📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

From Static to Smart: The Definitive Guide to Integrating ASRS and AGVs into Your Industrial Racking Warehouse Layout

The modern supply chain is a battlefield where efficiency, accuracy, and speed are the only metrics that matter. For decades, the backbone of this operation—the industrial racking warehouse layout—remained a static, predictable entity. Today, that static model is obsolete. The convergence of e-commerce velocity, complex SKU profiles, and relentless pressure on margins has ignited a revolution.

The future is not just automated; it is intelligently integrated. This definitive guide explores the profound transformation from a fixed storage facility to a dynamic, responsive ecosystem by strategically integrating Automated Storage and Retrieval Systems (ASRS) and Automated Guided Vehicles (AGVs). It provides a master blueprint for re-engineering the very DNA of an industrial racking warehouse layout to achieve unprecedented levels of performance and resilience.

The Strategic Imperative: Why an Integrated Industrial Racking Warehouse Layout is a Competitive Necessity

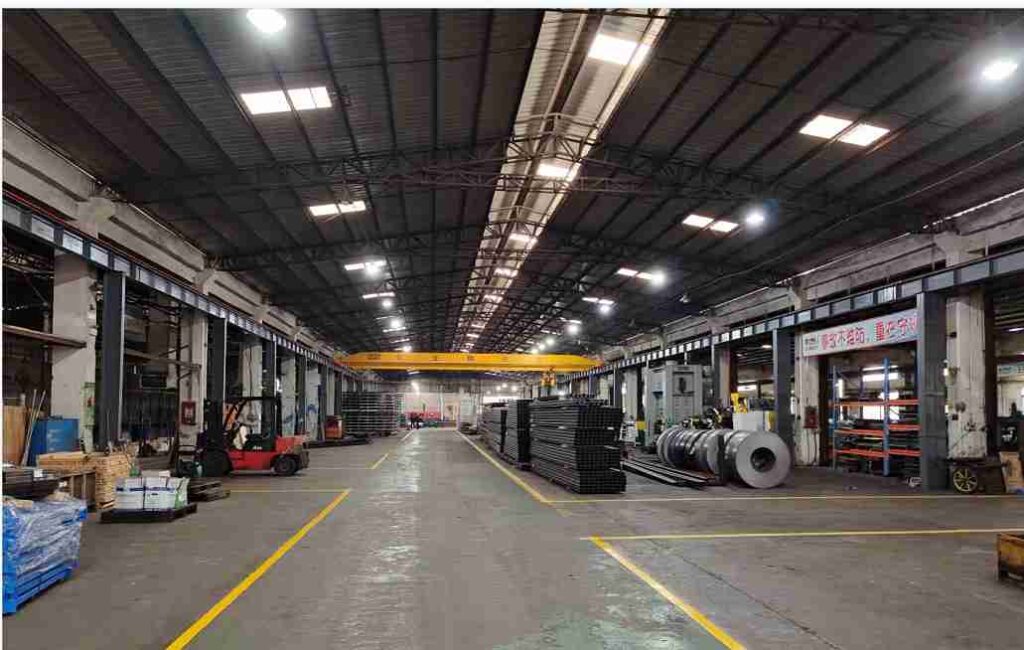

The decision to evolve from a manual, static system to an automated, smart one is no longer a speculative investment for industry leaders. It is a foundational strategy for survival and growth in a globalized market. A traditional industrial racking warehouse layout, reliant on manual labor and fixed storage logic, is fundamentally breaking under contemporary pressures.

The Critical Limitations of the Conventional Warehouse Model

Crippling Labor Dependency: The static model is built on the availability of a large, skilled, and reliable workforce—a resource that is increasingly scarce and costly. High turnover, training overheads, and the physical limitations of human labor create operational volatility and cap scalability.

Grossly Inefficient Space Utilization: A conventional industrial racking warehouse layout often fails to capitalize on its most valuable asset: the cubic air space. Without the precision of automation, maximizing height is fraught with risk, leading to significant wasted potential and an artificially inflated footprint.

Unacceptable Error Rates and Inventory Inaccuracy: Manual processes for picking, put-away, and cycle counting are inherently error-prone. These inaccuracies ripple through the supply chain, causing mis-ships, stockouts, and severe customer dissatisfaction, eroding brand trust and profitability.

Inflexible Throughput Bottlenecks: The physical and procedural constraints of a static industrial racking warehouse layout create a hard ceiling on daily order fulfillment capacity. When demand spikes, the system cannot adapt, leading to delayed shipments and lost revenue opportunities.

The Data Black Hole: In a traditional setup, inventory visibility is typically retrospective. Managers operate on data that is hours or days old, making it impossible to respond to real-time demands or optimize workflows proactively. This lack of live intelligence turns inventory management into a reactive, guesswork-heavy function.

The Synergistic Power of ASRS and AGV Integration

The true power of modern automation lies not in isolated technology but in the seamless integration of complementary systems. Combining ASRS and AGVs creates a holistic solution that is far greater than the sum of its parts.

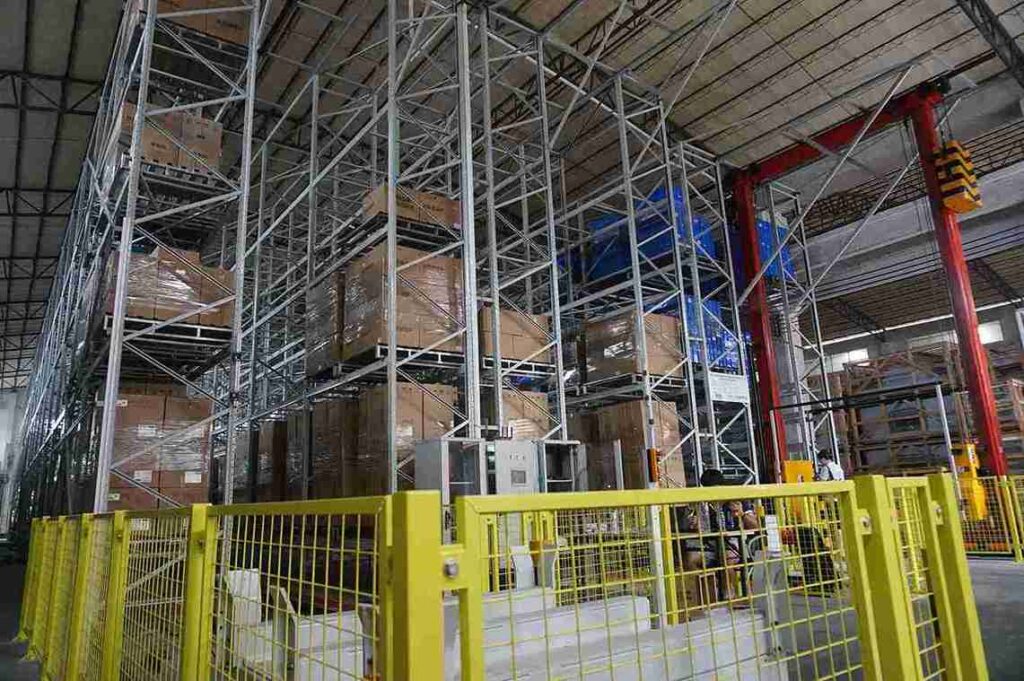

ASRS: The High-Density, High-Speed Anchor: An ASRS acts as the automated heart of the new industrial racking warehouse layout. It is a system of high-bay racking served by computer-controlled cranes that store and retrieve loads with perfect accuracy. It provides immense storage density, superior inventory control, and secure handling of goods, functioning as the central reservoir for all inventory.

AGVs: The Flexible, Unmanned Logistics Fleet: AGVs are the agile, mobile circulatory system. These driverless vehicles transport loads between the ASRS, receiving docks, workstations, and shipping areas. They replace traditional forklifts and manual carts, offering predictable, reliable, and continuous material movement.

The fusion of these two technologies transforms a disconnected series of manual tasks into a closed-loop, continuous-flow system. This redefines the industrial racking warehouse layout as a living entity where goods flow seamlessly from point to point with minimal human intervention, delivering maximum speed, accuracy, and operational intelligence.

The Pre-Integration Audit: Deconstructing and Diagnosing the Existing Industrial Racking Warehouse Layout

Building the smart warehouse of the future requires a brutally honest assessment of the present. A comprehensive pre-integration audit is the non-negotiable first step, forming the factual foundation upon which the entire new industrial racking warehouse layout will be designed.

A Deep Dive into Data and Workflow Analysis

This phase moves far beyond simple physical measurements. It involves a forensic-level analysis of the data and processes that constitute the warehouse’s operational lifeblood.

Granular SKU Profiling and Velocity Analysis: Every item in the inventory must be categorized not just by size and weight, but by its velocity—Fast (A), Medium (B), and Slow (C) movers. This analysis directly informs the storage logic within the new ASRS, ensuring that high-turnover items are positioned for optimal access speed. The entire industrial racking warehouse layout is orchestrated around this product velocity data.

Order Profile Deconstruction: The nature of outbound orders must be thoroughly understood. What is the average lines per order? Are they single-SKU pallets or complex, multi-SKU e-commerce totes? This profile dictates the picking strategy (e.g., discrete vs. batch picking) and fundamentally shapes the industrial racking warehouse layout, especially the design of goods-to-person stations.

Current State Value Stream Mapping: This process involves meticulously charting the journey of a single item or order through the current facility. The resulting map often reveals shocking inefficiencies: excessive travel distances, redundant handling, and convoluted paths. This exercise identifies the waste that the new, integrated industrial racking warehouse layout is specifically designed to eliminate.

Throughput and Peak Demand Modeling: Understanding average daily volume is insufficient. The audit must capture peak capacity requirements—during sales, holidays, or promotional events. The future industrial racking warehouse layout must be engineered to handle these peak loads gracefully, not just average-day traffic.

Rigorous Physical and Infrastructure Assessment

The physical shell of the building must be evaluated for its readiness to host a dense, power-hungry, and data-driven automated ecosystem.

Floor Flatness and Load-Bearing Capacity: This is arguably the most critical and often overlooked infrastructure element. AGVs require exceptionally flat floors (often with a tolerance of ±3mm over 3 meters) to navigate safely and accurately. The substructure must also support the immense point loads of a fully laden ASRS and the dynamic loads of moving AGVs.

Column Grid and Clearance Height Analysis: The placement of support columns can severely constrain the optimal configuration of an ASRS. Meanwhile, the clear ceiling height is a primary determinant of storage density. A detailed survey is essential to maximize the vertical potential of the new industrial racking warehouse layout.

Power and Data Network Ubiquity: An automated warehouse is a power and data hub. The audit must assess the facility’s electrical capacity for AGV charging stations, ASRS operation, and a pervasive, industrial-grade Wi-Fi/5G network. This network is the central nervous system, and any single point of failure can paralyze the entire operation.

Structural Integrity for High-Density Storage: The addition of a multi-story, fully-loaded ASRS imposes significant new loads on the building’s frame. A certified structural engineer must verify that the existing structure can support this weight or specify the necessary reinforcements, a crucial factor in the feasibility of the new industrial racking warehouse layout.

The Core Technologies: A Technical Examination of ASRS and AGVs

Selecting the right technologies is not about choosing the most advanced option, but the most appropriate one for the specific operational profile and the envisioned industrial racking warehouse layout.

Automated Storage and Retrieval Systems (ASRS): The Engine of Density

ASRS technology is not a monolith. It offers a spectrum of solutions tailored to different unit loads and throughput requirements, each influencing the overall industrial racking warehouse layout in distinct ways.

Unit-Load ASRS: These are the giants of automation, designed for pallet-sized loads. They utilize aisle-serving cranes, often exceeding 40 meters in height, to store and retrieve full pallets with superhuman speed and precision. They form the core of a high-volume industrial racking warehouse layout for manufacturing or bulk distribution.

Mini-Load ASRS: Engineered for smaller items stored in totes or bins, these systems are the workhorses of e-commerce and parts distribution. The cranes retrieve individual totes from high-density storage and deliver them to ergonomic pick stations. This “goods-to-person” principle is a cornerstone of the modern, efficient industrial racking warehouse layout.

Vertical Buffer Systems and Shuttles: For high-throughput, high-SKU environments, shuttle systems operating within a single aisle or vertical lift modules (VLMs) that bring shelves to the operator offer compelling density and speed. These can be integrated as high-density satellites within a broader industrial racking warehouse layout.

Automated Guided Vehicles (AGVs): The Architecture of Movement

The choice of AGV type and its navigation technology is a pivotal decision that dictates the flexibility and resilience of the material flow within the industrial racking warehouse layout.

Advanced Navigation Paradigms:

Laser Guidance (LiDAR): This is the modern standard for flexibility. AGVs use onboard lasers to create a real-time map of their surroundings, allowing for natural feature navigation. This eliminates the need for fixed paths and makes the industrial racking warehouse layout inherently adaptable to future changes.

Inertial and Geoguidance Navigation: Some systems use a combination of gyroscopes and magnetic tags embedded in the floor for highly accurate positioning. This offers a robust solution, though it is less flexible than LiDAR for layout modifications.

AGV Typology and Application:

Forklift AGVs: These are designed to autonomously perform the classic tasks of a human forklift operator, including lifting, transporting, and stacking pallets in both ASRS interfaces and conventional racking areas.

Tugger AGVs and Unit Load Carriers: Tuggers pull a series of carts, ideal for milk-run deliveries from a central ASRS to multiple production or packing lines. Unit load carriers, with their flat decks, are versatile for moving pallets, rolls, or custom containers, providing the connective tissue for the entire industrial racking warehouse layout.

The Master Blueprint: Designing the Integrated Industrial Racking Warehouse Layout

This is the phase where strategic analysis meets architectural and systems engineering. Designing the new industrial racking warehouse layout is a complex optimization puzzle balancing density, throughput, and future adaptability.

The Principle of Functional Zoning for Optimized Flow

A smart warehouse is not a monolithic space; it is a carefully orchestrated collection of functional zones. This zonal approach is the fundamental organizing principle of a high-performance industrial racking warehouse layout.

The High-Density ASRS Core: This zone is the fortress of inventory. It is where the ASRS is located, characterized by extreme density and restricted access. The design of this core—aisle dimensions, racking configuration, and crane performance—is the most critical calculation in the entire industrial racking warehouse layout.

Dedicated AGV Transit Corridors and Highways: Rather than allowing free-roaming chaos, a well-designed industrial racking warehouse layout establishes clear, optimized pathways for AGV traffic. These “highways” are designed with width, turning radii, and traffic management rules (e.g., roundabouts, passing lanes) to prevent congestion and ensure safety. The placement of these corridors is strategic, connecting all critical zones with maximum efficiency.

Goods-to-Person (G2P) Picking and Kitting Stations: This is the human-machine interface. In this zone, the automated system delivers the required goods directly to stationary operators. This single change—eliminating walking—can boost pick productivity by over 400%. The number, location, and ergonomics of these stations are vital components of the industrial racking warehouse layout, directly impacting overall throughput.

Dynamic Receiving and Staging Buffers: Incoming goods are not dumped directly into storage. They are received into a buffer zone where they are validated and staged. AGVs are then tasked to transport these loads from the buffer to the ASRS for put-away. The size and management of this buffer are crucial for smoothing out the variability of inbound logistics.

Outbound Shipping and Sortation Buffer: Completed orders are transported by AGVs to a designated buffer zone near shipping. Here, they are sequenced, consolidated with other orders, and loaded onto outbound trucks. The design of this zone within the industrial racking warehouse layout minimizes dock congestion and accelerates the loading process.

Engineering the Critical Handoff: ASRS and AGV Interface Design

The interface point between the static ASRS and the mobile AGV is a potential bottleneck. Its design requires meticulous engineering to ensure a seamless, high-velocity handoff.

Conveyor-Based Queuing Interfaces: In this common and efficient model, the ASRS discharges a load onto a short conveyor spur. This conveyor acts as a queue, presenting loads in sequence for pickup by the next available AGV. This decouples the two systems, allowing the AGV to complete other tasks while the ASRS prepares the next load.

Direct Pickup/Drop-off (PDO) Bays: This involves the AGV navigating to a specific, designated bay at the base of the ASRS. The ASRS crane delivers the load directly onto the AGV’s deck. This method requires millisecond-level synchronization between the Warehouse Control System (WCS), the ASRS, and the AGV fleet.

Modular Buffer Transfer Decks: For ultra-high-throughput systems, a bank of conveyor buffers or modular storage decks acts as a high-capacity intermediary. The ASRS deposits loads into any available buffer location, and AGVs independently retrieve from any location. This creates a highly flexible and scalable handoff system, a hallmark of a world-class industrial racking warehouse layout.

The Intelligent Control Layer: WMS, WCS, and the Power of Data

The physical automation is merely the body of the smart warehouse; the software is its brain and central nervous system. Without a sophisticated control layer, the most advanced ASRS and AGVs are just expensive metal.

The Command Hierarchy: WMS, WCS, and Real-Time Execution

Understanding the distinct roles of the Warehouse Management System (WMS) and the Warehouse Control System (WCS) is key to grasping how an integrated industrial racking warehouse layout functions.

Warehouse Management System (WMS): This is the strategic brain. It manages inventory, processes orders, and dictates what needs to be done at a high level (e.g., “fulfill Order #78910”). It operates on a batch-processing basis, managing tasks over minutes or hours.

Warehouse Control System (WCS): This is the tactical command center. It is the real-time, executional layer that translates the WMS’s commands into thousands of instantaneous instructions for the automated equipment. The WCS directs the ASRS crane to a specific location, commands an AGV to transport a load, and manages the traffic flow across the entire industrial racking warehouse layout. It is the irreplaceable orchestrator that makes the integration intelligent.

Leveraging the Digital Twin for Unparalleled Optimization

Before a single physical change is made, the entire industrial racking warehouse layout can be modeled, simulated, and optimized in a virtual environment known as a Digital Twin.

Virtual Commissioning and Bottleneck Identification: The Digital Twin allows engineers to run the entire operation in a simulated world. They can test different scenarios, identify potential bottlenecks at the design stage, and optimize AGV routes and tasking algorithms long before the system is built. This de-risks the project immensely.

Continuous Lifecycle Improvement: The Digital Twin is not discarded after implementation. It remains a live digital model of the physical warehouse. Operations managers can use it to test the impact of process changes, simulate the effect of a 30% demand increase, or train new staff in a risk-free virtual replica of their industrial racking warehouse layout.

The Human Capital Strategy: Evolving Roles in the Smart Warehouse

The integration of automation transforms the nature of warehouse work, shifting the focus from manual labor to cognitive and technical skills. A proactive human capital strategy is essential for a successful transition.

H3: Upskilling for High-Value Supervisory and Technical Roles

The workforce evolves from being the primary source of physical effort to being the managers, maintainers, and optimizers of the automated system.

Automation Systems Technicians: These individuals are trained to perform first-line troubleshooting and preventative maintenance on AGVs and ASRS, ensuring technical availability and minimizing downtime.

Flow Control Operators: Personnel who monitor the WCS interface, manage the daily workflow, handle system exceptions, and ensure the smooth operation of the entire industrial racking warehouse layout.

Data and Performance Analysts: These roles leverage the vast data generated by the system to uncover trends, identify inefficiencies, and provide actionable insights for continuous improvement of the industrial racking warehouse layout and its processes.

A transparent change management program, involving employees early and providing clear pathways for upskilling, is critical for securing buy-in and building a future-ready operational team.

The Investment Framework: Quantifying the ROI of a Smart Industrial Racking Warehouse Layout

The capital outlay for an integrated ASRS and AGV system is substantial, but the return on investment, when calculated holistically, is compelling and often rapid.

Tangible Financial Benefits and Cost Justification

Labor Productivity and Cost-Per-Unit Transformation: While headcount may be reallocated rather than reduced, the productivity per employee skyrockets. The system enables the handling of double or triple the volume with a similar-sized team, dramatically driving down the cost per pick, per pallet, or per line item.

Radical Real Estate and Footprint Optimization: By exploiting vertical space with an ASRS, companies routinely achieve the same storage capacity in 40-60% of the original floor space. This can eliminate the need for costly facility expansions or free up valuable square footage for revenue-generating activities like value-added services, a direct financial benefit of the new industrial racking warehouse layout.

Throughput Velocity and Revenue Capacity: A smart industrial racking warehouse layout shatters previous throughput ceilings. The ability to process more orders per day directly translates to increased revenue potential and the ability to capture market share.

Near-Zero Error Rates and Associated Cost Savings: The virtual elimination of picking and shipping errors saves substantial money on returns, reverse logistics, and credit notes, while simultaneously enhancing customer loyalty.

Perfect Inventory Integrity and Reduced Safety Stock: With 99.99%+ inventory accuracy in real-time, companies can operate with lower levels of safety stock, freeing up working capital and reducing inventory carrying costs.

The Intangible Strategic Advantages

Unmatched Operational Resilience: The automated industrial racking warehouse layout is less vulnerable to labor market fluctuations, absenteeism, and skills shortages, ensuring consistent service levels regardless of external pressures.

Inherent Scalability and Future-Proofing: The system is designed to be modular. More AGVs can be added, or the ASRS can be extended as business grows. The underlying industrial racking warehouse layout is designed for evolution, not revolution.

Enhanced Safety and Corporate Responsibility: By removing humans from potentially hazardous tasks like driving forklifts or working at height, the smart warehouse creates a fundamentally safer work environment, reducing accidents and reinforcing a culture of care.

24/7 Operational Capability: The automated system does not operate in shifts. It can run throughout the night for replenishment, cycle counting, and order preparation, enabling next-level service offerings like same-day or next-morning delivery.

The Implementation Roadmap: A Phased Journey to a Live Smart Warehouse

A “big bang” go-live is a high-risk strategy. A disciplined, phased implementation methodology is the proven path to success, ensuring minimal disruption to ongoing operations.

Phase 1: Deep Discovery and Detailed Engineering (2-4 Months)

This phase expands on the initial audit, culminating in a fully engineered design package. This includes all architectural and structural drawings, detailed industrial racking warehouse layout plans, equipment specifications, and a comprehensive project plan with milestones.

Phase 2: Software Core Configuration and Digital Twin Simulation (2-3 Months)

The WMS and WCS are configured to the specific business rules. The Digital Twin is built and used to simulate thousands of operational hours, validating the design, optimizing software parameters, and training the future operations team.

Phase 3: Site Preparation and Infrastructure Reinforcement (1-2 Months)

The physical preparation begins: floor grinding and leveling, electrical substation upgrades, network cabling, and any necessary structural steelwork to support the new industrial racking warehouse layout.

Phase 4: Phased Equipment Installation and Integration Testing (3-6 Months)

The ASRS is installed and calibrated first. AGVs are then introduced to the environment. Integration testing begins in isolated zones, methodically expanding to end-to-end process tests. A parallel run, where the old and new systems process a portion of live orders, validates performance and accuracy before full cut-over.

Phase 5: Go-Live and Hypercare Support (1-2 Months)

The system is switched to live operation, supported by an intense “hypercare” period where implementation experts are on-site 24/7 to rapidly resolve any teething issues and ensure a stable transition.

Phase 6: Continuous Optimization and Lifecycle Management (Ongoing)

The project’s conclusion is merely the beginning of the optimization journey. Using live performance data, the operations team continuously fine-tunes the system, unlocking new layers of efficiency within the industrial racking warehouse layout.

The Next Frontier: AI, Interoperability, and the Future Industrial Racking Warehouse Layout

The evolution of the smart warehouse is a continuous journey. The systems being implemented today are the foundation for the even more intelligent facilities of tomorrow.

AI and Machine Learning for Predictive Optimization: Beyond real-time control, AI will enable predictive optimization. Machine learning algorithms will forecast order spikes, prescriptively re-slot inventory for optimal flow, and predict equipment maintenance needs before they occur, transforming the industrial racking warehouse layout into a self-optimizing entity.

The Rise of Mobile Manipulation and Advanced Robotics: The next step is the fusion of mobility and dexterity. We will see the proliferation of AGVs equipped with robotic arms and advanced vision systems, capable of performing complex tasks like depalletizing mixed-SKU loads or picking individual items directly from a shelf, adding new layers of flexibility to the industrial racking warehouse layout.

The Open-Automation Ecosystem and Interoperability: The future lies in open standards that allow best-of-breed technologies from different vendors to communicate seamlessly. This will prevent vendor lock-in and foster a competitive ecosystem where the industrial racking warehouse layout can continually integrate the most innovative solutions.

Conclusion

The strategic migration from a static storage facility to a smart, integrated logistics hub represents the most significant operational advancement in a generation. It is a complex but essential undertaking that transcends the mere procurement of hardware. It demands a holistic strategy encompassing data-driven design, robust technological integration, sophisticated software, and a empowered workforce.

The seamless integration of ASRS and AGVs into the industrial racking warehouse layout is the definitive strategy for building a logistics operation that is not only efficient and accurate today but is also resilient, scalable, and intelligent enough to dominate the market of tomorrow. The era of the static warehouse has reached its end. The future belongs to those who embrace the dynamic, data-powered, and intelligently automated industrial racking warehouse layout.

Frequently Asked Questions (FAQs)

1. How does an integrated system handle exceptions, like a damaged pallet or an AGV blockage?

The Warehouse Control System (WCS) is programmed with sophisticated exception handling protocols. If an AGV’s onboard sensors detect an unexpected obstacle, it will safely stop and alert the WCS. The control system can then automatically reroute other AGVs around the blockage. For a damaged load identified at a pickup point, the WCS can flag the item for quarantine and dispatch an AGV to remove it, assigning the task to another available unit. This level of intelligent exception management is built into the core logic of a modern industrial racking warehouse layout.

2. What is the typical ROI period for such a significant investment in a new industrial racking warehouse layout?

The payback period is highly dependent on the specific operational profile, but for well-justified projects, it typically ranges from 2 to 4 years. This calculation must include both the hard cost savings (labor, real estate, error reduction) and the soft benefits (increased revenue capacity, improved customer satisfaction, enhanced resilience). A detailed feasibility study during the audit phase will generate a project-specific financial model with a precise ROI forecast.

3. Can we integrate this automation with our existing ERP and other enterprise software systems?

Absolutely. Integration is a standard requirement. The Warehouse Management System (WMS) acts as the primary intermediary between the automation control layer (WCS) and the enterprise software stack (ERP, TMS, OMS). Through standardized APIs (Application Programming Interfaces), the WMS ensures bidirectional data flow. For example, when a sales order is created in the ERP, it is pushed to the WMS, which then triggers the fulfillment process within the automated industrial racking warehouse layout.

4. How does the system adapt to seasonal peaks or a sudden, permanent increase in business volume?

The scalability of an integrated system is one of its core strengths. For seasonal peaks, the WCS can be programmed to operate in a “high-throughput” mode, prioritizing certain tasks and maximizing the utilization of the AGV fleet and ASRS cranes. For a permanent volume increase, the modular nature of the industrial racking warehouse layout allows for scaling. This can involve adding more AGVs to the fleet, extending the ASRS with additional modules, or expanding the number of goods-to-person stations. The Digital Twin is used to model these scaling scenarios beforehand to ensure a smooth expansion.

5. What kind of ongoing support and maintenance is required to ensure system longevity and uptime?

A successful implementation includes a comprehensive lifecycle support plan. This typically involves a combination of in-house, trained technicians for first-line support and a scheduled preventative maintenance program provided by the system integrator or technology OEM. This program includes regular inspections, wear-part replacements (e.g., sensors, bearings), and software updates. Remote monitoring services are also common, allowing experts to diagnose issues proactively and ensure the industrial racking warehouse layout operates at peak availability, often exceeding 98%.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com