📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Heavy-Duty Pallet Beams: The Ultimate Guide for Warehouse Mezzanine & Expansion

(Maximize storage with a warehouse mezzanine. This definitive guide explores heavy-duty pallet beams—engineering, load specs, safety, and integration. Unlock your space potential with our FREE, professional layout design service for a high-ROI expansion.)

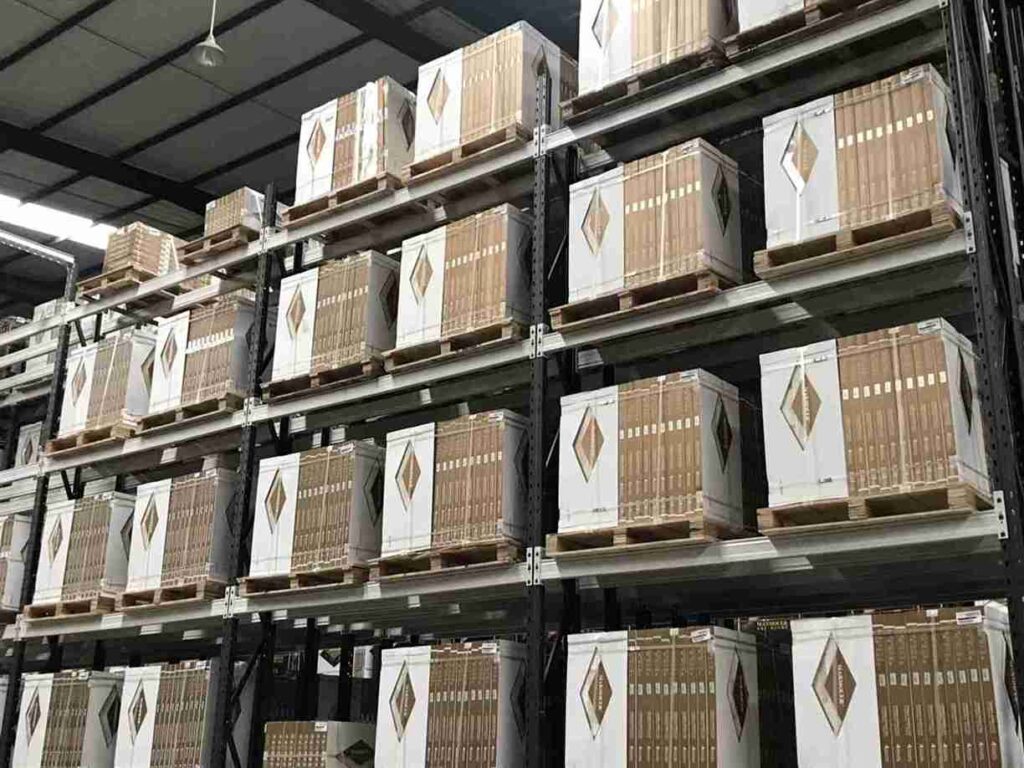

The relentless pressure to do more with less is a constant in modern logistics and warehousing. As order volumes fluctuate and inventory profiles become more complex, the physical footprint of a warehouse can feel increasingly restrictive. The conventional answer—relocating to a larger facility or undertaking new construction—is often a capital-intensive and operationally disruptive nightmare. There is, however, a profoundly smarter alternative that leverages the most underutilized asset in any warehouse: vertical air space. Constructing a warehouse mezzanine or executing a strategic vertical expansion represents the pinnacle of industrial efficiency, transforming unused cubic volume into high-value, productive storage or operational area.

The critical linchpin, the absolute determinant of success or failure in such a project, is the selection and engineering of the heavy-duty pallet beams that will form the primary support structure. These are not mere components; they are the engineered backbone upon which the entire system’s safety, durability, and performance rest. A failure in understanding the nuances of pallet beams can lead to catastrophic structural compromises, while a correct, meticulously planned approach creates a robust platform for growth for decades to come.

This comprehensive resource delves deep into the world of heavy-duty pallet beams, moving beyond basic specifications to explore the core engineering principles, integration strategies, and the critical importance of professional design in ensuring a successful warehouse mezzanine or expansion project. It also outlines how a Free Layout Design service from an industry leader can de-risk the entire process, transforming a complex capital project into a seamless, high-return investment.

The Unseen Workhorse: Why Pallet Beams are the Foundation of Your Mezzanine

To the untrained eye, a warehouse mezzanine is a simple steel deck. To an engineer or a seasoned warehouse manager, it is a complex load-bearing structure where every element plays a specific role. At the heart of this structure are the pallet beams. These horizontal members are tasked with a monumental responsibility: directly supporting the immense, concentrated weight of palletized goods, the decking material, and any dynamic live loads from personnel or equipment.

The distinction between standard shelving beams and those required for a warehouse mezzanine is not merely one of size; it is a fundamental difference in application and engineering intent. Standard beams are designed for relatively predictable, static loads. Heavy-duty pallet beams for a mezzanine, however, must be engineered to withstand a combination of forces:

Static Loads: The constant, dead weight of the stored inventory and the decking system itself.

Dynamic/Point Loads: The intense, focused pressure exerted by the legs of a fully laden pallet—often weighing 2,000 to 3,000 pounds—on a few square inches of the beam’s surface.

Impact Loads: The occasional, unforeseen forces from pallet placement, minor collisions, or shifting inventory.

Cyclical Fatigue: The constant, repetitive loading and unloading that can, over time, cause stress fractures in inferior or under-specified materials.

Choosing the incorrect pallet beams is the single most consequential error in an expansion project. The repercussions extend far beyond simple product failure:

Catastrophic Structural Collapse: The ultimate failure mode involves the bending, buckling, or shear failure of a pallet beam, potentially triggering a progressive collapse of a section or the entire mezzanine structure.

Compromised Worker Safety: An under-engineered mezzanine creates a perpetually hazardous work environment. The risk of pallet fall-through or total structural failure poses a direct and severe threat to personnel, leading to potential severe injuries and significant OSHA compliance violations.

Operational Paralysis and Financial Loss: The discovery of failing pallet beams necessitates immediate evacuation and shutdown of the affected area. The cost of emergency remediation—including inventory relocation, demolition, re-installation, and massive operational downtime—can dwarf the initial capital outlay for the entire project.

Therefore, the selection of heavy-duty pallet beams is not a place for compromise. It is the foundational investment upon which the safety and profitability of the entire expanded operation depends.

<h3>Deconstructing the Anatomy of a Superior Heavy-Duty Pallet Beam</h3>

What separates a standard beam from a truly heavy-duty pallet beam built for mezzanine applications? The difference lies in a combination of material science, geometric design, and manufacturing integrity.

High-Strength Low-Alloy (HSLA) Steel: Premium heavy-duty pallet beams are fabricated from HSLA steel, typically with a minimum yield strength of 36,000 PSI (Grade 36) and often 50,000 PSI (Grade 50) for the most demanding applications. This high yield strength is non-negotiable; it defines the stress level at which the steel will begin to deform plastically. A higher rating means the beam can support greater loads without permanent bending.

Precision Roll-Forming and Geometry: The cross-sectional profile of a pallet beam is not arbitrary. The most robust designs feature a deep, trapezoidal or hat-shaped profile with integrated vertical stiffeners. This geometry is engineered to maximize the moment of inertia—a key property that determines the beam’s resistance to bending under load. A deeper, well-stiffened beam will deflect less and support more weight than a shallow, simple box-section of the same weight.

Reinforced Flanges and Connector Points: The top and bottom flanges of the beam, where the load is primarily transferred, are often thickened or reinforced. Furthermore, the end-connectors—the critical interface where the pallet beam locks into the upright frame—are engineered for supreme strength. Look for designs that use thick, hot-rolled steel connectors with positive-locking tabs and reinforced weld points, ensuring a rigid, moment-resistant connection that prevents accidental dislodgement.

Advanced Corrosion Protection: The industrial environment is harsh, with humidity, temperature cycles, and potential chemical exposure. A superior finish is essential for the long-term integrity of the pallet beams. A electrostatically applied, thermosetting powder-coat epoxy finish provides a durable, uniform barrier that is far more resistant to chipping, scratching, and corrosion than standard liquid paint, safeguarding the steel and maintaining its load-bearing capacity for years.

A Methodical Framework for Mezzanine Design: The Central Role of Pallet Beams

Designing a safe and efficient mezzanine is a systematic, iterative process where the specifications of the pallet beams are both an input and an output of the calculations. It is a dialogue between operational requirements and structural physics. Here is a detailed breakdown of the methodology employed by expert engineers.

<h3>Step 1: The Critical Load Capacity Analysis for Pallet Beams</h3>

Accurately determining the load is the first and most vital step. An error here reverberates through the entire design. Two primary types of load must be calculated for the pallet beams:

Uniformly Distributed Load (UDL): This is the total load spread evenly across the entire deck area, expressed in pounds per square foot (PSF). It is calculated by considering the average weight of inventory, the decking material, and a live load allowance for personnel. While important for overall structural analysis, it is often not the governing factor for individual pallet beam selection.

Concentrated (Point) Load: This is the decisive calculation for pallet beams. It refers to the maximum force applied at a single, discrete point—specifically, the point where a pallet leg contacts the beam. A 2,200 lb. pallet resting on four legs places a point load of approximately 550 lbs. on each of the two pallet beams supporting it. However, this is a simplification; dynamic forces during placement can increase this instantaneous load significantly.

The Engineering Consultation Process: A professional assessment goes far beyond these basic numbers. It involves a deep dive into the client’s specific operation:

Inventory Profiling: What is the maximum weight of a single pallet? What are the pallet dimensions and type (e.g., block vs. stringer pallets)? Stringer pallets, for instance, can concentrate more weight on a smaller area of the pallet beam.

Handling Equipment: Will the mezzanine be serviced by forklifts, walkie-pallet jacks, or automated guided vehicles (AGVs)? Each imparts different dynamic forces. A forklift placing a pallet creates a greater impact load than a pallet jack.

Load Safety Factor: A responsible engineer will never design to the theoretical maximum capacity. Industry standards and professional ethics demand the application of a safety factor (e.g., 1.5 to 1.67 or higher). This means a pallet beam specified for a 3,000-lb point load is actually capable of supporting 4,500 to 5,000 lbs. before reaching its yield point. This margin is what ensures safety under unexpected or extreme conditions.

<h3>Step 2: The Interplay of Span, Spacing, and Beam Strength</h3>

Once the load requirements are crystalized, the physical layout of the pallet beams is determined by two key geometric factors: span and spacing.

Span’s Exponential Impact: The distance between the upright supports—the span—has a dramatic, non-linear effect on the required strength of a pallet beam. Doubling the span of a beam can require a member that is four, six, or even eight times stronger to resist the resulting bending moment. For longer spans, engineers must specify deeper, heavier-gauge pallet beams, or alternatively, introduce intermediate supports to reduce the effective span.

Spacing for Optimal Support: The spacing between parallel pallet beams directly influences the load on each one and the performance of the decking. Closer spacing of the pallet beams reduces the unsupported span of the decking and distributes the pallet’s weight across more members, which can allow for the use of a lighter-capacity beam. However, more pallet beams mean higher material and installation costs. The art of optimization lies in finding the perfect balance: the widest possible spacing of the lowest-capacity (and thus most cost-effective) pallet beams that still safely meets all load and decking requirements.

<h4>Application Deep Dive: Pallet Rack vs. Structural Mezzanine Beams</h4>

Understanding the context in which the pallet beams will operate is crucial. The two primary mezzanine types demand different considerations for the beams:

Pallet Rack Supported Mezzanine: In this configuration, the mezzanine deck is built directly upon a structure of upright frames and pallet beams that are identical or very similar to standard selective pallet racking. The pallet beams serve a dual purpose: supporting palletized loads in the racking bays below the deck and acting as the primary support for the deck itself above. The load capacity of the entire system is intrinsically tied to the capacity of these integrated pallet beams. This system is highly efficient for creating multi-tiered storage but requires meticulous analysis to ensure the point loads from the deck are within the capacity of the underlying pallet beams.

Standalone Structural Mezzanine: This system is a dedicated, independent structure with its own primary support columns and heavier primary beams. The pallet beams (often referred to as “purlins” in this context) span between these primary beams to support the deck. This design offers superior flexibility, as the pallet beams and the entire structure are engineered specifically for the deck loads, independent of any storage media below. This often allows for higher overall capacities and more creative layouts, as the pallet beams are part of a dedicated structural system.

Operationalizing the Mezzanine: Workflow Integration and Pallet Beam Considerations

A mezzanine is not an island; it must be fully integrated into the warehouse’s operational workflow. The design of the pallet beam grid can either facilitate or hinder this integration.

Material Flow and Access: How will inventory and personnel move to and from the new level? The placement of stairs, gates, and conveyor penetrations must be planned in conjunction with the pallet beam layout. Cutting a pallet beam post-installation to create an opening is not an option. These penetrations must be designed into the structure from the outset, with appropriate reinforcing to compensate for the interrupted beam.

Lighting, Fire Protection, and Utilities: The space beneath a mezzanine can become a dark cavern. The pallet beam structure must be coordinated with the relocation or addition of lighting fixtures. Similarly, sprinkler heads must be repositioned to provide adequate coverage both above and below the deck, often requiring careful routing through the pallet beam grid. Conduits for data or power for upper-level equipment also need a clear path.

Future-Proofing and Modularity: The most cost-effective mezzanine is one that can adapt to future change. A design based on a modular, bolt-together system with standardized pallet beams allows for future reconfiguration, expansion, or even disassembly and relocation. Specifying pallet beams that are part of a versatile, compatible system protects the long-term value of the investment.

The Value of Expertise: How a Free Layout Design Service Mitigates Risk

The complexity of designing a mezzanine system with the correct heavy-duty pallet beams cannot be overstated. It is a multidisciplinary task that blends structural engineering, logistics, and safety code compliance. This is precisely why a Free Layout Design service is not a mere sales gimmick; it is an essential risk-mitigation and value-creation tool.

This service, when provided by an established industry expert, involves a collaborative, multi-stage process:

Discovery and Needs Analysis: The process begins with a comprehensive discussion to understand not just the spatial and weight requirements, but the business objectives behind the expansion. What are the throughput goals? What are the pain points in the current operation? This holistic view ensures the solution addresses the root cause, not just the symptom of lacking space.

Dimensional and Site Assessment: Using advanced laser measuring tools, the team captures precise dimensions of the facility, noting the location of all columns, doors, sprinklers, electrical panels, and overhead obstructions. This data forms the real-world canvas for the design.

CAD-Based Engineering and Drafting: Engineers and CAD technicians then create a detailed, scaled plan. This is not a schematic; it is a full construction document that specifies:

The exact type, model, and location of every pallet beam.

The capacity and placement of every upright frame.

The decking type, layout, and direction.

All access points, guardrails, and safety gates.

Integration points with conveyors, VRCs, or existing racking.

Structural Load Report: A formal document is generated, outlining the calculated uniform loads, point loads, and the safety factors applied to every major component, especially the pallet beams. This report provides the transparency and confidence needed for internal approval and, often, for the building permit application.

Comprehensive Bill of Materials: The client receives a precise list of every component required for the project, from the largest heavy-duty pallet beam to the last bolt and safety clip. This eliminates budget ambiguity and ensures a smooth procurement and installation process.

By leveraging this service, clients effectively gain access to a full-time engineering team at no upfront cost, transforming a high-risk capital project into a predictable, well-defined execution plan.

Case in Point: Transforming a Distribution Center with Strategic Beam Selection

A national distributor of automotive parts faced a critical space constraint during a period of rapid growth. Their 30-foot clear-height distribution center was only using storage up to 18 feet. Relocation was quoted at a prohibitive cost with unacceptable operational downtime.

The Challenge: Design a multi-level mezzanine system to house a new, high-velocity pick module and bulk overflow storage. The system needed to support diverse loads—from heavy engine blocks on the bulk level to smaller, lighter parts in the pick module—and integrate with a new conveyor sortation system, all while maintaining full operation on the ground floor.

The Solution and Beam Specification: A phased, hybrid approach was developed, with the pallet beams being the key differentiator in each area.

Phase 1 – Bulk Storage Mezzanine: A standalone structural mezzanine was designed for the heaviest loads. This required the deepest, highest-capacity heavy-duty pallet beams in the portfolio, with a rated point load of 4,000 lbs. and a safety factor taking the ultimate capacity far beyond that. These specific pallet beams were critical to safely storing the palletized engines and transmissions.

Phase 2 – Pick Module Mezzanine: Beneath the bulk storage, a pallet rack supported mezzanine was constructed for the pick module. Here, a different class of pallet beams was used. These beams were optimized for the lower, more uniform loads of shelving units and carton flow racks, but were still specified from the same heavy-duty family to ensure connector compatibility and overall structural harmony. The pallet beams in this area were spaced to perfectly align with the shelving dimensions, creating an optimized pick face.

The provided Free Layout Design was instrumental, allowing the client’s team to walk through a virtual model of the entire system. The clear specification of every pallet beam type and its capacity gave the facilities and safety managers the confidence to approve the project. The result was an 85% increase in storage capacity, a 40% improvement in pick-line efficiency, and the avoidance of a multi-million dollar relocation expense—a testament to the power of correct pallet beam selection and professional design.

Frequently Asked Questions (FAQs)

1. What is the typical lead time for custom heavy-duty pallet beams?

Lead times are project-dependent. For standard-profile heavy-duty pallet beams, production typically ranges from 4 to 6 weeks. For projects requiring fully custom pallet beams with unique profiles or extreme capacities, the engineering and manufacturing timeline is longer, and a firm schedule is established during the design phase to align with the overall project timeline.

2. Can your pallet beams be integrated with other manufacturers’ existing racking systems?

While a fully integrated system from a single manufacturer is always recommended for guaranteed integrity and safety, our pallet beams are manufactured to common industrial standards. We can provide detailed connector specifications, and our engineering team will perform a compatibility and safety assessment during the free layout design to determine if integration with a third-party system is feasible without compromising structural performance.

3. Do you assist with the permitting process for a warehouse mezzanine?

Yes, extensively. The detailed CAD drawings and structural load calculations we provide as part of our Free Layout Design service are precisely the documents required by local building departments to obtain a permit. We provide the technical backbone and supporting data, working directly with your designated contractor or facilities team to ensure a smooth and successful permitting process.

4. What is the maintenance requirement for your powder-coated pallet beams?

The maintenance is minimal. The thermoset powder coating is exceptionally durable and resistant to chipping, chemicals, and corrosion. Routine visual inspections for any signs of impact damage that has penetrated the coating, coupled with occasional cleaning with a damp cloth to remove dust and grime, is all that is required to maintain the appearance and long-term corrosion protection of the pallet beams.

5. How does the expansion process work logistically? Do you deliver globally?

We have a robust global supply chain and logistics network, with extensive experience serving key growth markets in Southeast Asia, the Middle East, Africa, and Latin America. The process involves a carefully choreographed logistics plan, often with phased deliveries coordinated with your project’s construction schedule. This ensures that critical components like the heavy-duty pallet beams arrive on-site precisely when they are needed, preventing clutter and keeping the installation phase on track.

Conclusion: Building Your Vertical Vision on a Foundation of Engineered Pallet Beams

A warehouse mezzanine or vertical expansion is a strategic masterstroke, a direct conversion of unused air space into tangible operational capacity and financial return. Yet, the brilliance of this strategy is entirely contingent upon the integrity of its most fundamental component: the heavy-duty pallet beams. These engineered elements are the silent, unwavering guardians of safety, the enablers of density, and the platform upon which future growth is built.

Selecting a partner for this endeavor goes beyond transactional purchasing. It is about aligning with an organization that brings deep-seated expertise in structural engineering, a unwavering commitment to quality in its pallet beams, and a holistic understanding of warehouse dynamics. The provision of a Free Layout Design service is the ultimate testament to this partnership approach, de-risking the project from conception to completion and ensuring that every pallet beam is not just a component, but a correctly specified piece of a perfectly engineered whole.

The path to a safer, more productive, and more profitable warehouse is above you. The first step is to engage with experts who can provide the blueprint. Reach out to begin the conversation and to claim your Free Layout Design consultation. Let us demonstrate how the right pallet beams can elevate your entire operation.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com