In today’s fast-paced industrial and retail environments, optimizing storage space is critical for efficiency and cost-effectiveness. Adjustable warehouse racks have emerged as a versatile solution, allowing businesses to customize their storage layouts to meet evolving demands. This comprehensive guide explores the top adjustable warehouse rack systems, their benefits, key features, installation best practices, and future trends. Whether you’re managing a small warehouse or a large distribution center, this article will help you identify the ideal adjustable storage solutions to maximize space, improve organization, and enhance operational productivity.

1、What Are Adjustable Warehouse Racks?

Definition and Core Components

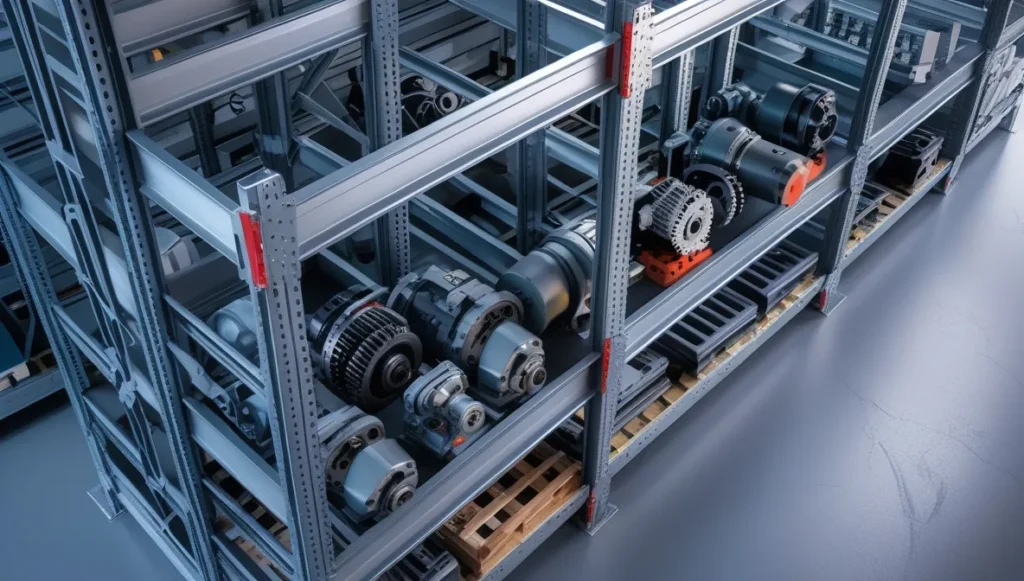

Adjustable warehouse racks are modular storage systems designed to accommodate varying load sizes and weights. Unlike fixed shelving, these racks feature beam heights and frame configurations that can be modified to suit changing inventory needs. Key components include:

- Vertical Uprights: Steel columns with slots or holes for height adjustments.

- Horizontal Beams: Support shelves or pallets and attach to uprights.

- Wire Decks or Particle Boards: Provide surfaces for storing items.

- Safety Pins and Connectors: Secure beams in place.

Types of Adjustable Warehouse Racks

- Pallet Racks: Ideal for heavy-duty storage, these accommodate standard pallet sizes (48”x40”) and support weights up to 30,000 lbs per shelf.

- Cantilever Racks: Designed for long, bulky items like pipes or lumber, with arms extending from a single column.

- Mobile Aisle Racks: Equipped with wheels to compress or expand aisles, maximizing space in compact warehouses.

- Multi-Tier Racks: Utilize vertical space with multiple levels, often used in automotive or retail storage.

2、Benefits of Adjustable Warehouse Racks

Flexibility and Scalability

The primary advantage of adjustable racks is their adaptability. Businesses can reconfigure shelf heights to store seasonal inventory, irregularly shaped items, or new product lines without purchasing additional systems. For example, a retailer transitioning from winter to summer stock can lower shelves for smaller apparel boxes, doubling storage capacity.

Cost-Effectiveness

While the initial investment in adjustable warehouse racks may be higher than fixed alternatives, their longevity and adaptability reduce long-term costs. Companies avoid the expense of replacing entire systems during growth phases or layout changes. A 2022 industry report found that businesses using adjustable racks saved 22% on storage costs over five years compared to those using static shelving.

Enhanced Space Utilization

By adjusting shelf heights and aisle widths, businesses can eliminate wasted vertical or horizontal space. Mobile aisle systems, for instance, reduce aisle widths from 8 feet to just 3 feet, increasing storage density by 40%.

3、Key Features to Consider When Choosing Adjustable Racks

Load Capacity

Always prioritize load capacity—the maximum weight each shelf can safely hold. Calculate requirements by:

- Weighing the heaviest item in your inventory.

- Dividing the total weight by the number of shelves. For example, 10,000 lbs spread across four shelves requires a 2,500 lbs per shelf capacity.

Material and Durability

Opt for hot-rolled steel frames for heavy-duty applications, as they resist bending under stress. For humid or corrosive environments, powder-coated or galvanized steel prevents rust and extends lifespan.

Adjustability Range

Look for systems with a minimum 6-inch adjustability increment to accommodate small or irregularly shaped items. Some high-end models offer 1-inch increments for precision.

Safety Features

Ensure racks include safety locks, anti-slip deck coatings, and earthquake-resistant bracing if operating in seismic zones. Compliance with OSHA and RALI standards is non-negotiable.

4、How to Select the Best Adjustable Rack System for Your Warehouse

Assess Inventory Characteristics

- Weight: Heavy pallets require structural steel beams, while lightweight boxes work with aluminum.

- Dimensions: Measure the largest item’s height, width, and depth to determine shelf spacing.

- Access Frequency: Frequently accessed items should be placed on middle shelves to minimize bending or ladder use.

Evaluate Floor Space and Layout

Map your warehouse floor plan to identify underutilized areas. Use CAD software or consult a storage engineer to design a layout that prioritizes high-traffic zones and minimizes forklift turnaround time.

Compare Brands and Warranties

Top brands like Unarco, Ridg-U-Rak, and Steel King offer 10–20-year warranties on structural components. Avoid suppliers without third-party load testing certifications.

Installation and Maintenance Best Practices

Professional Installation vs. DIY

While DIY assembly is possible for smaller systems, professional installation is recommended for large-scale setups. Experts ensure proper anchoring, weight distribution, and compliance with local building codes.

Routine Maintenance Checklist

- Monthly Inspections: Check for bent beams, loose bolts, or corrosion.

- Annual Load Testing: Verify that shelves maintain their rated capacity.

- Immediate Repairs: Replace damaged components promptly to avoid collapses.

Retrofitting Existing Systems

Many fixed racks can be retrofitted with adjustable beams and upright extenders. This approach costs 30–50% less than purchasing a new system.

5、Future Trends in Adjustable Warehouse Racking

Smart Rack Systems

IoT-enabled racks with weight sensors and automated height adjustment are gaining traction. These systems sync with warehouse management software (WMS) to optimize space in real time.

Sustainable Materials

Manufacturers are increasingly using recycled steel and biodegradable coatings to reduce environmental impact.

Hybrid Designs

Combining adjustable racks with conveyor belts or robotic retrieval systems streamlines order fulfillment in e-commerce warehouses.

6、Conclusion

Adjustable warehouse racks are a game-changer for businesses seeking to balance flexibility, cost savings, and space efficiency. By investing in the right system and adhering to safety protocols, companies can future-proof their storage infrastructure against evolving demands. Whether you’re storing automotive parts, retail inventory, or industrial machinery, the adaptability of these racks ensures your warehouse remains agile and productive for decades.

FAQs

1. Can adjustable racks support mezzanine platforms?

Yes, many heavy-duty adjustable systems can integrate mezzanines. Ensure the rack’s load capacity exceeds the combined weight of the platform and stored items.

2. How long does it take to reconfigure shelf heights?

Most adjustments take 5–10 minutes per shelf with two workers. Large-scale reconfigurations may require a full day.

3. Are adjustable racks suitable for cold storage facilities?

Absolutely. Look for models with stainless steel components and low-temperature lubricants to prevent freezing.

4. What’s the average lifespan of an adjustable rack system?

With proper maintenance, most systems last 15–25 years. Environmental factors like humidity or chemical exposure may reduce this by 5–10 years.

5. Can I add accessories like dividers or bins to adjustable racks?

Yes. Most systems are compatible with partition panels, drawer units, and label holders for enhanced organization.