Technical Specifications and Engineering Excellence in Storage Systems

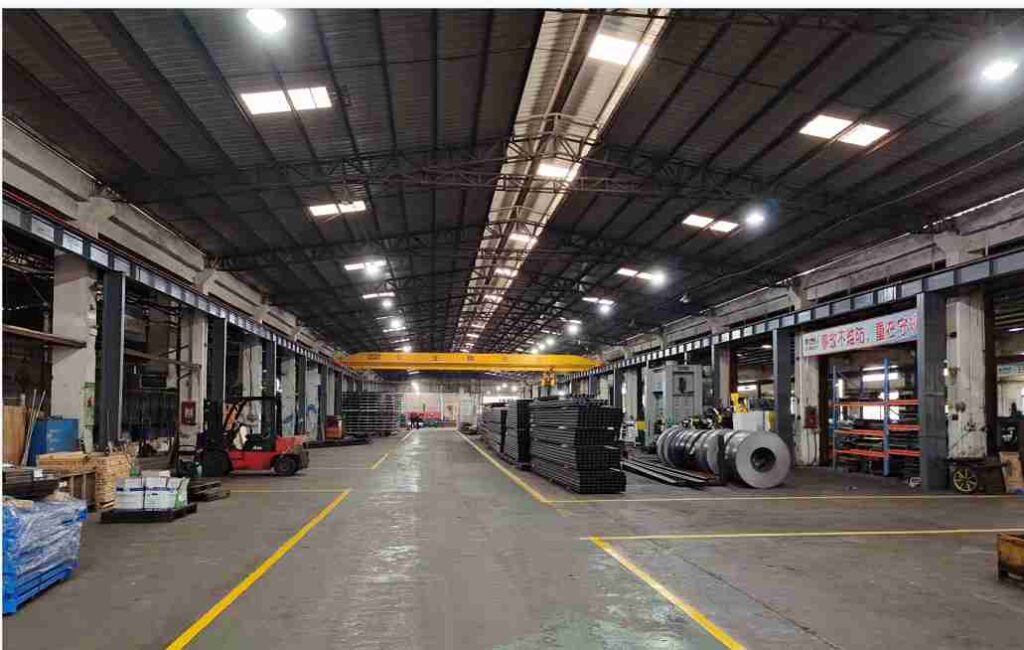

Professional warehouse operators understand that not all storage solutions meet the same quality standards. The engineering behind proper industrial racking near me involves complex calculations regarding load capacities, seismic ratings, and environmental factors specific to each facility.

When assessing potential industrial racking near me suppliers, technical decision-makers should insist on detailed documentation including structural load charts, material certifications, and comprehensive installation methodologies. The manufacturing quality of storage components—from steel thickness to protective coating specifications—directly affects system longevity and safety performance in demanding warehouse environments.

Material Science and Manufacturing Advancements

Contemporary storage systems benefit from significant advancements in materials engineering and manufacturing processes. The steel used in modern industrial racking near me installations typically features higher yield strengths and improved durability characteristics compared to earlier alternatives.

Protective coatings have evolved to include sophisticated epoxy and powder-based finishes that provide superior resistance to corrosion, chemical exposure, and mechanical abrasion—particularly important in challenging environments like cold storage facilities or coastal warehouses where environmental factors can rapidly degrade inferior storage solutions.

Operational Efficiency Metrics and Performance Measurement

Quantifying the return on investment for warehouse storage solutions requires tracking specific key performance indicators before and after implementation. Operations implementing new industrial racking near me systems typically monitor metrics such as storage density per square meter, inventory turnover rates, and picking efficiency.

The right storage configuration can dramatically improve these numbers, with many operations reporting 30-40% gains in storage capacity and 25-35% improvements in picking efficiency through proper design and implementation.

Throughput Optimization Through Strategic Layout Design

The spatial organization of warehouse storage directly influences material flow velocity and operational efficiency. Sophisticated operations increasingly utilize specialized software to simulate different storage configurations before implementation, identifying optimal layouts that minimize travel time and reduce congestion.

The strategic positioning of storage systems in relation to receiving docks, packing stations, and shipping areas requires careful analysis of product velocity patterns and seasonal fluctuations. Fast-moving items typically warrant placement in easily accessible locations, while slower-moving inventory can occupy higher or less accessible positions within the storage matrix.

Safety Protocols and Compliance Standards

The safe operation of warehouse storage systems demands rigorous adherence to established protocols and regular inspection routines. Comprehensive safety programs should include scheduled structural assessments, clear load capacity labeling, and thoroughly documented inspection histories.

Operations utilizing heavy-duty storage must establish strict protocols for reporting and repairing damage, particularly to critical structural elements like upright frames and beam connections. The implementation of safety features such as column guards, end-of-aisle protectors, and seismic bracing should be standard practice in all installations, especially in regions with specific regulatory requirements.

Maintenance and Long-Term Performance Preservation

Proactive maintenance represents a crucial aspect of storage system management that directly impacts operational safety and cost efficiency. Established maintenance programs typically include quarterly visual inspections, annual professional assessments, and immediate repairs following any impact incidents. Proper documentation should track inspection dates, findings, and corrective actions, creating an auditable safety record that supports continuous improvement and risk management.

Many successful operations maintain partnerships with their original suppliers for these services, leveraging specialized expertise in identifying potential issues before they escalate into serious safety concerns or operational disruptions.

Technology Integration and Digital Transformation

The evolution of warehouse storage continues to intersect with technological advancements in warehouse management systems and automation technologies. Modern storage installations increasingly incorporate technologies like RFID tagging, IoT sensors, and automated inventory monitoring systems. These smart solutions provide real-time data on inventory levels, location accuracy, and even structural stress factors, enabling predictive maintenance and optimized space utilization.

The integration of physical storage with digital control systems creates a seamless information ecosystem where storage infrastructure becomes an intelligent component of broader operational strategy.

Data-Driven Decision Making and Continuous Improvement

Advanced operations now utilize data analytics to continuously optimize their storage performance and space utilization. By analyzing usage patterns, inventory velocity, and space utilization metrics, managers can make informed decisions about reconfiguring storage layouts to better match evolving operational needs.

This data-driven approach to storage management helps identify underutilized areas, bottlenecks in material flow, and opportunities for further efficiency improvements. The analytical transformation turns static storage infrastructure into a dynamic tool for continuous operational improvement and cost optimization.

Sustainability and Environmental Considerations

Environmental responsibility has become an increasingly important factor in storage system selection and operation across global markets. Sustainable storage solutions prioritize recyclable materials, energy-efficient manufacturing processes, and designs that maximize space utilization to reduce the overall facility footprint.

The durability and reconfigurability of quality storage systems contribute to sustainability by extending product lifecycles and reducing waste through adaptive reuse. Additionally, efficient storage layouts that optimize space usage can indirectly reduce energy consumption by allowing operations to utilize smaller facilities or avoid the environmental impact of expansion construction.

Conclusion: Strategic Implementation for Long-Term Value

The selection and implementation of warehouse storage systems represents a long-term strategic decision with profound implications for operational efficiency, cost structure, and scalability. By approaching storage infrastructure as an integrated system rather than a simple commodity, operations can achieve significant competitive advantages in today’s demanding logistics environment.

The ongoing management and optimization of storage systems requires continuous attention to safety, technological integration, and operational data analysis to ensure these critical assets continue delivering maximum value throughout their service life while supporting broader business objectives and market positioning.

Frequently Asked Questions (FAQs)

What specific documentation should we request when evaluating storage system proposals?

When comparing potential suppliers, request detailed engineering calculations, material certifications, installation methodology statements, and compliance documentation relevant to your specific region. Reputable suppliers should provide comprehensive documentation packages that validate the structural integrity and safety compliance of their proposed solutions while addressing local regulatory requirements.

How does the procurement process for custom storage systems differ from standard configurations?

Custom storage solutions involve more extensive consultation, specialized engineering analysis, and typically longer lead times for fabrication and installation. The custom process requires closer collaboration between the client and supplier throughout design and implementation phases to ensure the final solution addresses specific operational requirements that standard configurations cannot adequately accommodate.

What training should our staff receive regarding new storage systems?

Comprehensive training programs should cover proper loading procedures, safety inspection protocols, and basic maintenance requirements. Staff working with storage systems should thoroughly understand load capacity limitations, recognize potential safety hazards, and know proper procedures for reporting damage or concerns about system integrity to maintain operational safety.

How do we establish an effective inspection routine for storage infrastructure?

Develop a formal inspection program that includes daily visual checks by operational staff, weekly supervisory inspections, and quarterly professional assessments. Document all inspections and maintain detailed records of any damage, repairs, or modifications to create a comprehensive safety history for your storage infrastructure that supports preventive maintenance and risk management.

What are the warning signs that current storage systems require replacement or significant upgrades?

Visible deformation in structural components, difficulty accommodating inventory changes, increasing product damage rates, or frequent need for repairs indicate that storage systems may require replacement or significant upgrading. Operations experiencing growth beyond original capacity projections should also evaluate whether existing storage infrastructure remains adequate for current and future operational needs.