📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

To fully appreciate the value proposition of mesh shelf racking, a comparative analysis with other common storage systems is essential. Facility managers often weigh options like solid-shelf steel shelving, rivet shelving, or even bulk pallet racking. Each has its place, but understanding their limitations highlights the superior design of mesh shelf racking.

Solid-shelf steel shelving, while offering a continuous surface, creates significant blind spots for workers. Locating a specific SKU at the back of a deep shelf requires extra time and movement. Furthermore, these solid surfaces impede air circulation and can trap moisture against stored goods, a critical failure point for many industries. In contrast, the open-grid design of mesh shelf racking ensures total visibility and unrestricted airflow from all angles, directly addressing these operational inefficiencies.

Rivet shelving, or boltless shelving, is popular for its ease of assembly. However, its strength often relies on the integrity of the rivet connections and the decking material, which is frequently particle board or a lighter-grade metal. For true durable industrial applications involving heavy loads or dynamic impacts, this construction can be a liability. The welded construction of high-quality mesh shelf racking creates a unified, robust structure that withstands the rigors of daily industrial use far more effectively. The racking system is inherently more stable.

When compared to the larger scale of pallet racking, mesh shelf racking serves a different, yet complementary, purpose. Pallet racking is designed for bulk storage of palletized goods, while mesh shelf racking is the optimal solution for smaller, hand-stacked items, bin storage, and smaller parts. In a sophisticated warehouse, these systems work in concert; pallet racking holds bulk inventory, while mesh shelf racking in the picking area facilitates efficient order fulfillment. The integration of mesh shelf racking into a broader racking and automation strategy is a hallmark of a well-designed facility.

The Technical Specifications: What Constitutes Premium Mesh Shelf Racking

Not all mesh shelf racking is created equal. Discerning buyers must look beyond the basic description and evaluate the technical specifications that dictate performance, safety, and longevity. A deep dive into the engineering details separates standard products from premium industrial-grade racking solutions.

Wire Diameter, Gauge, and Mesh Pattern Density

The strength of a mesh shelf racking deck begins with the thickness of the steel wire used in its construction. Manufacturers specify this through wire diameter and the gauge of the steel. A heavier gauge and a larger diameter directly correlate to a higher load capacity. For instance, a mesh shelf racking system designed for light-duty storage might use 12-gauge wire, while a system engineered for heavy-duty industrial applications would utilize a robust 7-gauge wire with a significantly thicker diameter.

Equally important is the mesh pattern density—the size of the open spaces within the grid. A very wide mesh might be unsuitable for small items, while an overly dense mesh could slightly reduce light and air penetration. Premium mesh shelf racking offers a balanced pattern that provides an optimal mix of support, visibility, and ventilation for a wide range of item sizes. The design of this pattern is a critical aspect of the racking engineering process.

Finish and Coating: Ensuring Corrosion Resistance

The raw steel of mesh shelf racking is susceptible to rust and corrosion, especially in environments with humidity, temperature fluctuations, or exposure to certain chemicals. Therefore, the type of finish applied is not merely cosmetic; it is a vital protective barrier.

Electrostatic Epoxy Powder Coating: This is the industry standard for high-quality mesh shelf racking. The process involves applying a dry powder to the electrically charged steel and then curing it under heat to create a hard, durable, and consistent finish. This coating is available in various colors and provides excellent resistance to chipping, scratching, and chemicals.

Galvanization: For extreme environments, such as cold storage warehouses or facilities storing highly corrosive materials, galvanized mesh shelf racking is the preferred choice. This process involves coating the steel in a layer of zinc, providing a sacrificial layer that protects the base metal from rust. Galvanized racking is exceptionally durable and offers a superior lifespan in harsh conditions.

The choice of finish should be a deliberate decision based on a facility’s specific environmental challenges, ensuring the long-term durable performance of the mesh shelf racking investment.

Advanced Configurations and Customization of Mesh Shelf Racking

The versatility of mesh shelf racking is one of its most compelling attributes. Unlike many one-size-fits-all storage solutions, a premium mesh shelf racking system can be customized and configured to meet highly specific operational requirements. This adaptability makes it a future-proof investment.

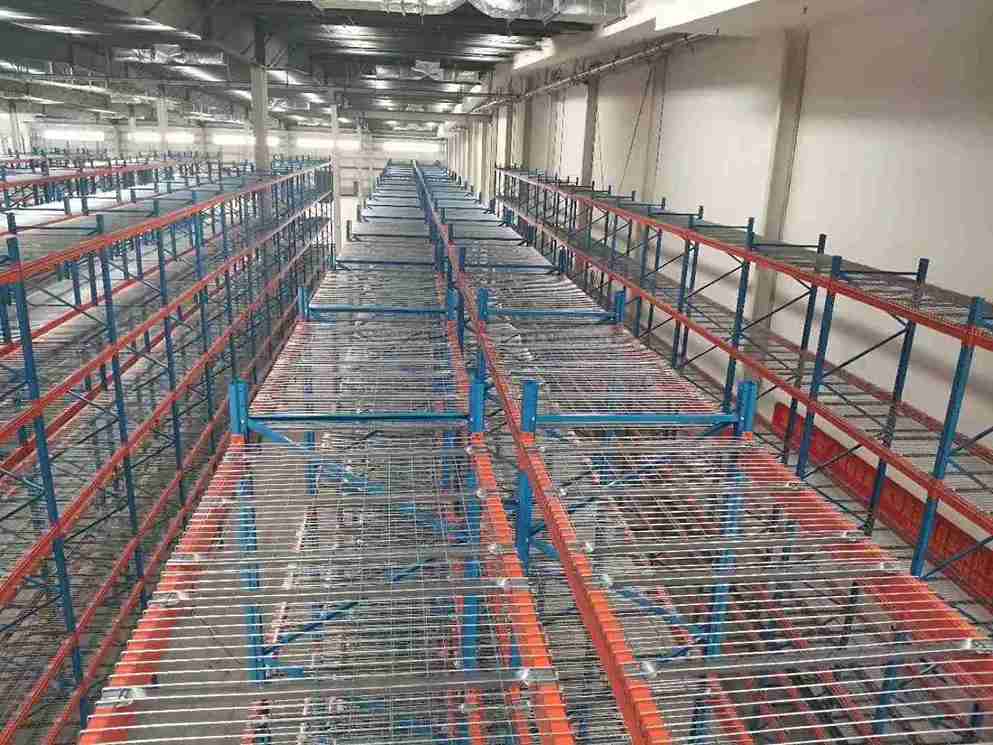

Mezzanine Integration: Doubling Your usable Space

For facilities constrained by footprint rather than height, mesh shelf racking can be seamlessly integrated with structural mezzanines. This creates a multi-level storage platform, effectively doubling or tripling the available storage area within the same building footprint. The mesh shelf racking is installed on the mezzanine deck, and its open design is crucial here: it maintains light penetration to the lower levels and ensures that the fire suppression system can function effectively throughout the entire volume of space. This integration of racking and mezzanine represents a high-efficiency spatial solution.

Mobile Aisle Systems: Maximizing Storage Density

In applications where storage density is the paramount concern, mesh shelf racking can be mounted on mobile carriage systems. Instead of having fixed aisles between each row of racking, the mobile system allows the racking to be condensed together, with only one “floating” aisle created where needed. This can increase storage capacity by up to 100% within the same area. The inherent strength and stability of durable mesh shelf racking make it an ideal candidate for such dynamic systems, as it can handle the movement and the concentrated loads without compromise.

Specialized Accessories for Enhanced Functionality

The functionality of a basic mesh shelf racking unit can be greatly expanded with a suite of specialized accessories. These include:

Dividers and End Stops: To secure bin boxes and prevent them from being pushed off the back of the shelf.

Label Holders: For clear, visible identification of inventory, crucial for any modern warehouse management system.

Security Panels and Locking Doors: To convert open mesh shelf racking into secure cages for high-value or controlled items.

Cantilever Arms: For the storage of long, awkward items like pipes, bars, or molding, which can be integrated with standard mesh shelf racking bays.

This high degree of customization ensures that the mesh shelf racking system is not just installed, but is expertly tailored to the precise workflow it is intended to support.

The Role of Mesh Shelf Racking in a Lean Warehouse Environment

The principles of Lean manufacturing and warehousing focus on the elimination of waste—waste of time, motion, space, and resources. Mesh shelf racking is inherently a Lean storage solution, as its design directly supports several core Lean tenets.

The principle of “Visual Management” is powerfully enabled by mesh shelf racking. Because inventory is always visible, problems like low stock, misplaced items, and disorganization are immediately apparent. This allows for quick corrective action, a concept known as “Jidoka” or autonomation. There are no hidden areas where excess inventory or defects can languish unnoticed.

Furthermore, the ease of adjustability in mesh shelf racking supports the Lean concept of “Flexibility.” As product lines change, seasonality affects inventory, or processes are improved, the racking system can be quickly and easily reconfigured without specialized tools or significant downtime. This contrasts sharply with welded, static shelving that creates process rigidity. The durable yet adaptable nature of mesh shelf racking makes it a cornerstone of a continuous improvement culture.

Implementing Your Mesh Shelf Racking System: A Phased Approach

The successful implementation of a new mesh shelf racking system is a project that benefits from a structured, phased approach. Rushing the installation can lead to costly errors and suboptimal performance.

Phase 1: Discovery and Planning

This critical first phase involves a detailed analysis of current and future needs. It includes cataloging all SKUs with their dimensions, weights, and turnover rates (ABC analysis). It also involves mapping current workflow and identifying pain points. The output of this phase is the detailed warehouse layout plan, which specifies the exact type, size, and configuration of the mesh shelf racking required.

Phase 2: Preparation and Site Readiness

Once the plan is finalized, the physical site must be prepared. This may involve clearing existing storage, deep-cleaning the floor, and ensuring the installation area is level and accessible. For larger projects, a phased rollout may be planned to minimize disruption to ongoing operations.

Phase 3: Installation and Assembly

The mesh shelf racking components are delivered and systematically assembled according to the engineered layout plans. Whether performed by a professional installation crew or a trained in-house team, precision is key. Every connection must be secure, and the entire racking system must be perfectly level and plumb to ensure its rated load capacity and stability.

Phase 4: Loading and Commissioning

The system is loaded with inventory according to the plan, with fast-moving “A” items placed in the most accessible “golden zone.” This is also the time to affix labels and barcodes and to update the Warehouse Management System (WMS) with the new storage locations.

Phase 5: Training and Continuous Optimization

Finally, warehouse staff must be trained on the new system, including the logic behind the layout and any new procedures for stocking and picking. The implementation is not the end, but the beginning of an ongoing process of monitoring and optimizing the use of the mesh shelf racking for peak efficiency.

Conclusion: Building a More Efficient and Safe Future with Mesh Shelf Racking

The decision to invest in a high-quality mesh shelf racking system reverberates throughout an organization. It is a strategic commitment to operational excellence, workplace safety, and scalable growth. The unique combination of durable construction and ventilated design directly addresses the most persistent challenges in modern inventory management. By providing unmatched visibility, promoting safety, ensuring product integrity, and offering unparalleled flexibility, mesh shelf racking proves to be far more than a simple storage product—it is an enabling technology for a more productive warehouse.

The journey to this optimized state begins with expert planning. Leveraging professional expertise to create a custom warehouse layout plan is the single most important step in unlocking the full potential of a mesh shelf racking installation. It transforms a generic procurement into a tailored solution, engineered to deliver a rapid and substantial return on investment. For any business serious about optimizing its storage logistics, embracing the advanced capabilities of modern mesh shelf racking is not just an option; it is an imperative.

Frequently Asked Questions (FAQs)

1. How does the weight of mesh shelf racking compare to other types of shelving, and does it impact freight costs?

Due to its robust construction and use of high-tensile steel, industrial-grade mesh shelf racking can be comparable in weight to other heavy-duty shelving. However, its modular nature often allows for more efficient packaging. While freight is a factor, the long-term benefits of a durable system that won’t need replacing far outweigh the one-time shipping cost. We provide precise weight and freight estimates upfront for all racking orders.

2. Can mesh shelf racking be safely used in seismic zones?

Yes, but it requires specific engineering. Standard mesh shelf racking is designed for vertical loads. In seismic-active regions, the racking must be evaluated and potentially reinforced to handle lateral forces. We offer seismic-rated mesh shelf racking systems that include specialized bracing and anchoring solutions designed to meet the strict building codes in these zones.

3. What is the typical lifespan of a properly maintained mesh shelf racking system?

A premium mesh shelf racking system, kept in a reasonable environment and not overloaded, has an exceptionally long lifespan. It is not uncommon for these racking systems to remain in full service for 20, 30, or even more years. The durable materials and finishes are designed to withstand decades of industrial use, making it a multi-generational asset.

4. Are there specific guidelines for anchoring mesh shelf racking to different types of flooring?

Absolutely. Anchoring is critical for the stability and safety of any racking system, especially tall units. Guidelines vary for concrete slab, epoxy-coated, or raised-access flooring. Our installation manuals and engineering teams provide specific anchoring requirements and recommended hardware for each floor type to ensure the mesh shelf racking is secured to its maximum rated capacity.

5. How does your company handle the procurement and logistics for a large, multi-site mesh shelf racking rollout?

For large-scale, multi-site projects, we assign a dedicated project manager who acts as your single point of contact. They coordinate everything from manufacturing schedules and phased deliveries to ensuring consistency across all sites. Our logistics expertise allows us to manage complex supply chains, ensuring the right mesh shelf racking components arrive at the right location at the right time, keeping your project on track.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com