📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Definitive Guide to Engineered Pallet Racking Wire Decking for Industrial Excellence

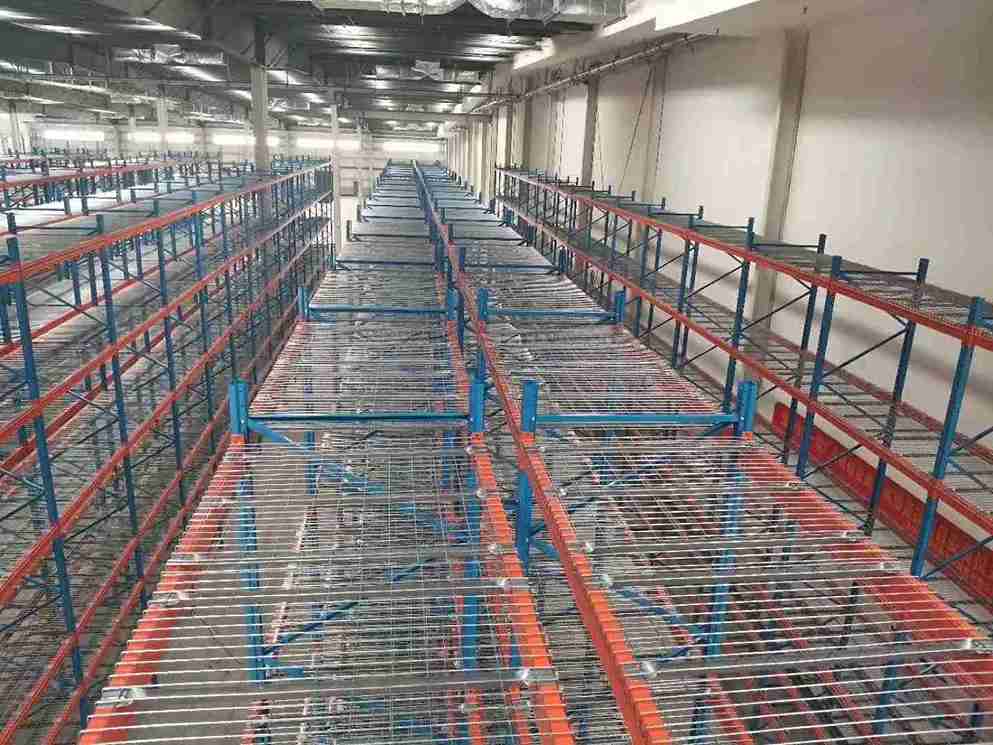

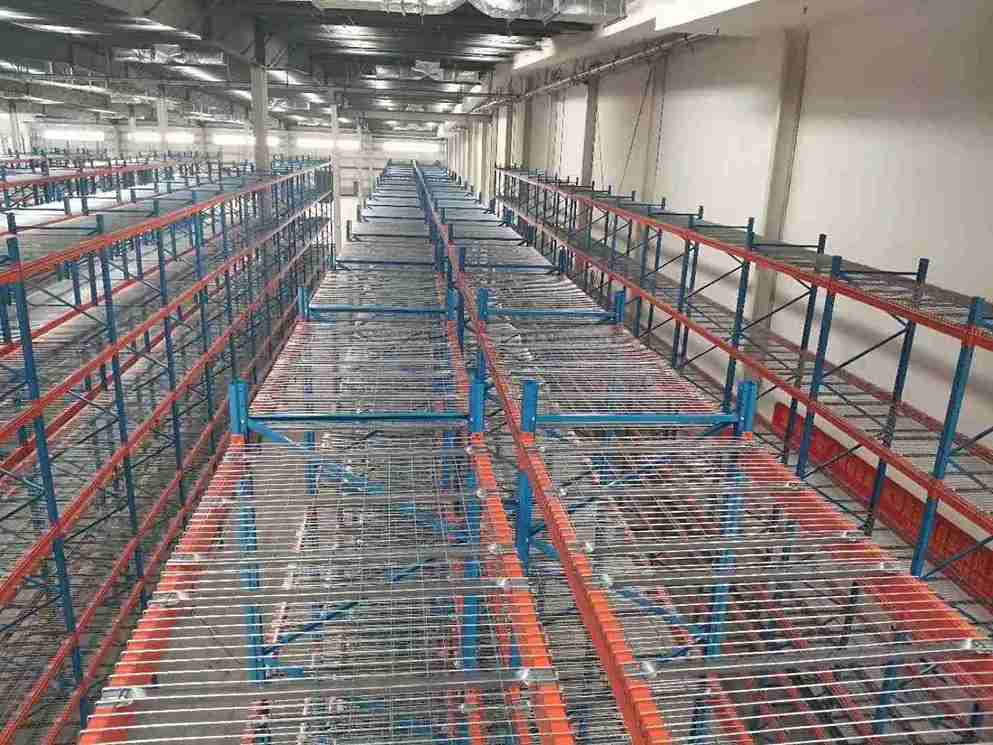

In the high-stakes world of industrial and logistics operations across emerging markets, efficiency is meticulously measured in centimeters saved and seconds shaved. At the very heart of this relentless pursuit lies a component so fundamental it is often underestimated: the pallet racking wire decking. This is not merely a shelf; it is the critical interface between a static storage structure and dynamic, valuable inventory.

For discerning facility managers, plant engineers, and logistics strategists in the manufacturing hubs of Central Asia and beyond, understanding the profound impact of specifying custom pallet racking wire decking is the differentiator between a mere storage area and a optimized, high-performance asset. This comprehensive exploration delves into the engineering, application, and strategic value of purpose-built wire decking, positioning it as the cornerstone of any serious storage optimization project aimed at driving tangible ROI, enhancing safety, and enabling scalable growth.

The Foundational Role of Wire Decking in Modern Storage Ecosystems

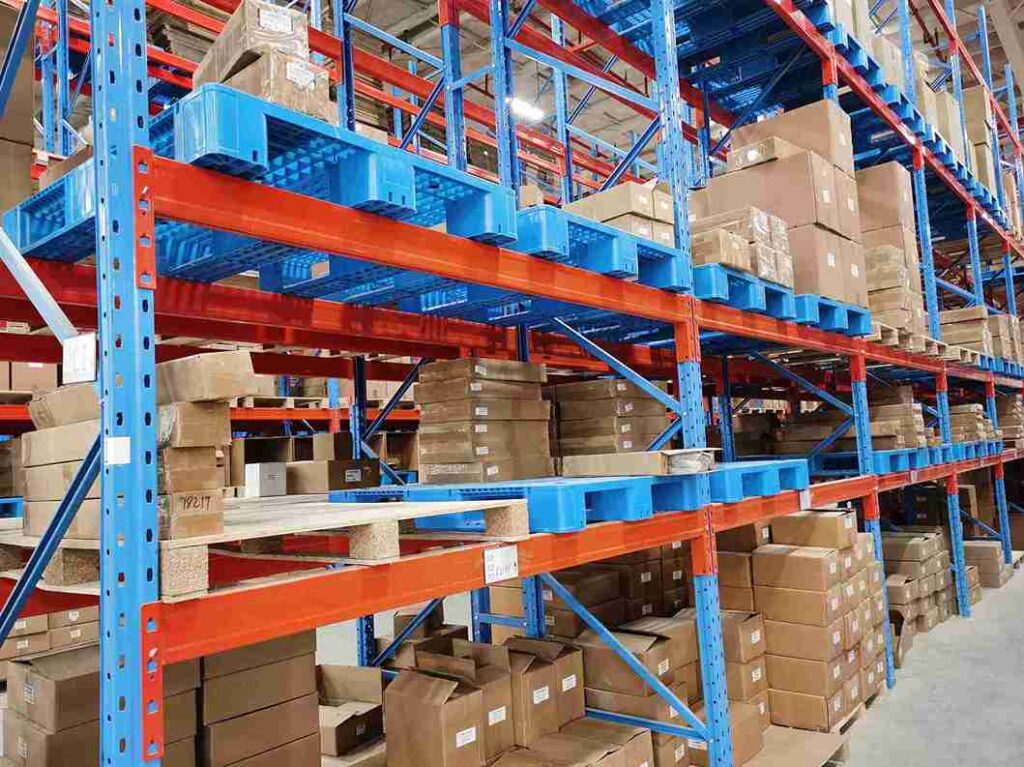

A storage system is only as strong, safe, and efficient as its load-bearing surface. While upright frames and beams define the skeleton, the pallet racking wire decking forms the operational musculature. Its primary function extends far beyond simply holding a pallet. Superior wire decking facilitates crucial air circulation, allows for vital sprinkler system penetration in case of fire, provides unparalleled visibility for inventory checks and forklift operators, and ensures debris and dust fall through, maintaining a cleaner and safer work environment.

In regions facing unique climatic and operational challenges, from the dust-laden plains of Uzbekistan to the humid coasts of Southeast Asia, the specification of the decking becomes a direct contributor to asset longevity and operational continuity. Off-the-shelf, generic solutions frequently fail to address these multifaceted demands, leading to premature wear, safety compromises, and inefficient use of costly cubic space. Therefore, the selection process for pallet racking wire decking must be elevated from a procurement task to an engineering decision.

Deconstructing the Anatomy of Superior Pallet Racking Wire Decking

To appreciate the value of customization, one must first understand the components of excellence in standard wire decking. High-quality pallet racking wire decking is a product of precise engineering, starting with the wire itself. The gauge, or thickness, of the steel wire determines its inherent strength.

This wire is then typically formed into a grid pattern—commonly a 2″ x 2″ or 4″ x 4″ mesh—through a resistant welding process where each intersection is fused for uniform strength. The perimeter is bound by a robust, formed channel frame, often made from heavier-gauge steel, which provides structural integrity and defines the safety lip that prevents pallets from sliding off. Finally, the entire assembly receives a protective coating.

It is at each of these stages—material selection, weld integrity, frame design, and finishing—that a custom approach radically amplifies performance. A truly engineered pallet racking wire decking solution considers each variable not in isolation, but as an integrated system designed for a specific mission.

Material Science: Selecting the Optimal Steel and Protective Finish

The journey to exceptional durability begins at the metallurgical level. For standard industrial environments, a high-tensile, low-carbon steel wire provides an excellent balance of strength and formability. However, for applications involving extreme loads or highly corrosive atmospheres—common in chemical storage or coastal logistics hubs—alloy steels with higher yield strengths may be specified.

The protective finish is arguably as critical as the base metal. While pre-galvanized wire is common, the gold standard for pallet racking wire decking destined for demanding environments is post-fabrication hot-dip galvanizing. In this process, the fully welded decking is immersed in a bath of molten zinc, creating a metallurgical bond that coats every surface and weld point uniformly, offering sacrificial protection even if scratched.

For environments requiring chemical resistance or specific color-coding for warehouse zoning, a durable powder coat can be applied over the galvanized layer. This dual-defense system is a hallmark of custom pallet racking wire decking built to last decades, not just years.

The Compelling Case for Customization Over Catalog Specifications

The catalog offers convenience, but the engineered solution delivers certainty. The argument for custom pallet racking wire decking is built on a foundation of addressing the specific, not the approximate. Consider a facility storing automotive components: one bay may hold heavy, compact engine blocks, while an adjacent bay stores fragile, lightweight body panels. A standard decking with a uniform load rating forces a compromise, potentially over-specifying for one area and under-specifying for another.

Custom wire decking allows for variable wire gauge and reinforcement within the same production run. The section for engine blocks may feature a 7-gauge wire with additional cross-braces, while the section for panels uses a lighter 9-gauge wire with a tighter mesh to prevent small parts from falling. This precision engineering ensures every square centimeter of storage capacity is utilized safely and cost-effectively.

Furthermore, custom pallet racking wire decking can be designed to accommodate non-standard pallet sizes prevalent in certain regional markets or to integrate perfectly with proprietary beam profiles from different racking manufacturers, eliminating the instability and hazard of makeshift adaptations.

Engineering for Precise Load Dynamics and Seismic Resilience

Load capacity on a spec sheet is a single number, but real-world loads are dynamic and complex. Professional engineers evaluating pallet racking wire decking distinguish between Uniformly Distributed Loads (UDL) and Concentrated Point Loads. A pallet of bagged material presents a UDL, while a pallet supporting a piece of machinery with four narrow feet presents severe point loads.

Custom wire decking is calculated and tested for the exact load profile it will encounter. This involves sophisticated modeling, often using Finite Element Analysis (FEA), to identify stress concentrations and reinforce them accordingly, perhaps by adding supplemental support wires or altering the weld pattern. In seismically active zones along Central Asia’s foothills, this engineering rigor extends to dynamic load calculations.

The pallet racking wire decking must be designed not only to hold weight statically but also to work in concert with the rack structure to dissipate seismic energy, preventing the catastrophic domino effect of collapsing inventory. The connection detail—how the decking positively locks onto the beam—becomes a critical safety feature in these specifications.

Synergy with Advanced Automation and Industry 4.0 Integration

As manufacturing and logistics in growth markets embrace automation, every physical component must meet the exacting standards of digital systems. Pallet racking wire decking is a pivotal enabler in this transition. For Automated Guided Vehicles (AGVs) and Automated Storage/Retrieval Systems (AS/RS), dimensional consistency is non-negotiable. Custom-fabricated wire decking guarantees a level, planar surface with minimal deflection under load, ensuring robotic retrieval devices can interface with pallets predictably, without misalignment or system faults.

The open mesh design of quality wire decking is also a key facilitator of data flow. It allows for unobstructed scanning; RFID readers mounted on uprights can read tags on the underside of pallets, and vision systems on autonomous forklifts can navigate by seeing through multiple levels of inventory. In essence, properly specified pallet racking wire decking transforms passive storage into a transparent, sensor-friendly grid that feeds real-time data into Warehouse Management Systems (WMS), forming the physical layer of the smart warehouse.

Facilitating Safety, Compliance, and Operational Visibility

Safety in a warehouse is a system, and the choice of decking directly impacts several risk vectors. The open grid of wire decking inherently supports fire safety strategies by preventing the accumulation of combustible debris and allowing heat and smoke to rise freely to activate sprinkler heads more quickly. From a daily operational safety perspective, the visibility offered by pallet racking wire decking is unparalleled.

Forklift operators can see through the deck to identify obstructions or workers below, and supervisors can conduct quick visual stock checks from the aisle. This transparency reduces accidents and improves inventory accuracy. Furthermore, by providing a secure, stable surface that prevents pallet distortion and load shift, high-quality wire decking mitigates the risk of load collapse—a major cause of warehouse accidents and product damage. When engineered to recognized international standards like FEM or EN, the custom pallet racking wire decking provides documented compliance, an essential factor for multinational corporations and insurers operating in these regions.

Strategic Applications Across Diverse Industrial Sectors

The versatility of engineered pallet racking wire decking reveals itself in its sector-specific applications. In the cold storage facilities serving Kazakhstan’s agricultural export sector, the decking’s open design ensures critical cold air circulation around palletized goods, preventing spoilage hotspots and maintaining consistent temperature control—a feature solid decks completely inhibit. In the Maintenance, Repair, and Overhaul (MRO) warehouses supporting Mongolia’s mining industry, heavy-duty pallet racking wire decking with reinforced capacities safely stores irregularly shaped, extraordinarily heavy drilling equipment and spare parts.

For the burgeoning e-commerce fulfillment centers in urban centers across Southeast Asia, the adaptability of custom wire decking allows for rapid re-configuration of storage slots to accommodate changing SKU profiles and fast-paced picking cycles, directly supporting scalability. Each scenario underscores that the pallet racking wire decking is not a commodity but a configurable tool for operational excellence.

The Total Cost of Ownership Analysis: Beyond the Initial Price Point

Procurement decisions based solely on the lowest initial price for pallet racking wire decking often result in the highest long-term cost. A sophisticated evaluation employs a Total Cost of Ownership (TCO) model. This model factors in the extended lifespan of hot-dip galvanized, custom-engineered decking versus the premature replacement cycle of lighter, inferior products. It quantifies the reduction in product damage achieved by a stable, sag-resistant surface.

It accounts for the energy savings in cold storage enabled by ventilated wire decking. Most significantly, it captures the efficiency gains and revenue protection afforded by a storage system that never becomes a bottleneck. The marginally higher upfront investment in superior pallet racking wire decking is amortized over a far longer service life and dwarfed by the continuous operational savings and risk mitigation it provides, making it the most rational economic choice for forward-thinking operations.

Implementing Success: The Partnership-Driven Design and Fabrication Process

Acquiring optimal pallet racking wire decking is a consultative journey, not a transaction. It begins with a deep-dive audit of the client’s operations—analyzing SKU mix, load weights, dimensions, handling equipment, and growth projections. This data informs a digital design phase, where CAD models and even warehouse simulation software create a virtual prototype of the storage solution. This collaborative process ensures the final specification for the custom pallet racking wire decking is perfectly aligned with operational reality.

The fabrication then follows under stringent quality control, with weld strength tests, coating thickness verification, and load testing on sample units. The culmination is not just the delivery of decking, but the provision of a performance-certified storage platform, complete with installation guidance and load configuration charts, ensuring the client’s team can operate the system both safely and at peak efficiency from day one.

Conclusion

In the architectural blueprint of a high-performance industrial facility, storage is strategic infrastructure. Within that framework, the specification of pallet racking wire decking represents a critical leverage point. Choosing generic, catalog-specified wire decking is an acceptance of compromise—on space utilization, on safety margins, on compatibility with future automation, and on the long-term durability of the asset. Conversely, partnering with experts to engineer custom pallet racking wire decking is an investment in precision, resilience, and operational sovereignty.

It is a declaration that every cubic meter of storage will perform to its maximum potential, safeguarding inventory, empowering the workforce, and providing a scalable foundation for growth. For industrial leaders across Central Asia, the Middle East, Africa, and Latin America looking to build unassailable competitive advantage, the path forward is clear: optimize from the ground up, and let that optimization begin with the engineered excellence of the pallet racking wire decking that forms the very platform of their storage strategy.

Frequently Asked Questions (FAQs)

1: Can custom wire decking be designed to handle both static storage and dynamic picking applications within the same rack system?

A: Absolutely. This is a key strength of a customized approach. Engineers can design zones within a span of pallet racking wire decking with different characteristics. For example, the lower levels designated for fast-moving pick faces can utilize a finer mesh to prevent small items from falling during order picking, while upper levels used for bulk storage can employ a heavier gauge wire optimized purely for maximum static load capacity. This creates a hybrid storage solution within a unified, safe structure.

2: How does the weight of custom wire decking impact the overall design and cost of the racking structure itself?

A: This is a crucial engineering consideration. While custom pallet racking wire decking may use heavier-gauge materials, the design optimizes material placement, potentially avoiding unnecessary weight. The final weight of the specified decking is a fundamental input for the structural engineer designing the upright frames and anchors. A professional provider will always calculate this, ensuring the rack system is designed as a holistic unit. The marginal potential increase in structural steel cost is invariably offset by the vastly increased safety, durability, and load-bearing precision of the total system.

3: For facilities with very high ceilings, are there special considerations for the wire decking used in the highest storage tiers?

A: Yes, several factors become paramount. First, wind loading in very tall warehouses can be a factor, and the open mesh of wire decking must be accounted for in the building’s overall wind load calculations. Second, the decking on higher tiers must have exceptional anti-deflection properties, as visual inspection from the floor is more difficult. Increased reinforcement to minimize sag under load is common. Finally, safety during installation and future maintenance is critical; decking for high-level applications may be designed in smaller, lighter sections for easier and safer manual handling during installation atop the racking.

4: What is the process for repairing or replacing a section of custom wire decking if it is damaged, given that it is not an off-the-shelf item?

A: Reputable providers of custom pallet racking wire decking maintain precise digital records of every project’s specifications, including wire gauge, mesh size, dimensions, finish, and connection details. In the event of localised damage, a replacement section can be fabricated to exact original specifications, ensuring a perfect fit. For critical operations, some clients opt to keep a small inventory of spare decks on hand for immediate swap-out, minimizing any operational downtime. The longevity and durability of properly specified decking make such events rare.

5: How does wire decking performance compare to solid metal or plywood decking in terms of hygiene for regulated industries like pharmaceuticals or food processing?

A: For hygiene-critical environments, wire decking is often the superior choice. Its open structure prevents the accumulation of dust, debris, and moisture that can foster microbial growth on solid surfaces. It allows for thorough cleaning and sanitization from all angles, including from above and below. High-quality pallet racking wire decking for these sectors would typically feature a smooth, electro-polished finish or a FDA-approved powder coat over galvanization, creating a non-porous, easy-to-clean surface that meets stringent sanitary standards, something difficult to achieve with permeable plywood or riveted solid sheet metal.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com