📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Engineering Superior Storage: The Strategic Advantage of Interlake Pallet Racking Systems

In the complex calculus of modern logistics, where every square foot and every minute of labor carries a direct cost, the selection of a storage system is a foundational strategic decision. Operations across Southeast Asia, the Middle East, Africa, and Latin America face unique challenges: rapidly scaling volumes, diverse product mixes, and often, constraints in existing facility footprints.

The solution transcends mere shelving; it demands a systematic, engineered approach to vertical space utilization. This is the precise domain where Interlake pallet racking establishes its unparalleled value. More than just storage equipment, a properly designed and implemented Interlake pallet racking system functions as the static, yet highly adaptable, central nervous system of a warehouse. It dictates flow, enforces safety, and ultimately, determines the ceiling of operational productivity.

For any professional seeking not just to store, but to optimize, understanding the depth and breadth of what a customized Interlake pallet racking solution entails is the first step toward transforming a logistical cost center into a competitive asset. This exploration delves beyond specifications into application, integration, and the long-term operational philosophy that these systems enable.

The Foundational Imperative: Why Storage Infrastructure Cannot Be an Afterthought

Consider the typical pain points voiced by warehouse managers globally. Aisles are clogged, limiting the throughput of forklifts and causing frustrating delays. Inefficient layouts force pickers to traverse excessive distances, inflating labor costs and order cycle times. Random columns and low ceilings create unusable pockets of space, effectively inflating the real cost of the leased or owned facility. Perhaps most critically, a generic racking system forces inventory—with its unique dimensions, weights, and turnover profiles—to conform to its limitations, rather than the other way around. This misalignment is a silent profit drain.

The installation of a Interlake pallet racking system, when approached as a custom-engineered project, is the definitive response to these challenges. It represents a shift from reactive storage to proactive storage strategy. The core objective is to create a perfect synergy between the physical structure and the dynamic flow of goods. Every decision, from the beam level height to the aisle width, is data-driven. It involves analyzing SKU cubic velocity, understanding the reach dimensions of material handling equipment (MHE), and forecasting future growth patterns.

A bespoke Interlake pallet racking layout is, therefore, a physical manifestation of a company’s unique operational data. It is this deliberate, analytical approach that unlocks true storage density, enhances safety by design, and provides a scalable framework for future automation or expansion. Choosing to invest in a tailored Interlake pallet racking system is, in essence, choosing to build operations on a foundation of efficiency and foresight.

Deconstructing the Design: The Engineering Principles Behind Interlake Durability

The market is replete with racking options, often competing on price alone. However, in critical infrastructure, the true cost is measured over decades of service, not in the initial purchase order. The renowned durability and reliability of Interlake pallet racking stem from a commitment to engineering excellence that is evident in every component.

Metallurgy and Structural Integrity: The journey begins with the selection of high-tensile, cold-rolled steel. This material is then precision-formed into upright frames with consistent, cleanly punched apertures. The profile of the column—whether a robust open-back “C” or a box-like “Omega” shape—is not arbitrary. It is calculated through finite element analysis to withstand specific load capacities while resisting torsional forces. The punched hole pattern, often a patented teardrop design, is engineered for both strength and the secure, tool-less engagement of beam connectors. This focus on the base material and structural form ensures that every upright in an Interlake pallet racking bay contributes to the system’s overall stability and longevity.

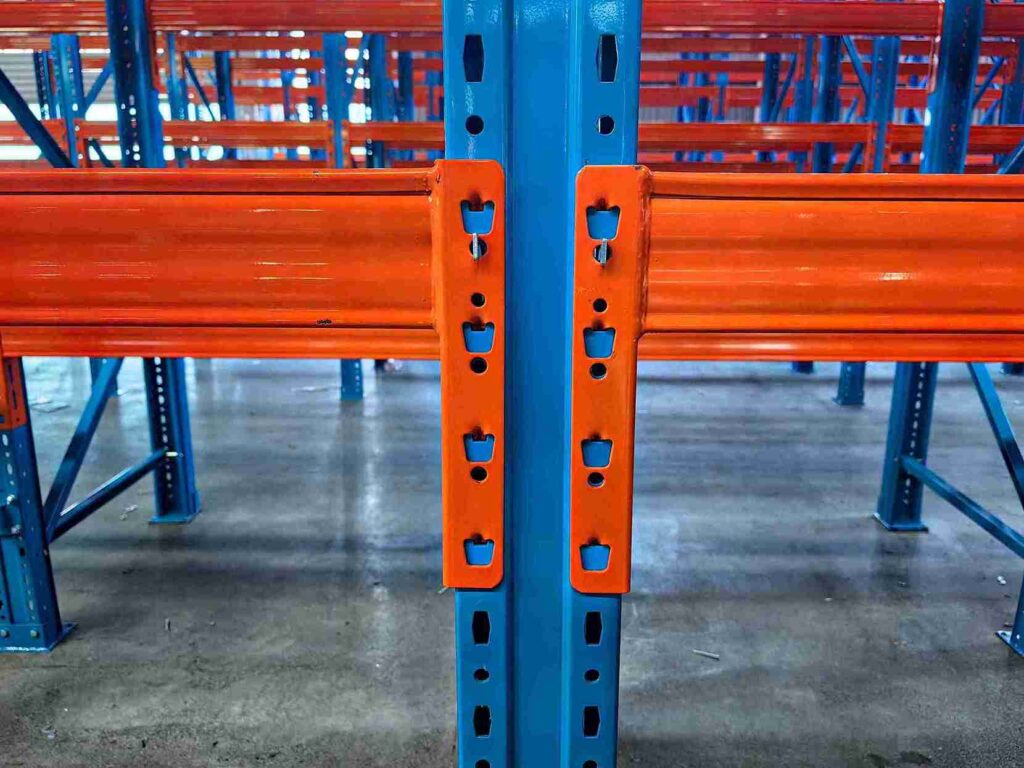

The Connector: Where Safety is Literally Locked In: The most dynamically stressed point in any racking assembly is the beam-to-upright connection. Compromises here are unacceptable. Interlake pallet racking systems typically employ a highly secure connection mechanism. The teardrop connector is industry-respected for its reliability. The beam end is forged to slot seamlessly into the upright’s teardrop-shaped hole. A secondary safety clip or lock is then engaged, physically preventing the beam from becoming dislodged due to vibration or incidental impact. This dual-stage security is a hallmark of professional-grade Interlake pallet racking, offering peace of mind that the structural integrity of the connection is maintained.

Transparency in Capacity: Load Beams and Clear Communication: Capacity is not a mystery. Every beam in an Interlake pallet racking system is clearly stamped with its load rating—both as a Uniformly Distributed Load (UDL) and a Concentrated Load. Uprights are labeled with capacity charts that detail allowable loads per level based on height and configuration. This transparency is a critical aspect of warehouse safety and risk management. It empowers floor managers and forklift operators to make informed decisions, preventing the dangerous practice of overloading. This clarity transforms the Interlake pallet racking system from a passive structure into an active communication tool for safe operations.

Strategic Configurations: Matching Interlake Racking to Inventory Dynamics

The phrase “one-size-fits-all” has no place in professional warehouse design. Different inventory profiles demand different storage modalities. The versatility of Interlake pallet racking lies in its ability to be configured into specialized layouts that align precisely with the velocity and characteristics of the stock being stored.

Selective Pallet Racking: The Cornerstone of Flexibility: This remains the most universally applied configuration of Interlake pallet racking. Its principle is direct accessibility: every single pallet position is immediately available from the main aisle. This makes it ideal for facilities with a high number of SKUs, where quick turnover and frequent order picking are the norms.

The customization within a selective Interlake pallet racking system is nuanced. It involves calculating the optimal beam length to minimize overhang, setting vertical beam spacings to reduce wasted air space above pallets, and, most critically, determining the precise aisle width. This last factor is a direct negotiation between storage density and equipment accessibility. A custom layout might specify aisles as narrow as 78 inches for a narrow-aisle reach truck or wider aisles for counterbalance forklifts, with the choice fundamentally impacting the total number of storage positions in the facility.

High-Density Solutions for Volume Storage: When operations involve deep storage of fewer SKUs, dedicating an aisle to every pallet face becomes inefficient. This is where high-density configurations of Interlake pallet racking reclaim vast amounts of space.

Drive-In and Drive-Through Racking: Here, the Interlake pallet racking structure is configured into deep lanes, with pallets stored on rails. A forklift drives directly into the lane to deposit or retrieve a load. Drive-in (LIFO, last-in-first-out) uses a single entry point, while drive-through (FIFO or LIFO) allows access from both ends. This configuration of Interlake pallet racking is exceptionally space-efficient, perfect for bulk storage in cold chain facilities, beverage distribution, or for seasonal goods. The depth and height of the lanes are fully customized to building dimensions and throughput needs.

Push-Back Racking: Offering a compelling balance, push-back racking utilizes a series of nested carts on inclined rails within a Interlake pallet racking frame. Pallets are loaded from the front, pushing the previous load back. Upon retrieval, the next pallet rolls smoothly forward. This system, typically operating on a LIFO basis, allows for storage 2 to 6 pallets deep while maintaining multiple SKUs per aisle. It is an excellent choice for medium-turnover finished goods where some selectivity is required alongside increased density.

Pallet Flow Racking: For uncompromising FIFO inventory management at high density, pallet flow racking is the premier solution. Integrated into a robust Interlake pallet racking structure, this system uses inclined tracks with wheel or roller conveyors. Pallets are loaded at the rear and glide by gravity to the front pick face. The speed and braking are carefully calibrated based on pallet weight. This configuration of Interlake pallet racking is indispensable for industries with strict expiry dates, such as food, pharmaceuticals, and certain chemicals, ensuring perfect stock rotation.

Mezzanine Systems: Creating a Multi-Level Warehouse Within a Warehouse: When lateral expansion is impossible, the only direction is vertical. A structural mezzanine, engineered and built using Interlake pallet racking uprights as its primary support columns, effectively doubles or triples usable floor space. This is not simply adding a shelf; it is constructing a second story. These systems are custom-designed for specific live loads (offices, packaging lines, storage) and integrate staircases, gates, decking, and safety kickplates. A well-planned mezzanine supported by Interlake pallet racking transforms underutilized vertical cube into highly functional space for lighter inventory, value-added services, or administrative functions.

The Blueprint for Customization: A Phased, Collaborative Methodology

Acquiring a custom Interlake pallet racking system is a consultative partnership, not a transactional purchase. The process is designed to extract operational data and translate it into an optimized physical layout.

Comprehensive Operational and Facility Audit: The engagement begins with an on-site discovery phase. Experts conduct detailed measurements of the facility’s clear height, column grid, floor flatness, door and sprinkler locations. Simultaneously, they analyze inventory data: pallet dimensions and weights, SKU counts, velocity profiles (ABC analysis), and growth projections. Interviews with operational staff provide context to the data, revealing workflow pain points and future aspirations.

Digital Twin Simulation and Layout Optimization: Using advanced warehouse design software, consultants create a digital twin of the facility. Multiple Interlake pallet racking layout scenarios are modeled and tested within this virtual environment. This allows for the simulation of material flow, equipment movement, and even pick paths to identify bottlenecks before installation. Clients can visually walk through different configurations of Interlake pallet racking, comparing the storage capacity, efficiency gains, and potential ROI of each option, leading to a fully informed, data-backed decision.

Phased Deployment and Certified Installation: Recognizing that warehouses cannot simply shut down, reputable providers develop meticulous phased implementation plans. Certified installation crews, trained specifically on Interlake pallet racking systems, execute the build according to engineered drawings. They ensure perfect plumb and level alignment, proper torque on all bolts and connectors, and full compliance with local building codes and the Rack Manufacturer’s Institute (RMI) guidelines. This professional installation is non-negotiable for guaranteeing the safety and rated performance of the Interlake pallet racking system.

The Automated Warehouse: Interlake Racking as the Structural Grid for Robotics and AS/RS

The future of warehousing is automated, and the storage structure must be prepared to serve as the host platform. Interlake pallet racking provides the precision-engineered, rigid framework required by advanced automation technologies.

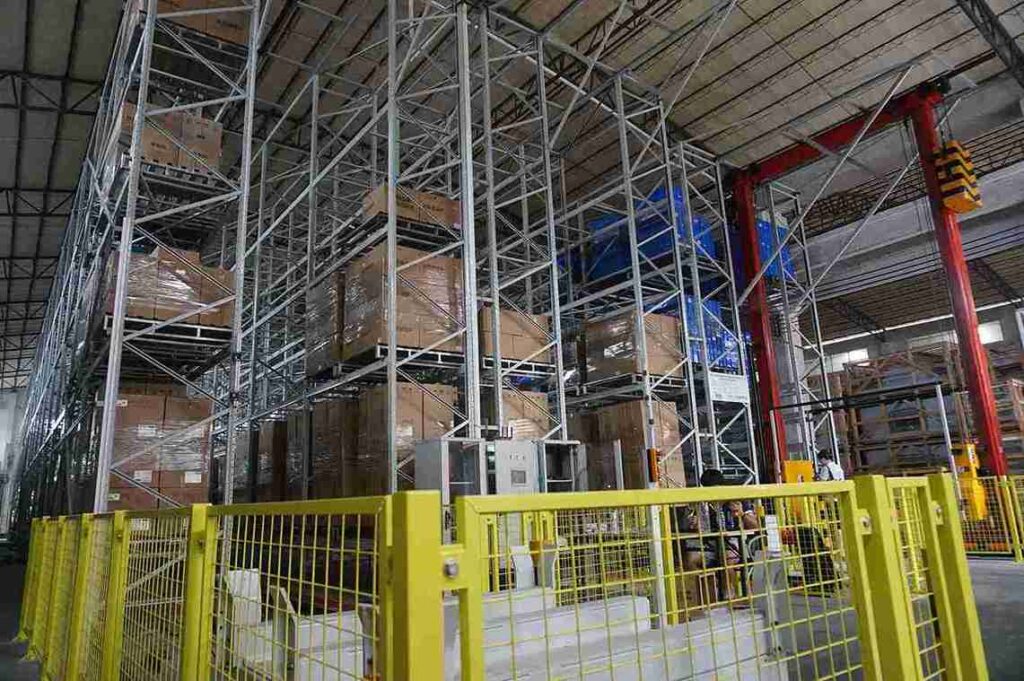

The Backbone of Automated Storage and Retrieval Systems (AS/RS): In high-throughput, high-density distribution centers, unit-load AS/RS are the pinnacle of efficiency. These systems rely entirely on the racking structure. The Interlake pallet racking, in this context, is not a standalone product but an integral component of the AS/RS. Automated stacker cranes travel within the narrow aisles of the Interlake pallet racking, often with their guide rails mounted directly onto the rack uprights. The absolute precision, strength, and consistency of the Interlake pallet racking are critical, as they directly impact the crane’s speed, positioning accuracy, and overall system reliability.

Enabling AGV and AMR Integration: As fleets of Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) become commonplace, the racking interface must be deliberately designed. This involves standardizing pick-face heights across the Interlake pallet racking layout to match robot lift mechanisms, ensuring clear and consistent floor paths, and potentially incorporating physical or digital fiducial markers into the rack structure to aid in robotic navigation and pallet identification. The Interlake pallet racking system becomes a key landmark in the facility’s digital control map.

Seamless Conveyor and Picking System Interfacing: A holistic warehouse design ensures the Interlake pallet racking storage zones are perfectly synchronized with material transport systems. This means designing rack bays to align with inbound/outbound conveyor spurs, creating dedicated zones within the Interlake pallet racking grid for goods-to-person picking stations, or configuring flow racks to discharge directly onto merge lines. The goal is a seamless, automated handoff from storage to sortation, minimizing manual touches and maximizing throughput.

Lifecycle Management: Safety, Maintenance, and Calculating Total Cost of Ownership

The investment in a superior Interlake pallet racking system is protected through diligent lifecycle management. Its value is preserved and enhanced by proactive care and a clear understanding of its economics.

Integrated Safety Systems and Proactive Maintenance: Safety accessories are integral to a complete Interlake pallet racking solution. Column guards (post protectors) shield uprights from forklift impacts at aisle ends. Wire mesh decking contains small items and provides a secure walking surface for mezzanines. Pallet supports and load backrests ensure stability for non-standard loads. Beyond hardware, implementing a formal, periodic rack inspection protocol is essential. Trained personnel should look for signs of damage, deflection, or loosened connections, using inspection reports to schedule preventative maintenance. This culture of care ensures the Interlake pallet racking system performs safely for its entire designed lifespan.

The True Economics: Analyzing Total Cost of Ownership (TCO): Evaluating a Interlake pallet racking system on purchase price alone is a myopic view. The Total Cost of Ownership provides the complete financial picture. A custom-engineered Interlake pallet racking solution may have a higher initial cost but delivers superior value over 15-20 years through: Dramatically reduced product damage from a stable structure; Avoided costs of unplanned downtime and emergency repairs; Optimal space utilization delaying or eliminating the need for costly facility expansion; Inherent flexibility to be reconfigured for new needs without replacement. When these factors are quantified, the premium for a professionally designed and installed Interlake pallet racking system reveals itself as a wise, long-term capital investment with a compelling ROI.

Conclusion: The Strategic Foundation for Logistics Excellence

In the relentless pursuit of supply chain optimization, warehouse managers and business leaders must look beyond quick fixes and scrutinize their core infrastructure. The storage system is not a commodity; it is the strategic platform upon which all other processes—picking, packing, shipping, and increasingly, automation—are built. Selecting and implementing a custom-engineered Interlake pallet racking system represents a commitment to that foundational strength.

It is an investment in a framework engineered for safety, designed for density, and built for integration. From the initial audit and simulation to the precision installation and ongoing support, the process surrounding a true Interlake pallet racking solution ensures the final installation is a perfect fit for both the physical facility and the operational model it supports. This approach does not merely solve today’s storage problem; it creates a scalable, adaptable asset that empowers growth, embraces efficiency, and forms the ready-made skeleton for the automated warehouses of the future. For operations across emerging and established markets alike, the choice is clear: build on a foundation of structural steel and strategic insight, build on Interlake pallet racking.

Frequently Asked Questions (FAQs)

Q1: How does the design process for a custom Interlake pallet racking system account for seismic activity, a concern in many global regions?

Seismic design is a critical engineering consideration, not an add-on. For regions with seismic risk, the structural calculation for the Interlake pallet racking system incorporates specific seismic zone parameters. This influences several design aspects: the specification of heavier-duty upright profiles, the potential use of specialized seismic baseplates that anchor the rack to the floor with greater force, and often, the inclusion of cross-bracing or moment frames to enhance lateral stability. The engineered drawings for the Interlake pallet racking layout will explicitly state the seismic design criteria met, ensuring compliance with local building codes and providing crucial safety assurance.

Q2: We handle a mix of standard and non-standard pallet sizes (e.g., Euro, CHEP, or region-specific sizes). Can a single Interlake pallet racking system accommodate this variety?

Absolutely. This is a common scenario and a key strength of a customized Interlake pallet racking solution. The system can be designed with adjustable beam levels to create dedicated zones within the warehouse for different pallet heights. Furthermore, beam lengths can be specified to safely support various pallet depths, often using combinations of standard beams with add-on support bars or custom-length beams. Decking options—such as wire mesh or steel channels—can be tailored to different pallet bottom designs. The flexibility inherent in Interlake pallet racking allows it to be configured as a unified system that expertly manages pallet diversity.

Q3: What are the fire safety considerations when installing a large-scale Interlake pallet racking system, particularly regarding sprinkler systems?

Fire safety is paramount and is integrated into the layout planning. National Fire Protection Association (NFPA) codes, or their local equivalents, dictate clearances between rack storage and overhead sprinkler heads to ensure proper water dispersion. The design of the Interlake pallet racking layout must coordinate with the existing or planned sprinkler grid. This may involve creating specific flue spaces within the Interlake pallet racking array or designing the rack heights to maintain mandatory clearances. A professional provider will always ensure the final Interlake pallet racking installation is fully compliant with all relevant fire safety regulations.

Q4: For operations in highly humid or corrosive environments (e.g., coastal areas, chemical storage), what material specifications are recommended for Interlake pallet racking?

Standard mill finish steel may not suffice in corrosive atmospheres. For these demanding environments, specifying the correct protective finish for the Interlake pallet racking components is essential. Options include hot-dip galvanizing, where the steel is immersed in molten zinc, providing a thick, durable barrier. An even more robust specification is powder-coating over galvanized steel, which adds an extra layer of chemical and abrasion resistance. For the most severe conditions, specialized epoxy coatings can be applied. Consulting with a supplier during the design phase to specify the appropriate finish for the Interlake pallet racking ensures longevity and protects the structural investment.

Q5: How does the load capacity of an Interlake pallet racking system interact with the warehouse floor’s load-bearing specification?

This is a crucial interface often overlooked. The load capacity of the Interlake pallet racking system and the point-load capacity of the warehouse floor slab must be aligned. The engineered design of the Interlake pallet racking will calculate the load transmitted through each baseplate to the floor. This data must be compared against the facility’s structural drawings or through a floor core test if drawings are unavailable. In cases of heavy-duty Interlake pallet racking configurations or older facilities, floor reinforcement or the use of spreader plates under the baseplates may be required. A reputable provider will always address this structural interaction to ensure the safety and integrity of both the rack and the building.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com