📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

A Deep Dive: How Pallet Rack Post Types Form the Backbone of Efficient Logistics Operations

In the fast-paced world of modern global supply chains, warehousing has transcended its traditional role as a mere storage space. It is now a central nervous system for driving efficiency, speed, and cost-effectiveness. At the heart of this complex ecosystem lies a seemingly simple yet profoundly critical component: pallet rack post types. These structural elements form the skeleton of every storage system, and their selection directly dictates a facility’s storage density, safety protocols, automation compatibility, and overall return on investment.

For operators from e-commerce fulfillment centers in Jakarta to free-trade zone warehouses in Dubai, and from manufacturing plants in São Paulo to distribution hubs in Lagos, understanding the nuances of pallet rack post types is a strategic imperative. This article serves as the ultimate resource, delving deep into the world of pallet rack post types, offering insights that go beyond spec sheets and illuminating how this critical decision impacts operational success across industries and continents.

Chapter 1: Deconstructing the Post – Moving Beyond the “Metal Column”

To the uninitiated, pallet rack post types might appear as simple vertical steel beams. However, for logistics engineers and warehouse planners, they are precision-engineered components designed to bear calculated loads, dynamic stresses, and environmental factors. Each category of pallet rack post types carries unique performance characteristics suited for specific applications.

At its core, the term “post” or “upright” refers to the vertical structural members that form the two sides of a rack frame. These posts are connected by horizontal beams and diagonal braces to create stable structural bays. However, the concept of pallet rack post types encompasses a wider range of attributes: the metallurgy of the material, the geometry of the cross-section, the pattern of perforations, the connection mechanism, and the post-fabrication finish.

For instance, a common pallet rack post type for selective pallet racking is a roll-formed post with standardized “teardrop” perforations that allow for quick, tool-less beam connection. Conversely, the pallet rack post type for high-density drive-in racking is often a structural post with a closed tubular or boxed cross-section, providing the torsional rigidity necessary to resist impacts and loads from multiple directions.

Understanding the different pallet rack post types available is the first step in designing a warehouse that not only meets current storage needs but is also adaptable to future growth and technological upgrades. Selecting the wrong pallet rack post type can lead to capacity limitations, safety hazards, and costly retrofitting when attempting to integrate automated retrieval systems or accommodate new product dimensions.

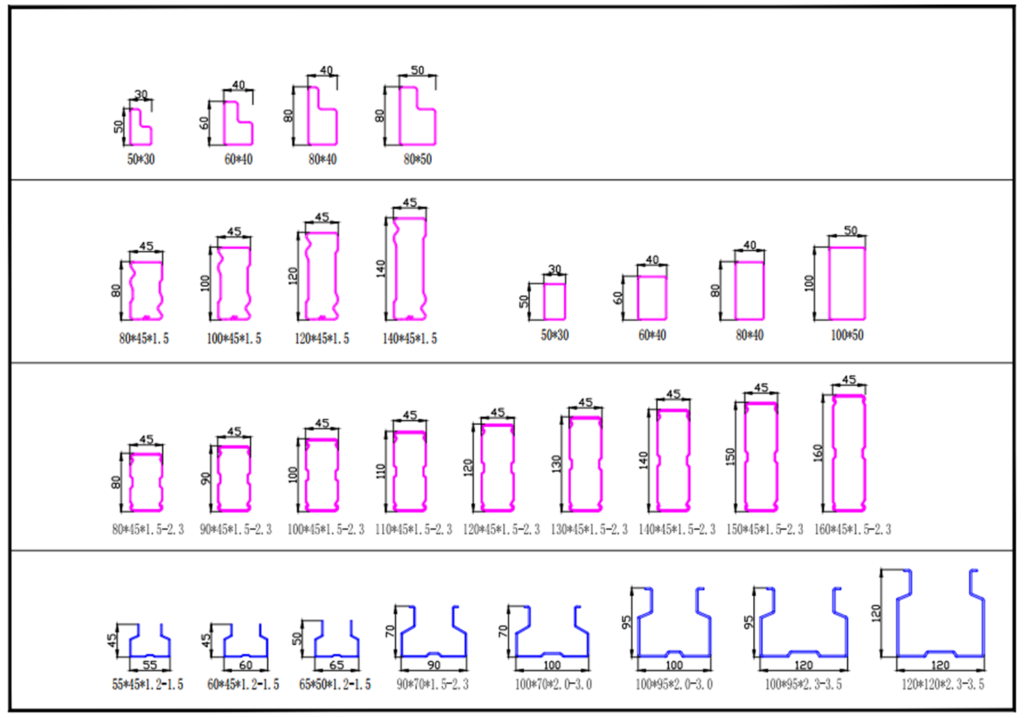

Chapter 2: A Detailed Taxonomy: From Standard to Structural Post Types

The market offers a spectrum of pallet rack post types, each optimized for specific performance criteria. The primary classifications are roll-formed posts and structural posts, with several subtypes within each.

1. Roll-Formed Post Types

These pallet rack post types are created by passing a continuous coil of steel through a series of dies that roll the material into a lightweight yet strong profile. They are ubiquitous in selective racking applications due to their cost-effectiveness and flexibility.

Teardrop Posts: This is arguably the most common pallet rack post type globally. The perforations on the post are a distinctive teardrop shape, mating with clips on the beam ends. This design allows for rapid installation and highly adjustable shelf positions without the need for bolts or tools. This pallet rack post type is ideal for warehouses with a wide variety of SKUs where layout may need frequent adjustment.

Keyhole Posts: Another popular pallet rack post type, featuring perforations shaped like a keyhole. Beams typically have a tab or bolt that inserts into the larger hole and then slides into the narrower slot to lock. Certain designs offer advantages in security and tamper-resistance.

Plate-Connected (Bolt-Together) Posts: This pallet rack post type is characterized by a series of uniformly spaced round holes along its length. Beams are bolted to these holes using separate connector plates. While adjustment is not as rapid as a teardrop system, it is often considered to provide an extremely secure and rigid connection, suitable for very heavy loads or environments with vibration concerns.

2. Structural Post Types

When applications demand handling extraordinary loads, withstanding significant impact, or forming part of high-density storage systems like drive-in, drive-through, or push-back racking, structural pallet rack post types become the necessary choice.

Box/Tubular Posts: This pallet rack post type is constructed from square or rectangular steel tubing, offering superior torsional strength. Its closed cross-section allows it to handle forces from all directions evenly, which is critical for drive-in systems where forklifts operate within the rack structure. This pallet rack post type is a cornerstone for heavy industry, cold storage, and beverage distribution applications.

Structural C-Posts: Fabricated from heavier structural steel (like I-beams or channels), this pallet rack post type is used in the most demanding applications. It is common in modular storage structures, very high (15m+) racking, or integrated as the runway for stacker cranes in Automated Storage and Retrieval Systems (AS/RS). Selecting this pallet rack post type typically signifies a project requiring custom-engineered solutions.

The choice between roll-formed and structural pallet rack post types ultimately comes down to a detailed analysis of load capacity, density requirements, automation level, and total cost of ownership.

Chapter 3: The Engineering & Design Factors Dictating Post Selection

Choosing the correct pallet rack post type is far more than selecting a profile that looks sufficiently robust. It is an engineering process influenced by multiple variables, each impacting the system’s safety, efficiency, and cost.

Load Capacity & the Post Chart: Every pallet rack post type comes with an engineer-certified capacity chart. This document is the blueprint for system safety. It specifies the maximum permissible load per pair of posts for a given vertical beam spacing and rack depth. Ignoring this chart is an invitation for disaster. Load capacity is influenced by the post’s steel thickness (gauge), the yield strength of the steel (e.g., 50 KSI vs. 36 KSI), and the overall geometry of the post. For instance, a heavier gauge and higher yield strength directly translate to a higher load-bearing capacity, a critical consideration when selecting a pallet rack post type for a warehouse planning to store dense products or utilize multi-tier storage.

Rack Height & Post Stability: The clear height of a warehouse is a key determinant of the required pallet rack post type. As racking grows taller, posts become more slender and susceptible to lateral forces, such as seismic activity or forklift impact. Taller racks often necessitate a more robust pallet rack post type, potentially with thicker steel, more密集的 diagonal bracing, or even structural post sections at critical points. The “torsional stiffness” of a post—its resistance to twisting—is paramount in elevated applications.

System Compatibility & Adjustability: The selected pallet rack post type must be fully compatible with the overall racking system. Teardrop posts require teardrop beams; plate-connected posts require corresponding connector plates. Furthermore, the pattern and spacing of the perforations determine the adjustability of shelf levels. For facilities with fast inventory turnover or variable product dimensions, a pallet rack post type with fine perforation spacing (allowing adjustment in 25mm or 1-inch increments) offers unparalleled flexibility.

Environment & Corrosion Resistance: The warehouse environment profoundly influences the required finish for pallet rack post types. In humid or corrosive atmospheres, such as coastal regions in Southeast Asia or the Middle East, standard paint coatings are insufficient. In these cases, specifying hot-dip galvanized (HDG) pallet rack post types is critical. The galvanizing process applies a thick layer of zinc to the steel, providing sacrificial protection. For extreme environments like cold storage or chemical storage, a powder coat over galvanization may be specified. Therefore, assessing environmental conditions is a key step in selecting the appropriate protective finish for your pallet rack post type.

Chapter 4: Regional Considerations for Global Operations

The pallet rack post type solution perfect for a temperature-controlled warehouse in the Netherlands may not be ideal for a facility in Chile or Kazakhstan. Climate, building codes, local material availability, and typical operational practices differ.

High Humidity & Coastal Regions (Southeast Asia, parts of the Middle East): As noted, corrosion is the primary concern. Beyond galvanization, selecting a pallet rack post type designed to minimize moisture traps is wise. Posts with closed cross-sections or smooth profiles are preferable to those with crevices or gaps where water can accumulate.

Seismically Active Zones (Andean regions of Latin America, parts of Central Asia): In earthquake-prone areas, the design of pallet rack post types must adhere to stringent seismic codes. This often means using specially engineered pallet rack post types capable of dissipating lateral energy through robust bracing systems and calculated baseplate anchoring. The connection points between posts and beams may also require reinforcement.

Rapidly Developing Markets (Africa, South Asia): In these regions, initial investment cost is often a primary consideration, but lifecycle cost is more critical. Opting for a slightly more expensive but more durable, thicker-gauge pallet rack post type often proves more economical than the long-term costs of frequent replacement or downtime. The focus should be on a pallet rack post type that can withstand sometimes less-than-precise forklift operation and provide a long service life.

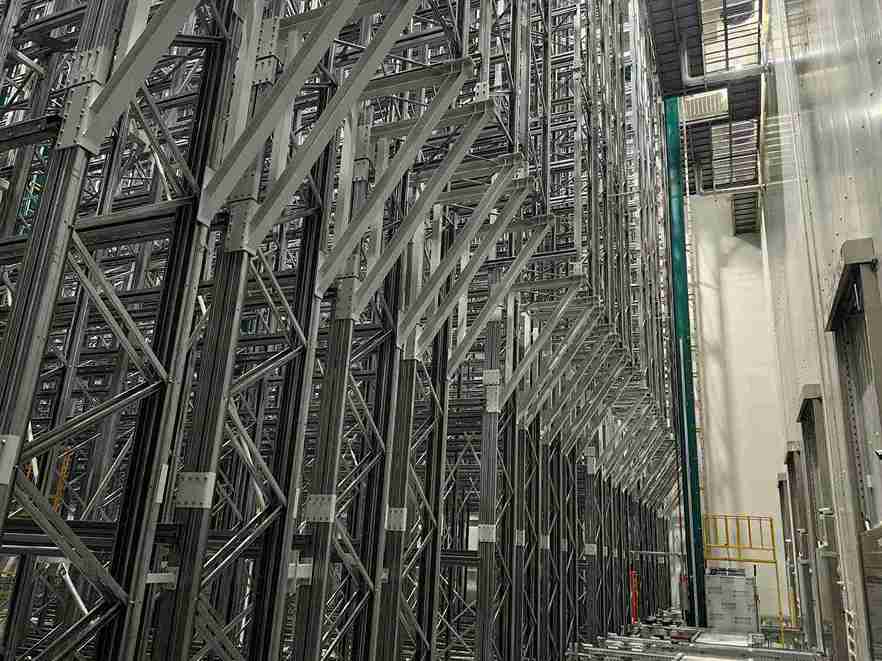

Chapter 5: Automation Integration: How Posts Interface with Smart Warehousing

The modern warehouse is evolving towards automation, integrating Automated Guided Vehicles (AGVs), AS/RS, and automated conveyors. The chosen pallet rack post type can either facilitate or hinder this integration.

For rack aisles interacting with AGVs, the frontal profile of the post is significant. A smooth, consistent surface facilitates the mounting of guidance tapes, reflectors, or LiDAR targets. A pallet rack post type with protruding components or an irregular shape might interfere with the proper functioning of sensors.

In an AS/RS, the role of the pallet rack post type changes fundamentally. They are not just supports but often serve as the runway for stacker cranes. This application demands the highest level of precision and rigidity. The pallet rack post type selected for this purpose is custom-fabricated, manufactured to tight tolerances, and designed with specialized interfaces to ensure smooth and accurate crane movement. Choosing the wrong pallet rack post type for an AS/RS can lead to alignment issues, increased wear, and catastrophic failure.

Therefore, planning for future automation means selecting a pallet rack post type with a clean design, robust construction, and the ability to accommodate add-ons for sensors and guidance systems. Structural pallet rack post types with closed or flat front profiles are often the preferred choice for automation-ready facilities.

Chapter 6: Installation, Maintenance, and Safety Best Practices

Even the best pallet rack post type will fail if installed improperly or neglected. Installation must be performed by experienced professionals following the manufacturer’s specifications, with particular attention paid to floor leveling, post plumb, and anchor bolt torque.

Regular inspection is paramount to ensuring the continued integrity of any pallet rack post type. A schedule should be implemented to check posts for dents, bends, or cracks—especially near the base in vulnerable impact zones. Connection points, beam locks, and anchor bolts should also be inspected for looseness or damage. Many warehouses employ post protectors, which are sacrificial barriers bolted to posts to guard against forklift impact.

Safety protocols must be aligned with the capacity of the installed pallet rack post types. Overloading is a primary cause of rack collapse. Clear load signage, operator training, and adherence to the engineer-approved layout are essential for maintaining a safe working environment.

Chapter 7: Case in Point: How Post Selection Influences Operational Outcomes

Consider a real-world scenario: A rapidly growing third-party logistics (3PL) provider in Bangkok wants to increase its storage density by 40%. They initially used standard, lower-capacity teardrop pallet rack post types. After evaluating their options, they decided to upgrade to teardrop pallet rack post types with a higher yield strength and heavier gauge. This change allowed them to safely add an additional shelf level within the same footprint and handle heavier unit loads, achieving the desired density boost without expensive expansion. The perforation pattern of their newly chosen pallet rack post type also allowed finer adjustments, optimizing space for different client products.

Another example is a large retail distribution center in Dubai integrating an automation module. They opted for structural pallet rack post types with a boxed cross-section, not only for strength but also for their clean surface, which facilitated the installation of AGV guidance infrastructure. This forward-looking pallet rack post type selection made the automation integration smoother, less costly, and significantly shortened the return on investment timeline.

Chapter 8: Conclusion: Making an Informed Post Choice

In warehousing and logistics, the details define success. The decision regarding pallet rack post types is a foundational, far-reaching detail. It influences everything from daily operational efficiency to the long-term adaptability and safety of a facility. By understanding the different pallet rack post types, their engineering principles, and their interaction with operational goals and environmental conditions, warehouse managers and decision-makers can make informed choices that drive sustainable growth and efficiency.

Whether planning a new facility or modernizing an existing operation, partnering with a provider that offers expert guidance, reliable quality, and comprehensive engineering support is crucial. The right pallet rack post type is more than a component that holds goods; it is the foundational backbone of an efficient, safe, and future-ready logistics operation.

Frequently Asked Questions on Pallet Rack Post Types

1. Our existing warehouse floor has some unevenness. Will this affect our choice or installation of pallet rack post types?

Yes, floor flatness is a critical factor. Most professional-grade pallet rack post types are designed with adjustable base plates that can compensate for a certain degree of floor variance (often up to several inches). During installation, shims or threaded adjustments are used to ensure each post is perfectly vertical and level. For severely uneven floors, leveling prior to installation may be required, or specific pallet rack post types with larger, more complex adjustable bases might be selected to maintain the system’s structural integrity.

2. How do we balance initial cost versus long-term Total Cost of Ownership (TCO) when selecting pallet rack post types?

While certain lower-priced pallet rack post types may have an attractive upfront cost, it’s crucial to evaluate their TCO. More robust, thicker-gauge, and better-protected pallet rack post types often have a higher initial price but offer a longer service life, require less maintenance, and better withstand impacts, reducing replacement needs and downtime. In the long run, investing in high-quality pallet rack post types typically results in a lower TCO through increased reliability, safety, and adaptability.

3. Can we upgrade our existing standard roll-formed pallet rack post types to structural posts in the future to increase capacity?

Directly “upgrading” existing posts is generally not recommended. A racking system is an engineered whole. Replacing roll-formed posts with structural ones without re-evaluating and potentially reinforcing beams, connectors, and foundations can create mismatches and unsafe conditions. A more viable approach to increasing capacity often involves adding supplementary support frames, reinforcing existing posts, or installing a new, higher-capacity system with the appropriate pallet rack post types in an expanded area of the facility. An on-site assessment by a qualified engineer is essential.

4. How do different pallet rack post types impact warehouse fire safety?

The choice of pallet rack post type can influence fire hazards and suppression system design. Dense storage configurations, often enabled by specific pallet rack post types, create narrower aisles and tighter commodity grouping, which can impede water flow from sprinklers and affect fire spread. Some building codes may require the use of pallet rack post types with open perforations or mesh designs to allow better penetration of water or gaseous suppression agents. Always consult with fire safety experts to ensure the selected pallet rack post type and overall layout comply with local regulations.

5. Are there specialized pallet rack post types for warehouses storing non-standard dimension or shaped items, like piping or sheets?

Yes, for non-palletized storage, specialized rack systems exist with correspondingly different pallet rack post types. For example, cantilever racks for long materials use heavy-duty structural pallet rack post types with adjustable arms. Shelving for small parts uses different post and rail systems. The key is to define the load characteristics and then select the pallet rack post type and overall rack design that provides safe, accessible support for those specific items.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com