📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

In today’s fast-paced industrial landscape, proper industrial racking installation isn’t just an option—it’s a necessity for businesses that rely on efficient, safe, and high-capacity storage solutions. Whether managing a bustling distribution center, an automotive parts warehouse, or a food and beverage storage facility, companies need industrial racking installation that delivers both structural integrity and operational efficiency.

At [Geelyracks], decades of hands-on experience in industrial racking installation have proven one critical fact: cutting corners leads to costly mistakes. From improperly anchored uprights to overloaded beams, poor installation can result in catastrophic failures, OSHA violations, and lost productivity. This guide dives deep into industrial racking installation best practices, ensuring businesses make informed decisions that maximize storage, enhance safety, and improve workflow.

Why Professional Industrial Racking Installation is Non-Negotiable

The High Stakes of Heavy-Duty Storage Systems

Every year, warehouses experience avoidable accidents due to subpar industrial racking installation. Collapsed racks, bent beams, and misaligned load beams aren’t just inconvenient—they’re dangerous. Proper industrial racking installation ensures:

✔ Structural Stability – Prevents rack failures under heavy loads.

✔ Optimal Space Utilization – Maximizes vertical and horizontal storage capacity.

✔ Regulatory Compliance – Meets OSHA, FEM, and ANSI MH16.1 standards.

✔ Long-Term Cost Efficiency – Reduces repair costs and downtime.

Common Mistakes in Industrial Racking Installation (And How to Avoid Them)

Improper Anchoring – Racks must be secured to reinforced concrete floors with high-strength bolts.

Incorrect Beam Levels – Uneven beams cause uneven weight distribution, leading to collapses.

Ignoring Load Capacity Limits – Exceeding weight limits per shelf is a leading cause of failure.

Skipping Post-Installation Inspections – Even minor alignment issues can escalate into major hazards.

Types of Industrial Racking Systems & Their Installation Requirements

1. Selective Pallet Racking – The Gold Standard for Industrial Racking Installation

Best For: Warehouses with frequent SKU rotation

Load Capacity: 3,000–5,000 lbs per shelf

Installation Key Points:

Upright frames must be anchored with M12 or larger bolts.

Beam connectors should use lock-in safety clips to prevent dislodging.

2. Drive-In Racking – High-Density Industrial Racking Installation

Best For: Cold storage, beverage, and bulk goods

Load Capacity: 4,000–6,000 lbs per pallet

Installation Key Points:

Requires laser-guided leveling for rail alignment.

Floor must withstand 6,000+ PSI due to continuous forklift traffic.

3. Cantilever Racking – Heavy-Duty Industrial Racking Installation for Long Loads

Best For: Steel, lumber, and piping industries

Load Capacity: Up to 12,000 lbs per arm

Installation Key Points:

Base plates need epoxy anchoring for seismic stability.

Arms must be torque-tested to prevent sagging.

4. Push-Back Racking – LIFO-Based Industrial Racking Installation

Best For: High-turnover inventory like pharmaceuticals

Load Capacity: 2,000–4,500 lbs per pallet

Installation Key Points:

Slope must be precisely calibrated (typically 3°–5°).

Requires low-friction roller tracks for smooth operation.

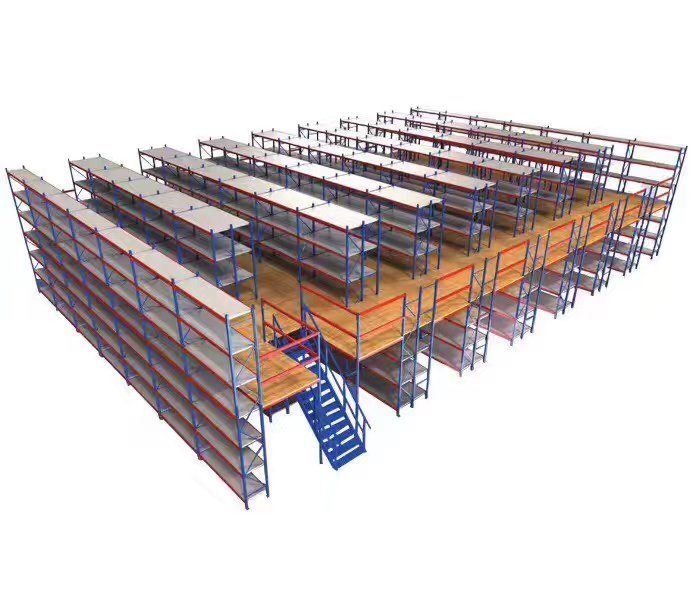

5. Mezzanine Racking – Multi-Level Industrial Racking Installation

Best For: Warehouses needing vertical expansion

Load Capacity: 300–1,000 lbs/sq ft

Installation Key Points:

Structural engineering review is mandatory.

Must integrate with sprinkler systems and emergency exits.

Critical Pre-Installation Assessments for Industrial Racking

1. Warehouse Floor Evaluation

Concrete Thickness: Minimum 4 inches for light racks, 6+ inches for heavy-duty systems.

Floor Flatness: Variations beyond 1/8″ per foot require self-leveling compounds.

2. Seismic & Wind Load Considerations

High-risk zones require cross-bracing and seismic locks.

Wind-rated racks need additional base reinforcements for outdoor use.

3. Future-Proofing Your Industrial Racking Installation

Modular designs allow for easy reconfiguration.

AGV/AMR compatibility ensures automation readiness.

Step-by-Step Industrial Racking Installation Process

Phase 1: Engineering & Planning

3D laser scanning maps warehouse dimensions.

FEM 10.2.02 calculations determine load distribution.

Phase 2: Structural Assembly

Anchor Uprights – Use Hilti HVU bolts for seismic zones.

Install Beams – Torque to 25–30 ft-lbs per manufacturer specs.

Add Safety Components – Decking, column guards, and end-of-aisle protectors.

Phase 3: Load Testing & Certification

Incremental loading (25%, 50%, 100% capacity).

Third-party certification for insurance compliance.

Maintenance Protocols for Industrial Racking Systems

Weekly: Visual checks for dents, cracks, or loose bolts.

Quarterly: Professional inspection using ultrasonic thickness testing.

Post-Impact: Immediate evaluation after forklift collisions.

Why Leading Companies Trust [Your Company] for Industrial Racking Installation

✅ 30+ Years Specializing in Heavy-Duty Industrial Racking Installation

✅ FEM 10.2.02 & OSHA 1910.176 Compliant Solutions

✅ Turnkey Projects – From Design to Ongoing Maintenance

✅ Free On-Site Assessment With Custom CAD Layouts

Conclusion

Superior industrial racking installation separates high-performing warehouses from those plagued by inefficiencies and safety risks. By prioritizing engineered designs, precision installation, and proactive maintenance, businesses unlock:

15–40% More Storage Capacity

Near-Zero Downtime From Rack Failures

Full Compliance With Global Safety Standards

📞 Schedule Your Free Industrial Racking Installation Consultation Today – Let’s Build a Storage System That Grows With Your Business.

FAQs About Industrial Racking Installation

1. How much weight can industrial racking hold after installation?

Properly installed selective pallet racks handle 3,000–5,000 lbs per shelf, while drive-in systems support up to 6,000 lbs per pallet.

2. What’s the lifespan of professionally installed industrial racking?

With annual maintenance, 20–30 years is typical. Environments with high humidity or chemicals may require stainless steel racks.

3. Can existing racking be modified after initial installation?

Yes, but modifications require recalculation of load capacities by a certified engineer.

4. How do I know if my floor can support industrial racking?

A core sample test determines concrete PSI rating. Most warehouses need ≥4,000 PSI for heavy-duty racks.

5. What’s the lead time for industrial racking installation?

Standard systems install in 1–3 weeks. Custom designs may take 4–8 weeks including manufacturing.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com