📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Definitive Protocol: Mastering the Pallet Racking Inspection Checklist for Global Warehouse Integrity

Introduction: The Unseen Backbone of Every Successful Operation

Within the bustling activity of a modern warehouse—from the automated guided vehicles silently navigating in Dubai to the high-reach forklifts operating in a Manila logistics hub—lies a silent, static framework that bears the immense physical and financial weight of the entire enterprise: the pallet racking system. Its integrity is the non-negotiable foundation for safety, efficiency, and profitability. However, this integrity is not a permanent state; it is a condition that degrades under constant, often invisible, stress.

For facility managers, logistics directors, and safety officers across Southeast Asia, the Middle East, Africa, and Latin America, the single most powerful tool to safeguard this asset is not a piece of advanced machinery, but a meticulously applied and deeply understood pallet racking inspection checklist. This document, when executed with expert rigor, transforms from a simple administrative task into a dynamic risk management protocol and a strategic operational blueprint.

The following guide delves beyond superficial advice, offering a master-level exposition on architecting, implementing, and leveraging a pallet racking inspection checklist that not only prevents catastrophe but builds a culture of proactive asset management, directly supporting the integration of advanced automation and driving bottom-line results.

The High Cost of Checklist Negligence: Why Generic Forms Fail

Many organizations operate under the dangerous illusion that having a pallet racking inspection checklist on file equates to having an effective inspection program. This is a critical error. A poorly designed or perfunctorily executed checklist creates a false sense of security, often masking accumulating defects until a triggering event causes failure. The consequences of a deficient pallet racking inspection checklist regimen are quantifiable across three axes:

Catastrophic Safety Failures: A collapsing rack bay is a chaotic, violent event. The kinetic energy stored in loaded beams and uprights poses a lethal threat to personnel. A rigorous pallet racking inspection checklist is designed to identify the precursor conditions—the bent connector, the over-depth dent, the loosened anchor—that precede such an event. Without it, the first sign of a problem is the collapse itself.

Crippling Financial and Legal Repercussions: Beyond the human toll, the financial impact is devastating. Regulatory fines from authorities (be it DOSH in Malaysia, the Ministry of Human Resources in Saudi Arabia, or similar bodies worldwide) can be substantial. Civil liability lawsuits from injured parties or affected customers can reach millions. Insurance providers routinely audit warehouse safety practices; a lack of a documented, systematic pallet racking inspection checklist program can lead to denied claims or policy cancellations.

Operational Disruption and Hidden Costs: A single red-tagged bay can disrupt carefully optimized picking paths, block crucial access aisles, and create inventory logjams. The cost of emergency repairs, inventory write-offs, lost productivity, and reputational damage from missed shipments far exceeds the minimal, scheduled investment in a robust inspection program powered by a comprehensive pallet racking inspection checklist.

The initial step toward excellence is recognizing that the pallet racking inspection checklist is the central nervous system of a warehouse’s structural health monitoring program. Its design, frequency, and execution quality directly correlate to operational resilience.

Anatomy of a World-Class Pallet Racking Inspection Checklist

A best-in-class pallet racking inspection checklist is not a one-page form with generic “check for damage” prompts. It is a multi-faceted, hierarchical system of documents and processes tailored to the specific racking types, operational intensity, and regional challenges of a facility.

1. The Hierarchical Inspection Framework:

An effective program operates on three distinct levels, each with its own specialized version of the pallet racking inspection checklist.

Level 1: Operator Visual Checklist (Daily/Shift-Based). This is a rapid, focused visual scan conducted by forklift operators, AGV controllers, and floor staff at the start of a shift or after any known impact. It targets obvious, immediate hazards: a heavily leaning upright, a dislodged beam, or fresh impact marks on column guards. This pallet racking inspection checklist is simple, graphical, and quick to complete, often via a mobile device. Its purpose is immediate hazard identification and reporting.

Level 2: Functional Systematic Checklist (Weekly/Monthly). This is the core program workhorse. Conducted by a trained supervisor or dedicated safety officer, this pallet racking inspection checklist is exhaustive. It involves a slow, methodical walk-down of every accessible rack bay using specialized tools. It follows a defined path (e.g., a warehouse grid system) to ensure 100% coverage over a planned period. This checklist is component-specific, quantitative, and requires detailed notation.

Level 3: Expert Engineering Audit (Annual/Biannual or Post-Incident). This audit is performed by a competent person—typically an external engineer certified by the racking manufacturer or a similarly qualified professional. This audit uses the most detailed pallet racking inspection checklist, which includes precise measurements, load capacity verification against original design drawings, and assessment of systemic issues like floor levelness or seismic bracing adequacy. This checklist provides a legal and technical baseline for the racking system’s fitness for service.

2. Critical Components of the Functional Systematic Checklist:

The following sections break down what each element of a professional pallet racking inspection checklist must entail, moving from a vague instruction to a precise, actionable directive.

Upright Frames: The Vertical Load-Bearing Pillars.

Checklist Item (Poor): “Inspect uprights for damage.”

Checklist Item (Expert): “Using a calibrated racking damage gauge, measure and record the maximum depth of any dent, tear, or deformation on all faces of each upright, particularly in the middle 60% of its height and at baseplate level. Any measurement exceeding the gauge’s ‘RED’ limit (typically >10mm for a standard upright) must be tagged RED. Simultaneously, check upright plumb using a laser level; deviation exceeding 1/240 of the height requires engineering review.”

Rationale: Specificity eliminates inspector subjectivity. The damage gauge provides a binary, defensible judgment. Focusing on the middle third targets the zone of highest bending moment.

Beam-to-Upright Connections: The Most Critical Interface.

Checklist Item (Poor): “Check beam connections are secure.”

Checklist Item (Expert): “For each beam end: (1) Visually confirm the connector hook is fully seated in the upright column’s teardrop or keyhole. (2) Physically verify the positive engagement of the safety lock (pin, clip, or flip latch). Attempt to dislodge the beam vertically with a specialized pry bar (per procedure). (3) Inspect the weld between the beam end connector and the beam tube for any crack or fatigue. (4) Note any beam deflection (sag) under load exceeding L/200 (span/200).”

Rationale: Beam disengagement is a primary collapse mode. A visual check is insufficient; positive verification of the safety lock is mandatory.

Load Bearers and Accessories: Decking, Wire Grids, and Supports.

Checklist Item (Poor): “Check decking condition.”

Checklist Item (Expert): “Verify wire mesh decking is properly seated on all four beam ledges with no more than 25mm overhang. Inspect for broken or disconnected welds at the border wire/ cross-rod intersections. For particle board decking, check for sag, water damage, or delamination that compromises load capacity. Ensure all pallet support bars are present and correctly oriented.”

Rationale: Damaged decking can lead to pallet collapse and load instability, creating a falling hazard and potential domino effect on the racking structure.

Anchorage and Base Environment: The Foundation.

Checklist Item (Poor): “Check anchors are tight.”

Checklist Item (Expert): “Inspect each anchor bolt for proper torque using a calibrated wrench (refer to OEM torque specs). Examine the concrete floor within a 150mm radius of the baseplate for cracks, spalling, or uplift, indicating anchor movement or overload. Ensure baseplates are in full contact with the floor; shims, if used, must be solid steel and full-contact.”

Rationale: The entire rack structure relies on secure anchorage to resist lateral and uplift forces. Loose anchors or failed concrete are fundamental failures.

Signage, Configuration, and Environment.

Checklist Item (Expert): “Confirm a legible, permanently affixed Safe Working Load (SWL) plate is present on each unique rack configuration. Verify that actual loads per beam level do not exceed the SWL. Check for adequate clearance (as per local fire code) between racked goods and sprinkler heads, lighting, or HVAC ducts. Document any evidence of flooding, excessive condensation, or corrosive chemical exposure.”

Rationale: Proper signage informs all operators and is a regulatory requirement. Environmental factors are major contributors to long-term degradation, especially in tropical or coastal regions.

Executing the Checklist: From Documentation to Action

A finding on a pallet racking inspection checklist is meaningless without a clear, escalated response protocol. The checklist itself must integrate with a Corrective Action Request (CAR) system.

Standardized Damage Coding: Every finding on the pallet racking inspection checklist should be classified:

Code Green: No action required. (e.g., superficial paint scratch).

Code Yellow: Minor defect. Schedule repair within 30 days. Monitor. (e.g., small dent within gauge tolerance, slightly loose brace).

Code Red: Critical defect. IMMEDIATE ACTION. Unload the affected bay immediately, cordon off the area, and attach a physical DANGER/DO NOT USE tag. Repair or replacement by qualified personnel must occur before reactivation.

The Digital Advantage: Moving the pallet racking inspection checklist from a paper clipboard to a mobile digital platform (a CMMS or specialized app) revolutionizes the process. Inspectors can geo-tag photos, automatically generate work orders for repairs, and create an unalterable, time-stamped audit trail. Data analytics can then identify damage-prone zones (e.g., near busy intersections), guiding operational changes like traffic rerouting.

The Closed-Loop Process: The final step in the pallet racking inspection checklist cycle is verification of corrective actions. Once a repair is completed, a supervisor must reinspect, sign off on the work, and update the digital record, closing the loop and ensuring accountability.

Regional Adaptations of the Pallet Racking Inspection Checklist

A pallet racking inspection checklist used in a climate-controlled facility in Santiago, Chile, may require modifications for a warehouse in the humid, salty air of Ho Chi Minh City, Vietnam. The expert-designed pallet racking inspection checklist must be adaptable.

High-Humidity and Coastal Zones (Southeast Asia, Gulf States, West Africa): The checklist must include enhanced frequency and scrutiny for corrosion. Inspectors must be trained to probe rust spots with a pick to distinguish surface rust from section loss. The pallet racking inspection checklist should mandate specific checks on base plates where moisture collects and at weld points where galvanization may be compromised.

Seismic Regions (Parts of Latin America, Indonesia, Philippines): The pallet racking inspection checklist must include dedicated sections for seismic bracing, overhead ties, and special anchorage. Inspectors check for loose bolts in moment connections, deformation in braced frames, and the integrity of any seismic sway rods.

Markets with High Ad-Hoc Modification: In some fast-growing markets, unauthorized rack modifications (home-made extensions, unapproved beam levels) are common. The pallet racking inspection checklist must empower inspectors to identify non-OEM components and flag them for immediate engineering review, as they represent severe, unquantified risks.

Synergy with Automation: The Checklist as an Enabler

For operations investing in AGVs, AS/RS, or conveyor sortation, the pallet racking inspection checklist takes on even greater strategic importance. Automated systems demand millimeter-level precision and predictable interfaces.

AGV/AMR Navigation: Autonomous vehicles rely on consistent rack faces for LiDAR and camera-based navigation. A lean or bulging upright, identified on a pallet racking inspection checklist, can cause navigation errors, mission failures, or collisions.

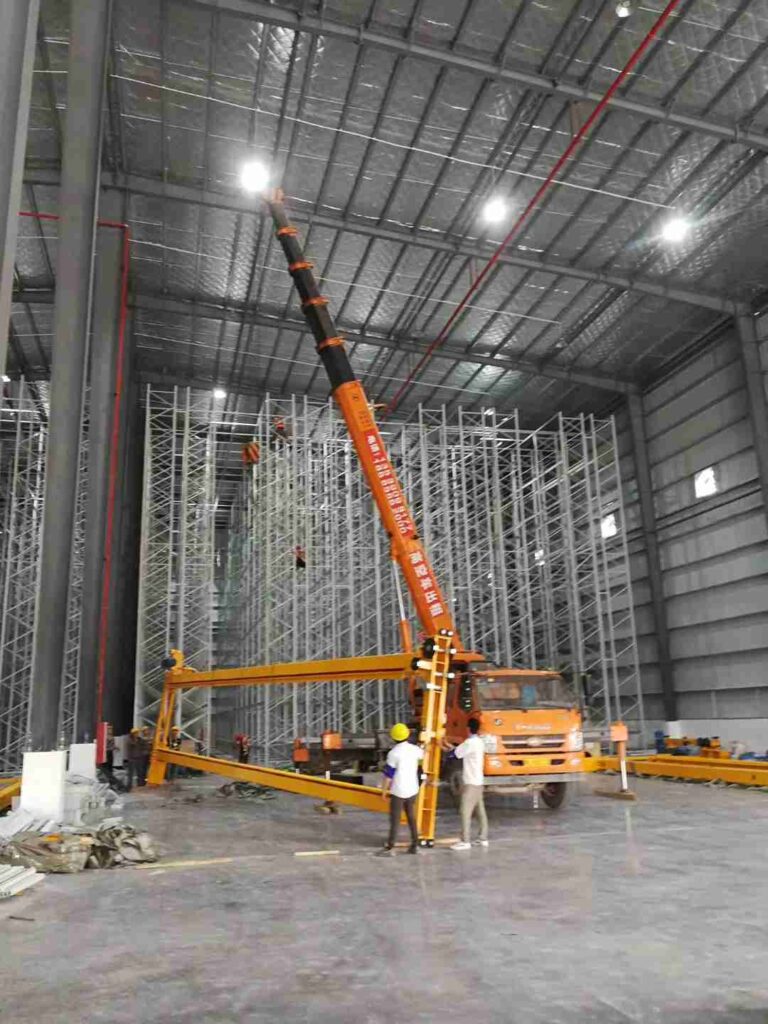

AS/RS Integration: In an automated storage and retrieval system, the racking is the machine’s runway. The S/R machine’s rails are mounted directly to the rack uprights. Any rack deflection or misalignment, which a precise pallet racking inspection checklist is designed to catch, translates directly into machine misalignment, causing excessive wear, downtime, and potentially catastrophic machine-to-rack impacts.

Predictive Maintenance Synergy: Data from a digital pallet racking inspection checklist can be combined with telematics from forklifts and AGVs (which log impact events). Analytics can correlate impact locations with subsequent damage found on inspections, allowing for predictive modeling and proactive reinforcement of high-risk zones.

Building a Culture Around the Checklist

Ultimately, the most sophisticated pallet racking inspection checklist fails if the organizational culture views it as a bureaucratic hurdle. Success requires:

Leadership Buy-in and Visibility: Management must explicitly and frequently champion the pallet racking inspection checklist program, allocating resources for tools, training, and repair parts.

Training that Transcends the Form: Training should not be about “how to fill out the pallet racking inspection checklist.” It should be about “understanding why a 12mm dent at mid-height is a crisis.” Use damaged components as teaching aids. Explain the physics of failure.

Positive Accountability: Incentivize the reporting of damage and diligent checklist completion. Celebrate catches that prevented incidents. The goal must be to find and fix problems, not to punish the operator who caused an impact (unless due to recklessness).

Conclusion: The Checklist as a Strategic Asset

In the final analysis, a masterfully crafted and diligently applied pallet racking inspection checklist is far more than a safety document. It is a strategic management tool that protects human capital, safeguards physical assets, ensures operational continuity, and enables technological advancement. It provides the documented due diligence required by regulators and insurers.

For warehouse operators across emerging global markets, investing the time and expertise to develop and implement a world-class pallet racking inspection checklist program is one of the highest-return investments possible. It transforms the passive structure of storage racking into an actively managed, predictable, and safe asset, forming the reliable backbone upon which supply chain excellence is built. The journey begins with a commitment to moving beyond the generic form and embracing the checklist as a living, dynamic protocol for enduring warehouse integrity and performance.

Advanced FAQs From Warehouse Engineers

1. How does this pallet racking inspection checklist differ from RMI’s version?

While RMI provides excellent baseline standards, this pallet racking inspection checklist incorporates materials science advancements and failure mode analytics from 400+ actual collapse investigations.

2. What’s the most overlooked item in pallet racking inspection checklists?

Baseplate creep—the gradual shifting of anchors under cyclic loading that escapes visual detection until catastrophic failure.

3. Can ultrasonic testing replace traditional pallet racking inspection checklists?

No—while UT identifies micro-fractures, it must complement (not replace) the visual and dimensional checks in standard pallet racking inspection checklists.

4. How frequently should pallet racking inspection checklists be updated?

Every 24 months to incorporate new research—the 2024 update added harmonic vibration analysis protocols.

5. What percentage of warehouses use inadequate pallet racking inspection checklists?

OSHA estimates 68% use outdated paper forms missing critical fatigue life calculation fields.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com