📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Definitive Global Playbook for Mastering Narrow Aisle Width Requirements

The Unseen Geometry of Warehouse Profitability

In the relentless calculus of modern logistics, empty space is not merely vacant—it is a glaring line item of wasted capital. For warehouse operators and logistics managers across Southeast Asia, the Middle East, Africa, and Latin America, the pressure to do more within existing footprints is a daily reality. The single most powerful lever to pull in this equation is the strategic optimization of narrow aisle width requirements. This is not a minor technical adjustment; it is a fundamental re-engineering of storage geometry that directly dictates profitability, scalability, and competitive resilience.

Mastering narrow aisle width requirements is the cornerstone of achieving transformational storage density gains—often cited as 40% or more. However, this promise is contingent upon a holistic, system-integrated approach. This guide moves beyond simplistic definitions to deliver a masterclass in the engineering, planning, and execution of high-density storage.

It will dissect how precise calculations around narrow aisle width requirements directly inform the selection of specialized equipment—from Articulated Forklifts and Very Narrow Aisle (VNA) turret trucks to automated guided vehicles (AGVs) and automated storage and retrieval systems (AS/RS). We will explore the symbiotic relationship between rack design, floor specification, operational workflow, and regional infrastructure, providing a actionable blueprint for warehouse transformation.

Deconstructing the Aisle: From Empty Corridor to Precision Engineered Envelope

The journey begins with a paradigm shift: an aisle is not merely the space between racking structures. It is a dynamically calculated operational envelope—the three-dimensional zone required for equipment to store and retrieve unit loads safely, efficiently, and repeatedly. Misunderstanding this concept is the root cause of underperforming projects. True expertise in narrow aisle width requirements involves dissecting every component of this envelope.

The foundational formula seems straightforward: Aisle Width = Load Width + (2 x Operational Clearance) + Equipment Width. Yet, each variable holds layers of complexity critical for emerging markets. Consider a ubiquitous 1200mm x 800mm Euro pallet, stored with its 1200mm side facing the aisle. In a conventional layout with a 1200mm-wide counterbalance forklift, the math leads to a sprawling 2700mm+ aisle. The path to high density lies in systematically attacking each variable, with the most significant gains found in minimizing Equipment Width through specialized machinery.

However, focusing solely on this formula is a rookie mistake. Veteran planners know that real-world narrow aisle width requirements are dictated by a host of “forgotten” factors. These include the physical protrusion of rack uprights (which can consume 50-100mm of clearance per side), the reality of non-standard or damaged pallets, and the critical influence of operator skill.

A seasoned VNA operator, trained in precise load handling, can reliably work within tighter tolerances than a novice, effectively reducing the operational clearance needed. Furthermore, the building itself plays a role; column placements, door openings, and traffic flow patterns upstream and downstream of the racking area must be factored into the overall aisle network design, ensuring the narrow aisle width requirements for the storage zone do not create bottlenecks elsewhere.

The Storage Spectrum: Mapping Technology to Operational Ambition

Warehouse storage configurations exist on a clear spectrum defined primarily by their aisle width requirements. Selecting the appropriate point on this spectrum is the first major strategic decision, balancing density goals with operational flexibility and capital expenditure.

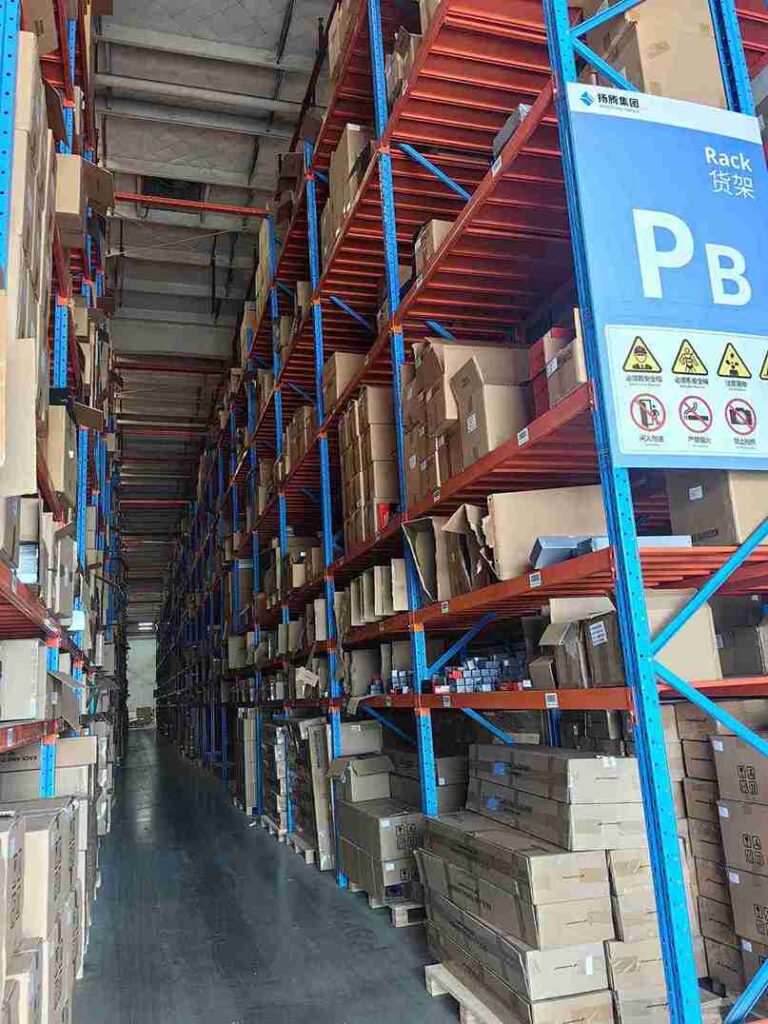

Narrow Aisle (NA) Storage, typically defined by aisles between 2.0 and 2.8 meters, represents the entry point into high-density operations. Here, the standard reach truck or, more effectively, the Articulated Forklift, becomes the workhorse. These machines eliminate the need for a 90-degree turn within the aisle by using a pivoting chassis or a pantograph mechanism to place loads.

The meticulous calculation of narrow aisle width requirements for NA systems focuses on the load, the racking, and the static width of the truck. This configuration can reliably yield a 20-30% increase in storage positions compared to wide-aisle designs and is often the most adaptable starting point for operations in regions like Southeast Asia and Latin America, where flexibility and growth are paramount.

Ascending the density ladder brings us to Very Narrow Aisle (VNA) Storage, where aisles shrink to between 1.5 and 1.8 meters. This regime demands a total system commitment. VNA trucks, or turret trucks, operate with the operator elevating with the forks. Guided by rails or wires, they travel perfectly centered in the ultra-narrow channel. The forks rotate 180 degrees to either side, depositing and retrieving loads. In this context, narrow aisle width requirements are defined almost entirely by the load dimensions and the safety clearances, as the truck itself does not turn.

Achieving this demands impeccable floor flatness (governed by standards like FEM 10.2.02), robust guidance systems, and high-bay racking. For markets in the Middle East with high-ceilinged facilities, or for cold storage operations in any region where cubic space is extremely expensive, mastering VNA narrow aisle width requirements is the key to unlocking unparalleled storage efficiency and ROI.

At the pinnacle of density lies the Automated & Hybrid Solution, where the aisle becomes a dedicated machine pathway. In Automated Storage and Retrieval Systems (AS/RS), the narrow aisle width requirements can be minimized to as little as 1.3 meters, as the system is designed for a single, precise machine. Similarly, modern AGVs can be programmed to navigate aisles built to NA or VNA specifications, using LiDAR and vision systems instead of physical guides.

When planning for automation, the narrow aisle width requirements are locked in during the design phase and are non-negotiable, as they are hard-coded into the facility’s physical and digital architecture. This approach is gaining traction in sectors with high labor costs or demanding multi-shift operations, offering a compelling blend of density, speed, and precision.

The Structural Partner: Racking Design That Enables Narrow Aisles

The storage racking is far from a passive skeleton; it is the critical, enabling partner to the material handling equipment. Its design fundamentally dictates what is achievable regarding narrow aisle width requirements. A failure to co-specify racking and equipment in unison is a common project pitfall.

For the ubiquitous Selective Pallet Racking system, adaptation for narrow aisles involves specific engineering choices. Upright frames are selected with minimized depths to provide a larger “clear opening” for fork access, directly impacting the operational clearance variable in the narrow aisle width requirements formula. Beam connectors must feature positive locking mechanisms to prevent accidental dislodgement from any angle of approach—a vital safety consideration in tight spaces. The precise calculation of beam levels (vertical beam spacing) is also crucial; minimizing the “overhead clearance” above each pallet maximizes the utility of the vertical cube in a high-bay VNA installation, improving the overall ROI of the system built around stringent narrow aisle width requirements.

Other racking types offer alternative density strategies. Drive-In/Drive-Through systems essentially eliminate aisles for bulk storage, representing the ultimate in floor-space density for homogeneous products. While not involving narrow aisle width requirements in the traditional sense, they require a different set of precision calculations around lane depth and load-bearing specifications for the guiding rails within the structure. Push-Back Racking, storing 3-5 pallets deep in a single lane, requires a single access aisle.

The narrow aisle width requirements for that front aisle are calculated similarly to a selective system, but the dynamic load handling within the rack’s depth adds another layer of design complexity. The choice between these systems is driven by SKU profile and inventory rotation policy (FIFO vs. LIFO), but the access aisle’s design remains governed by the core principles of calculating narrow aisle width requirements.

The Non-Negotiable Foundation: Floor Flatness and Guidance

The most meticulously calculated narrow aisle width requirements are rendered irrelevant by an inadequate floor. This is the point where theoretical design collides with physical reality. A VNA truck operating in a 1.6-meter aisle with a 1200mm load may have a functional clearance of just 200mm per side. A floor deviation that causes a mere 10mm of mast sway can lead to catastrophic rack impact, load instability, and systemic failure.

The international benchmark for floor specification in high-density warehousing is the FEM 10.2.02 standard. It classifies floors for different use cases. For VNA operations, Class 100 (or sometimes stricter) is typically mandated, specifying extremely tight tolerances for local elevation changes (e.g., no more than 3mm deviation over a 300mm measuring span).

Achieving this often requires professional assessment with laser scanning equipment. In existing facilities, remediation may involve diamond grinding, application of specialized self-leveling toppings, or, in severe cases, a partial re-pour. For operators in Africa or parts of Southeast Asia, where local construction standards may vary, insisting on a pre-installation floor survey and contractual flatness guarantees is not an optional extra—it is essential risk mitigation for any project involving tight narrow aisle width requirements.

Guidance systems are the technological counterpart to physical flatness. Wire Guidance, a proven and robust technology, uses a buried wire emitting a low-frequency signal. Rail Guidance employs a physical steel rail, offering supreme precision and handling lateral forces during high-level order picking. Inertial or Laser Guidance uses onboard gyroscopes and lasers targeting wall-mounted reflectors, offering greater route flexibility. The choice of guidance is integral to defining the operational narrow aisle width requirements, as it ensures the machine’s path is predictable and repeatable, safeguarding the minimal clearances the entire design is based upon.

A Regional Blueprint: Tailoring Solutions to Local Realities

A textbook solution applied without local context is a prelude to failure. Success in global markets hinges on adapting the principles of narrow aisle width requirements to regional climates, infrastructures, and economic realities.

In Southeast Asia, high humidity and rapid, scalable growth are defining factors. Humidity can affect wooden pallet dimensions and promote corrosion. Solutions must incorporate hot-dip galvanized racking and MHE built with corrosion-resistant components. The growth trajectory of e-commerce favors scalable systems. A strategic approach often involves implementing a robust NA system on a properly prepared slab, with a racking design that can later support conversion to a guided VNA or AGV system as volumes justify. The initial focus is on achieving significant density gains with flexible narrow aisle width requirements that allow for future technological evolution.

The Middle East presents challenges of extreme heat, dust, and often, expansive building heights. Dust infiltration is a primary concern for the optical sensors of AGVs and automated systems, necessitating enclosed units or rigorous cleaning protocols. The high ambient temperature impacts battery performance and requires MHE with specifically rated cooling systems. However, the common availability of high-clearance warehouses makes VNA systems an exceptionally compelling option. The significant upfront investment in super-flat flooring and climate-controlled operator cabins pays off dramatically in the utilization of the valuable cubic airspace, making the strict narrow aisle width requirements of VNA a highly profitable specification.

Across many parts of Africa, the key considerations are infrastructure adaptability and Total Cost of Ownership (TCO). Intermittent power supply can cripple fully automated systems without robust backup plans. The focus shifts toward highly durable, mechanically robust NA systems with excellent local serviceability. Semi-automated solutions, or lean NA designs using articulated forklifts, often provide the optimal balance—delivering meaningful improvements in storage density through optimized narrow aisle width requirements while remaining operable and maintainable in less predictable environments. Durability and support trump technological complexity.

Latin America’s diverse industrial base, from agriculture to advanced manufacturing, demands a tailored approach. In the food and beverage sector, Push-Back racking accessed by NA trucks is immensely popular for its density and natural FIFO product flow. Across the board, there is a sharp, calculated focus on demonstrable ROI. Projects must clearly articulate the payback period derived from the capacity gains unlocked by redefining narrow aisle width requirements. Phased implementations that start with a high-quality racking system and later add automation as volumes grow are a commonly successful model, allowing capital expenditure to align with proven business growth.

The Implementation Odyssey: From Data to Operational Reality

Translating the theory of narrow aisle width requirements into a live, high-performing warehouse is a phased, disciplined odyssey. Skipping steps is the fastest route to costly underperformance.

The voyage begins with Data-Driven Discovery. This is not a cursory glance at inventory lists. It involves a deep analysis of the SKU profile: dimensions, weights, turnover velocity (ABC analysis), seasonality, and projected growth. This data forms the immutable bedrock for all subsequent decisions about narrow aisle width requirements and storage media. Following this, Conceptual Design & Simulation uses this data to model multiple layout scenarios. Advanced software can simulate throughput, identify potential bottlenecks at receiving/shipping docks, and stress-test different narrow aisle width requirements under peak load conditions. This virtual prototyping is invaluable for de-risking the capital investment.

Concurrently, a Site Infrastructure Audit is non-negotiable. This includes the formal floor flatness survey, but also extends to assessing electrical supply for charging stations, lighting levels for high-bay picking, and the adequacy of fire suppression systems for dense storage layouts. Once the site capability is understood, the Total System Specification can be finalized. This is the stage where racking engineers and MHE specialists must work in lockstep. The racking design (beam levels, upright strength) informs the lift height and capacity of the truck, and the truck’s turning radius and mast design confirm the final narrow aisle width requirements. This co-specification ensures harmony between all system components.

The physical Phased Implementation should be meticulously planned, often around low-activity periods. Creating a pilot zone—a single aisle or bay—allows for the training of operators, the verification of WMS slotting logic, and the ironing out of process kinks before full-scale rollout. Finally, Training & Process Transformation is the critical human element. New equipment with different operational characteristics requires certified training. New, denser layouts mandate revised pick paths and put-away logic within the Warehouse Management System (WMS). Investing in this change management ensures the sophisticated system designed around precise narrow aisle width requirements is operated to its full potential.

The True ROI Calculation: Quantifying the Transformation

While the headline figure of a 40% storage increase is compelling, the true Return on Investment (ROI) from optimizing narrow aisle width requirements is multifaceted and profound.

Direct Real Estate Savings or Deferral: The most obvious benefit. Increasing capacity within the existing envelope can defer or eliminate the need for expensive new construction or leased space, a significant capital outlay.

Operational Efficiency Gains: Shorter, more direct travel paths within narrow aisles can reduce cycle times for put-away and retrieval by 15-25%. This means existing staff can handle higher throughput, or fleet sizes can be optimized, reducing labor and MHE costs.

Enhanced Accuracy and Safety: A structured, guided system minimizes ad-hoc behavior and reduces the incidence of rack impacts and product damage. Improved inventory visibility and control are natural byproducts of a more organized, cube-optimized facility.

Energy and Sustainability Benefits: Electric-powered NA/VNA trucks are far more energy-efficient than traditional internal combustion forklifts. They consume energy primarily for lifting, not for traversing vast distances. Reducing the warehouse footprint also lowers lighting and HVAC costs per stored pallet.

The Holistic ROI Formula: A comprehensive analysis looks like this: Total Project ROI = (Value of Gained Storage Capacity + Annual Operational Savings + Reduction in Inventory Shrinkage) / (Total Project Cost + Annual Increased Maintenance & Training). A well-executed project based on rigorous narrow aisle width requirements analysis typically demonstrates a payback period of 2 to 4 years, after which the gains flow directly to the bottom line.

Conclusion: Building Your Strategic Pathway

Optimizing narrow aisle width requirements is, ultimately, a strategic declaration—a commitment to treating warehouse space as a precious, high-performance asset rather than a passive container. It is a journey from intuition to engineering, from corridors of wasted potential to precision-engineered supply chain arteries.

For logistics leaders in Bangkok, Dubai, Lagos, or São Paulo, the principles are universal, but the application demands local intelligence. The journey begins not with a purchase order, but with a question: “What is the true operational cost of our existing aisles?” From there, the path unfolds through data analysis, system design, and disciplined implementation. By mastering the intricacies of narrow aisle width requirements, businesses do not just store more—they build a foundation for agility, resilience, and sustained competitive advantage in an ever-demanding global marketplace.

Frequently Asked Questions (FAQs)

1. How do seismic activity considerations in certain regions, like parts of Southeast Asia or Latin America, influence narrow aisle width requirements and racking design?

Seismic zones demand a fundamental re-evaluation of both racking design and the associated narrow aisle width requirements. Racking must be engineered to specific seismic codes (e.g., IBC, FEM 10.2.08) with increased load capacities, specialized bracing, and base plates designed to resist lateral forces. Crucially, the narrow aisle width requirements may need to be increased slightly to account for calculated rack deflection during an event, ensuring aisles do not become blocked by bent uprights. Furthermore, guide rails for VNA systems must be securely anchored, and the entire system design must prioritize stability over absolute minimum aisle dimensions. A qualified structural engineer must be involved in the design process from the outset.

2. For businesses handling a wide mix of pallet and non-palletized goods, is a narrow aisle strategy still viable?

Absolutely, but it requires a hybrid “warehouse-within-a-warehouse” approach. The core bulk storage for palletized goods can be organized in a high-density zone with optimized narrow aisle width requirements served by NA or VNA equipment. Adjacent to this, or in a separate zone, smaller, non-palletized items can be stored in carton-flow shelving or on mezzanines.

The key is integrating the two zones through the WMS and material flow. The NA/VNA equipment can bring pallets to a transfer point, where items are broken down for manual picking. This strategy maximizes density where it counts most (bulk pallets) while maintaining flexibility for smaller SKUs. The narrow aisle width requirements are thus applied strategically to the portion of the inventory that will yield the greatest space and efficiency return.

3. What are the critical differences in calculating narrow aisle width requirements for double-deep racking compared to standard selective racking?

Double-deep racking, which stores two pallets deep per facing, introduces a significant complexity: the need for a telescopic fork. The narrow aisle width requirements calculation must now account for the extended length of the fork when retrieving the second pallet. While the aisle itself can be similar to a standard NA aisle (as the truck doesn’t turn), the truck’s mechanism is more complex.

The primary constraint shifts slightly from pure aisle width to the “reach” capability of the truck and the associated deflection of the extended forks. The load beams must also be designed to handle the dynamic forces of a pallet being pulled from the second position. The calculation becomes less about a simple width formula and more about matching the specific truck’s telescopic capabilities to the specific racking depths and load weights.

4. In regions with high costs or limited availability of specialized MHE technicians, what are the best practices for maintaining NA/VNA systems to protect our investment?

Proactive, prevention-focused maintenance is paramount. Develop a rigorous, calendar-based schedule that includes daily operator checklists (for guidance system alerts, fork carriage movement), weekly inspections of critical wear parts (fork tips, guide wheels, sensor cleanliness), and quarterly technical services by a qualified provider, even if they must be flown in. A key strategy is to invest in comprehensive operator training to prevent abuse and enable early fault identification.

Stocking a critical spare parts inventory on-site (fork carriage components, guidance sensors, common hydraulic seals) can drastically reduce downtime waiting for international shipments. Choosing equipment brands with a strong regional support network, even if at a premium, is often the most cost-effective decision long-term for protecting the system built upon precise narrow aisle width requirements.

5. How does the rise of the “phygital” fulfillment model (combining bulk B2B and direct-to-consumer e-commerce) impact planning for narrow aisle width requirements?

The phygital model creates a dual demand on storage: deep pallet reserves for bulk replenishment and active, broken-case picking for e-commerce orders. This often leads to the adoption of hybrid racking systems in the same aisle. For example, the lower levels (up to 5m) might be configured as carton-flow or shelving modules for high-velocity picking, while levels above 5m are standard selective pallet racking for reserve storage. The narrow aisle width requirements for such an aisle must satisfy both functions.

It must be wide enough for an order-picking truck (like a Combi or pick-at-height truck) to operate comfortably at lower levels, while also allowing the same or a different NA truck to service the upper pallet locations. This often results in an aisle width that is a compromise between pure pallet VNA specs and efficient manual picking, typically in the 2.2m-2.6m range, and requires exceptionally careful simulation and workflow planning.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com