📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Beyond Compliance: The Definitive Guide to Engineered Warehouse Rack Safety Barriers for Automated Storage Systems

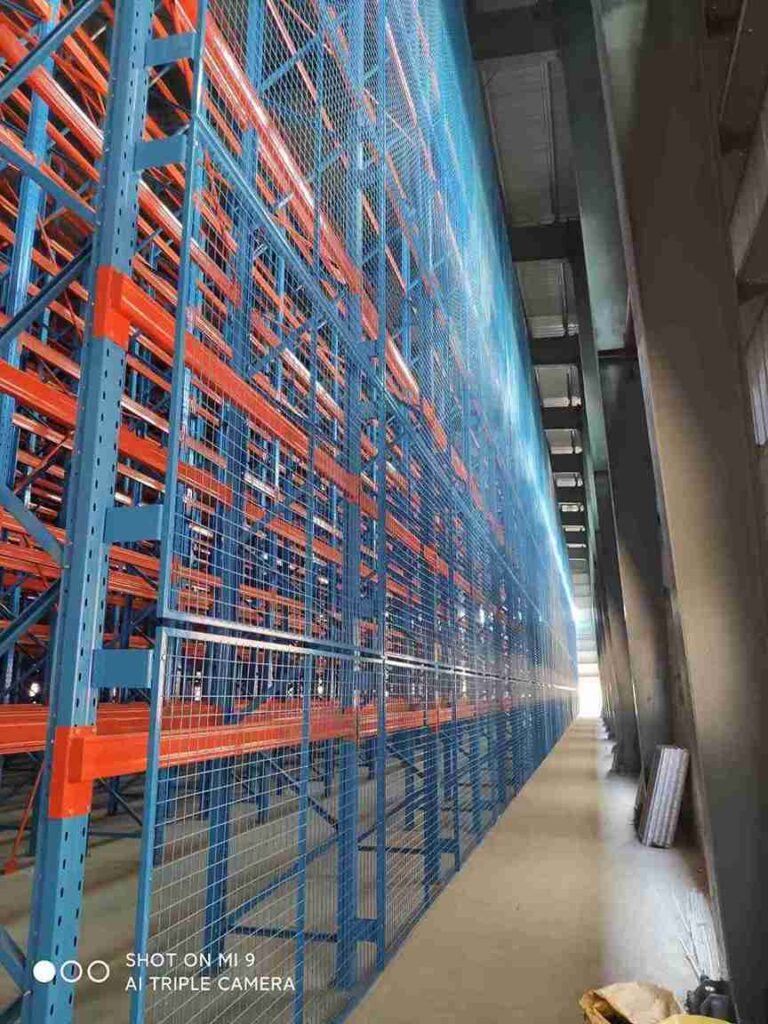

In the high-stakes realm of modern logistics, where automation drives efficiency, the integrity of the storage infrastructure becomes paramount. Warehouse rack safety barriers are no longer passive accessories; they are actively engineered defense systems critical to the operational continuity, financial health, and human safety of any facility utilizing automated guided vehicles (AGVs), autonomous mobile robots (AMRs), or Automated Storage and Retrieval Systems (AS/RS).

This authoritative guide explores why generic, off-the-shelf protection is a profound liability for automated environments. It details the science, strategy, and specifications behind designing and fabricating custom warehouse rack safety barriers that not only meet but exceed international safety standards, proactively safeguarding the unique and demanding dynamics of automated storage systems. From advanced impact engineering and material selection to seamless integration protocols and quantifiable ROI, this document serves as the comprehensive blueprint for securing the backbone of automated logistics.

The Automated Warehouse: A New Paradigm of Risk Demands a New Standard of Protection

The integration of robotics and high-density storage creates an environment of unparalleled productivity. Yet, this very efficiency introduces a sophisticated spectrum of kinetic risks that traditional manual warehouses rarely encountered with such frequency or potential consequence. The static racking structure and the dynamic robotic fleet exist in a delicate balance, one that hinges on the performance of correctly specified warehouse rack safety barriers.

Understanding the Kinetic Threat of Automation

Automated systems operate on programmed pathways at consistent speeds, often around the clock. This predictability is their operational advantage but also a focal point for potential systemic failure. A software anomaly, a sensor calibration drift, a pallet misalignment, or a minor floor debris event can transform a laden AGV or unmanned forklift into a mass with significant kinetic energy. The resulting impact is not a mere nuisance; it is a high-energy event calculated by physics (Force = Mass x Acceleration).

Standard, catalog-specification warehouse rack safety barriers are typically designed for the lower speeds and occasional human error of manual forklift operation. They frequently lack the specific energy-absorption capacity, structural geometry, and anchoring integrity required to withstand the repeated or high-force collisions inherent in dense automated traffic zones. Deploying inadequate warehouse rack safety barriers in such an environment is a calculated risk with potentially catastrophic financial and operational repercussions.

The Domino Effect of Downtime in an Automated Ecosystem

In a conventional warehouse, a racking collision might result in localized damage and repair. Within an automated storage system, a single impact can trigger a cascade of failures. A compromised upright can halt an entire AS/RS crane’s retrieval sequence, freeze inventory movement in a zone serviced by a dedicated AGV fleet, and paralyze downstream packing and shipping operations.

The cost of downtime per hour in these environments is staggering, encompassing frozen capital (inventory), missed SLA penalties, idled robotic assets, and emergency repair crews. Therefore, the primary function of superior warehouse rack safety barriers extends beyond protecting steel beams; they are the guardians of operational continuity and throughput integrity. A custom-engineered barrier system is the most robust and proactive investment to prevent a minor incident from escalating into a full-scale operational crisis.

Dual-Asset Protection: Safeguarding Both the Rack and the Robot

The capital investment in an automated warehouse is twofold: the storage structure itself and the sophisticated robotics that navigate it. A severe collision jeopardizes both. Impact can cause catastrophic damage to an AGV’s guidance LiDAR, navigation sensors, drive mechanisms, and structural frame. Professionally engineered warehouse rack safety barriers are designed to absorb and dissipate impact energy in a controlled manner, acting as a sacrificial shield. This protects not only the rack upright but also the often more expensive robotic vehicle from irreparable damage, safeguarding the total system investment.

The Imperative of Customization: Why “One-Size-Fits-All” is a Fallacy in Automation

For automated environments, customization of warehouse rack safety barriers is not a premium offering; it is a fundamental engineering requirement. True customization begins with a forensic analysis of the facility’s unique operational DNA, moving far beyond simple dimensional adjustments.

The Foundational Step: Comprehensive, Site-Specific Risk Assessment

The design process for effective warehouse rack safety barriers must be grounded in data. A professional assessment audits:

Vehicle Dynamics: Precise specifications of all automated vehicles—type (unit-load AGV, tow tractor, autonomous forklift), maximum laden mass, operating speed ranges, and crucially, the vehicle’s impact profile (e.g., fork height, chassis geometry).

Operational Traffic Patterns: Mapping of high-density traffic zones, intersection points, charging locations, and transfer stations. Frequency of vehicle passes near racking faces is analyzed.

Storage System Profile: Detailed analysis of the racking system—upright profile and gauge, beam levels, maximum stored unit weights, anchor types, and any existing seismic bracing.

Environmental & Infrastructure Factors: Floor condition and flatness, ceiling height constraints, proximity to fire suppression systems, and required egress paths.

Integration by Design, Not by Accident

The most effective warehouse rack safety barriers are architecturally integrated into the warehouse’s layout. This involves:

Harmonization with Guidance Systems: Designing barrier profiles and placements that do not interfere with magnetic tape, LiDAR fields, optical targets, or inertial guidance systems used by AGVs. This ensures flawless navigation without “blind spots.”

Engineered for Serviceability: Incorporating strategically placed removable sections, lockable access panels, or quick-disconnect features to allow maintenance personnel easy access to rack components, floor utilities, or automation hardware without compromising the protection scheme’s integrity.

Modularity for Future Flexibility: Designing systems with reconfiguration in mind. As operational needs evolve, modular warehouse rack safety barriers can be relocated or expanded with minimal cost and disruption, protecting the long-term value of the investment.

The Engineering Core: Materials, Design, and Fabrication of High-Performance Barriers

The superiority of a custom solution is materialized in the rigorous selection of materials, the application of impact engineering principles, and precision fabrication.

Advanced Material Science for Maximum Resilience

High-Strength, Low-Alloy (HSLA) Steels: Often specified for critical components, HSLA steels provide a superior strength-to-weight ratio. This allows for the creation of warehouse rack safety barriers that offer higher impact resistance with a slimmer physical profile, preserving valuable floor space.

Precision-Formed Structural Sections: Using cold-formed or hot-rolled steel with certified yield strengths ensures predictable, consistent performance under load, a non-negotiable aspect of reliable warehouse rack safety barriers.

Composite & Polymer Elements: For specific applications, integrating ultra-high-molecular-weight polyethylene (UHMWPE) impact plates or energy-absorbing polymer composites can offer exceptional abrasion resistance and energy dissipation for lower-speed impacts or as part of a hybrid system.

Principles of Impact Energy Management

A premier warehouse rack safety barrier is not merely a solid wall; it is an energy-management system. Its objective is to absorb, dissipate, and redistribute kinetic energy in a controlled, calculated manner.

Controlled Deformation: Utilizing principles akin to automotive crumple zones, certain barrier designs include engineered weak points or corrugated sections that deform predictably upon impact, converting the vehicle’s kinetic energy into mechanical work (deforming the steel), thereby decelerating the vehicle more gradually and reducing peak impact force transmitted to the rack and anchors.

Dampening Technology Integration: In ultra-high-risk zones—such as those adjacent to high-speed transfer cars or at the end of long AGV runways—warehouse rack safety barriers can be integrated with hydraulic or elastomeric dampeners. These devices dramatically increase the system’s energy absorption capacity far beyond that of static steel alone.

Structural Load-Path Optimization: Every angle of a brace, every weldment, and every anchor point is calculated to create an optimal load path. Upon impact, forces are spread across multiple structural members and distributed into the warehouse floor slab over a larger area, preventing point-load failures at the connection to the rack upright.

Fabrication Integrity and Protective Finishes

Certified Welding Procedures: Critical load-bearing joints are executed using robotic or certified manual welding processes following defined WPS (Welding Procedure Specifications). This ensures consistent, full-penetration welds with known mechanical properties, eliminating the weakness of ad-hoc fabrication.

Abrasion-Resistant and High-Visibility Finishes: After fabrication and surface preparation (e.g., shot blasting), components are coated with multi-layer, industrial-grade epoxy or polyurethane paints. Abrasion-resistant paint in high-visibility colors (e.g., safety yellow) is standard, enhancing both durability and visual awareness for personnel and vehicle systems.

Anchoring Systems Engineered for the Substrate: The barrier is only as strong as its connection to the ground. Engineers specify anchoring systems—be it high-tensile chemical anchors, mechanical through-bolts, or specialty fixtures for specific slab conditions—based on a concrete pull-out strength analysis, ensuring the entire assembly performs as a unified, grounded safety structure.

Specialized Applications: Fortifying Automated Storage and Retrieval Systems (AS/RS)

The protection requirements for high-density AS/RS, whether unit-load or mini-load, demand an even more meticulous approach, as the rack structure itself is part of the active machinery.

Runway and Upright Protection for AS/RS Cranes

In narrow-aisle AS/RS, the rack uprights serve as the runway for the storage crane. Any deflection or damage to an upright can misalign the entire runway, causing crane malfunction or catastrophic derailment. Warehouse rack safety barriers for these applications, often called runway column guards, are designed to provide maximum deflection resistance with an absolute minimum footprint. The clearance between the guard and the crane’s mast or guide rollers is calculated with millimeter precision to ensure unimpeded crane operation while offering formidable protection.

End-of-Aisle and System Interface Hardening

The ends of rack runs and the interfaces with pick stations, conveyor transfer points, or AGV hand-off zones are ultra-high-probability impact locations. Protection here often involves a layered defense strategy. This may combine a continuous run of heavy-duty warehouse rack safety barriers with strategically placed, independently anchored impact panels and bollards. This approach creates a graduated defense that can stop a stray vehicle at multiple stages, protecting both the rack end-frame and the sensitive automation interface equipment behind it.

The Installation Imperative: Precision Execution for Guaranteed Performance

The most expertly engineered warehouse rack safety barriers can be rendered ineffective by poor installation. Field execution must match design intent with precision.

Methodology-Driven Installation

Professional installation follows a site-specific Method Statement. Certified technicians, working from detailed IFC (Issued for Construction) drawings, ensure that every anchor hole is drilled to the correct depth and diameter, every bolt is torqued to a specified value, and every section is aligned and levelled correctly. This process turns a collection of components into a performance-guaranteed system.

Commissioning and Performance Verification

Upon installation completion, a commissioning protocol is followed. This includes a full geometric survey to verify alignment and clearance, a torque audit of critical connections, and a visual inspection of all welds and finishes. For critical applications, a performance verification test—such as a controlled, low-energy impact using a test weight—may be conducted to empirically validate the system’s response before live operations commence around it.

The Compelling ROI of Engineered Warehouse Rack Safety Barriers

Investing in custom-engineered warehouse rack safety barriers is a strategic business decision with a clear and multi-faceted return on investment:

Direct Asset Preservation: Protects the racking system (a major capital asset) and the automation fleet from repair or replacement costs.

Business Continuity Assurance: Prevents the massive revenue loss associated with automated warehouse downtime, safeguarding customer commitments and market reputation.

Risk Mitigation and Insurance Optimization: Demonstrating proactive risk management through engineered warehouse rack safety barriers can positively influence liability insurance premiums and is undeniable evidence of due diligence.

Long-Term Operational Stability: Prevents the cumulative, hidden damage from minor impacts that gradually compromises racking integrity, extending the service life of the entire storage system.

Foundation for a Safety Culture: Tangibly reinforces an organizational commitment to safety, protecting personnel and fostering a responsible operational environment.

A Proven Process: From Concept to Long-Term Partnership

Engaging with specialists for warehouse rack safety barriers is a collaborative, phased journey:

Phase 1: Discovery & Risk Assessment. On-site audit and data collection.

Phase 2: Engineering & Design. 3D modeling, load calculations, and drawing production.

Phase 3: Fabrication. Manufacturing in a quality-controlled environment.

Phase 4: Certified Installation. Execution by trained crews.

Phase 5: Ongoing Support. Offering periodic inspection services and life-cycle management advice.

Conclusion: The Non-Negotiable Safeguard for Automated Logistics

As warehouses evolve into highly automated, interconnected ecosystems, the margin for error shrinks while the cost of failure skyrockets. In this context, warehouse rack safety barriers transform from a commodity into a critical, engineered subsystem. Generic protection is a false economy; it addresses the letter of compliance but ignores the specific, vigorous realities of robotic material handling. True security lies in custom warehouse rack safety barriers—systems born from a rigorous risk assessment, designed to definitive international standards like FEM 10.2.02, and fabricated to endure the unique challenges of your operation.

They are the indispensable, high-performance interface between dynamic automation and static storage, engineered not just to prevent accidents, but to ensure resilience, protect capital, and guarantee the uninterrupted flow of commerce. The strategic question for any operator of automated storage systems is clear: can you afford anything less than the definitive protection offered by professionally engineered warehouse rack safety barriers?

Frequently Asked Questions (FAQs)

1: For a new greenfield automated warehouse project, at what stage should warehouse rack safety barriers be incorporated into the planning?

Warehouse rack safety barriers should be considered during the initial design phase, concurrent with the racking layout and automation path planning. Integrating them early allows for a holistic design where barriers are accounted for in space planning, AGV navigation programming, and electrical conduit routing. This prevents costly redesigns, field modifications, or operational compromises that occur when warehouse rack safety barriers are treated as a late-stage add-on. Early engagement ensures the barriers are an optimized part of the system, not an obstruction to it.

2: How do you determine the correct energy absorption rating (e.g., FEM Class) needed for our specific warehouse rack safety barriers?

The rating is determined through the initial risk assessment. Key inputs are the mass (weight) of the heaviest automated vehicle in its fully laden state, its maximum operational speed in the protected zone, and the designated impact angle (typically 90 degrees for straight runs). Engineers plug these variables into kinetic energy formulas (KE=½mv²) to calculate the energy in Joules that the warehouse rack safety barriers must absorb. A safety factor is then applied, and the required FEM class (e.g., Class 4 for 6,700 Joules) is selected. This data-driven method ensures the warehouse rack safety barriers are neither under-specified (a risk) nor grossly over-specified (an unnecessary cost).

3: Can warehouse rack safety barriers be effectively used to protect other critical infrastructure, like electrical panels, HVAC units, or building columns?

Absolutely. The same engineering principles used to protect racking apply to any critical infrastructure. Custom-designed warehouse rack safety barriers and protection booths can be fabricated to shield fire sprinkler risers, main electrical switchgear, control cabinets, and structural building columns from vehicle impact. These are often designed as freestanding structures or building-column wraps, providing targeted protection for assets whose damage would cause widespread facility disruption.

4: What is the typical lead time for a project involving custom-designed warehouse rack safety barriers for a large-scale automated facility?

Lead time is project-dependent but follows a predictable sequence. Following the 1-2 week assessment and design phase, fabrication for a large project may take 4-8 weeks, depending on complexity and volume. Installation duration depends on the facility’s size and accessibility but is typically planned to be executed efficiently by trained crews to minimize operational interference. A total project timeline from kickoff to completion for a major installation often ranges from 10 to 16 weeks. Phasing is always an option for brownfield sites to align with production windows.

5: Do you provide digital twins or CAD models of the proposed warehouse rack safety barriers for integration into our facility’s BIM (Building Information Modeling) model?

Yes, industry-leading providers offer this service. Delivering 3D CAD models (e.g., .DWG, .STEP, .IFC files) of the proposed warehouse rack safety barriers is a standard part of the design package for sophisticated projects. This allows the client’s engineering team to integrate the barriers directly into the overall facility BIM model. This enables clash detection with other services (electrical, plumbing, ventilation), accurate visualization, and seamless coordination between all trades during construction or retrofit projects, ensuring perfect fit and function from the outset.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com