📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Engineered for Extremes: The Definitive Guide to Heavy-Duty Adjustable Warehouse Shelving in Corrosive Environments

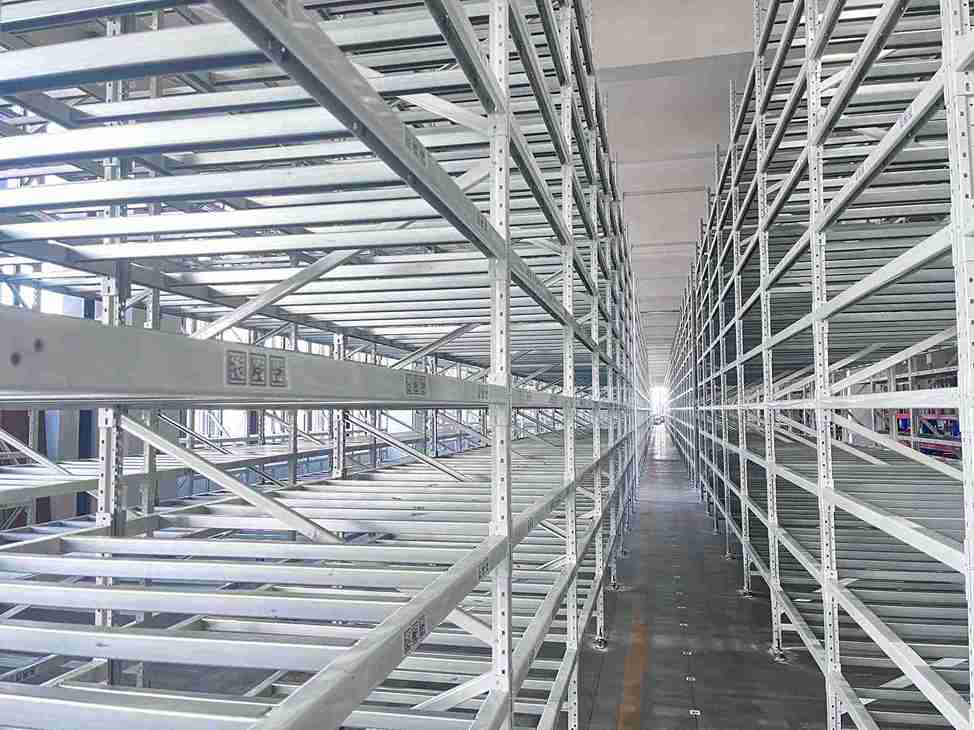

In the high-stakes world of global supply chains, storage infrastructure is the unsung hero—or the silent failure point. For logistics managers, warehouse operators, and business owners across Southeast Asia, the Middle East, Africa, and Latin America, the climate itself is a relentless adversary. Standard storage solutions quickly succumb to the triumvirate of high humidity, salt aerosol, and extreme temperature swings, leading to catastrophic structural failures, product contamination, and operational paralysis.

This comprehensive guide is dedicated to a singular, powerful solution: heavy-duty adjustable warehouse shelving engineered specifically for harsh environments. It delves beyond marketing claims into the core engineering principles of truly corrosion-resistant systems, providing a masterclass in selecting, implementing, and leveraging this critical asset. The focus is on building a storage framework that is not only strong and versatile but is inherently durable, transforming a operational vulnerability into a competitive advantage that drives efficiency and protects the bottom line in the world’s most demanding markets.

The Unseen Battle: Deconstructing Environmental Threats to Storage Integrity

The journey to a resilient warehouse begins with a clear understanding of the enemy. Standard adjustable warehouse shelving, designed for temperate, controlled climates, possesses fatal flaws when deployed in tropical or industrial settings.

The Accelerated Corrosion Cycle in Tropical Climates

Corrosion is an electrochemical process, and tropical conditions provide the perfect storm for its acceleration. With relative humidity consistently above 80%, a continuous film of moisture forms on metal surfaces. This moisture acts as an electrolyte, facilitating the flow of ions that convert iron into iron oxide—rust. This process is exponentially worsened by salt aerosol in coastal regions, which lowers the electrical resistance of the moisture, creating a super-charged corrosive soup.

Furthermore, daily thermal cycling causes metal to expand and contract, stressing and micro-fracturing inferior paint systems, creating fresh pathways for this corrosive attack to reach the vulnerable base metal. A standard adjustable warehouse shelving unit might last a decade in a dry, inland warehouse, but the same unit could become a safety hazard in a Malaysian or UAE coastal facility within 18 months.

The Domino Effect of Storage System Failure

The consequence of installing inadequate adjustable warehouse shelving in these zones is a cascade of operational and financial disasters. The most critical risk is the loss of structural integrity. As corrosion eats away at the metal, the load-bearing capacity of the heavy-duty adjustable warehouse shelving is progressively compromised. What was rated for 1000 kg per shelf may safely hold only a fraction of that after a few years, creating a ticking time bomb that risks a catastrophic collapse endangering both personnel and inventory.

Beyond safety, product contamination is a massive concern. Flaking rust and corrosion debris from overhead adjustable warehouse shelving can ruin sensitive products like pharmaceuticals, high-value electronics, and food items. The financial drain of constant maintenance—scraping, repainting, and replacing components—combined with the potential for complete system failure and operational downtime, makes the initial savings on a cheaper, non-spec system a profoundly poor investment.

The Core Anatomy of Industrial-Grade Corrosion-Resistant Shelving

True protection is not a feature; it is a fundamental characteristic engineered into every component of the adjustable warehouse shelving. This involves a meticulous, multi-stage approach to material science and finishing.

Strategic Material Selection: The First Line of Defense

The choice of base metal sets the ceiling for performance and longevity. Providers of industrial-grade adjustable warehouse shelving typically offer a tiered approach:

High-Tensile Carbon Steel with Fortified Coatings: For the vast majority of applications requiring maximum strength and cost-effectiveness, this is the preferred choice. The critical factor is the protective coating system, which we will detail next. This material allows for the creation of truly heavy-duty adjustable warehouse shelving capable of supporting palletized loads and dense inventory without deflection.

Hot-Dip Galvanized (HDG) Steel: This process involves immersing fabricated steel components into a kettle of molten zinc. The result is a thick, metallurgically bonded zinc coating that provides robust protection. A key advantage of HDG adjustable warehouse shelving is its sacrificial nature; if the coating is scratched, the surrounding zinc will corrode preferentially to the steel, stopping rust in its tracks.

Austenitic Stainless Steel (Grades 304 and 316): This is the pinnacle of corrosion resistance for adjustable warehouse shelving. Grade 304 stainless offers excellent general resistance, while Grade 316, with its added molybdenum, is essential for combating chlorides, making it the undisputed champion for shelving in direct coastal or aggressive chemical environments. While at a higher cost, the lifecycle value of stainless steel adjustable warehouse shelving is unmatched in extreme applications.

Advanced Coating Technologies: The Protective Shield

For carbon steel-based systems, the coating is not paint; it is an engineered armor. The process for premium adjustable warehouse shelving is far more sophisticated than a simple spray job.

Seven-Stage Pre-Treatment: Before any powder is applied, components for the adjustable warehouse shelving undergo a rigorous cleaning and conditioning process involving alkaline cleaning, rinsing, surface activation, and phosphating. This removes oils and impurities and creates a uniform crystalline phosphate layer that dramatically enhances coating adhesion and corrosion resistance.

Electrostatic Epoxy-Polyester Powder Coating: This is the industry standard for high-performance adjustable warehouse shelving. The electrostatically charged powder is applied to the grounded parts, ensuring an even coat on all edges and hard-to-reach areas. The parts are then cured at high temperatures, fusing the powder into a seamless, durable, and chemically resistant skin. The specific formulation of the powder—often a hybrid epoxy-polyester—is selected for its exceptional resistance to UV degradation, chipping, and moisture penetration, which is non-negotiable for adjustable warehouse shelving in harsh environments.

Combination Systems (Duplex): For the most severe conditions, a duplex system is employed. This involves applying a powder coating over a hot-dip galvanized substrate. This combination provides the superior barrier and sacrificial protection of zinc with the added mechanical, chemical, and aesthetic benefits of the powder coat, creating the most resilient adjustable warehouse shelving possible without moving to stainless steel.

The Synergy of Strength and Flexibility: Engineering Principles of Heavy-Duty Adjustable Systems

A shelving system can be highly corrosion-resistant but fail if it lacks the structural integrity for the intended load or cannot adapt to changing inventory profiles. The best heavy-duty adjustable warehouse shelving masters this balance.

Decoding Load Capacity and Structural Dynamics

Understanding the nuances of load ratings is critical for safety and performance. Reputable manufacturers provide clear specifications for their adjustable warehouse shelving:

Uniformly Distributed Load (UDL): This is the maximum safe load when weight is evenly spread across the entire shelf surface. This is the primary rating for most palletized or bin-based storage.

Concentrated Load Capacity: This indicates how much weight can be applied to a small area of the shelf. This is crucial for storing heavy machinery parts or dense individual items on an adjustable warehouse shelving system.

Seismic and Impact Considerations: In regions with seismic activity or high forklift traffic, the design of the adjustable warehouse shelving must account for dynamic forces. Robust, bolt-free connection systems can offer superior energy absorption and resilience compared to traditional bolted designs, which are prone to loosening under vibration.

The Innovation of Tool-Less Adjustability

The true value of modern adjustable warehouse shelving lies in its reconfigurability without compromising strength. The days of struggling with wrenches and loose bolts are over for those who specify advanced systems.

Patented Connector Technology: Leading adjustable warehouse shelving systems feature unique beam-to-post connectors that lock securely into the upright profiles with a hammer blow or a simple hand tool. This creates a rigid, moment-resistant connection that is both faster to assemble and more secure than bolted alternatives.

Inch-Perfect Vertical Optimization: Upright frames are perforated with slots or holes at precise, tight intervals (e.g., every 1″ or 25mm). This allows for fine-tuned adjustments of the adjustable warehouse shelving shelves, enabling businesses to eliminate wasted vertical space and maximize storage density, a critical factor in optimizing warehouse cubic volume.

Industry-Specific Deployments: Tailoring the Solution for Maximum Impact

The versatility of heavy-duty adjustable warehouse shelving allows it to be precisely engineered for the unique challenges of different sectors across target markets.

The Cold Chain Conundrum: Shelving for Freezer and Chill Storage

Perhaps the most punishing cycle for any storage system is the constant transition between a warm, humid ambient environment and a sub-zero freezer. This causes rapid condensation and freeze-thaw cycles that destroy standard coatings.

Specialized Low-Temperature Powder Coatings: Standard powders can become brittle at -25°C. Specially formulated coatings for freezer-grade adjustable warehouse shelving remain flexible and adherent, preventing micro-cracking.

Thermal Break Design: Engineers can design adjustable warehouse shelving with minimized thermal bridging, reducing ice buildup on the shelves and improving the energy efficiency of the refrigeration system.

Stainless Steel for Hygiene and Performance: For food and pharmaceutical cold chains, 304 or 316 stainless steel adjustable warehouse shelving is often mandated. Its non-porous surface is easy to clean, prevents bacterial growth, and is completely immune to the corrosive effects of constant condensation.

Conquering Coastal and Maritime Logistics Hubs

In port-side warehouses from the Philippines to Durban, salt is the primary antagonist. The specification for adjustable warehouse shelving in these facilities must be unequivocal.

The 316 Stainless Steel Mandate: For installations in open-sided warehouses or facilities within a few kilometers of the coast, 316 stainless steel adjustable warehouse shelving is the only reliable long-term solution. Its resistance to pitting and crevice corrosion from chlorides is unparalleled.

Robust Hot-Dip Galvanized Solutions: For enclosed but non-climate-controlled warehouses in coastal areas, a heavy-duty hot-dip galvanized adjustable warehouse shelving system provides excellent protection. The specification must mandate a minimum coating thickness to ensure longevity.

Agricultural and Chemical Storage: Resisting Spills and Fumes

Storing fertilizers, pesticides, or industrial chemicals requires adjustable warehouse shelving that can resist both atmospheric corrosion and potential chemical exposure.

Chemical-Resistant Coating Options: Manufacturers can specify powder coatings with enhanced resistance to a wide range of agricultural and industrial chemicals, ensuring that accidental spills do not immediately compromise the integrity of the adjustable warehouse shelving.

Integrated Spill Containment: Shelves can be fitted with welded lip edges or integrated spill decks, creating a contained system that prevents liquids from dripping to lower levels, protecting both the structure and the facility floor.

The Automated Warehouse: Corrosion-Resistant Shelving as the Backbone of Automation

A modern warehouse is a dynamic, automated ecosystem. The storage system must be the stable, precise foundation upon which this automation is built. This is where the precision of high-quality adjustable warehouse shelving becomes paramount.

Seamless Integration with AGVs and AMRs

The operational margin of error for Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) is measured in millimeters.

Dimensional Fidelity and Consistency: Precision-manufactured adjustable warehouse shelving ensures that every bay, every aisle width, and every shelf height is identical. This repeatability allows AGVs to operate with flawless accuracy, navigating tight spaces and retrieving loads without colliding with the structure. Inferior adjustable warehouse shelving with warped beams or inconsistent dimensions would cause constant navigation errors and system failures.

Impact-Resistant Design: The upright frames and protective components of the adjustable warehouse shelving are designed to withstand minor, inadvertent impacts from automated equipment without buckling or compromising the overall structure’s stability.

The Foundational Role in High-Density and AS/RS

Heavy-duty adjustable warehouse shelving is often the first step in a warehouse’s technological evolution, forming the core of more complex systems.

The Pathway to AS/RS: A rigid, perfectly aligned adjustable warehouse shelving installation can be seamlessly upgraded into a full-fledged Automated Storage and Retrieval System (AS/RS). The strength and precision of the initial adjustable warehouse shelving structure are non-negotiable prerequisites for such an upgrade.

Synergy with Conveyor and Picking Systems: This robust adjustable warehouse shelving can be directly integrated with conveyor systems, pick-to-light, and put-to-light technologies. This creates a cohesive, high-throughput workflow where the durability of the adjustable warehouse shelving ensures the entire system remains operational and efficient, even in challenging environmental conditions.

The True Investment: A Total Cost of Ownership Analysis

For financial decision-makers, the initial purchase price is a misleading metric. The true cost of adjustable warehouse shelving is measured over its entire operational lifespan—the Total Cost of Ownership (TCO).

Initial Outlay vs. Operational Lifespan: A premium, corrosion-resistant adjustable warehouse shelving system may carry a 50-80% higher initial cost compared to a standard painted system. However, if the premium system lasts 20 years in a harsh environment while the standard system fails in 5 years, the annualized cost of the premium adjustable warehouse shelving is significantly lower. It is an investment in predictability and capital expenditure planning.

Quantifying the Cost of Downtime: The operational disruption of replacing a failed adjustable warehouse shelving system is enormous. It involves shutting down warehouse sections, relocating inventory (twice), and lost productivity. These indirect costs can easily surpass the direct cost of the new adjustable warehouse shelving itself.

Eliminating Recurring Maintenance Costs: A high-performance adjustable warehouse shelving system eliminates the annual cycle of touch-up painting and rust remediation, providing direct savings in labor, materials, and allocated maintenance time.

The Partner Selection Criteria: Beyond the Product Spec Sheet

Choosing a supplier for adjustable warehouse shelving in international markets is a strategic decision. The partner must demonstrate proven capability and deep domain knowledge.

A Portfolio of Proven Performance: A credible supplier will have a rich portfolio of case studies and installations specifically in challenging climates—projects in Indonesia, Qatar, Nigeria, or Brazil that demonstrate their adjustable warehouse shelving performing years after installation.

Adherence to International Standards: Look for a manufacturer whose adjustable warehouse shelving production is certified to ISO 9001 for quality management. The protective coatings should be tested per ASTM B117 (Salt Spray Test) standards, providing objective data on corrosion resistance rather than vague marketing claims.

In-Region Technical Support and Expertise: The supplier must have a network of local technical partners or a dedicated international support team capable of conducting site assessments, providing installation guidance, and offering swift after-sales support. This ensures that the client is never left alone to manage the adjustable warehouse shelving system.

Conclusion: Forging a Resilient and Adaptive Supply Chain Foundation

In the fast-growing but environmentally demanding markets of Southeast Asia, the Middle East, Africa, and Latin America, supply chain resilience is the ultimate currency. The storage infrastructure is the bedrock of this resilience. Specifying and investing in industrial-grade heavy-duty adjustable warehouse shelving that is scientifically engineered to combat corrosion is not an operational expense; it is a strategic capital allocation.

It is a decision that safeguards human safety, protects valuable inventory, ensures operational continuity, and provides the flexible foundation for future automation and growth. By partnering with an expert provider and focusing on the long-term Total Cost of Ownership, businesses can transform their warehouse from a vulnerable point into an unbreakable link in their global supply chain, ready to withstand the tests of climate and time.

Frequently Asked Questions (FAQs)

1. How does the weight capacity of corrosion-resistant adjustable warehouse shelving compare to standard systems?

The corrosion resistance of adjustable warehouse shelving is independent of its load capacity. A high-quality, corrosion-resistant adjustable warehouse shelving system is available in the same, and often higher, load capacity ranges as standard systems. The strength is derived from the steel gauge and structural design, while the corrosion resistance comes from the material and coating. You can specify a heavy-duty adjustable warehouse shelving system with 2000 kg per shelf capacity that is also hot-dip galvanized or made from 316 stainless steel.

2. Can we retrofit new, corrosion-resistant beams and shelves onto our existing, slightly rusty upright frames?

This is strongly discouraged. Retrofitting new components onto a compromised structure jeopardizes the entire system’s integrity. The existing uprights are likely already weakened by corrosion, and the connection points may not be precise. The safety and performance of a adjustable warehouse shelving system rely on it functioning as a unified, engineered structure. A phased replacement of specific bays is a safer approach than a piecemeal component mix.

3. What are the key questions we should ask a supplier when requesting a quote for adjustable warehouse shelving for a high-humidity environment?

Ask for:

Coating Specification Data: Request the specific powder coating code or galvanizing standard (e.g., ASTM A123) and the associated salt spray test hours (e.g., >1000 hours to red rust).

Material Certifications: Ask for Mill Certificates for the steel and coating materials.

Regional Case Studies: Demand examples of installations in similar climatic conditions.

Detailed Load Charts: Request official load tables showing both UDL and point load capacities for the specific adjustable warehouse shelving model.

4. For a multi-use warehouse that stores both dry goods and chemicals in separate sections, is it possible to have a hybrid shelving system?

Absolutely. A proficient supplier will often recommend a hybrid approach to optimize the TCO. The dry goods section might use a high-performance powder-coated carbon steel adjustable warehouse shelving, while the chemical storage area would be outfitted with a 316 stainless steel adjustable warehouse shelving system. This tailored strategy ensures maximum protection where needed without overspending on areas with lower corrosive risk.

5. What is the typical lead time for a large, custom-configured order of heavy-duty adjustable warehouse shelving destined for a project in a remote location?

Lead times are project-specific. For a standard container load of pre-engineered adjustable warehouse shelving, lead times are typically 4-6 weeks ex-works. For highly customized projects—such as those involving special sizes, extensive stainless steel fabrication, or complex integration requirements—lead times can extend to 8-12 weeks. A reliable supplier provides a detailed project timeline and has proven logistics expertise to ensure timely delivery to the final destination, regardless of its remoteness.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com