A static, heavy-duty application benefits from bolt-together robustness; a dynamic fulfillment center prioritizes clip-in adaptability to minimize future reconfiguration costs.

5. What are the critical questions to ask a potential racking supplier to assess their capability beyond providing a basic cost per square foot quote?

“Can you provide site-specific seismic/wind load calculations and certifications compliant with our local regulations?”

“What is your process for analyzing our SKU data and operational flow to propose an optimized design, not just a layout?”

“Can you present case studies or engineering plans for integrating your racking systems with automation (AGV/AS/RS) for future scalability?”

“What is your detailed supply chain and project management process to ensure on-time delivery and installation, especially for our region?”

“What is the specific corrosion protection specification (coating type, thickness) you recommend for our climate, and what is the expected service life?”

The answers to these questions reveal whether a supplier is a strategic partner invested in minimizing your total pallet racking cost per square foot or merely a commodity vendor.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com