📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Revolutionizing Warehouse Efficiency with Industrial Racking Supplies

In today’s competitive industrial landscape, warehouse managers face mounting pressure to maximize storage capacity while minimizing operational expenses. Industrial racking supplies have emerged as the cornerstone of modern warehouse optimization, offering tailored solutions that can help businesses save up to 40% on space and costs while dramatically improving operational efficiency.

Unlike generic storage systems, custom industrial racking systems are engineered to fit the exact dimensions, weight requirements, and workflow patterns of a facility. This precision engineering eliminates wasted space, reduces product damage, and streamlines material handling – delivering measurable ROI from day one.

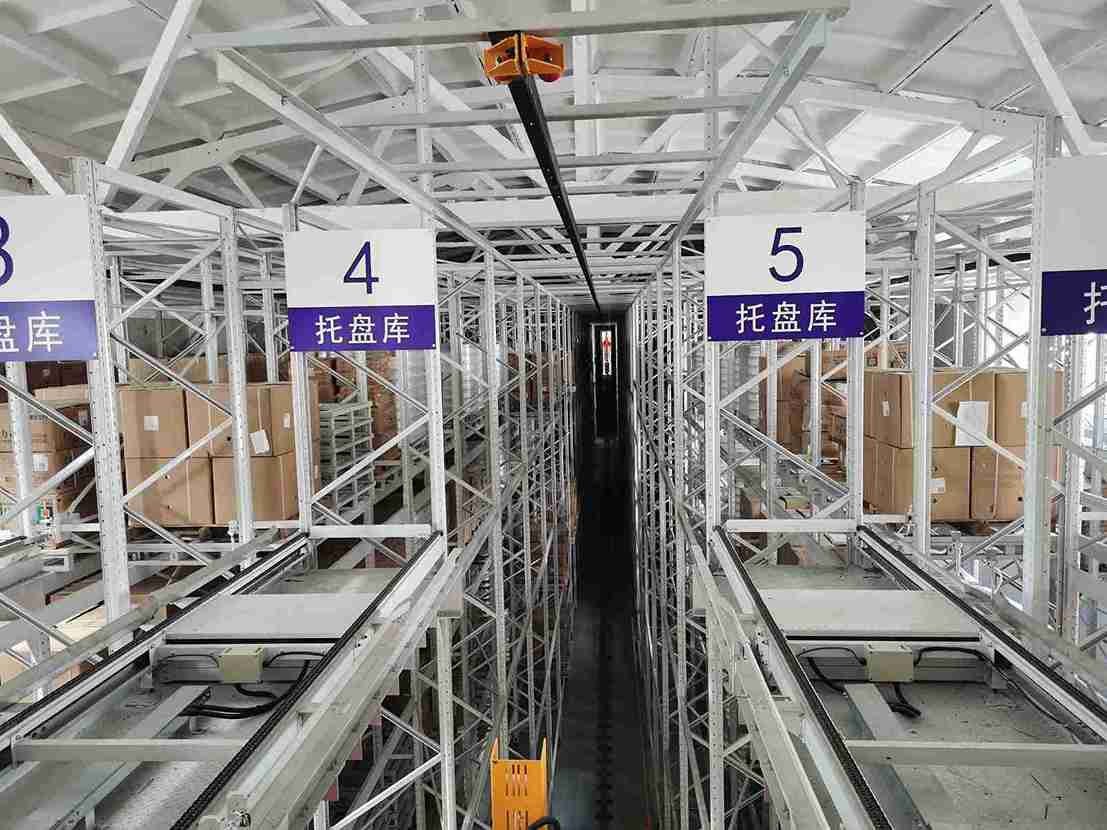

At [Geelyracks], engineers and logistics experts specialize in designing, manufacturing, and installing high-performance industrial racking supplies that transform underutilized warehouses into models of efficiency. From heavy-duty pallet racking to fully automated storage and retrieval systems (AS/RS), these solutions address the most pressing challenges in modern warehousing:

Vertical space utilization – Capitalizing on often-overlooked overhead space

Inventory accessibility – Ensuring fast, safe access to all SKUs

Workflow optimization – Minimizing unnecessary forklift travel

Future-proof scalability – Accommodating business growth without costly retrofits

This comprehensive guide explores how leading operations are leveraging industrial racking supplies to achieve unprecedented efficiency gains. Through detailed case studies, technical specifications, and implementation strategies, warehouse managers will gain actionable insights into transforming their storage infrastructure.

1. The Critical Role of Industrial Racking Supplies in Modern Warehousing

1.1 The Storage Crisis Facing Today’s Warehouses

The explosive growth of e-commerce and just-in-time manufacturing has created unprecedented demands on warehouse space. Industry reports indicate that:

78% of warehouses operate at or above capacity

43% of facilities cite storage limitations as their top challenge

Average storage costs have increased by 28% since 2020

Industrial racking supplies provide the most cost-effective solution to this crisis. Unlike traditional storage methods, modern racking systems:

Convert vertical dead space into usable storage

Support 2-3 times more inventory in the same footprint

Reduce required aisle widths through innovative designs

Integrate seamlessly with automation technologies

1.2 How Customization Delivers Superior Results

Off-the-shelf racking systems force warehouses to adapt their operations to the equipment’s limitations. In contrast, custom industrial racking systems are designed around the facility’s specific:

Inventory profiles (size, weight, turnover frequency)

Material handling equipment (forklift reach, AGV navigation paths)

Growth projections (5-10 year capacity planning)

Safety requirements (seismic zones, weight distribution)

This tailored approach explains why leading logistics operations achieve:

30-50% higher storage density

25% faster order picking speeds

40% reduction in product damage

60% longer equipment lifespan

2. Comprehensive Guide to Industrial Racking Supplies

2.1 Selective Pallet Racking: The Workhorse of Warehousing

As the most widely implemented industrial racking supplies, selective systems offer unmatched flexibility:

Configuration Options:

Roll-formed vs. structural frames

Standard, narrow, or very narrow aisle designs

Boltless vs. bolted beam connections

Standard or seismic-rated uprights

Performance Specifications:

Load capacities from 1,000 to 30,000 lbs per shelf

Adjustable beam heights (1-3″ increments)

Up to 40′ clear ceiling heights

Compatible with all forklift types

Recent innovations in selective racking include:

Light-directed picking systems that increase accuracy to 99.9%

Modular decking options for small parts storage

RFID-enabled racks for real-time inventory tracking

2.2 High-Density Storage Solutions

For operations storing large quantities of similar SKUs, specialized industrial racking supplies deliver dramatic space savings:

Drive-In Racking:

Eliminates aisles by storing pallets in depth

Ideal for cold storage with limited product variety

LIFO (Last-In-First-Out) inventory rotation

Push-Back Racking:

Cart-mounted pallets flow on inclined rails

Typically 2-5 pallets deep per lane

Combines high density with good selectivity

Pallet Flow Racking:

Gravity-fed roller systems

Perfect for FIFO (First-In-First-Out) requirements

Throughput speeds up to 50% faster than selective

2.3 Specialized Racking for Unique Applications

Beyond standard pallet storage, industrial racking supplies include solutions for challenging storage scenarios:

Cantilever Racking:

Stores long, bulky items (lumber, piping, furniture)

No front columns for unobstructed access

Arm lengths from 4′ to 20′

Mobile Shelving Systems:

Compact storage for small parts

Aisles appear/disappear as needed

Up to 80% space savings versus static shelving

Mezzanine Systems:

Creates elevated work platforms

Doubles usable floor space

Integrated with racking below

3. The Automation Advantage: Industrial Racking Supplies 4.0

3.1 AGVs and Robotic Integration

Modern industrial racking systems increasingly incorporate:

Laser-guided vehicles that navigate narrow aisles

Automated storage/retrieval machines reaching 100′ heights

Robotic palletizers with 3D vision systems

These technologies achieve:

24/7 operation without labor constraints

99.99% inventory accuracy

70% reduction in energy costs versus traditional systems

3.2 Smart Warehouse Technologies

Cutting-edge industrial racking supplies now feature:

IoT sensors monitoring load weights in real-time

Predictive analytics identifying maintenance needs

Digital twin simulations for layout optimization

4. Implementation Roadmap for Industrial Racking Supplies

4.1 Facility Assessment Protocol

Professional installers evaluate:

Floor load capacities and levelness

Clear ceiling heights and obstructions

HVAC and sprinkler system clearances

Electrical requirements for automation

4.2 Safety Considerations

All industrial racking systems must comply with:

OSHA 1910.176 standards

RMI (Rack Manufacturers Institute) guidelines

Local seismic and wind load requirements

5. ROI Analysis: Quantifying the Savings

A typical 100,000 sq. ft. warehouse investing in custom industrial racking supplies can expect:

| Metric | Before | After | Improvement |

|---|---|---|---|

| Storage Capacity | 12,000 pallets | 18,000 pallets | +50% |

| Order Picking Speed | 60 lines/hr | 85 lines/hr | +42% |

| Product Damage Rate | 3.2% | 1.1% | -66% |

| Labor Costs | $850,000/yr | $620,000/yr | -27% |

Conclusion: The Future of Warehouse Storage

As inventory demands continue escalating, industrial racking supplies will play an increasingly vital role in warehouse operations. The latest generation of custom industrial racking systems represents not just storage equipment, but strategic infrastructure that can determine a company’s competitive edge.

Forward-thinking operations are moving beyond basic storage to intelligent, automated systems that:

Dynamically adapt to inventory fluctuations

Integrate with enterprise software platforms

Continuously optimize storage configurations

Provide real-time operational analytics

For warehouse managers ready to transform their storage operations, the time to act is now. With lead times for premium industrial racking supplies extending to 6-8 months in some cases, early planning ensures businesses can capitalize on peak seasons with optimized facilities.

FAQs: Expert Insights on Industrial Racking Supplies

1. How do seismic requirements affect racking system design?

Seismic zones mandate specific engineering considerations including:

Increased base plate sizes

Additional cross-bracing

Lower height-to-depth ratios

Special anchorage requirements

2. What’s the typical lifespan of industrial racking systems?

With proper maintenance:

Structural racking: 25-30 years

Roll-formed racking: 15-20 years

Automated systems: 10-15 years (with component upgrades)

3. How often should racking systems be inspected?

OSHA requires annual inspections

High-traffic facilities should inspect quarterly

Post-impact inspections are mandatory

4. Can existing racking be reinforced for higher capacities?

Possible modifications include:

Adding beam connectors

Installing additional uprights

Upgrading decking materials

Adding overhead guards

5. What’s the lead time for custom racking systems?

Current industry averages:

Standard systems: 8-12 weeks

Custom configurations: 12-16 weeks

Automated solutions: 20-24 weeks

Geelyracks specializes in the production of warehouse racks and is a global rack customization expert

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com