📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Unbreakable Framework: Mastering Pallet Racking Inspection Frequency for Unshakeable Warehouse Safety and Efficiency

For the warehouse manager in Jakarta, the logistics director in Dubai, the operations head in Lagos, or the supply chain coordinator in Santiago, the silent, towering structures of pallet racking represent both the backbone of productivity and a latent, monumental risk. The discipline that governs this risk—the systematic, unwavering adherence to a scientifically defined pallet racking inspection frequency—is what separates thriving, resilient operations from those one incident away from financial and human catastrophe.

This is not a topic of casual compliance; it is the core strategic imperative for any facility storing value above ground level. A haphazard, reactive approach to racking inspection is an open invitation to collapse, crippling fines, and irreparable brand damage. In contrast, a meticulously optimized and executed pallet racking inspection frequency protocol is the ultimate insurance policy—a dynamic, living system that actively safeguards assets, people, and profitability.

This definitive guide transcends basic checklists. It presents a holistic, deeply engineered philosophy for optimizing pallet racking inspection frequency, transforming it from a periodic chore into a continuous, data-driven pillar of operational excellence. It addresses the unique environmental, regulatory, and operational pressures faced across Southeast Asia, the Middle East, Africa, and Latin America, providing a actionable blueprint for safety, compliance, and superior ROI.

The Anatomy of Risk: Why Ad-Hoc Inspections Fail and Frequency is Non-Negotiable

The gravitational pull of daily operational chaos often relegates racking integrity to an afterthought. The prevalent “eyeball” inspection—a hurried glance down an aisle—is a perilous illusion of safety. Structural compromises in storage racking systems rarely announce themselves with dramatic cracks. They begin insidiously: a 3mm dent from a forgotten forklift impact, a slight twist in an upright frame from an unbalanced load, a gradually loosening anchor bolt on a concrete floor subjected to constant vibration. Without a regimented, frequent inspection schedule, these minor faults accumulate, compounding stress until the system’s design tolerance is breached, often with sudden, devastating results.

The financial and operational calculus of neglect is unequivocally negative. The direct costs of a pallet racking collapse are staggering: total inventory loss, destruction of adjacent racking systems and material handling equipment (like AGVs or forklifts), and days or weeks of business interruption. However, the indirect liabilities are far more severe. Regulatory fines in markets like Singapore, Saudi Arabia, or Chile are becoming aggressively punitive.

Insurance premiums can skyrocket, or coverage can be voided entirely if a proven inspection frequency protocol was not in place. Worst of all is the human cost—the potential for life-altering injury or fatality, a moral and reputational failure from which a company cannot recover. Establishing a rigorous pallet racking inspection frequency is the fundamental barrier against this cascade of disaster.

The Tri-Hedged Shield: A Multi-Tiered System for Pallet Racking Inspection Frequency

Industry best practice, codified by bodies like the Storage Equipment Manufacturers Association (SEMA) and the Rack Manufacturers Institute (RMI), unequivocally advocates for a layered defense. Relying on a single inspection frequency is inadequate. The most robust safety ecosystems are built on three distinct tiers of scrutiny, each with its own defined scope, actor, and critical frequency.

Tier 1: Operational Vigilance – The Daily/Shiftly Visual Scan

This is the pervasive, frontline layer of awareness, designed to catch immediate, obvious hazards.

Defined Frequency: Before every operational shift, or at minimum, daily. In high-traffic, multi-shift environments, this inspection frequency becomes pre-shift.

Actors: Empowered equipment operators and floor staff. These individuals are in constant proximity to the racking and are most likely to witness or cause an impact.

Protocol & Tools: A simplified, visual checklist—increasingly digital for audit trails—guides a 5-minute scan. The focus is on glaring issues: fresh impact damage on uprights or beams, dislodged safety locks, pallets improperly seated or overhanging, and any visible leaning. The mandate is immediate reporting and tagging. The culture must be: “If you see it, you own the response.” This high frequency, low-depth check is the essential early-warning system.

Tier 2: Tactical Review – The Formal Visual Inspection

This is the procedural backbone, a scheduled, documented deep-dive that identifies developing issues before they become critical.

Defined Frequency: Quarterly is the universally recommended baseline inspection frequency for active warehouses. Facilities with very high forklift traffic, congested layouts, or older racking should consider increasing this frequency to monthly.

Actors: A designated, trained supervisor or maintenance lead with specific knowledge of racking components and load principles. This person moves beyond visual cues to use basic tools like a plumb bob or laser level.

Protocol & Tools: A comprehensive checklist drives a methodical aisle-by-aisle audit. It includes measuring upright plumb (seeking deviations >0.5% of height), quantifying dent depth and location (using a dent gauge), checking beam deflection against tolerances, verifying load weights against the rack’s load placards, and inspecting for corrosion or environmental wear. Every finding is logged against a specific rack location. This tier generates the trend data essential for optimizing the broader pallet racking inspection frequency plan.

Tier 3: Strategic Audit – The Expert “Written Report” Inspection

This is the gold-standard, forensic assessment that provides legal and technical certitude.

Defined Frequency: Annual, without exception. This is the minimum inspection frequency mandated by most insurers and prudent risk management. For racking over 10 years old, facilities in corrosive environments, or those with a history of incidents, a bi-annual frequency is strongly advised.

Actors: A qualified storage equipment specialist. This is most effectively an independent, third-party expert, such as a certified rack inspector, who brings objectivity and specialized diagnostic tools. Their credentials are paramount.

Protocol & Tools: This is an engineering-level evaluation. It involves ultrasonic thickness testing for corrosion, torque wrench checks on all anchor bolts, precise measurement of frame twist and beam-end connector engagement, and a full assessment against original design drawings and current applicable standards (FEM, EN 15635). The deliverable is a formal Written Report, often with a Red/Amber/Green rating per component, that dictates mandatory repairs and provides a professional certification of safety. This report is the cornerstone of legal due diligence.

Calibrating Your Frequency: The Key Variables That Demand Adjustment

A static inspection frequency is a suboptimal inspection frequency. The intelligent warehouse manager treats frequency as a dynamic variable, adjusted in response to operational and environmental feedback loops.

Throughput and Traffic Density: A warehouse with 50 forklift movements per hour has a radically different risk profile than one with 10. High-congestion zones, especially near picking aisles or receiving docks, inherently require a more aggressive inspection frequency. Tier 1 checks here are non-negotiable, and Tier 2 frequency should be monthly.

Equipment Type and Operator Skill Level: Facilities utilizing man-up order pickers or very narrow aisle (VNA) trucks subject uprights to consistent, low-level contact. Conversely, a site with novice forklift operators will see more impactful incidents. Both scenarios necessitate a tightened pallet racking inspection frequency.

Racking Age and Design: Older racking, particularly pre-dating modern design codes, has less inherent damage tolerance. Its inspection frequency must be higher, with Tier 3 expert audits potentially bi-annual. Similarly, the inspection frequency for push-back or drive-in racking, where damage is harder to see, must account for the need for more invasive checks during low-inventory periods.

Environmental Stressors: This is critical for target markets. In the humid, saline air of Southeast Asian ports, corrosion accelerates. Inspection frequency must prioritize close, quarterly checks for rust, especially at weld points. In seismic zones of Latin America or the Middle East, the frequency of anchor bolt and upright connection checks must be heightened. Dust in arid climates can mask damage, requiring more frequent cleaning prior to inspection.

The Optimization Engine: A Step-by-Step Plan to Implement and Refine Your Inspection Regime

Implementing a world-class pallet racking inspection frequency program is a project in itself. This phased plan ensures systematic rollout and continuous improvement.

Phase 1: Foundation and Baseline (Months 1-2)

Commission the Tier 3 Audit: Begin with a comprehensive expert “Written Report” inspection. This is not an expense but a critical capital investment in knowledge. It establishes the true baseline condition, identifies all latent damage, and provides the engineering benchmark for all future comparisons.

Create the Asset Register: Develop a digital map or numbering system for every racking bay, upright frame, and beam level. Log the design specifications (maker, type, UDL capacity) against each. This digital twin becomes the framework for all data logging.

Phase 2: System Design and Deployment (Months 2-3)

3. Develop Tiered Procedures: Craft clear, illustrated, and multilingual Standard Operating Procedures (SOPs) for Tier 1 and Tier 2 inspections. The Tier 1 SOP must be visual and intuitive; the Tier 2 SOP must be technical and precise.

4. Implement the Tag-Out Ecosystem: Procure a robust, standardized rack tagging system (Red: DO NOT USE; Yellow: INSPECTION PENDING; Green: CLEARED). Integrate the tag-out action into the digital workflow—scanning a tag should auto-create a work order in your CMMS (Computerized Maintenance Management System).

5. Launch Competency-Based Training: Conduct mandatory training for all operators on Tier 1 procedures and the profound “why” behind the pallet racking inspection frequency. Certify Tier 2 inspectors through formal courses on damage assessment and load safety.

Phase 3: Operational Rhythm and Data Analysis (Ongoing)

6. Execute to Schedule: Adhere religiously to the defined frequencies. Use calendar reminders and CMMS scheduling. The integrity of the entire system depends on unwavering discipline.

7. Analyze, Adapt, and Optimize: Quarterly, review the aggregated data from all inspection logs. This is where pallet racking inspection frequency is truly optimized. Are 70% of impacts in a specific cross-aisle? Increase the frequency of Tier 2 checks there and consider protective barriers. Is corrosion progressing faster than modeled? Increase the frequency of targeted checks. This data-driven feedback loop allows for intelligent, risk-based allocation of inspection resources, moving from a blanket frequency to a precision-calibrated one.

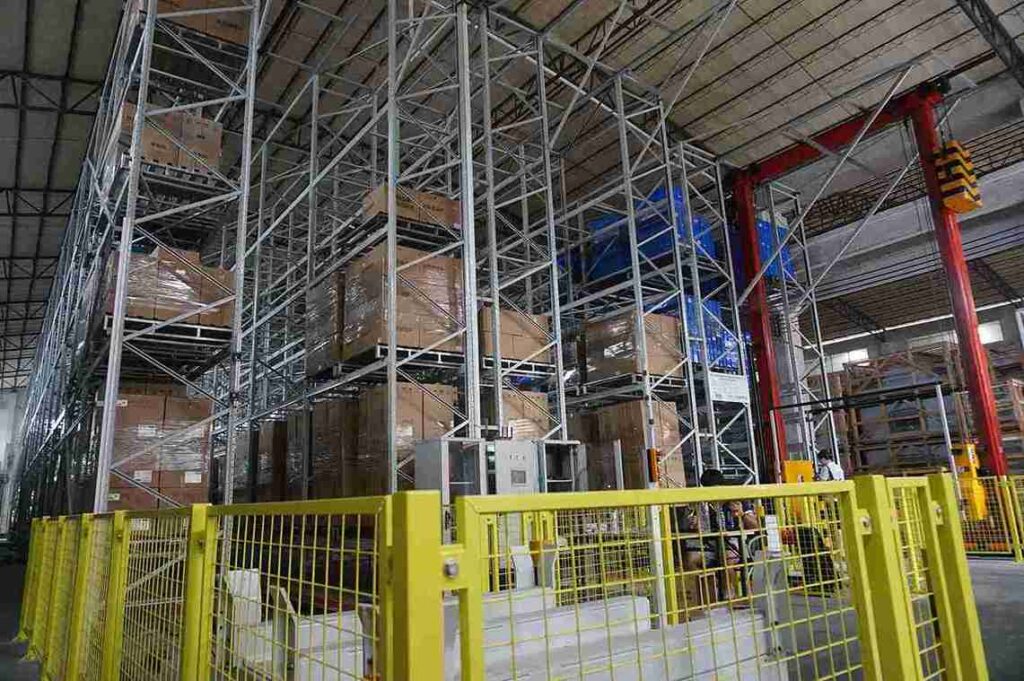

The Automated and High-Density Warehouse: Specialized Inspection Frequency Imperatives

The advent of automation and high-density storage solutions does not eliminate the need for pallet racking inspection frequency; it redefines its methodology and criticality.

Inspection Frequency for Automated Storage and Retrieval Systems (AS/RS)

Within a fully automated AS/RS or pallet shuttle system, manual human access is restricted or impossible. Here, the inspection frequency is governed by a combination of predictive technology and planned maintenance shutdowns.

Technology-Enabled Monitoring: Vibration sensors on crane rails can detect misalignment that may transfer stress to the rack structure. Regular thermal imaging surveys can identify unusual friction points. This data informs the frequency of physical interventions.

Shutdown-Based Expert Audits: The annual Tier 3 expert inspection becomes a major planned maintenance event. It requires a full system shutdown to allow inspectors physical access to every aisle. The frequency of these shutdowns is absolute and non-negotiable, though their scope can be informed by data from continuous monitoring.

Safeguarding Automated Guided Vehicle (AGV) Pathways

In facilities where AGVs and humans coexist, the pallet racking inspection frequency for uprights along travel paths must be exceptionally high.

Impact Risk Concentration: Uprights at the end of aisles and at corridor intersections are at extreme risk from both AGV and forklift traffic. A weekly, documented visual check (an elevated Tier 1/Tier 2 hybrid) of these specific uprights is recommended.

Integration with Fleet Management: The ideal system integrates the racking inspection protocol with the AGV software. If an AGV’s LiDAR or bumper sensor registers an unexpected contact with a rack leg, it should automatically generate a high-priority inspection ticket for that specific location, creating a real-time, incident-driven inspection frequency overlay.

The Global Manager’s Playbook: Navigating Regional Regulations and Insurance with Your Inspection Log

While the physics of gravity are universal, the regulatory landscape for warehouse safety varies across target markets. A sophisticated pallet racking inspection frequency program is both a shield and a passport.

Southeast Asia: Countries like Malaysia (Factories and Machinery Act) and Thailand (Occupational Safety, Health and Environment Act) have explicit provisions for equipment and structural safety. A documented, frequent inspection schedule is primary evidence of compliance during audits.

Middle East: In the UAE and Saudi Arabia, adherence to international standards (ISO 45001, FEM 10.2.02) is often required for major logistics parks and free zones. Local civil defense authorities may conduct surprise inspections. A formal, annual “Written Report” from a recognized expert carries significant weight.

Africa and Latin America: Even where local enforcement is evolving, multinational clients and global insurers demand world-class safety practices. A demonstrably rigorous pallet racking inspection frequency program is a competitive differentiator in tender processes and a key factor in securing comprehensive liability insurance at reasonable rates.

The insurance correlation is direct. Underwriters assess risk. A warehouse that can present a digital history of quarterly inspections, immediate damage repair logs, and annual professional certifications presents a fundamentally lower risk profile. This translates directly into lower premiums and clearer coverage terms. In the event of a claim, this documentation is the definitive proof of due diligence.

The Return on Prevention: Quantifying the Value of Optimized Inspection Frequency

Framing pallet racking inspection frequency as a cost center is a critical error. It is a high-return strategic investment in business continuity.

Cost Avoidance (The Primary ROI): Calculate the potential loss from a single bay collapse: inventory value (e.g., $150,000), equipment damage ($50,000), business interruption ($100,000/day), fines ($250,000), and litigation (millions). Contrast this with the annual cost of a full inspection program (e.g., $15,000). The ROI is exponentially positive.

Uptime and Productivity: Unplanned racking failures cause catastrophic downtime. A proactive inspection frequency identifies issues during planned maintenance windows, ensuring uninterrupted operations.

Asset Longevity: Just as regular oil changes extend an engine’s life, a disciplined inspection and maintenance frequency maximizes the service life of the racking asset, protecting the capital investment and deferring costly system-wide replacements.

Reputational Capital: In an era of social transparency, a warehouse collapse is a global news story. A reputation for operational excellence and safety attracts better talent, more demanding clients, and premium partnerships.

Conclusion: From Frequency to Philosophy – Building an Impregnable Safety Culture

Ultimately, mastering pallet racking inspection frequency is not about ticking boxes on a calendar. It is about instilling a philosophy where structural integrity is as valued as picking speed, where every employee is a guardian of safety, and where data dictates proactive action. It is the recognition that the static racking framework is, in fact, a dynamic component in a living, breathing logistical organism.

For the global warehouse leader overseeing facilities from Manila to Monterrey, from Jeddah to Johannesburg, implementing this tri-tiered, data-adaptive approach to pallet racking inspection frequency is the definitive strategic advantage. It systematically eliminates the risk of catastrophic accidents and the debilitating fines that follow. It transforms the warehouse from a vulnerable cost center into a resilient, trustworthy, and optimized engine of growth. The question is no longer if you can afford to implement a rigorous pallet racking inspection frequency, but how you can possibly afford not to. Let your commitment to its meticulous optimization be the unshakeable foundation of your operational legacy.

Frequently Asked Questions (FAQs)

1. We have a mix of very old and new racking in the same warehouse. Should the inspection frequency be the same for all?

Absolutely not. A risk-based approach is essential. Older racking, especially if its provenance or design specs are unknown, demands a significantly heightened inspection frequency. It should be subject to more frequent Tier 2 visual inspections (e.g., monthly) and its annual expert Tier 3 audit should be non-negotiable. Consider segregating older zones in your asset register and applying a specific, more aggressive inspection frequency to them until they can be phased out or professionally recertified.

2. How do we effectively train a multi-lingual, transient workforce on Tier 1 inspection procedures?

The key is visual, intuitive standardization. Use graphic-rich checklists with minimal text, employing universal symbols (a red X over a dented upright, a green check over a secure lock). Implement short, mandatory video-based training modules during onboarding, available in key languages, that show real-world examples of damage. Incorporate a simple, picture-based quiz to verify understanding. The act of tagging must be made as simple and routine as scanning a barcode.

3. What specific tools are essential for a proper Tier 2 Formal Visual Inspection?

Beyond the checklist, a basic Tier 2 kit should include: a plumb bob or laser plumb line for measuring upright verticality; a dent depth gauge (a simple calibrated probe) to quantify impacts against RMI/SEMA tolerances; a torque wrench (set to the manufacturer’s specification) for checking anchor bolts; a measuring tape; and a camera (integrated into a digital inspection app) for photographing all findings. The use of calibrated tools elevates the inspection from subjective opinion to objective measurement.

4. After a significant seismic event in our region, what immediate changes to our inspection frequency are required?

Even if no collapse occurs, a seismic event is a major shock-loading event for your racking. Your standard pallet racking inspection frequency must be immediately suspended and replaced with a 100% Tier 2 (or even Tier 3) emergency audit. Every anchorage must be checked for loosening or concrete cracking. Every upright must be inspected for twist or column failure. Every beam-to-upright connection must be verified. This post-event inspection is critical and should be mandated in your emergency response plan before operations are allowed to resume.

How can we justify the budget for an annual third-party expert inspection to our finance department?

Frame it not as a cost, but as risk transfer and asset valuation. Present the annual expert report as a formal asset condition certification, akin to an elevator or fire system inspection—non-negotiable for both insurance and liability. Quantify the potential cost of a single incident (use the ROI calculation above) versus the fixed, known cost of the audit. Emphasize that this report protects the company’s directors from personal liability in the event of a workplace accident by demonstrating due diligence. It is one of the most cost-effective risk mitigation investments a logistics company can make.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com