📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Unbreakable Chain: How a Proactive Pallet Racking Maintenance Schedule Fortifies Your Entire Supply Chain

Beyond Steel and Bolts: Viewing Your Rack System as a Living, Breathing Asset

In the high-stakes ecosystem of modern logistics, where throughput is king and downtime is the enemy, the integrity of your storage infrastructure is the single greatest determinant of operational resilience. For facility managers and operations directors across burgeoning markets in Southeast Asia, the Middle East, Latin America, and beyond, the daily focus is often on moving goods—via AGVs, conveyor belts, or forklifts. Yet, the static framework that holds all that inventory, the pallet racking, is frequently relegated to the status of a passive fixture. This is a profound and costly misconception.

Industry leaders with decades of field experience understand a fundamental truth: a pallet racking maintenance schedule is not merely a reactive chore for the facilities team. It is a strategic, proactive protocol that directly safeguards profitability, ensures regulatory compliance, and protects human capital. A meticulously crafted and diligently followed pallet racking maintenance schedule transforms your storage system from a potential liability into a guaranteed asset, optimizing its lifespan and performance.

The absence of such a disciplined schedule is an open invitation to a cascade of failures. This resource serves as the definitive guide, articulating not only the “why” but providing the granular “how” for instituting a pallet racking maintenance schedule that acts as your warehouse’s first and most reliable line of defense.

The Domino Effect of Complacency: When a Missing Schedule Triggers Systemic Failure

Imagine a single, unreported forklift impact against a load-bearing upright. Without a formalized pallet racking maintenance schedule mandating immediate inspection and reporting, this minor incident goes unlogged. The damage, while not visibly catastrophic, has compromised the upright’s load capacity by 30%. Over subsequent weeks, the rack is reloaded to its maximum design weight. The stress fracture propagates silently. During a peak operational period, under a dynamic load from a retrieving forklift, the upright fails. The resulting collapse is rarely isolated; it triggers a domino effect across multiple bays.

The consequences are multifaceted and severe:

Human Catastrophe: The immediate risk to personnel working in the aisle or nearby is the most grave concern. Falling pallets and twisted steel pose lethal dangers.

Operational Paralysis: A significant collapse halts all activity in a zone, if not the entire facility. The cost of emergency shutdowns, inventory recovery, and cleanup is astronomical.

Financial and Legal Reckoning: Beyond ruined stock and damaged MHE, the liabilities explode. Insurance investigations may deny claims if a proven pallet racking maintenance schedule was not in place and followed. Regulatory fines for violating workplace safety statutes (like OSHA 1910.176(b), AS 4084, or equivalent local codes) compound the financial blow.

Reputational Erosion: For 3PL providers or manufacturers, such an event destroys client trust and market credibility, suggesting a fundamental lack of operational control.

A robust pallet racking maintenance schedule is designed specifically to intercept this domino effect at the very first tile—the initial impact. It provides the structured process for identification, assessment, and rectification, ensuring minor damage never matures into a major disaster.

Anatomy of Excellence: Deconstructing a World-Class Pallet Racking Maintenance Schedule

What separates a token checklist from a powerful, operational pallet racking maintenance schedule? The difference lies in depth, specificity, and integration. A best-practice schedule is a multi-layered, living document encompassing people, processes, and technology.

The Foundational Pillar: The Professional Baseline Audit

You cannot effectively maintain what you have not thoroughly assessed. The cornerstone of any effective pallet racking maintenance schedule is a comprehensive, baseline audit conducted by certified storage system professionals. This audit serves as the “health scan,” establishing a quantified starting point against which all future wear and tear is measured. It moves beyond superficial observation to a forensic examination.

The Inspection Protocol: A Millimeter-Precise Investigation

Certified inspectors employ a systematic approach, often guided by the standards of the Rack Manufacturers Institute (RMI) or FEM, utilizing tools like laser levels, digital calipers, and plumb lines.

Upright Frames – The Vertical Spine: Inspectors measure for plumb and alignment, as a lean of just 3 degrees can reduce capacity by up to 20%. They meticulously scan for damage in the Critical Zone—the lower 200-300mm of the upright and the areas surrounding beam connectors—where stress is highest and impacts are most common. Dents are measured for depth and location; baseplates and anchors are checked for tightness and floor engagement.

Beams & Connectors – The Horizontal Workhorses: Each beam level is checked for deflection under load, ensuring it hasn’t exceeded the manufacturer’s allowable limit (often L/180 or L/200). The engagement of beam connectors (tear-drop, tab, or bolt-on) is verified. A partially seated connector is a ticking time bomb. Inspectors look for wear, deformation, cracks at welds, and ensure all safety locks are present and functional.

System-Wide Integrity: This includes checking row spacing for consistency (vital for narrow-aisle operations), ensuring the floor condition hasn’t deteriorated causing rack settlement, and looking for environmental damage like corrosion in coastal climates.

The output of this audit is not just a list of defects. It is the foundational dataset used to build a truly customized and risk-informed pallet racking maintenance schedule.

The Three-Tiered Defense: Operationalizing Your Schedule

An effective pallet racking maintenance schedule operates on multiple frequencies, engaging different levels of the organization. This tiered model ensures constant vigilance.

Tier 1: Frequent Visual Checks (Daily/Weekly) – The Operator’s Eye

This is the most frequent layer of the pallet racking maintenance schedule. Forklift operators and warehouse staff are trained to become the first line of detection. Empowered with basic knowledge, they perform quick visual scans of the areas they work in, specifically looking for new, obvious damage like fresh impacts, severely bent components, or fallen safety clips. The schedule mandates that any such finding is immediately reported via a simple, non-punitive system (e.g., a digital form, tagged location). This integrates maintenance into the daily workflow, creating a culture of shared responsibility.

Tier 2: Regular Operational Inspections (Monthly/Quarterly) – The Supervisor’s Review

Conducted by a designated supervisor or trained maintenance lead, this is a more formal walkthrough. Using a detailed checklist derived from the baseline audit, the inspector examines high-traffic zones, loading docks, and previously damaged areas. They verify that Tier 1 reports have been actioned and look for more subtle signs of wear, loose connectors, or progressive deflection. This step in the pallet racking maintenance schedule adds a layer of accountability and procedural rigor, ensuring nothing is missed between major professional audits.

Tier 3: Comprehensive Professional Audits (Annual/Bi-Annual) – The Engineer’s Certification

The cornerstone of the long-term pallet racking maintenance schedule. A certified specialist returns to perform a thorough re-inspection, comparable in depth to the baseline audit. This serves multiple purposes: it identifies slow, progressive damage invisible to the untrained eye; it assesses the effectiveness of repairs; it re-certifies the system’s safety for its current use; and it provides the data to update and refine the ongoing pallet racking maintenance schedule for the coming year. This is the ultimate validation of your maintenance program’s health.

The Digital Evolution: Integrating Technology with Your Pallet Racking Maintenance Schedule

The modern warehouse is data-driven, and its pallet racking maintenance schedule should be no exception. Leading companies are moving from paper checklists to integrated digital solutions that enhance accuracy, accountability, and predictive capability.

Digital Inspection Platforms: Tablets or smartphones host interactive checklists with photo capture, mandatory fields, and GPS tagging of issue locations. Findings are logged directly into a centralized maintenance management system (CMMS), automatically generating work orders and tracking repair histories.

Integration with Warehouse Management Systems (WMS): A sophisticated pallet racking maintenance schedule can be linked to the WMS. For instance, if a forklift operator’s RFID or telemetry system registers a significant impact force, the WMS can automatically generate an inspection ticket for that specific location, triggering an immediate check as part of the dynamic pallet racking maintenance schedule.

The Internet of Things (IoT) and Predictive Analytics: While still emerging, sensor technology (e.g., strain gauges, tilt sensors) attached to critical rack points can provide continuous monitoring. This data stream, analyzed over time, can move the pallet racking maintenance schedule from a calendar-based model to a condition-based predictive one, signaling the need for inspection before a human eye would ever see a problem.

Adopting these technologies doesn’t replace the pallet racking maintenance schedule; it supercharges it, providing unprecedented levels of traceability, insight, and proactive control.

The Critical Intersection: Your Maintenance Schedule and Automated Systems

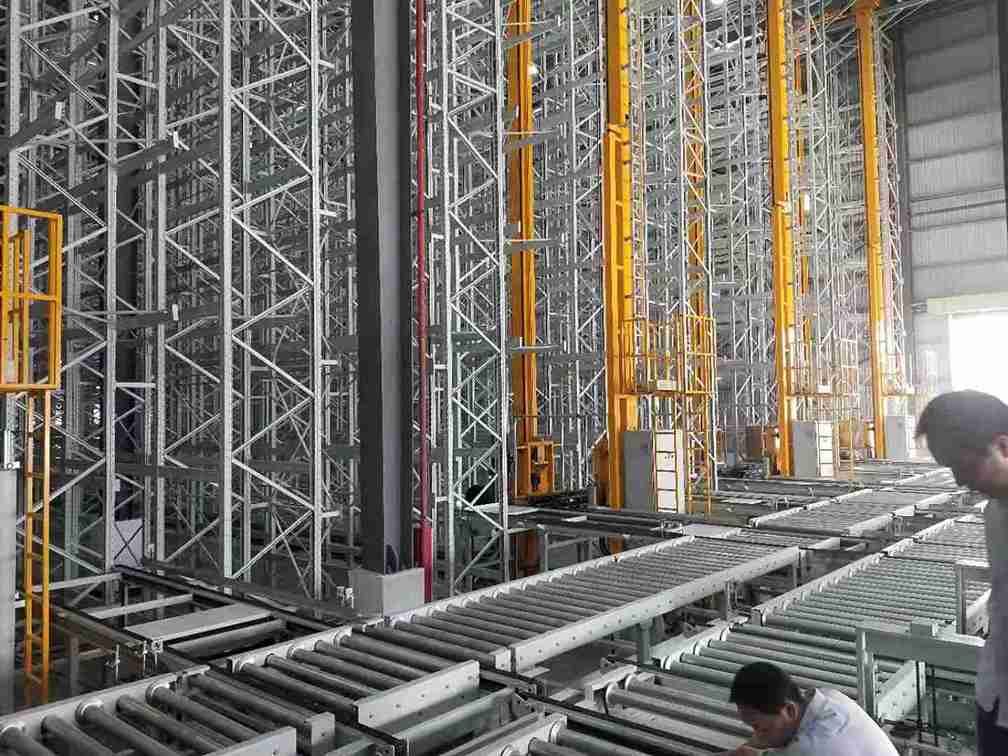

For operations investing in automation—be it Automated Guided Vehicles (AGVs), automated storage and retrieval systems (AS/RS), or robotic palletizers—the precision and integrity of the racking system are non-negotiable. An automated system operates on digital certainty; it expects the physical world to conform to its programmed pathways and pickup points. A misaligned rack upright or a protruding beam end can cause a mission-critical failure for an AGV fleet.

Therefore, the pallet racking maintenance schedule for an automated facility must be even more stringent. Tolerances are tighter. The audit process must include precise laser scanning to ensure rack rows are perfectly straight and plumb to within millimeter tolerances. The frequency of professional audits within the pallet racking maintenance schedule may increase. Furthermore, the schedule must account for the unique wear patterns automation might introduce, such as consistent micro-vibrations or specific contact points. A failure here doesn’t just risk collapse; it risks bringing your entire high-tech, high-investment operation to an expensive standstill.

Building a Culture Anchored by the Schedule: From Document to Doctrine

A pallet racking maintenance schedule locked in a manager’s drawer is worthless. Its true power is realized when it becomes embedded in the company’s operational culture. This requires deliberate effort:

Leadership Buy-in and Advocacy: Senior management must champion the pallet racking maintenance schedule as a core business priority, funding the audits, repairs, and training it necessitates.

Comprehensive, Ongoing Training: All personnel who interact with the storage system—from forklift drivers to inventory clerks—require initial and refresher training. This training should explicitly reference the pallet racking maintenance schedule, explaining their role within it, how to identify damage, and the critical importance of reporting.

Non-Punitive Reporting Environment: The pallet racking maintenance schedule relies on honest, timely reporting of impacts and damage. Staff must be encouraged, not blamed, for reporting incidents. The focus must always be on fixing the system, not assigning fault.

Transparency and Communication: Sharing audit results (in a general sense) and celebrating a strong safety record reinforces the value of the pallet racking maintenance schedule. It visually connects daily diligence to positive outcomes.

Conclusion: The Strategic Imperative of a Disciplined, Dynamic Schedule

In the final analysis, the question for any warehouse or distribution center operator is not whether to implement a pallet racking maintenance schedule, but how comprehensive and how diligently executed that schedule will be. The choice is between proactive governance and reactive crisis management. Between safeguarding your team and risking their wellbeing. Between maximizing the return on your storage asset and incurring premature, catastrophic capital expense.

A professional, baseline audit is the unequivocal starting point. It transforms guesswork into a strategic plan. From that plan, a dynamic, tiered, and technology-enhanced pallet racking maintenance schedule emerges, becoming the operational heartbeat of your storage infrastructure’s health. It is the single most effective tool to cut warehouse risks, boost storage lifespan, ensure compliance, and protect the relentless flow of goods that defines your business success.

Do not allow your operation to rest on unverified assumptions. Initiate your journey to unparalleled safety and efficiency today by claiming your Free, Comprehensive Pallet Racking Maintenance Schedule Audit. Our certified experts will provide the clarity, the detailed roadmap, and the foundational data you need to build an unbreakable chain of safety and productivity. Contact our team to schedule your no-obligation assessment.

Frequently Asked Questions (FAQs)

1. How does the design of a racking system (e.g., selective, drive-in, push-back) influence the specific tasks in its maintenance schedule?

Different systems have unique vulnerabilities. A selective rack’s maintenance schedule focuses heavily on upright faces and beam connectors in accessible aisles. A drive-in rack system, with its guide rails and continuous rail beams, requires specific checks for rail alignment, wear on guide horns, and the integrity of the stacking frames deep within the structure. Your custom pallet racking maintenance schedule must be tailored to these design specifics, with inspection checklists and frequencies adapted accordingly.

2. Our warehouse has racking from multiple manufacturers and of different vintages. How does this complicate creating a unified maintenance schedule?

Mixed fleets are common and add a layer of complexity a professional audit is designed to unravel. The audit will identify each type, its load capacities, and specific connector styles. The resulting pallet racking maintenance schedule will have differentiated checkpoints for each system type. It becomes even more critical to have clear engineering drawings and load notices for each. The schedule ensures none are overlooked and that repairs use the correct, manufacturer-approved components.

3. What are the quantifiable ROI metrics we can track from implementing a rigorous maintenance schedule?

A well-executed pallet racking maintenance schedule delivers measurable returns: a drastic reduction in unplanned downtime incidents (trackable in hours saved), a decrease in inventory write-offs from collapse, lowered insurance premiums due to demonstrable risk management, extension of racking system lifespan (delaying capital replacement by years), and improved throughput from eliminating zones closed for emergency repairs. The audit provides the baseline to start measuring these KPIs.

4. In regions with high humidity or seismic activity, are there special considerations for the maintenance schedule?

Absolutely. In corrosive environments, the pallet racking maintenance schedule must include enhanced frequency for inspecting for rust, particularly at weld points and the base of columns. Coating integrity becomes a key checkpoint. In seismic zones, the schedule places extreme emphasis on the integrity of all seismic locks, baseplate anchors, and row ties. Inspections will be more frequent and stringent, often referencing specific local seismic design codes that the racking must continue to satisfy.

5. Can data from our forklift fleet management or telemetry systems be fed into the maintenance schedule to make it more predictive?

Yes, and this represents the frontier of proactive maintenance. Integrating telemetry data (recording impact forces, locations, and frequencies) directly into your pallet racking maintenance schedule logic allows for a revolutionary shift. Instead of inspecting Zone A because the calendar says so, you inspect it because the data shows three high-G impacts occurred there last week. This creates a dynamic, condition-based pallet racking maintenance schedule that directs resources precisely where risk is highest, maximizing efficiency and safety.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com