📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Industrial vs Manual Racking Cost: The Definitive Strategic Analysis for Modern Warehouses

The central debate in warehouse optimization, the critical evaluation of industrial vs manual racking cost, has long been misunderstood. For decades, the decision was skewed by a simplistic comparison of initial price tags. This perspective is not only outdated but financially perilous. A deep, analytical examination reveals that the true industrial vs manual racking cost equation extends far beyond upfront investment.

It encompasses a complex matrix of spatial efficiency, labor dynamics, operational accuracy, and long-term scalability. This comprehensive guide dismantles the myths and provides a data-driven framework for understanding how advanced industrial automated racking systems deliver a superior lifetime value by fundamentally redefining the parameters of cost. The analysis presented here is designed for logistics directors, operations managers, and business owners who view their warehouse not as a static cost center, but as a dynamic, strategic asset.

The ultimate conclusion in the industrial vs manual racking cost debate is clear: the higher initial investment in automation is not an expense, but a capital deployment that generates massive, recurring returns by maximizing storage density and systematically eliminating the vast, hidden costs of manual labor.

Deconstructing the True Cost Paradigm in Warehouse Storage

The journey to a sound financial decision in the industrial vs manual racking cost debate begins with a fundamental shift in perspective. One must transition from looking solely at the capital expenditure (CAPEX) invoice to modeling the total cost of ownership (TCO) over a 10 to 20-year horizon. The initial price of manual racking is a compelling lure, but it is a siren’s call that obscures a treacherous landscape of ongoing operational expenditures.

The real analysis of industrial vs manual racking cost is an analysis of risk, efficiency, and future-proofing. It forces a business to quantify the unquantified: the cost of a missed order, the cost of a damaged product, the cost of a preventable accident, and the opportunity cost of unused vertical space. When these factors are integrated into the financial model, the narrative around industrial vs manual racking cost undergoes a dramatic and irreversible transformation.

The Unsustainable Escalation of Manual Labor Expenses

Any honest assessment of industrial vs manual racking cost must place labor at the forefront. Manual racking systems are inherently labor-intensive, creating a direct and volatile variable cost that is subject to market forces and human limitations.

The Direct Wage Inflation Trap: The recurring cost of employing forklift operators is subject to constant upward pressure from minimum wage legislation and competitive job markets. This makes the operational cost of a manual racking system inherently inflationary.

The Scarcity Premium and Retention Challenges: The pool of skilled, reliable forklift operators is shrinking globally. The cost of recruitment, signing bonuses, and training for manual racking operations has become a significant, recurring line item. High turnover further amplifies these costs.

The Full Burden of Employment: The true cost of an operator for a manual racking system is 1.25 to 1.4 times their base salary when benefits, insurance, payroll taxes, and management overhead are included. This multiplier effect drastically alters the industrial vs manual racking cost calculation.

The Inconsistency Tax: Human operators cannot maintain peak performance. The cost of fatigue, breaks, and variable work pace is a hidden tax on the productivity of any manual racking operation, leading to lower overall throughput than the theoretical maximum.

In the industrial vs manual racking cost analysis, labor is the single greatest differentiator. Industrial automated racking converts this large, unpredictable variable cost into a small, fixed, and manageable one.

The Prohibitive Cost of Spatial Inefficiency in Manual Racking

The physical footprint of a warehouse represents one of its largest fixed costs. The spatial economics of industrial vs manual racking cost reveal a staggering disparity. Manual racking systems, by their very design, are profoundly wasteful with this expensive asset.

The Aisle Tax: Conventional manual racking requires aisles of 10 to 13 feet in width to accommodate the turning radius of a counterbalance forklift. In a typical facility, this “aisle tax” can consume over 50% of the total floor space. Companies are literally paying rent, utilities, and property taxes on empty space. This is a monumental and often accepted inefficiency in the manual racking cost structure.

The Vertical Utilization Gap: While manual racking can be built to great heights, the practical reach of a standard forklift operator is limited. Levels above 20-25 feet become increasingly inefficient and hazardous to access. This underutilized vertical air space represents a massive opportunity cost in the industrial vs manual racking cost comparison. Industrial automated racking systems, like AS/RS, utilize 95% or more of the available building height without any performance degradation.

The Honeycombing Effect and Its Labor Cost: As inventory in a manual racking system is depleted, it creates scattered empty slots. The labor-intensive process of consolidating inventory to reclaim this space, known as de-honeycombing, is often deferred due to its cost, leading to a gradual but steady decline in effective storage capacity. This is a silent cost creep that plagues manual racking operations.

When the industrial vs manual racking cost analysis fully accounts for the value of cubic space, the density advantages of industrial automated racking often alone justify the investment by postponing or eliminating the need for costly facility expansion.

The Hidden Liabilities: Error, Damage, and Safety Costs

The human element in manual racking operations introduces a spectrum of risks that directly and negatively impact profitability. These are the “soft costs” that are frequently omitted from initial budgets but which relentlessly erode the bottom line.

The Direct and Indirect Cost of Damage: Forklift impacts with racking uprights and stored inventory are a daily reality in manual environments. The cost includes not only the damaged goods but also the repair or replacement of the racking system itself and the forklift. Even a minor impact can compromise structural integrity, creating a long-term safety hazard and a future cost.

The Profit Erosion of Inaccuracy: Mis-picks and mis-placed inventory in a manual racking system lead to incorrect orders, shipping delays, and customer chargebacks. In sectors like e-commerce, the cost of a single error can wipe out the profit margin from multiple successful orders. The labor cost of investigating and correcting these errors further compounds the problem.

The Unacceptable Cost of Workplace Incidents: Warehouses reliant on manual racking and forklift operations statistically have a higher rate of accidents. The associated costs—including workers’ compensation claims, increased insurance premiums, regulatory fines, and downtime—are substantial. There is also an immense, though less quantifiable, cost in diminished morale and corporate reputation.

In the final industrial vs manual racking cost tally, these hidden liabilities represent a continuous financial drain for manual systems, a drain that is virtually eliminated by the precision and inherent safety of industrial automated alternatives.

Industrial Automated Racking: A Technical Examination of Cost-Disruption

To fully comprehend the positive disruption in the industrial vs manual racking cost debate, one must understand the technological sophistication of modern industrial automated racking systems. These are not merely storage structures; they are integrated, software-driven material handling ecosystems.

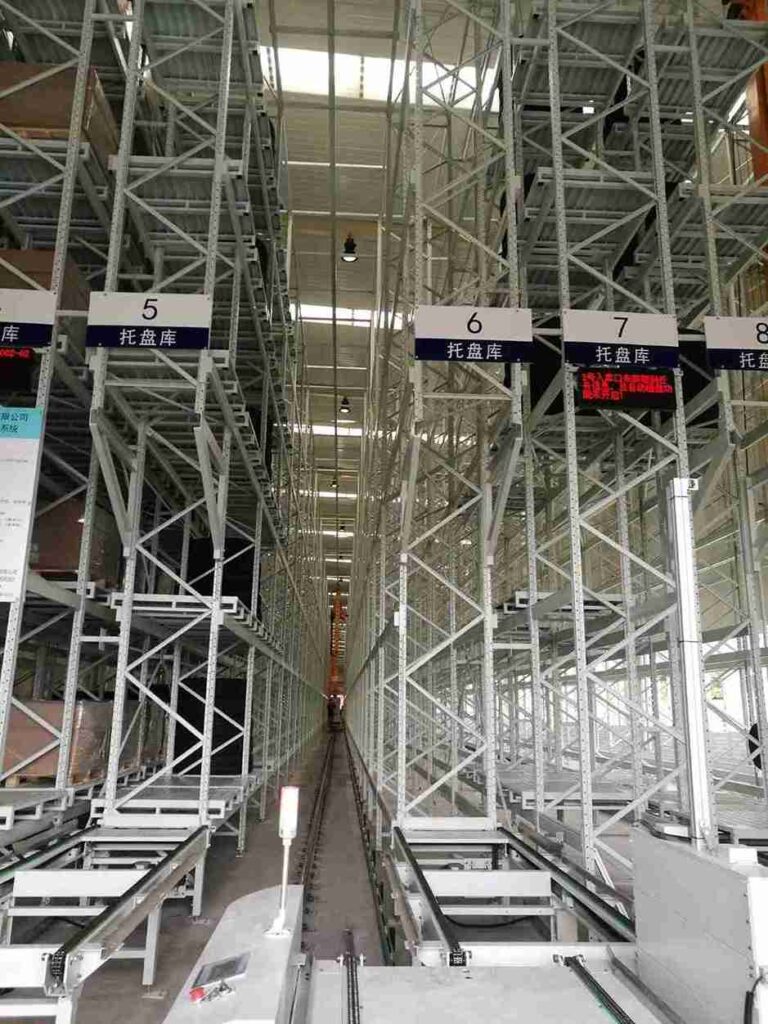

Unit-Load AS/RS: The Pinnacle of Density and Control

The Automated Storage and Retrieval System (AS/RS) for unit loads represents the most comprehensive solution for redefining industrial vs manual racking cost.

Radical Density as a Cost Advantage: The cost savings from an AS/RS begin with its physical design. Aisles are typically only 6-8 inches wider than the load itself, increasing storage density by up to 85% compared to manual racking. This direct attack on the “aisle tax” is a core component of its favorable cost profile.

Labor Cost Elimination through Automation: A single, computer-controlled crane replaces multiple forklifts and operators. The system is directed by a Warehouse Management System (WMS), which optimizes every movement for speed and efficiency. The labor cost is transformed from a fleet of operators to a handful of system supervisors and maintenance technicians, creating a dramatic shift in the industrial vs manual racking cost calculation.

Ideal Applications for Maximum ROI: The cost-benefit of an AS/RS is most pronounced in high-volume environments, cold storage (where it minimizes heat loss and labor in harsh environments), and operations handling heavy or high-value goods where damage cost and security are paramount.

Automated Pallet Shuttle Systems: The Agile Buffer Solution

For operations requiring high-density storage without a full-scale AS/RS, the automated pallet shuttle system offers a compelling middle ground in the industrial vs manual racking cost spectrum.

Semi-Automated Cost Efficiency: This system uses a battery-powered shuttle that runs inside the racking lanes, transporting pallets from the front to the back. It offers a significant cost advantage over pure manual racking by intensifying density without a full industrial automation investment.

Optimized Labor Cost: A forklift operator interfaces with the system only at the lane entrance, placing a pallet for the shuttle to store. This drastically reduces the operator’s travel time and labor per pallet movement, effectively allowing one operator to achieve the throughput of several in a pure manual racking setup. This hybrid model effectively balances the industrial vs manual racking cost equation for many firms.

Strategic Deployment: It is perfectly suited for buffer storage in manufacturing, high-density FIFO or LIFO applications, and as a dense staging area within a larger manual racking warehouse, effectively lowering the overall cost per pallet position.

The Synergistic Role of AGVs and AMRs

The evolution of industrial automated racking is incomplete without considering the horizontal transport provided by Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs).

Creating a Truly End-to-End System: These robots seamlessly integrate with industrial automated racking, ferrying loads from receiving docks to the AS/RS input stations and from retrieval points to shipping. This integration closes the loop on automation, further marginalizing the cost and need for manual forklift operation.

The Flexibility Dividend in Cost Calculations: The ability of AMRs, in particular, to dynamically adapt their paths offers unparalleled flexibility. This reduces the cost of future reconfigurations and allows the material flow to be optimized continuously, a level of efficiency unattainable in a static manual racking environment.

The Inescapable Financials: A Data-Driven Cost-Benefit Model

The theoretical advantages in the industrial vs manual racking cost debate must be solidified with quantifiable data. The following model, based on a representative 50,000 pallet-position warehouse, provides a clear, financial verdict.

The Capital Investment: A Strategic Deployment

The higher initial cost of an industrial automated racking system is the most frequently cited barrier. This includes the racking, machinery, software, and commissioning. It is crucial, however, to frame this not as a simple cost, but as a strategic capital investment that actively displaces a wide range of future operational costs associated with manual racking.

Operational Cost Savings: The Annual Windfall

This is where the TCO model for industrial vs manual racking cost becomes decisively lopsided. The annual savings are not incremental; they are transformational.

| Cost Category | Manual Racking System (Estimated Annual Cost) | Industrial Automated Racking (Estimated Annual Cost) | Annual Savings |

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com