📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Maximize Storage & Efficiency: The Definitive Guide to Tailored Custom Industrial Racking Solutions

In the high-stakes world of global logistics, a warehouse is the strategic core of the supply chain. However, when constrained by generic storage systems, it transforms into a primary bottleneck, stifling growth and eroding profitability. Standard shelving and one-size-fits-all pallet racks are fundamentally incapable of addressing the unique volumetric and operational challenges faced by businesses today. This exhaustive resource articulates a powerful, evidence-based truth: achieving true storage density and workflow efficiency is an engineering challenge, solvable only through a meticulously planned and executed custom industrial racking solutions strategy.

This article will serve as a masterclass in how a bespoke approach—one that harmonizes advanced storage technology with precise operational workflows—can revolutionize a facility. From a deep analysis of inventory dynamics and the strategic deployment of high-density systems like Narrow Aisle and Push Back Racking, to the seamless integration of automation, this guide provides the comprehensive framework necessary for logistics managers, warehouse operators, and business owners to unlock transformative performance gains. The focus is squarely on delivering actionable insights for markets in Southeast Asia, the Middle East, Africa, and Latin America, where agility and scalability are paramount.

The Unsustainable Burden of Generic Storage Systems

A walkthrough of an underperforming warehouse often reveals a predictable landscape of inefficiency. Congested aisles, underutilized vertical airspace, and frustrated personnel navigating a labyrinth of disorganization are common symptoms. The root pathology is a profound misalignment between the storage infrastructure and the inventory it is meant to house. Off-the-shelf racking forces operational compromises, creating a reactive environment where problems are managed rather than solved.

The financial implications of this misalignment are severe and multifaceted:

Profligate Real Estate Expenditure: Inefficient cube utilization directly translates to paying for unnecessary square footage. In burgeoning industrial markets where land and construction costs are escalating, this is a persistent drain on capital that could be deployed for growth initiatives.

Spiraling Labor Costs: Manual order picking remains one of the most significant cost centers, and a disorganized layout exacerbates this. Workers expend excessive time in non-value-added travel and search activities, directly impacting throughput and scalability.

Compromised Safety and Product Integrity: Poorly configured layouts lead to forklift congestion and increased risk of rack impact, product damage, and workplace accidents. The resultant costs—from damaged goods to insurance premiums and potential litigation—can be devastating.

Operational Inflexibility: A static storage system cannot adapt to dynamic business needs. The introduction of new product lines or shifts in seasonal demand render generic setups obsolete, necessitating costly and disruptive overhauls.

The strategic alternative is a fundamental shift towards custom industrial racking solutions. This is not merely a product procurement exercise; it is a consultative partnership aimed at designing a system that systematically converts these cost centers into robust competitive advantages.

Deconstructing the Anatomy of a True Custom Industrial Racking Solution

The term “custom” is often diluted in the industry, sometimes referring to minor modifications. In its most potent form, a custom industrial racking solutions project represents a holistic, data-driven engineering discipline. It is the process of architecting a storage ecosystem that is intrinsically tailored to a client’s exclusive operational DNA.

(H3) The Foundational Elements of a Bespoke Storage Design

The development of superior custom industrial racking solutions is predicated on four critical pillars:

Comprehensive Operational Diagnostics: The process transcends physical dimensions. It begins with an in-depth warehouse efficiency audit, encompassing SKU velocity profiling, order history analysis, and a granular review of material flow from receiving to shipping. This intelligence forms the bedrock of a truly optimized design for any custom industrial racking solutions project.

Precision Cube Maximization: Engineering for cubic volume is a science. It involves calculating not just clear height, but the precise spatial requirements for specialized Material Handling Equipment (MHE)—such as narrow aisle forklifts or stacker cranes—to operate safely and efficiently at maximum height, a core objective of any custom industrial racking solutions design.

Forward-Looking Technology Integration: Authentically custom industrial racking solutions are conceived with future automation in mind. The structural design, including lane dimensions, load specifications, and interface points, must be pre-engineered to accommodate technologies like AGVs (Automated Guided Vehicles) or a full Automated Storage and Retrieval System (AS/RS). This future-proofing is a hallmark of advanced custom industrial racking solutions.

Contextual Material Science: For the harsh, humid climates of Southeast Asia or the corrosive environments in certain manufacturing sectors, the specification of materials is critical. High-tensile steel with advanced corrosion-resistant coatings is non-negotiable for ensuring the longevity and structural integrity of custom industrial racking solutions in demanding conditions.

The Centrality of SKU Profiling in Customization

The intelligence that animates a custom industrial racking solutions design is derived from a masterful understanding of inventory. A rigorous ABC analysis is conducted:

‘A’ Items (High-Velocity): These high-turnover products are strategically positioned in the easily accessible “golden zone.” Solutions often incorporate carton flow racking to enable dynamic, high-speed FIFO (First-In, First-Out) picking, a common feature in efficient custom industrial racking solutions for distribution.

‘B’ Items (Medium-Velocity): These SKUs are typically housed in selective pallet racking within a secondary zone, creating an optimal balance between accessibility and space utilization in a well-planned custom industrial racking solutions layout.

‘C’ Items (Low-Velocity): Slow-moving or archival goods are ideal candidates for high-density systems like drive-in racking, where maximizing storage density is the primary goal, a key consideration for custom industrial racking solutions aimed at freeing up prime space.

By architecting the storage system around the actual inventory profile, a custom industrial racking solutions provider creates an intuitive, logical, and highly efficient product flow path.

Engineering Maximum Density: A Technical Look at Custom Racking Systems

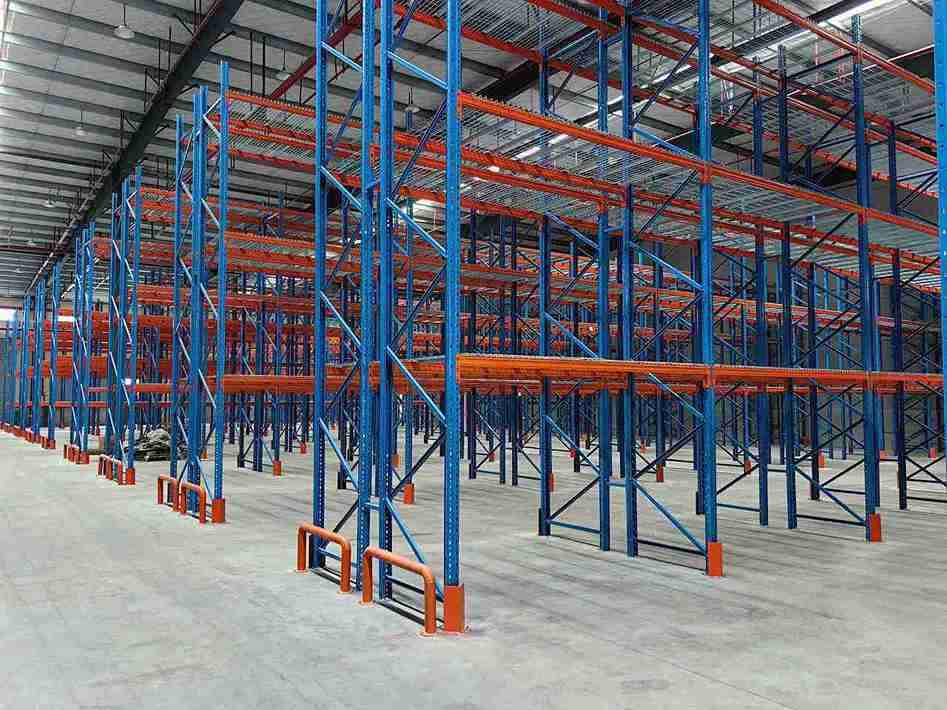

The imperative to maximize storage is frequently addressed through high-density storage configurations. These systems are the cornerstone of a high-performance custom industrial racking solutions strategy, dramatically increasing pallet positions within an existing footprint.

Narrow Aisle & Very Narrow Aisle (VNA) Racking Systems

This approach represents a quantum leap in storage density without physical expansion. By reducing aisle widths from a conventional 12 feet to as little as 5 feet, facilities can achieve a 40-50% increase in storage capacity, a primary goal of many custom industrial racking solutions projects.

Operational Mechanics: Narrow aisle racking is dependent on specialized MHE, such as narrow aisle forklifts or turret trucks, which are engineered for precision operation in confined spaces at significant heights. The accompanying custom industrial racking solutions must be designed for taller profiles and require a high-quality, level floor.

Ideal Application: This system is exceptionally effective for facilities with high-SKU counts and robust inventory turnover, a common scenario in the e-commerce and distribution sectors across Latin America and Southeast Asia. The integration of wire or rail guidance systems further enhances the safety and efficiency of these sophisticated custom industrial racking solutions.

Drive-In and Drive-Through Racking: The Bulk Storage Powerhouse

For high-density storage of homogeneous, high-volume products, drive-in racking systems offer an unparalleled solution. They effectively consolidate multiple aisles into deep storage lanes where the forklift operates within the rack structure itself.

Operational Mechanics: Pallets are stored on continuous rails, with multiple loads positioned deep within a single lane. This configuration typically operates on a LIFO (Last-In, First-Out) basis. The drive-through racking variant, with access from both ends, facilitates FIFO management, which is critical for industries like food and beverage, a key sector for custom industrial racking solutions.

Ideal Application: This is the go-to custom industrial racking solutions for cold storage facilities, the beverage industry, or any business managing large quantities of a single SKU, particularly across markets in Africa and the Middle East.

Push Back Racking: Strategic Density with Selectivity

Push back racking masterfully balances high-density storage with selective accessibility. It offers greater SKU accessibility than drive-in systems while still storing multiple pallets deep.

Operational Mechanics: Pallets are stored on nested carts that ride on inclined rails. When a new load is placed, it pushes the existing loads backward. Upon retrieval, the subsequent pallet automatically moves forward to the pick face. This allows for dense storage of 2-6 pallets deep per lane in a typical custom industrial racking solutions implementation.

Ideal Application: This system is perfectly suited for businesses with multiple SKUs that require a balance of medium-density storage and controlled inventory rotation (FIFO or LIFO). It is a versatile and popular component in modern custom industrial racking solutions.

The Automated Warehouse: The Ultimate Expression of Custom Racking Solutions

A state-of-the-art custom industrial racking solutions project is inherently designed with automation as a core consideration. The physical storage structure and the automated technology must function as a single, integrated organism.

Architecting Racking for AGVs and Autonomous Mobile Robots (AMRs)

The integration of AGVs or AMRs demands a higher degree of precision in the design of custom industrial racking solutions. Key considerations include:

Ultra-Precise Tolerances: The clearances between rack uprights and the defined navigation paths of the robots must be exact to ensure flawless, uninterrupted operation, a critical specification for these advanced custom industrial racking solutions.

Enhanced Structural Integrity and Stability: While automated systems handle loads with consistent precision, the custom industrial racking solutions must be engineered for absolute stability to withstand potential micro-impacts and ensure safety in an un-manned environment.

Dedicated Interface Zones: The design must incorporate optimized pick-up and drop-off (P&D) stations that are ergonomically designed for seamless interaction between robots and human operators, a sophisticated feature of integrated custom industrial racking solutions.

Automated Storage and Retrieval Systems (AS/RS): The Apex of Efficiency

For the ultimate achievement in density, speed, and accuracy, AS/RS represents the pinnacle of warehouse innovation. These are not mere machines; they are a complete synthesis of racking, robotics, and software.

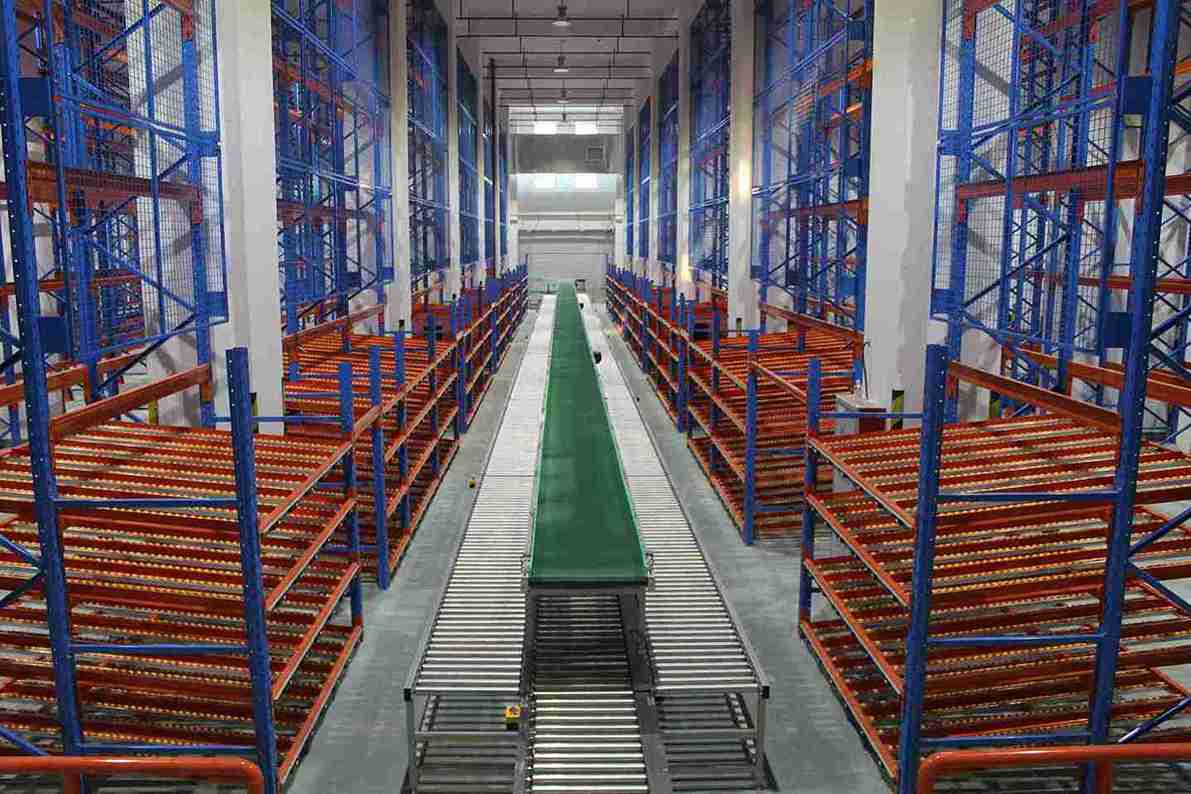

Unit-Load AS/RS: These monumental systems utilize stacker cranes that operate within the racking aisles to store and retrieve full pallets. The aisles are exceptionally narrow, as no human or forklift entry is required. The custom industrial racking solutions that form the backbone of an AS/RS require engineering and installation tolerances within millimeters, representing the most precise category of custom industrial racking solutions.

Mini-Load AS/RS: Engineered for smaller items in bins or totes, these systems are the driving force behind high-velocity e-commerce fulfillment. The custom industrial racking solutions structure holds the inventory, while robotic retrievers move in three dimensions to deliver items to workstations with breathtaking speed and accuracy.

Beyond Pallets: Specialized Custom Industrial Racking Solutions for Complex Inventories

A holistic strategy for warehouse efficiency must encompass solutions for a diverse range of goods beyond standard pallets.

Mezzanine Floors: Creating a Multi-Level Facility Within a Single Envelope

When lateral or vertical expansion with standalone racking is not feasible, a mezzanine floor effectively creates new operational levels. Professionally engineered custom industrial racking solutions often incorporate mezzanines to serve as multi-tiered storage for smaller items, dedicated packing stations, or even office space, all within the existing building footprint.

Dynamic Storage Systems for High-Velocity Order Fulfillment

For case-level and piece-pick operations, carton flow racking is a transformative technology. By utilizing gravity-fed rollers, it enforces perfect FIFO inventory control and drastically accelerates order picking speed and accuracy, directly targeting and reducing the most significant labor cost in the warehouse—a smart objective for any custom industrial racking solutions plan.

The Collaborative Journey: A Step-by-Step Guide to Your Custom Industrial Racking Solutions

Transparency and partnership define the process of implementing world-class custom industrial racking solutions. Here is the structured methodology that ensures success:

Phase 1: Discovery and Data Intelligence: The engagement begins with a comprehensive consultation and on-site audit to diagnose pain points, define strategic objectives, and gather all necessary operational data.

Phase 2: Engineering and Immersive Design: A dedicated team of structural and logistics engineers employs advanced CAD and simulation software to create a dynamic 3D model of the proposed facility. This allows stakeholders to conduct a virtual walkthrough of their optimized operation before manufacturing commences, a critical step in refining the custom industrial racking solutions design.

Phase 3: Transparent Proposal and Project Scoping: A detailed proposal is presented, including final layout plans, performance projections, a clear investment breakdown, and a phased implementation timeline designed to minimize operational disruption.

Phase 4: Precision Manufacturing and Quality Assurance: The approved custom industrial racking solutions components are manufactured in controlled factory environments using state-of-the-art equipment, with rigorous quality checks at every stage.

Phase 5: Flawless Execution and Knowledge Transfer: Certified installation teams execute the plan with precision, ensuring the custom industrial racking solutions are installed to exact specifications. Comprehensive training for operational staff is provided to ensure optimal system utilization.

Phase 6: Sustained Partnership and Performance Support: The relationship continues post-installation with ongoing support services, scheduled rack safety inspections, and readily available spare parts to guarantee the long-term peak performance of the custom industrial racking solutions.

Evidence in Action: A Regional Distribution Hub Transformed

A leading consumer goods distributor in Vietnam faced a critical 40% capacity deficit, forcing reliance on expensive off-site storage. Their existing conventional racking was inefficient, with wasted aisle space and low height utilization.

The Deployed Custom Industrial Racking Solutions:

Executed a full operational audit, including SKU analysis and workflow mapping.

Engineered a hybrid system: Very Narrow Aisle (VNA) racking for fast-moving palletized goods, combined with a structural mezzanine floor incorporating shelving for slow-movers and case-picking.

Specified a fleet of high-reach turret trucks to operate within the narrow aisles of the new custom industrial racking solutions.

The Quantifiable Outcomes:

Storage Capacity Skyrocketed by 90% within the original building, eliminating off-site storage costs.

Order Picking Productivity Surged by 35% due to an optimized layout and drastically reduced travel time.

Achieved a complete Return on Investment (ROI) in under 18 months through hard cost savings and operational efficiencies, validating the strategic investment in custom industrial racking solutions.

Conclusion: Architecting the Future of Your Logistics Operations

The pursuit of maximum storage and efficiency is a strategic imperative, a capital investment in operational superiority. It demands a partnership with experts who can visualize the potential latent within a facility and possess the technical prowess to unlock it. Generic storage products yield generic, easily replicated results. In the competitive arenas of emerging global markets, mediocrity is a liability. By commissioning a truly custom industrial racking solutions project, an enterprise does more than install steel; it codifies a smarter, more resilient, and more profitable operational future.

It builds a logistics infrastructure capable of scaling with ambition, adapting to volatility, and delivering an unassailable market advantage. The pivotal question for business leaders is no longer about the cost of implementing advanced custom industrial racking solutions, but about the far greater cost of continued operational stagnation.

(H2) Frequently Asked Questions (FAQs)

1. What is the typical lead time from design to installation for a custom racking system?

The project timeline is directly proportional to its scale and complexity. A standard implementation of custom industrial racking solutions typically requires 8-14 weeks from design finalization to project completion, encompassing detailed engineering, manufacturing, and on-site installation. Larger, more complex projects involving AS/RS or extensive warehouse automation can have timelines of 6-12 months. A detailed, phased project plan is always provided upfront for precise operational planning.

2. How do you ensure the structural integrity and safety of your custom racking designs, especially in regions prone to seismic activity?

Structural integrity is the non-negotiable foundation of our custom industrial racking solutions. All designs are executed by certified professional engineers who perform rigorous structural calculations based on specific load requirements and stringent local building codes. For seismically active zones, such as parts of South America and Southeast Asia, our custom industrial racking solutions incorporate advanced seismic design protocols, including higher load capacities, specialized bracing systems, and connection details engineered to absorb and dissipate seismic energy, ensuring paramount safety for personnel and assets.

3. Can a custom racking system be reconfigured if our storage needs change in the future?

Absolutely. A fundamental advantage of a properly engineered custom industrial racking solutions project is its inherent modularity and adaptability. Systems like selective pallet racking are specifically designed for reconfiguration. While high-density systems like drive-in racking are more fixed, our initial design process for custom industrial racking solutions always prioritizes future flexibility, allowing for the cost-effective expansion or re-optimization of specific zones with minimal operational downtime.

4. What kind of maintenance do these systems require?

Proactive maintenance is essential for the safety, performance, and longevity of any custom industrial racking solutions. We strongly recommend and can provide scheduled annual or semi-annual rack safety inspections conducted by qualified personnel to identify any damage, misalignment, or component wear. For systems integrated with AGVs or AS/RS, maintenance also includes strict adherence to the equipment manufacturer’s service guidelines. Comprehensive service-level agreements are available to manage all maintenance aspects proactively.

5. How do you handle the installation process to minimize disruption to our ongoing warehouse operations?

Minimizing operational disruption is a core tenet of our project management philosophy for custom industrial racking solutions. We develop a meticulous phasing plan, which may involve installing the new system in designated sections, performing work during off-peak hours, or utilizing temporary staging areas. Our seasoned installation teams are experts at working efficiently and safely within active logistics environments, ensuring a seamless transition with a minimal impact on daily throughput and order fulfillment.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com