📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Definitive Masterclass: How to Install Pallet Racking Safely for Automated Warehouse Success

For logistics managers, warehouse operators, and project engineers across Southeast Asia, the Middle East, Africa, and Latin America, the question of how to install pallet racking safely takes on a radically new dimension in the age of automation. This is not a simple assembly task; it is a precision engineering discipline that forms the critical foundation for any Automated Guided Vehicle (AGV) or Automated Storage and Retrieval System (AS/RS).

A standard approach to how to install pallet racking safely is insufficient. This exhaustive guide provides a masterclass in the advanced methodologies, safety protocols, and integration-focused techniques required to ensure that the physical storage infrastructure not only holds weight but also communicates seamlessly with robotic systems. Mastering this integrated approach to how to install pallet racking safely is the single most effective strategy to mitigate systemic risk, guarantee operational uptime, and protect a multi-million-dollar automation investment. The ultimate goal is a flawless, safe handshake between steel and software.

The Foundational Mindset: Why “Safe Installation” Means “System Integration”

Understanding how to install pallet racking safely in an automated environment begins with a fundamental paradigm shift. In a manual warehouse, safety focuses on static load capacity and worker awareness. In an automated one, safety expands to encompass dynamic systems integrity. The racking is no longer a passive storage structure; it is an active, mission-critical component of a larger cyber-physical system.

A minor deviation tolerated by a human forklift operator can be catastrophic for a pre-programmed AGV. Therefore, the core philosophy of how to install pallet racking safely here is grounded in precision, predictability, and proactive risk mitigation for both hardware and data flow. This mindset must be adopted by every stakeholder, from the project manager to the technician on the floor with a torque wrench.

The High-Stakes Calculus: Cost of Failure in Automated Systems

The financial and operational rationale for re-engineering the approach to how to install pallet racking safely becomes starkly clear when examining the cost of failure. A typical safety incident in a manual warehouse might involve a single pallet collapse. In an automated zone, the failure modes are multiplied and cascading.

An undetected installation error, such as a beam mounted a few millimeters too low, can cause an AS/RS shuttle to collide repeatedly, leading to a systemic shutdown. The domino effect includes: costly damage to highly sensitive robotics, complete cessation of throughput, data corruption in the Warehouse Management System (WMS), and severe safety hazards from falling loads and rogue machinery. Thus, the advanced protocols for how to install pallet racking safely are not an added expense but a critical insurance policy.

They are the essential procedures that answer the pressing question for any automation investor: how to install pallet racking safely to ensure the entire ecosystem’s reliability.

Phase 1: The Blueprint for Safety – Pre-Installation Engineering

The most crucial phase of how to install pallet racking safely occurs before a single upright is uncrated. It is in the digital and planning stage where risks are identified and designed out.

Collaborative Design: The Convergence of Structural and Software Engineering

The first step in how to install pallet racking safely for automation is a forced marriage between two often-siloed disciplines: structural engineering and automation software engineering. Their collaborative review must mandate:

Dynamic vs. Static Load Calculations: The racking design must account for the constant micro-forces exerted by AGVs (acceleration/deceleration, lifting dynamics) and the vibrational harmonics from high-speed AS/RS cranes. The safety factor is elevated, often requiring a 25-50% increase over standard static ratings. This is a non-negotiable first principle in how to install pallet racking safely for robotics.

Digital Twin Alignment: The racking layout CAD files must perfectly align with the AGV’s navigation grid and the AS/RS pick-face matrix in the digital twin. Any discrepancy here will manifest as a physical collision later. The installation team uses these synchronized drawings as their bible.

Interface Point Precision: Defining the exact 3D coordinate for the AGV interface point is paramount. This coordinate, derived from the automation system’s requirements, dictates the final installed height and depth of every load beam. It is the golden reference for the entire physical installation process of how to install pallet racking safely.

Site Preparation: Creating a Precision Foundation

A perfect rack installed on an imperfect floor is an unsafe rack. The site preparation step is where the theory of how to install pallet racking safely meets the reality of the construction site.

Floor Flatness (FF/FL) as a Safety Spec: For automated systems, the standard warehouse floor is inadequate. Achieving a Floor Flatness (FF) of 50 and Floor Levelness (FL) of 40 is a common specification. An uneven floor causes racking to rack (lean), inducing hidden stresses and misaligning pick-faces from their programmed locations, fundamentally undermining all subsequent efforts in how to install pallet racking safely.

Anchor Strategy as Part of System Design: The type, location, and installation method of anchor bolts must be planned in concert with the automation layout. This prevents conflicts with embedded AGV guide wires or future expansion. The choice between chemical and mechanical anchors is made based on substrate analysis and the dynamic load requirements—a key detail in the manual for how to install pallet racking safely in high-stress environments.

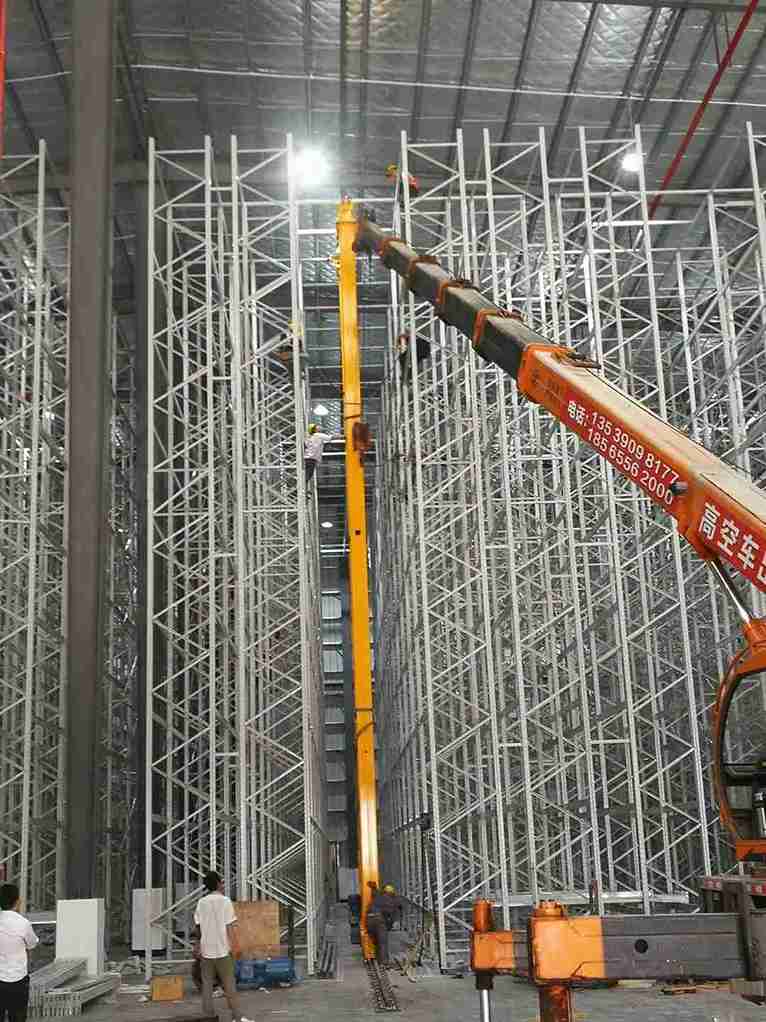

Phase 2: The Art and Science of Precision Installation

This is the execution phase, where the calibrated eye of an experienced installer and laser-guided technology combine to bring the digital plan to life. It is the physical manifestation of the plan for how to install pallet racking safely.

Establishing the “Golden Datum”: The Birth of On-Site Accuracy

Before assembly begins, certified surveyors establish permanent, unchanging datum points around the warehouse perimeter, tied directly to the master digital drawings. Every subsequent measurement for how to install pallet racking safely flows from these points. Laser levels and total stations are used, not string lines and spirit levels. This eradicates cumulative error and ensures the entire racking system is a single, perfectly aligned entity.

Upright Frame Erection: Setting the Perfect Vertical

The process for how to install pallet racking safely hinges on the absolute verticality of upright frames.

Plumbness Tolerance: The tolerance is tightened to 1:500 (approx. 3mm over 3m height). Each upright is checked in two planes. A row of 10 frames must also have a cumulative tolerance within strict limits. This precision is what allows an AS/RS crane to travel 20 meters vertically without a single guiding roller bearing undue stress.

Anchor Torque Verification – The Ritual of Safety: This is a sacramental step in how to install pallet racking safely. Each anchor is torqued to the engineer’s specification with a calibrated wrench. A digital log—recording location, torque value, installer, and inspector—is created. This log is a legal and safety document, providing traceability and ensuring no anchor is left to chance.

Load Beam Placement: Where the Digital Meets the Physical

The load beam is the literal interface between the pallet and the robot. The procedure for how to install pallet racking safely reaches its most critical point here.

Height and Level Consistency: Using cross-line lasers, installers ensure each pair of beams is perfectly level. More critically, the height from the finished floor to the beam’s supporting surface must be consistent across the entire installation to within ±1.5mm. This microscopic tolerance is the difference between a smooth pickup and a catastrophic collision. It is the ultimate test of a team that truly knows how to install pallet racking safely for automation.

Beam Lock Integrity: Standard snap-in clips may not suffice. Vibration from continuous automation can cause “walk-off.” The safe installation method often involves positive-locking bolts, secondary locking pins, or specially designed clips that resist vibrational loosening. This is a detail often overlooked in basic guides on how to install pallet racking safely.

Installing for Integration: The Critical Ancillaries

How to install pallet racking safely extends beyond the rack itself to the protective and interactive elements.

Proactive Protection Installation: Heavy-duty column guards, AGV guide rail protection, and end-of-aisle barriers are installed before automation equipment arrives. Their placement is factored into the AGV’s clearance map from day one.

Sensor and Reflector Mounting: Brackets for LiDAR reflectors, proximity sensors, or location barcodes are installed at precise coordinates during racking erection. Their alignment is as crucial as the beam height, as they form the “road signs” for the automated vehicles.

Integrated Wire Management: Conduits or cable trays are installed along the racking superstructure to neatly house future cabling for sensors, lights, or communication modules, preventing snag hazards for AGVs.

Phase 3: Validation & Commissioning – The Safety Gates

Installation completion is not the end. It is the beginning of a rigorous validation process that confirms the team knew how to install pallet racking safely and correctly.

The As-Built Survey: Closing the Loop with Reality

A 3D laser scan of the installed racking is performed. This point cloud data creates the “As-Built Digital Twin.” This model is compared against the original design. More importantly, it is used to calibrate the automation control software. The robots are taught to navigate the actual warehouse, not the theoretical one. This step is the final, irrevocable proof of a successful process for how to install pallet racking safely.

Structured Load Testing for a Dynamic Environment

Prior to system handover, a two-stage load test validates the installation.

Static Load Test: Applying 110% of rated capacity to selective bays checks for permissible deflection, verifying the structural aspect of how to install pallet racking safely.

Dynamic Interaction Test: With loads in place, AGVs and cranes perform slow, scripted maneuvers in adjacent aisles. Engineers monitor the racking for any unusual vibration or resonance, ensuring the dynamic aspect of how to install pallet racking safely is also validated.

The Final Safety Audit and Clearance Certification

A cross-functional team conducts a line-by-line audit, checking every safety lock, anchor log, clearance zone, and protective device. The culmination is a signed Clearance Certification—a formal document stating the racking environment is safe and ready for automated operations. This certificate is the deliverable that answers the project’s overarching question: how to install pallet racking safely for our automated future.

The Living Installation: Operations and Maintenance

In an automated warehouse, the question of how to install pallet racking safely evolves into how to keep it safe. The installation’s precision enables a data-driven maintenance regime.

Scheduled Metrology Checks

Bi-annual precision surveys re-check plumbness and beam height, creating a performance degradation timeline. This predictive data is invaluable for planning maintenance or reinforcement before a tolerance breach causes an incident. It’s the ongoing application of the principles of how to install pallet racking safely.

The Non-Negotiable Damage Protocol

A strict “Red Tag & Isolate” protocol is mandatory. Any impact triggers immediate WMS deactivation of that location, physical tagging, engineer inspection, and certified repair. This protocol is the operational extension of the safety culture embedded during the initial phase of how to install pallet racking safely.

Regionalizing Safety: Installation Challenges in Growth Markets

The approach to how to install pallet racking safely must be adapted to local conditions in Southeast Asia, the Middle East, Africa, and Latin America.

Seismic Zones: In the Philippines or Chile, how to install pallet racking safely includes seismic bracing and moment-resisting connections. Installation torque values and weld inspections (per AWS D1.1 or equivalent) are paramount. The installation is not just about precision, but also about ductility and resilience.

Climate Extremes: In the humid tropics of Southeast Asia, specifications for galvanized or powder-coated finishes, and the use of specific anchor chemistries, are part of how to install pallet racking safely to prevent corrosion. In the dusty Middle East, installation plans include considerations for sensor cleaning access.

Navigating Local Expertise Gaps: The most robust plan for how to install pallet racking safely accounts for potential skill gaps. This involves simplified, visual installation checklists, enhanced supervision by expatriate engineers, and mandatory tool calibration sessions for local crews. The goal is to transfer the stringent knowledge of how to install pallet racking safely for automation into the local team’s practice.

Conclusion

The journey to mastering how to install pallet racking safely within an automated warehouse is a comprehensive discipline that spans digital design, micrometer-precise execution, and rigorous lifecycle management. It is a specialized field that separates basic storage projects from world-class, resilient logistics hubs. For decision-makers in emerging markets driving automation forward, investing in this depth of knowledge and precision is not a line-item cost; it is the foundational investment for operational excellence.

By adhering to these advanced protocols for how to install pallet racking safely, businesses do more than erect storage—they commission a reliable, high-performance, and intrinsically safe backbone for their automated future, ensuring their competitive edge is built on a foundation of absolute integrity and safety.

Frequently Asked Questions (FAQs)

1. Q: We are planning a phased automation rollout. Should we install all racking to the automated standard now, or can we upgrade later?

The most cost-effective and safest strategy is to install all racking to the full automated standard from the outset. Retrofitting precision (e.g., re-aligning thousands of beams to within 1.5mm) in a live warehouse is exponentially more expensive and disruptive than building it correctly initially. This proactive step is the core of strategic planning for how to install pallet racking safely for future growth.

2. Q: What is the single most common installation error that compromises safety in automated systems?

The most frequent and critical error is inadequate attention to floor flatness and anchoring. Installing world-class racking on an uneven floor without properly specified and torqued anchors guarantees systemic misalignment and hidden stress points. Any guide on how to install pallet racking safely must begin with a stringent site preparation protocol.

3. Q: How does the role of the installation supervisor differ in an automated project versus a standard one?

The supervisor transforms from a foreman to a systems integration coordinator. They must be fluent in reading complex digital layout drawings, interpreting laser survey data, and enforcing microscopic tolerances. Their role is to be the guardian of the digital plan in the physical world, a crucial link in the chain of how to install pallet racking safely for robotics.

4. Q: For brownfield sites with existing racking, is it ever safe to retrofit for automation?

It is possible but requires extreme diligence. The existing structure must undergo a full structural audit and as-built survey. Often, only the upright frames can be reused, requiring all beams, connectors, and anchors to be replaced and installed to the new precision standard. The process for how to install pallet racking safely in a retrofit is more akin to surgery than new construction.

5. Q: Can the WMS compensate for minor installation inaccuracies?

No, and this is a dangerous misconception. A WMS or warehouse control system (WCS) operates on precise coordinates. It can no more compensate for a misaligned beam than a GPS can move a building. The software expects the physical world to match its map. Ensuring this match is the entire purpose of the advanced methodology for how to install pallet racking safely. The software is a conductor, but the orchestra (the physical racking) must be perfectly in tune.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com