📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

ASRS-Compatible Racking: The Ultimate Guide to Future-Proof Warehousing Operations

Introduction: The Warehouse Revolution Powered by ASRS-Compatible Racking

The logistics industry stands at a crossroads where manual storage systems simply can’t keep pace with modern demands. ASRS-compatible racking (Automated Storage and Retrieval Systems) has emerged as the cornerstone of next-generation warehousing, enabling businesses to dramatically increase storage density, slash operational costs, and eliminate inefficiencies plaguing traditional setups.

This definitive guide dives deep into why ASRS-compatible racking represents the single most important infrastructure upgrade for progressive warehouses, how it integrates with cutting-edge automation, and what separates high-performance installations from mediocre ones.

For supply chain directors, warehouse managers, and operations executives, this resource delivers actionable intelligence on selecting, implementing, and optimizing ASRS-compatible racking to achieve:

✔ 40-60% higher storage capacity in existing footprints

✔ 90%+ accuracy rates in inventory management

✔ 24/7 operational capabilities without labor constraints

✔ Future-proof scalability for business growth

H1: ASRS-Compatible Racking Defined: The Engine of Automated Warehouses

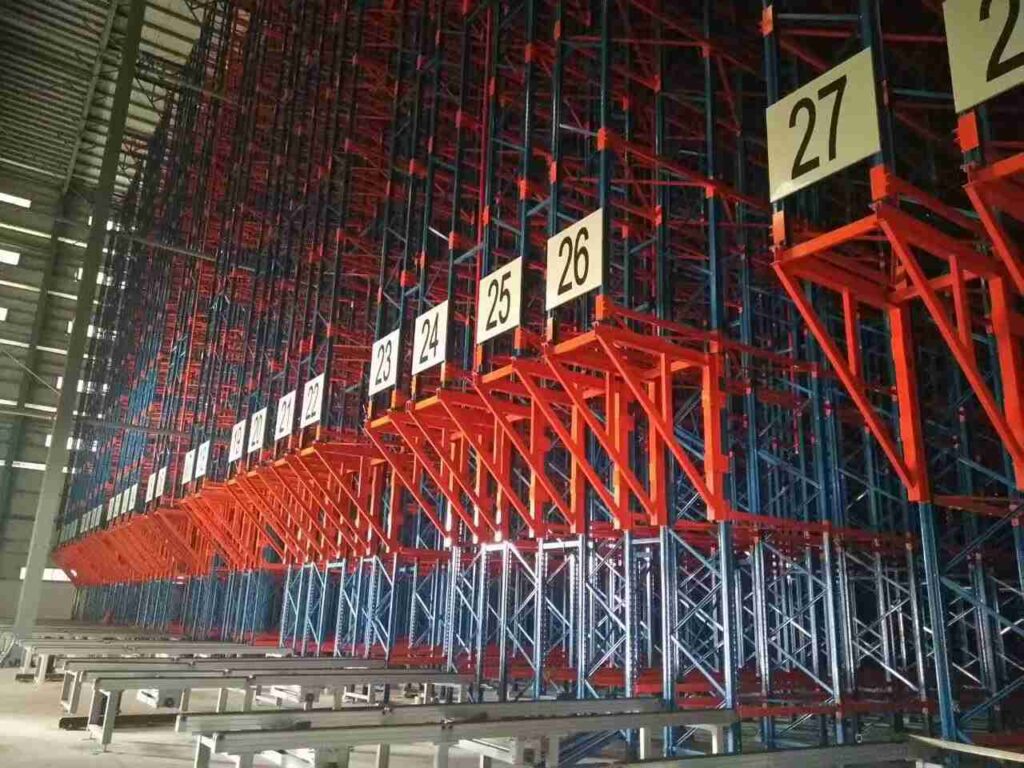

H2: The Fundamental Architecture of ASRS-Compatible Racking

Unlike conventional storage solutions, ASRS-compatible racking systems are precision-engineered structures designed specifically for seamless integration with automated material handling equipment. These systems feature:

- Ultra-precise structural tolerances (±2mm alignment) for robotic operations

- Reinforced load-bearing capacity (up to 50% stronger than standard racking)

- Standardized interface points for automated cranes and shuttles

- Modular expansion capabilities for phased implementation

H3: The Critical Differences from Conventional Racking

Where traditional selective pallet racking requires 12-15 foot aisles for forklift access, ASRS-compatible racking enables:

| Feature | Traditional Racking | ASRS-Compatible Racking |

|---|---|---|

| Aisle Width | 10-15 ft | 5-8 ft (narrow aisle) or 0 ft (deep lane) |

| Operational Speed | 15-20 pallets/hour | 50-80 pallets/hour |

| Storage Height | Typically <30 ft | Up to 120 ft in high-bay configurations |

| Accuracy Rate | 92-95% | 99.9%+ with automation |

This paradigm shift allows ASRS-compatible racking to deliver 3-5X greater throughput while occupying 30% less floor space.

H1: The Transformational Benefits of ASRS-Compatible Racking

H2: 1. Revolutionary Space Utilization

ASRS-compatible racking redefines warehouse density through:

➔ Vertical Maximization

- Enables storage heights exceeding 100 feet where local codes permit

- Converts previously unusable overhead space into high-value inventory zones

➔ Dynamic Slotting Algorithms

- AI-driven storage optimization based on pick frequency, product dimensions, and expiration dates

- Continuously reorganizes inventory placement for peak efficiency

Case Study: A European pharmaceutical distributor achieved 58% more storage capacity within their existing 150,000 sq ft facility by implementing ASRS-compatible racking with automated vertical lift modules.

H2: 2. Unparalleled Operational Precision

ASRS-compatible racking eliminates the ”human factor” in warehouse operations:

✔ Zero mis-picks through barcode/RFID verification at every touchpoint

✔ Millimeter-perfect positioning via servo-controlled automation

✔ Real-time inventory visibility with <1% variance

Operational Impact:

- Order accuracy improves from industry-average 95% to 99.99%

- Returns processing decreases by 60-75%

- Cycle counting becomes fully automated

H2: 3. Financial Advantages That Compound Over Time

While the capital expenditure for ASRS-compatible racking exceeds traditional systems, the total cost of ownership tells a different story:

| Cost Category | 5-Year Savings |

|---|---|

| Labor Reduction | 3.5M per 100,000 sq ft |

| Energy Efficiency | 25-40% lower HVAC/lighting costs |

| Inventory Shrinkage | 80% reduction in lost/damaged goods |

| Insurance Premiums | 15-25% discounts for automated facilities |

ROI Benchmark: Most operations achieve full payback within 2.5-4 years through these cumulative savings.

H1: The Four Primary Types of ASRS-Compatible Racking Systems

H2: 1. Unit-Load ASRS (Pallet-Handling Systems)

Ideal For:

- Full pallet storage/retrieval

- High-volume distribution centers

- Heavy industrial applications

Technical Specifications:

- Load capacity: Up to 3,000 kg per pallet position

- Throughput: 50-80 pallets/hour per crane

- Height capability: 25-45 meters

Best Practice: Combine with automated stretch wrapping stations for complete pallet handling automation.

H2: 2. Mini-Load ASRS (Tote & Bin Systems)

Perfect For:

- E-commerce fulfillment

- Spare parts logistics

- Pharmaceutical storage

Key Features:

- Dual-command cycles (simultaneous storage/retrieval)

- Integrated weighing systems

- LED pick-to-light interfaces

Innovation Spotlight: Next-gen mini-load ASRS-compatible racking now incorporates 3D vision systems for mixed-SKU handling.

H2: 3. Shuttle-Based ASRS (High-Density Storage)

Breakthrough Advantages:

- 100% first-in, first-out (FIFO) compliance

- Ultra-deep lane storage (up to 50 pallets deep)

- Energy-recovery braking systems

Implementation Tip: Ideal for cold storage facilities where energy efficiency is paramount.

H2: 4. Vertical Buffer Modules (VBM)

Specialized Applications:

- Production line feeding

- Kitting operations

- High-value item security

Technical Edge:

- 5-second retrieval times

- Climate-controlled options

- Integrated fire suppression

H1: Implementing ASRS-Compatible Racking: A Step-by-Step Framework

H2: Phase 1: Comprehensive Facility Assessment

Critical Evaluation Points:

- Structural Analysis

- Floor load capacity

- Ceiling height clearances

- Column spacing limitations

- Operational Profiling

- Current vs projected SKU count

- Seasonal volume fluctuations

- Growth projections

H2: Phase 2: System Customization & Engineering

Customization Options:

- Multi-depth configurations

- Hybrid manual/automated zones

- Specialized load-handling attachments

Engineering Considerations:

- Seismic reinforcement for high-bay installations

- Vibration dampening for precision operations

- Corrosion-resistant coatings for harsh environments

H2: Phase 3: Integration With Warehouse Ecosystem

Must-Have Interfaces:

- WMS (Warehouse Management System)

- ERP connectivity

- Automated guided vehicle (AGV) pathways

- Packaging automation hand-off points

Integration Challenge:

Overcoming legacy system incompatibilities through:

✔ Middleware solutions

✔ API-based architecture

✔ Data normalization protocols

H1: The Future of ASRS-Compatible Racking: 2025 & Beyond

H2: AI-Driven Predictive Optimization

Emerging machine learning algorithms will enable ASRS-compatible racking systems to:

- Anticipate stock movements before orders arrive

- Self-reconfigure storage patterns based on predictive analytics

- Automatically rebalance loads to minimize energy consumption

H2: Sustainable Warehouse Revolution

Next-generation ASRS-compatible racking contributes to:

♻ Regenerative braking systems that return energy to the grid

♻ Solar-integrated rack structures that double as power generators

♻ Biodegradable composite materials for eco-conscious operations

H2: Human-Machine Collaboration 2.0

Advanced ASRS-compatible racking installations will feature:

- Augmented reality interfaces for maintenance staff

- Voice-controlled override systems

- Collaborative robotics work zones

H1: Conclusion – The Strategic Imperative of ASRS-Compatible Racking

For forward-thinking operations, ASRS-compatible racking has transitioned from competitive advantage to operational necessity. The combination of unmatched density, flawless accuracy, and continuous operational readiness creates an insurmountable lead for early adopters.

Three Strategic Takeaways:

- The cost of inaction now exceeds implementation costs for most operations

- System flexibility allows phased adoption to manage capital outlay

- Technology convergence with AI/IoT makes this the ideal implementation window

FAQs: Expert Insights on ASRS-Compatible Racking

1. What’s the minimum warehouse height for ASRS-compatible racking?

While 8-meter clearances enable basic systems, optimal performance requires 12+ meter heights to capitalize on vertical storage advantages.

2. How does ASRS-compatible racking handle irregularly shaped items?

Custom load-handling attachments (clamps, forks, platforms) accommodate 95% of industrial products, with specialized solutions for unique items.

3. What maintenance downtime should we expect?

Premium ASRS-compatible racking systems feature <1% annual downtime through:

- Predictive maintenance alerts

- Hot-swappable components

- Redundant system architectures

4. Can we retrofit our existing racking to be ASRS-compatible?

Limited structural reinforcement projects can upgrade certain systems, but purpose-built ASRS-compatible racking delivers superior performance and longevity.

5. What workforce training is required?

Transition focuses on system monitoring rather than manual handling:

- 40 hours for control center operators

- 16 hours for maintenance technicians

- 8 hours for inventory managers