📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Introduction: The Calculus of Scale in Modern Logistics Infrastructure

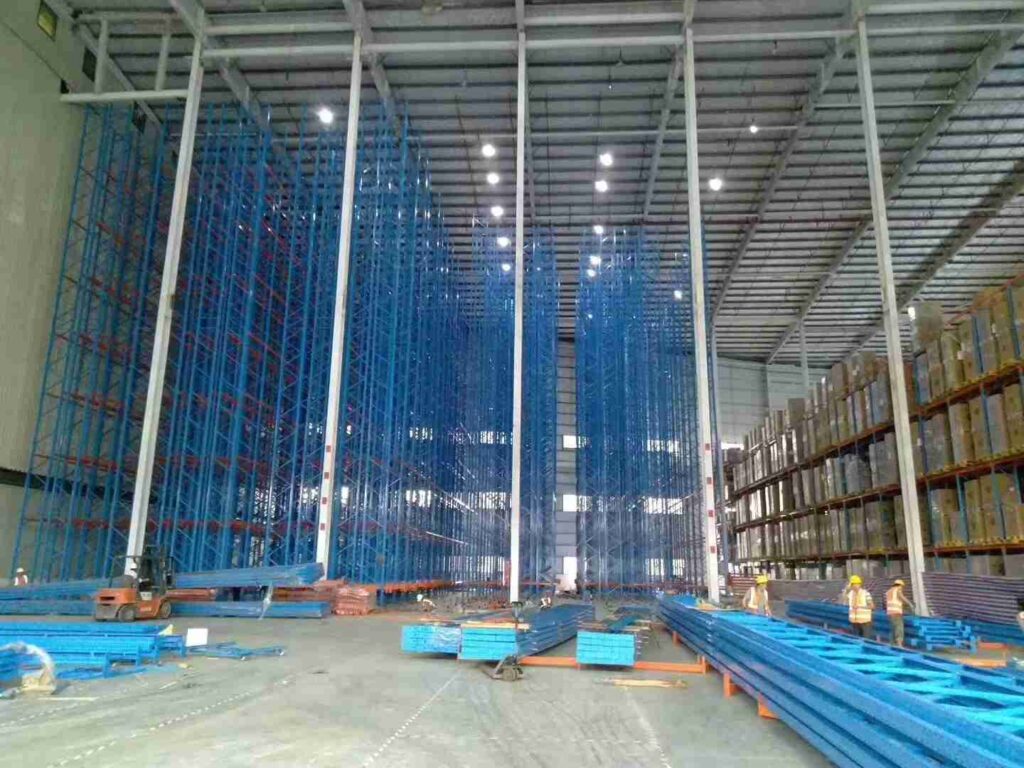

For the strategic decision-maker orchestrating the development of a major logistics hub in the burgeoning markets of Southeast Asia or Africa, the procurement of storage infrastructure transcends a simple capital expenditure line item. It represents a foundational, long-term investment in operational resilience, scalability, and competitive velocity. In this high-stakes environment, securing genuine bulk pallet racking discounts is not merely a purchasing tactic; it is a critical component of financial and operational strategy. However, the most astute developers recognize that the lowest per-unit price is a hollow victory if it compromises system integrity, delays project commissioning, or limits future adaptability.

This comprehensive guide articulates a more profound value proposition. It details how partnering with a specialist engineering firm transforms the pursuit of bulk pallet racking discounts into a holistic strategy for building superior, future-ready storage capacity. The focus is on achieving those significant economies of scale while simultaneously guaranteeing the structural performance, rapid deployment, and automation-ready design that define world-class logistics hubs in regions like Vietnam’s industrial corridors, Thailand’s EEC, or Nigeria’s port-distribution networks. The ensuing discourse will demonstrate how true value is engineered into every component, long before the first upright frame is erected.

Section 1: Deconstructing True Value in Bulk Pallet Racking Procurement

The surface-level allure of a discounted price per pallet position is understandable. Yet, for projects involving thousands of positions, a myopic focus on this single metric invites significant downstream risk and cost. A sophisticated procurement approach redefines value around total lifecycle performance.

The Multifaceted Nature of Bulk Pallet Racking Discounts

Authentic bulk pallet racking discounts emerge from efficiencies across the entire supply and engineering chain. A reputable provider leverages the scale of a large order to optimize:

Raw Material Sourcing: Procuring high-tensile steel in mill quantities, not in fragmented batches, ensures material consistency and secures better pricing, a saving passed directly to the client.

Production Line Optimization: Dedicating a factory line to a single, large order eliminates the downtime and recalibration inherent in multiple small runs. This streamlined manufacturing is a primary engine for bulk pallet racking discounts.

Unified Logistics: Consolidating the shipment of hundreds of tonnes of racking into a coordinated freight operation—from factory to port, through customs, to final site delivery—dramatically reduces per-unit shipping costs and administrative overhead. This logistical efficiency directly contributes to the overall bulk pallet racking discounts offered.

Engineering Amortization: The structural design and calculation effort for a 10,000-pallet system is not ten times that of a 1,000-pallet system. This engineering efficiency allows for robust, custom-designed solutions without proportional cost escalation, enhancing the value of the bulk pallet racking discounts.

The Critical Interplay Between Discounts and Design Specifications

A common pitfall is comparing bulk pallet racking discounts between suppliers without rigorous specification alignment. A quoted discount is meaningless without absolute clarity on:

Steel Grade and Yield Strength: Are uprights manufactured from S235, S355, or higher-grade steel? The difference directly impacts load capacity and longevity.

Connection Method: Are beams secured with standard safety clips, or with bolted, moment-resisting connections for seismic zones or exceptional stability requirements?

Finish Specification: Is the powder coating a standard 60-micron thickness, or an 80-micron+ epoxy-polyester finish for humid, corrosive environments common in coastal Southeast Asia and West Africa?

The most advantageous bulk pallet racking discounts are those applied to a transparent, performance-based specification, not a vague commodity offering. True value is realized when these bulk pallet racking discounts are secured on a system engineered to a precise technical data sheet, ensuring every component meets the hub’s specific duty cycle.

Section 2: Engineering High-Capacity Systems for Extreme Duty Cycles

The term “high-capacity” in a regional logistics hub context must encompass both static weight-bearing and dynamic operational endurance. These systems are subject to constant loading/unloading cycles, occasional impacts, and the relentless demand of multi-shift operations.

Structural Philosophy: Beyond Catalog Ratings

Providers offering serious bulk pallet racking discounts for large-scale projects must back them with demonstrable engineering rigor. This involves:

Dynamic Load Analysis: Calculating loads not in a perfect static state, but accounting for the kinetic energy of a laden pallet being placed into the rack at operational speeds. Engineering software models these forces to ensure beam deflection remains within safe, functional limits (typically < L/200).

Upright Frame Integrity: Specifying closed-section or reinforced open-section uprights for clear heights above 10 meters is non-negotiable. This prevents column buckling and ensures vertical alignment, which is paramount for narrow-aisle operations. The design of the base plate and its anchor bolt pattern is meticulously calculated for the specific slab construction and seismic loads of the region.

System-Wide Safety Factors: Adherence to international standards (FEM, RMI) is the baseline. For critical infrastructure, responsible engineers apply additional, project-specific safety factors, particularly for areas with less predictable forklift operator training or where maintenance intervals may be extended. These factors are built into the design before bulk pallet racking discounts are calculated, ensuring safety is never discounted.

Configuration for Optimal Density and Throughput

High capacity is a function of both strength and spatial intelligence. Intelligent design leverages bulk pallet racking discounts to create denser, more accessible storage.

Push-Back and Drive-In Racking for High-Density Bulk Storage: For hubs storing large quantities of homogeneous SKUs (e.g., beverages, packaged goods), combining bulk pallet racking discounts with push-back or drive-in configurations can increase storage density by up to 75% compared to selective racking. This is a strategic use of the bulk pallet racking discounts to maximize the ROI on expensive warehouse cubic volume.

Integration with Material Handling Equipment (MHE): The racking design cannot be isolated from the equipment that serves it. Detailed collaboration ensures aisle widths are optimized for the client’s chosen fleet—whether standard counterbalance forklifts, reach trucks, or turret trucks. This synergy, planned during the initial design phase where bulk pallet racking discounts are secured, prevents costly operational bottlenecks and maximizes the utility of every square meter purchased with those bulk pallet racking discounts.

Section 3: Regional Adaptation: The Hallmark of a Strategic Partner

A storage system destined for a hub in Indonesia must perform as reliably as one in South Africa, yet the environmental and operational challenges differ markedly. A supplier worthy of a large-scale contract and its associated bulk pallet racking discounts must demonstrate deep regional competence.

Climatic and Corrosion Defence Strategies

The humidity of Bangkok, the salty air of Dar es Salaam, and the variable conditions in Nairobi demand proactive corrosion protection. This is not an area for cost-cutting disguised as bulk pallet racking discounts.

Advanced Surface Preparation: Prior to coating, steel undergoes a multi-stage chemical pretreatment (e.g., zinc phosphate) to create a microcrystalline layer that dramatically improves paint adhesion and corrosion resistance.

Coating Technology: Electrostatic application of epoxy-polyester hybrid powders provides a uniform, durable finish. For extreme environments, a chromate-free pretreatment combined with a specific primer and topcoat system may be specified. These technical choices, factored into the project cost before final bulk pallet racking discounts are applied, safeguard the structural asset for its intended 20+ year lifespan.

Hot-Dip Galvanizing Options: For projects in highly corrosive port-side locations or for clients in the chemical industry, hot-dip galvanizing (HDG) after fabrication offers unparalleled protection. A competent partner will manage the complex logistics of HDG for bulk orders, integrating this cost effectively to preserve the value of the bulk pallet racking discounts.

Navigating Local Supply Chains and Skills Availability

A key risk for large projects in emerging markets is dependency on a single, distant supply chain. Strategic partners mitigate this by:

Regional Manufacturing Hubs: Utilizing production facilities within the target regions (e.g., Southeast Asia, the Middle East) to reduce lead times, lower transport costs, and provide more responsive support. This regional presence often enables more competitive and stable bulk pallet racking discounts.

Local Capacity Building: The installation methodology incorporates training for locally sourced labor under the supervision of certified expatriate or regional supervisors. This not only controls installation costs but also builds a local knowledge base for future maintenance and modifications, protecting the long-term value of the investment made with the bulk pallet racking discounts.

Section 4: The Fast-Track Deployment Methodology: From Quote to Operation

The promise of bulk pallet racking discounts is financially compelling, but delayed project timelines erode those savings swiftly. A guaranteed fast-track deployment process is therefore an inseparable part of the value equation.

Phased Delivery and Just-in-Time Logistics

Rather than a single, overwhelming delivery, a sophisticated provider implements a phased delivery schedule synchronized with the construction timeline.

Site Readiness Coordination: Delivery of initial components is timed with the completion of the sealed warehouse envelope and floor. Subsequent shipments arrive as installation progresses.

Digital Tracking and Customs Facilitation: Clients are provided with real-time tracking for every container. The supplier’s logistics team manages all customs documentation and clearance in the destination country, a critical service that prevents costly port delays and ensures the schedule underpinning the bulk pallet racking discounts is maintained.

Professional Installation: The Final Crucible of Quality

The most expertly engineered racking, procured with advantageous bulk pallet racking discounts, can be compromised by poor installation. The industry-leading approach is a turnkey installation service.

Certified Installation Teams: Deployment is led by factory-trained and certified installation supervisors using calibrated torque wrenches, laser levels, and proprietary assembly jigs. They enforce a strict quality control protocol, verifying plumb, level, and torque at every stage.

Sequential Build Strategy: Installation follows a pre-planned grid sequence, allowing other trades (sprinkler fitters, electricians) to work in parallel without conflict, compressing the overall project critical path. This disciplined execution is the final, critical step in realizing the full value of the bulk pallet racking discounts by ensuring the asset is operational on or ahead of schedule.

Section 5: Future-Proofing the Investment: The Automation-Ready Platform

A logistics hub built today must be designed for the automation of tomorrow. The upfront pursuit of bulk pallet racking discounts must not foreclose this evolutionary path.

Designing for Dimensional Fidelity and Interface Precision

Automated storage and retrieval systems (AS/RS), shuttle systems, and AGVs demand exceptional precision from their physical environment.

Tolerance Stack-Up Management: Engineering design accounts for cumulative tolerances in manufacturing, installation, and floor flatness. The stated goal is often a system vertical alignment within ±5mm over 15 meters of height, a specification that must be committed to before bulk pallet racking discounts are finalized.

Standardized Interface Points: The racking design incorporates standardized mounting points for guide rails (for rack-guided VNA cranes), RFID tags for inventory location, and provisions for integrating pick-to-light or put-to-light systems. This foresight, embedded in the initial design and covered by the bulk pallet racking discounts, makes future automation projects plug-and-play, avoiding prohibitively expensive retrofitting.

The Digital Handover: Data as a Lasting Asset

Upon project completion, the client receives more than a physical structure. They are provided with a comprehensive digital twin package:

As-Built Drawings (CAD & PDF): Reflecting any minor adjustments made during installation.

Full Bill of Materials (BOM): A critical document for asset management, insurance, and future procurement.

Load Certification Documents: Signed and stamped by chartered engineers, affirming the system’s design integrity.

This data package, an integral part of the service accompanying the bulk pallet racking discounts, becomes a permanent asset for facility management and future planning.

Conclusion: The Confluence of Scale, Engineering, and Execution

For the developer of a major logistics hub in Southeast Asia or Africa, the journey to secure bulk pallet racking discounts is, in reality, a vetting process for a long-term engineering and operational partner. The most significant bulk pallet racking discounts are those delivered by a partner who views the project through the same strategic lens: as a critical piece of infrastructure that must be cost-effective, supremely robust, rapidly deployable, and inherently adaptable.

The superior outcome is achieved when the pursuit of bulk pallet racking discounts is seamlessly integrated with a commitment to region-specific engineering, a militaristic project deployment methodology, and a visionary design philosophy that embraces future automation. It is at this confluence that true value is architected—value measured not just in immediate capital savings, but in decades of reliable, efficient, and scalable warehouse operations that form the competitive backbone of a leading logistics hub. The dialogue begins not with a request for a discount, but with a shared blueprint for success.

FAQs (Frequently Asked Questions)

1. How are your bulk pallet racking discounts structured for a multi-phase project where storage needs may be installed over 18-24 months?

We employ a contractual price-hold mechanism for phased projects. Upon commitment to the master plan, clients lock in the tiered bulk pallet racking discounts for the entire project volume. Each phase is then triggered and invoiced as needed, protecting against raw material inflation and ensuring budget certainty. This approach allows developers to secure the most advantageous bulk pallet racking discounts upfront while aligning expenditures with their construction cash flow.

2. Can you provide independent third-party load testing certificates for your racking components, especially when seeking bulk pallet racking discounts on ultra-high-capacity systems (e.g., beams rated > 3,000kg UDL)?

Absolutely. For all high-capacity components, especially those procured under significant bulk pallet racking discounts, we provide certified test reports from accredited laboratories (e.g., SGS, TÜV). These reports document destructive and non-destructive tests on sample beams and connections, validating the published load capacities. This independent verification is a non-negotiable part of our quality assurance, ensuring the structural promises behind the bulk pallet racking discounts are empirically grounded.

3. What is your protocol for conducting a site-specific seismic analysis, and how does this impact the final design and the offered bulk pallet racking discounts?

Our engineering team initiates a location-specific seismic risk assessment based on local building codes (e.g., IBC, Eurocode 8, or national standards). This analysis determines the required seismic design category. The racking design is then modeled using specialized software to apply the relevant lateral forces. While seismic reinforcement (e.g., additional bracing, moment-resisting connections) may influence the final system cost, our bulk pallet racking discounts are applied to the total engineered solution. We never compromise on life-safety specifications to preserve a discount rate.

4. How do you manage the interface and potential liability demarcation between your racking installation and the client’s chosen automation integrator (e.g., for an AS/RS crane installation)?

We establish a clear tripartite interface agreement. Our scope, covered by the bulk pallet racking discounts, includes delivering a racking structure that meets the agreed dimensional and alignment tolerances specified by the automation vendor. We provide foundational anchor points and interface drawings. The automation integrator is then responsible for installing and calibrating their machinery onto our certified structure. This clear demarcation, defined in early project meetings, prevents scope gaps and ensures seamless integration, protecting the value engineered into the system through the bulk pallet racking discounts.

5. For a greenfield site with limited local technical support, what post-installation support and training packages do you offer alongside the bulk pallet racking discounts?

Our support extends beyond installation. We offer tiered annual service contracts that include scheduled inspections, bolt re-torquing services, and damage assessment. Crucially, we conduct comprehensive “handover training” for the client’s facility management team, covering daily inspection checkpoints, basic maintenance, and protocols for reporting incidents. This commitment to lifecycle support ensures the infrastructure secured with bulk pallet racking discounts remains a performing asset, maximizing its operational lifespan and safeguarding the initial investment.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com