📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Strategic Investment: Unlocking Growth with Cost-Effective Warehouse Racking

For small and medium-sized enterprises (SMEs) driving economic growth across Southeast Asia, the Middle East, Africa, and Latin America, the warehouse is more than a storage space—it’s the operational nexus where supply chain efficiency and profitability converge. In these dynamic, competitive markets, the pressure to optimize every dollar is immense. The choice of storage infrastructure becomes a pivotal strategic decision, one where the allure of the lowest initial price often clashes with the imperative of long-term operational viability. This is where the true meaning of cost-effective warehouse racking must be understood.

It is a concept far beyond mere cheap shelving; it is a holistic approach to storage that balances initial capital outlay with profound gains in space utilization, workflow efficiency, safety, and scalability. A genuinely cost-effective warehouse racking system is not an expense but a transformative investment, a tool that converts logistical overhead into a tangible competitive advantage. This comprehensive guide delves into the engineering, economics, and strategic planning that define superior cost-effective warehouse racking solutions, providing SME owners and logistics managers with the insights needed to make an informed decision that will fuel their growth for years to come.

Deconstructing Cost-Effectiveness: A Total Cost of Ownership Perspective

The most common error an SME can make when selecting storage solutions is evaluating options based solely on the purchase price. This narrow focus ignores the systemic financial impact of a racking system over its entire operational lifespan. A truly cost-effective warehouse racking strategy is built on the principle of Total Cost of Ownership (TCO), a comprehensive financial model that accounts for all direct and indirect costs.

The TCO for any warehouse racking system includes:

Direct Acquisition Costs: The invoice price of the racking components, shipping, and professional installation.

Operational Efficiency Costs: The labor expenses associated with storing, picking, and put-away. An inefficient layout leads to excessive forklift travel time and worker hours, which constitutes the single largest ongoing cost in any warehouse.

Space Utilization Costs: The financial value of the warehouse’s cubic air space. A system that fails to leverage the full clear height of the facility is essentially leaving money on the table, paying rent for unused volume.

Maintenance and Downtime Costs: The expenses related to repairs, system inspections, and operational stoppages due to failure. Low-quality systems are prone to damage, requiring frequent, costly fixes and creating unsafe work environments.

Scalability and Adaptability Costs: The future capital required to modify or replace a system that cannot accommodate business growth or changing inventory profiles. A modular, adaptable cost-effective warehouse racking system avoids the need for a complete, expensive overhaul down the line.

By analyzing these factors, it becomes clear that the most cost-effective warehouse racking solution often has a higher initial price but a dramatically lower TCO, delivering superior value and a stronger return on investment throughout its service life.

The SME Storage Arsenal: An In-Depth Analysis of Racking Types and Their Economic Impact

Selecting the appropriate type of racking is paramount to achieving warehouse cost-effectiveness. Each system is engineered for specific operational profiles, and a mismatch can lock in inefficiencies for years. The following analysis breaks down the most relevant systems for SMEs in growth markets.

Selective Pallet Racking: The Unrivaled Standard for Accessibility

As the most ubiquitous form of warehouse racking, selective pallet racking offers direct, unimpeded access to every single pallet load. Its simple design of upright frames and horizontal beams provides unparalleled flexibility, making it a cornerstone of cost-effective warehouse racking for a vast range of industries.

Ideal Operational Profile: Businesses with a high number of SKUs requiring rapid, random access. It is the default choice for distributors, third-party logistics (3PL) providers, and manufacturers practicing First-In, First-Out (FIFO) inventory management. Its compatibility with standard counterbalance and reach trucks makes it a practical, cost-effective warehouse racking solution.

TCO Analysis for SMEs:

Advantages: The high accessibility translates directly into faster order picking cycles and reduced labor costs. Its modular nature allows for easy reconfiguration as inventory needs change, protecting the business from future adaptability costs. The relatively straightforward installation process keeps initial setup expenses manageable.

Disadvantages: The requirement for multiple access aisles results in a lower storage density compared to high-density systems. For SMEs paying a premium for warehouse space in urban centers, this can represent a significant ongoing cost.

Expert Recommendation: To maximize the cost-effective nature of selective racking, SMEs should insist on a design that utilizes 90% or more of the facility’s clear ceiling height. Investing in taller frames from the outset, combined with the appropriate Material Handling Equipment (MHE), is a far more economical strategy than retrofitting the system later.

Drive-In and Drive-Thru Racking: Mastering Storage Density for Bulk Goods

When the priority shifts from individual pallet accessibility to maximizing storage volume, drive-in racking systems present a powerful cost-effective warehouse racking alternative. This system functions as a multi-level storage tunnel, where the forklift driver enters the rack structure itself to deposit or retrieve loads.

Ideal Operational Profile: Perfect for businesses with high-volume storage of a limited number of SKUs. Industries such as food and beverage, cold storage, and chemicals frequently utilize this cost-effective warehouse racking solution for batch storage, typically operating on a Last-In, First-Out (LIFO) basis, or FIFO with a drive-thru configuration.

TCO Analysis for SMEs:

Advantages: The primary financial benefit is a dramatic increase in storage density—often up to 75% more than selective racking—by eliminating all but a few access aisles. This directly reduces the cost per pallet position and can delay or eliminate the need for facility expansion.

Disadvantages: Throughput speed is slower, and it requires highly skilled, cautious forklift operators to prevent collisions. Selectivity is low; retrieving a specific pallet from deep within the system can be time-consuming.

Expert Recommendation: SMEs should view drive-in racking as a strategic tool for specific inventory segments, not a facility-wide solution. It is an exceptionally cost-effective warehouse racking approach for storing seasonal products, raw materials, or finished goods that are moved in large, predictable batches.

Cantilever Racking: The Specialized Solution for Awkward Loads

Attempting to store long, bulky, or irregularly shaped items—such as timber, piping, sheet metal, or furniture—on standard pallet racking is inefficient and unsafe. Cantilever racking, with its strong vertical columns and unobstructed horizontal arms, is the definitive cost-effective warehouse racking answer for these challenges.

Ideal Operational Profile: SMEs in the construction, manufacturing, plumbing, and furniture industries find cantilever systems indispensable. It is the most practical and cost-effective warehouse racking for handling non-palletized inventory that cannot be easily stacked.

TCO Analysis for SMEs:

Advantages: The absence of front-column posts allows for seamless loading and unloading of lengthy goods, drastically reducing handling time and the risk of product damage. This specialized efficiency is the core of its cost-effective proposition.

Disadvantages: The cost per storage position is typically higher than selective racking, and it is wholly unsuitable for standard unit loads. It is a specialist investment for a specific need.

Expert Recommendation: The key to a truly cost-effective warehouse racking cantilever installation is arm adjustability. Specifying a system where the arms can be spaced closely and repositioned vertically with ease provides the flexibility to store a wide variety of item dimensions without wasting space, future-proofing the investment.

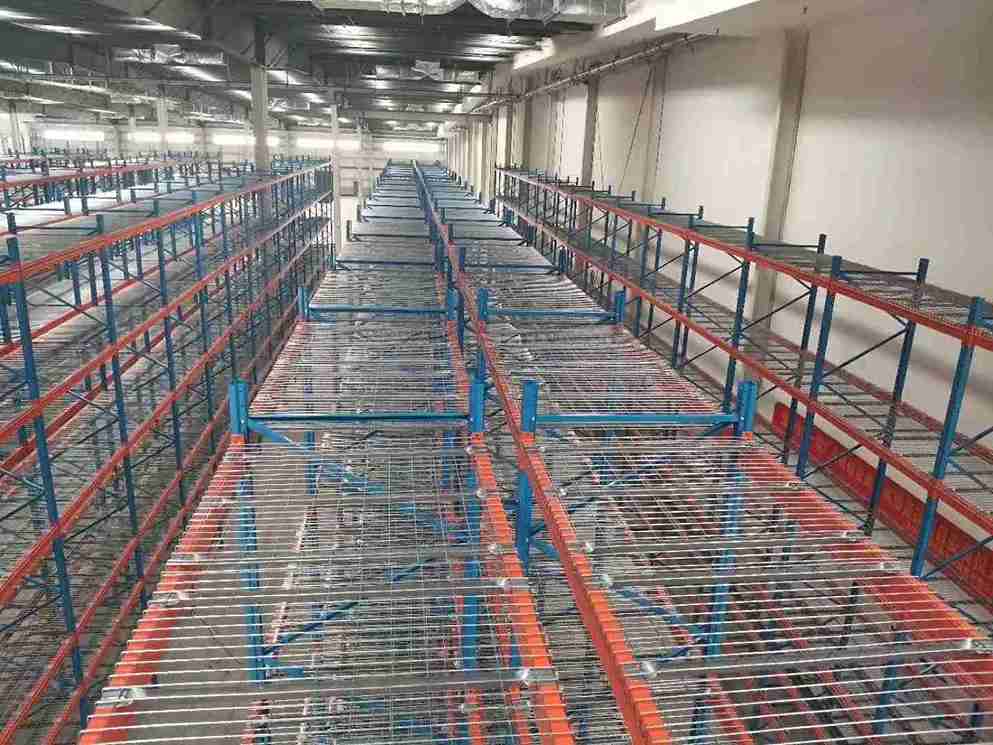

Mezzanine Floors: The Ultimate Space Multiplication Strategy

For SMEs locked into a facility with a fixed footprint, the only direction to grow is up. A structural mezzanine floor is a premier cost-effective warehouse racking and operational solution that creates a second or even third level within the existing building envelope.

Ideal Operational Profile: Businesses in densely populated cities where expansion is impossible or prohibitively expensive. Mezzanines are ideal for creating dedicated order-picking zones, housing office space, supporting light assembly operations, or storing slow-moving inventory.

TCO Analysis for SMEs:

Advantages: The return on investment is exceptionally high, as it creates new, functional square footage at a fraction of the cost of relocating or constructing a new building. It is the epitome of a cost-effective warehouse racking strategy that leverages wasted vertical air space.

Disadvantages: Requires significant structural engineering, may involve building permits, and represents a permanent modification to the facility. The initial investment is substantial but must be weighed against the alternative of leasing additional space.

Expert Recommendation: A shelving mezzanine, where the mezzanine structure is integrated with a multi-level shelving system, offers one of the most dense and accessible forms of storage. For an SME looking for a highly cost-effective warehouse racking and space-creation solution, this integrated approach is often unbeatable.

The Non-Negotiable Pillars of a Truly Cost-Effective System

Achieving a genuinely cost-effective warehouse racking installation rests on three foundational pillars that transcend the choice of racking type: professional design, material quality, and inherent scalability.

Professional Design and Engineering: The Blueprint for Efficiency and Safety

Treating warehouse racking as a simple commodity purchase is the most significant risk an SME can take. Off-the-shelf, non-engineered solutions are a liability. Professional design is not an optional extra; it is the very process that ensures a system is cost-effective, safe, and optimized.

A reputable provider delivers a comprehensive design service that includes:

Detailed Facility Audit: Precise measurements of floor flatness, column placements, clear heights, and sprinkler locations.

Operational Workflow Analysis: A deep dive into the business’s inventory turnover, picking profiles, and peak season demands to create a layout that supports, rather than hinders, operations.

Computer-Aided Design (CAD) and Simulation: Advanced software is used to create a virtual model of the proposed cost-effective warehouse racking system, optimizing travel paths and storage zones for maximum throughput before a single component is ordered.

Structural Integrity Certification: Every beam, upright, and connector is specified based on precise load calculations and engineered to meet or exceed international and local safety standards, a critical consideration in seismically active regions of Southeast Asia and Latin America.

Skipping this engineering phase inevitably leads to a system that is inefficient, unsafe, and ultimately, the opposite of cost-effective.

The Critical Role of Material Quality and Manufacturing Precision

The durability and safety of a cost-effective warehouse racking system are directly determined by the quality of its steel and the precision of its manufacturing. Inexpensive, low-grade steel may seem like a bargain but carries hidden long-term costs.

Steel Grade and Properties: High-grade, cold-rolled steel has a superior tensile strength, allowing it to bear heavier loads with less material. This results in a stronger, more resilient system. Inferior, hot-rolled steel is softer, more susceptible to deformation under load, and prone to fatigue failure over time.

Fabrication Tolerances: The holes in upright frames must be punched with laser-like precision, and beams must be roll-formed to exact specifications. This ensures a tight, secure connection that distributes loads evenly and prevents the micro-movements that weaken a structure over years of use. A poorly manufactured connection is a point of failure.

Corrosion Protection: In the humid climates of Vietnam or the coastal environments of the UAE, a high-quality powder-coat finish or hot-dip galvanization is essential. This is not a cosmetic feature but a vital protective layer that prevents rust, ensuring the long-term structural integrity and safety of the cost-effective warehouse racking investment.

Choosing quality materials is a direct investment in a lower Total Cost of Ownership and operational peace of mind.

Future-Proofing Through Scalability and Automation Readiness

A storage system that cannot evolve with a business quickly becomes a bottleneck. The most cost-effective warehouse racking solutions are those designed with future growth in mind, offering both scalability and the potential for technological integration.

Inherent Modularity: Systems like selective pallet racking are designed to be expanded. An SME can start with a configuration that meets current needs, with a clear, economical path to add more bays and levels as inventory grows.

Design for Reconfiguration: Beam levels should be easily adjustable without tools to accommodate changing inventory profiles. This flexibility prevents the need for costly new purchases when product dimensions change.

Planning for Technological Integration: The future of logistics in emerging markets is increasingly automated. When designing a cost-effective warehouse racking system today, forward-thinking SMEs should consider factors like aisle width compatibility with Narrow-Aisle (NA) trucks or even Automated Guided Vehicles (AGVs). This foresight can save millions in future retrofit costs. Semi-automated solutions, such as mobile racking operated by a manual push-button, offer a middle ground that is both highly dense and surprisingly cost-effective.

Case Study: Driving E-Commerce Efficiency in a Dynamic Market

A rapidly scaling e-commerce SME in Bangkok was grappling with the limitations of its ad-hoc storage. Using a combination of cheap, imported shelving and floor-stacked pallets, the company faced slow order fulfillment, high product damage rates, and was on the verge of signing a lease for a second, costly warehouse facility.

The Strategic Intervention: A full operational audit was conducted, leading to a custom-designed, hybrid cost-effective warehouse racking solution.

The bulk storage area was fitted with a high-strength selective pallet racking system, utilizing the full 9-meter clear height for fast-moving goods.

A two-tier shelving mezzanine was constructed over the picking area, dedicated to slow-moving and single-item SKUs, effectively creating over 500 square meters of additional operational space.

For the highest-velocity items, a gravity-fed carton-flow system was installed at ground level for rapid, ergonomic order picking.

The Quantifiable Outcome: Within one quarter, the company reported a 45% reduction in average order picking time, a 95% decrease in inventory damage, and a complete cancellation of the planned second warehouse lease. The investment in a professionally engineered cost-effective warehouse racking system paid for itself in under ten months through saved rental costs and dramatic operational improvements, solidifying its status as a foundational business asset.

Beyond Static Storage: The Rise of Semi-Automated and High-Density Solutions

For SMEs aiming to achieve a step-change in operational productivity, static racking is the starting point, not the finish line. The next evolutionary step involves integrating technology to create semi-automated systems that represent the pinnacle of modern cost-effective warehouse racking.

Mobile Pallet Racking: This system mounts entire rows of racking on electrically driven carriages that move on rails, eliminating all but one access aisle. While the initial investment is higher, the space savings can exceed 100%, making it the most cost-effective warehouse racking solution in terms of cost per pallet position in high-rent districts.

Dynamic Flow Systems: Using gravity, carton-flow and pallet-flow systems ensure perfect FIFO inventory rotation. Products are loaded from the rear and glide forward to the pick face, slashing walking and searching time for order pickers. This integration is a hallmark of a highly efficient, cost-effective warehouse racking strategy for distribution centers.

AGV/AMR Integration: The marriage of robust warehouse racking with Autonomous Mobile Robots (AMRs) creates a flexible, hybrid automation model. AMRs can be deployed for automated material movement between the storage area and packing stations, working alongside human staff to boost throughput without the need for a full-scale, capital-intensive automation overhaul. This represents a scalable and increasingly cost-effective warehouse racking and automation synergy for forward-thinking SMEs.

The Localized Partner Advantage: Navigating Regional Complexities

Sourcing and implementing a cost-effective warehouse racking system in Manila, Dubai, or Nairobi presents unique challenges that a remote, international supplier may not grasp. Success hinges on a partner with deep regional expertise and a localized support structure.

Key differentiators of a local expert include:

Regional Regulatory Knowledge: Understanding local building codes, seismic zone requirements, and fire safety regulations is paramount for a compliant and safe installation.

Supply Chain and Logistics Agility: Maintaining local inventory of critical components ensures shorter lead times and protects against global supply chain disruptions, a crucial factor for project timelines.

On-the-Ground Technical Teams: Access to certified installation crews and service technicians provides assurance of quality workmanship and readily available support for maintenance and inspections. This long-term partnership is integral to preserving the cost-effective nature of the investment.

Choosing a partner entrenched in the regional landscape is not a minor detail but a critical success factor for any SME seeking a reliable, high-performance, and genuinely cost-effective warehouse racking solution.

Conclusion: Building a Foundation for Sustainable Growth

In the fast-paced economic landscapes of Southeast Asia, Africa, the Middle East, and Latin America, SMEs cannot afford logistical inefficiencies. The pursuit of cost-effective warehouse racking is a strategic imperative that demands a sophisticated understanding of engineering, economics, and operational workflow. It is a deliberate move away from short-term savings and toward long-term value creation.

By prioritizing professional design, investing in quality materials, selecting the right system for the operational profile, and partnering with an expert with local knowledge, business owners can transform their warehouse from a cost center into a powerful engine for growth. A truly cost-effective warehouse racking system is more than steel and bolts; it is the backbone of a resilient, scalable, and profitable supply chain, ready to meet the demands of today and the opportunities of tomorrow.

Frequently Asked Questions (FAQs)

1. What is the typical lead time for a custom-designed racking system in a region like Southeast Asia?

Lead times can vary based on project complexity and system customization. For a standard selective pallet racking system, a typical timeline from finalized design to completed installation is 5 to 9 weeks. More complex projects, such as those involving mezzanines or high-density systems, may require 10 to 14 weeks. A reputable provider will always provide a detailed project schedule after the initial site survey.

2. How does the procurement process work, and what information do you need to provide a quotation?

The process begins with a consultation to understand your business needs. To generate an accurate proposal for a cost-effective warehouse racking system, we require key details: a list of your pallet sizes and weights, your inventory profile (fast vs. slow movers), a detailed warehouse layout drawing with column locations and clear heights, and information about your material handling equipment. This allows us to engineer a solution that is precisely tailored to your operation.

3. Are there any hidden costs we should be aware of when budgeting for a new racking system?

Transparency is key. The quotation for a cost-effective warehouse racking system should clearly itemize all major costs: racking components, delivery, professional installation, and any necessary site preparation work. Potential “hidden” costs often arise from unforeseen site conditions, such as an uneven floor that requires leveling, or additional electrical work for lighting under a mezzanine. A professional site survey aims to identify and quantify these potential issues upfront.

4. Can your racking systems be integrated with the warehouse management system (WMS) we plan to implement next year?

While the physical racking itself does not directly interface with a WMS, a well-designed, logical storage layout is the fundamental enabler for an effective WMS. We design the cost-effective warehouse racking system with a clear, systematic location numbering scheme that can be seamlessly incorporated into your future WMS, ensuring a smooth digital transition and maximizing the software’s efficiency gains.

5. What happens if we need to expand or reconfigure the system in two years? Do you offer those services?

Absolutely. The modular nature of our cost-effective warehouse racking solutions is a core design feature. We provide expansion and reconfiguration services, supplying additional components and our technical team to modify the existing layout. This ensures the system continues to evolve with your business, protecting your initial investment and maintaining its cost-effective performance over its entire lifespan.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com