📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Strategic Pallet Racking Installation: A Proven Framework to Reduce Logistics Costs by 30% and Boost Operational Efficiency

For logistics managers, warehouse operators, and supply chain directors across Southeast Asia, the Middle East, Africa, and Latin America, the decision to install or upgrade pallet racking is a significant capital expenditure. The initial pallet racking installation cost often becomes the primary focus, but this myopic view can be costly in the long run. True value isn’t found in the cheapest upfront price; it’s engineered through a holistic process that optimizes every facet of the project—from initial design and component quality to precision installation and long-term maintenance.

This comprehensive guide outlines a strategic framework that has consistently enabled businesses to achieve up to a 30% reduction in total project costs while simultaneously enhancing storage density, improving safety, and future-proofing their operations. Understanding the true drivers behind the pallet racking installation cost is the first step toward making an intelligent investment that pays dividends for years to come.

Deconstructing the True Cost of Pallet Racking Installation

When most businesses inquire about the pallet racking installation cost, they are typically referring to the invoice for the racking components. This is a critical mistake. The real investment encompasses a wide range of visible and hidden factors that, if not managed strategically, will inflate your budget and undermine your warehouse’s performance. A sophisticated cost analysis moves beyond the component price tag to include a multitude of variables that directly influence the final pallet racking installation cost and its long-term value.

Beyond the Price Tag: The Visible and Hidden Cost Components

A professional project quote should provide a transparent breakdown, demystifying the complete pallet racking installation cost. Here’s what discerning clients should be looking for:

Racking Components & Materials: This is the most obvious component of the pallet racking installation cost. It includes upright frames, beams, wire mesh decking, row spacers, and footplates. The quality of the steel, its gauge (thickness), and the manufacturing tolerances directly impact the price and the long-term durability of the system. Opting for lower-grade steel to reduce the initial pallet racking installation cost is a common but costly error, leading to premature wear and safety hazards.

Professional Design & Engineering Services: This is where value creation begins and where significant influence over the pallet racking installation cost is exerted. A certified structural engineer must design the layout specifically for your facility, inventory, and equipment. This service ensures compliance with local building codes and safety standards, preventing catastrophic failures. Skipping this to save money is an immense risk that can exponentially increase the ultimate pallet racking installation cost through rework, fines, or accidents.

Site Preparation & Civil Works: Is your warehouse floor perfectly level? Does the slab have the required compressive strength to handle the point loads of fully loaded racks? Often, sites require floor grinding, patching, or even reinforcement—expenses that are frequently overlooked in initial budgets for the pallet racking installation cost. A thorough site survey is essential to accurately forecast this portion of the pallet racking installation cost.

The Installation Labor: This is not a task for a general contractor. Certified installers with specific experience in pallet racking are non-negotiable. Their expertise ensures the structure is plumb, level, and torqued to exact specifications, guaranteeing its rated capacity and safety. The labor component is a critical part of the pallet racking installation cost, as improper installation can void warranties and create unsafe conditions.

Ancillary Equipment & Safety Features: This includes end-of-aisle guards, column protectors, pallet supports, and signage. These are not optional “extras”; they are essential investments in asset and personnel protection. While they add to the upfront pallet racking installation cost, they protect against far greater costs from damage and liability.

Post-Project Documentation: You should receive a complete set of “as-built” drawings, load capacity certificates, and a comprehensive maintenance guide. This documentation is crucial for insurance, future modifications, and resale value. A provider that includes this in the pallet racking installation cost is demonstrating a commitment to long-term partnership.

Why the Cheapest Quote is Often the Most Expensive Long-Term Investment

The allure of a low-ball quote for your pallet racking installation cost is strong, but it often signals corner-cutting that will cost you dearly. Inferior steel quality leads to premature fatigue and failure, necessitating early replacement. A non-optimized design wastes valuable cubic space, forcing you to rent a larger facility than necessary—a recurring expense that dwarfs any initial saving on the pallet racking installation cost.

Poor installation, perhaps using unskilled labor, creates misaligned racks that are unstable, difficult for forklift operators to use, and prone to impact damage. The eventual costs of rework, inventory loss from collapse, increased insurance premiums, and potential liability from accidents will dwarf the initial “savings” on the pallet racking installation cost. A professional understands that the goal is to optimize the total cost of ownership, not just the initial pallet racking installation cost.

Our Proven 5-Phase Framework for Maximizing Value and Minimizing Costs

This methodology is systematic and collaborative. It is designed to eliminate waste, prevent errors, and ensure that every dollar spent on the pallet racking installation cost contributes directly to operational goals. This framework provides a clear roadmap for managing the pallet racking installation cost from conception to completion.

Phase 1: In-Depth Discovery and Holistic Needs Analysis

This phase is about deep understanding, laying the groundwork for an accurate and justified pallet racking installation cost.

Operational Workflow Mapping: Analysts map the entire flow of goods—from receiving to put-away, picking, and dispatch. This helps design a layout that minimizes travel time and handling, directly influencing labor costs and justifying the pallet racking installation cost through efficiency gains.

Inventory Profiling and SKU Analysis: Understanding the size, weight, turnover rate (ABC analysis), and special handling requirements of every product is the foundation of an efficient design. This data ensures the pallet racking installation cost is aligned with actual storage needs, not a generic template.

MHE (Material Handling Equipment) Integration: The racking design must be perfectly synchronized with your existing or planned forklifts, reach trucks, and order pickers. Specifying clear aisle widths, turning radii, and lifting heights ensures the pallet racking installation cost includes a system that works in harmony with your equipment.

Future-Proofing and Scalability Assessment: Where do you see your business in 5 years? Designing with expansion and reconfiguration in mind ensures the system can grow with you, protecting the pallet racking installation cost investment from premature obsolescence.

Phase 2: Precision Engineering and 3D Simulation

This is where the warehouse is built in the digital world first, saving immense time and money and providing certainty to the projected pallet racking installation cost.

Advanced CAD & 3D Modeling: Photorealistic 3D models and virtual walkthroughs of the proposed layout allow clients to “experience” the new warehouse before a single component is ordered. This enables feedback and adjustments at zero cost, preventing expensive change orders later that inflate the pallet racking installation cost.

Structural Integrity and Seismic Calculations: For regions prone to seismic activity, engineering includes detailed seismic calculations. This non-negotiable aspect of the pallet racking installation cost ensures the racking can withstand specific zone requirements, safeguarding both inventory and personnel.

Throughput and Capacity Simulation: Using sophisticated software, operations can be simulated under peak load conditions. This identifies and eliminates potential bottlenecks in advance, ensuring the pallet racking installation cost delivers a system capable of meeting performance demands.

Phase 3: Strategic Sourcing and Logistics Management

Global presence and volume allow for the sourcing of high-quality materials at competitive prices, directly controlling a significant portion of the pallet racking installation cost.

Global Supply Chain Leverage: Established relationships with certified steel mills and component manufacturers worldwide ensure resilience against disruptions, providing stability to the pallet racking installation cost.

In-Region Inventory for Critical Parts: For key markets, strategic inventories of fast-moving parts are maintained to reduce lead times and keep the project on schedule, preventing delays that can indirectly increase the overall pallet racking installation cost.

Consolidated Shipping and Customs Handling: Managing the complexities of international shipping and customs presents the client with a single, streamlined logistics solution, bringing predictability to the shipping portion of the pallet racking installation cost.

Phase 4: Certified Installation and Rigorous Quality Assurance

The blueprint becomes reality in this phase, executed by a team of specialists whose expertise is a critical component of the pallet racking installation cost.

Deployment of Certified Installation Crews: Installation teams are trained and certified to international standards. They use calibrated torque wrenches and laser levels, ensuring the value promised in the pallet racking installation cost is realized in a safe, compliant structure.

Real-Time Project Management: A dedicated project manager provides daily progress reports, ensuring transparency and immediate issue resolution, protecting the project timeline and the agreed-upon pallet racking installation cost.

Multi-Stage Quality Control Checkpoints: The QC process is continuous, with checks at critical stages. This proactive approach is built into the pallet racking installation cost to guarantee final quality and prevent costly post-installation repairs.

Phase 5: Comprehensive Handover and Ongoing Support

The relationship doesn’t end when the last bolt is tightened; it evolves to protect the investment made in the pallet racking installation cost.

Operator and Safety Training: Mandatory training sessions for warehouse staff focus on proper loading and damage prevention, a simple practice that protects the integrity of the system and justifies the pallet racking installation cost through extended lifespan.

Delivery of the “As-Built” Package: A complete digital portfolio containing all final drawings and warranties is provided, a vital deliverable included in a professional pallet racking installation cost proposal.

Preventive Maintenance and Audit Programs: Scheduled maintenance contracts allow technicians to inspect racking and identify minor issues, a service that proactively manages the long-term asset value derived from the initial pallet racking installation cost.

Case Study: Achieving 34% Cost Savings for a Distribution Center in Vietnam

A multinational consumer goods company was expanding its distribution hub in Ho Chi Minh City. The initial project scope called for a conventional selective pallet racking system, and they had received several quotes focusing solely on the component pallet racking installation cost.

The Challenge: The client’s primary concern was the high pallet racking installation cost and the projected 8-week downtime during installation, which would have severely disrupted their peak season operations. The perceived pallet racking installation cost was prohibitive.

Our Solution: The team conducted a new needs analysis and proposed a hybrid solution that redefined the pallet racking installation cost model.

Narrow Aisle Pallet Racking was used in the high-density storage area, reducing the number of aisles required and thus, the component count and associated pallet racking installation cost.

A mezzanine floor was integrated above the receiving area for value-added services, creating new space without expanding the building’s footprint, a creative solution that added value beyond the core pallet racking installation cost.

Large sections of the racking were pre-assembled off-site, allowing for a rapid, “just-in-time” installation that cut on-site time to just 3 weeks, dramatically reducing the labor impact on the total pallet racking installation cost.

The Result: The optimized design not only increased storage capacity by 45% but also reduced the total project cost by 34%, a significant saving on the effective pallet racking installation cost when factoring in avoided costs of business disruption. The client achieved a rapid Return on Investment, proving that a strategic view of the pallet racking installation cost is paramount.

**<h2>Integrating Pallet Racking with Your Broader Automation Strategy</h2>

Pallet racking is the skeleton of your warehouse. To maximize its value, it must integrate seamlessly with the muscles and nerves—your automation systems. This integration profoundly affects the planning and justification of the pallet racking installation cost.

Designing for AGV and Forklift Compatibility

The rise of AGVs (Automated Guided Vehicles) and unmanned fork trucks demands higher precision from racking systems. Designs must incorporate tighter tolerances and perfect alignment, which may involve a slight increase in the engineering and installation portions of the pallet racking installation cost. This is essential to ensure seamless interaction with automated equipment, protecting the much larger investment in automation. The pallet racking installation cost must be viewed in this integrated context.

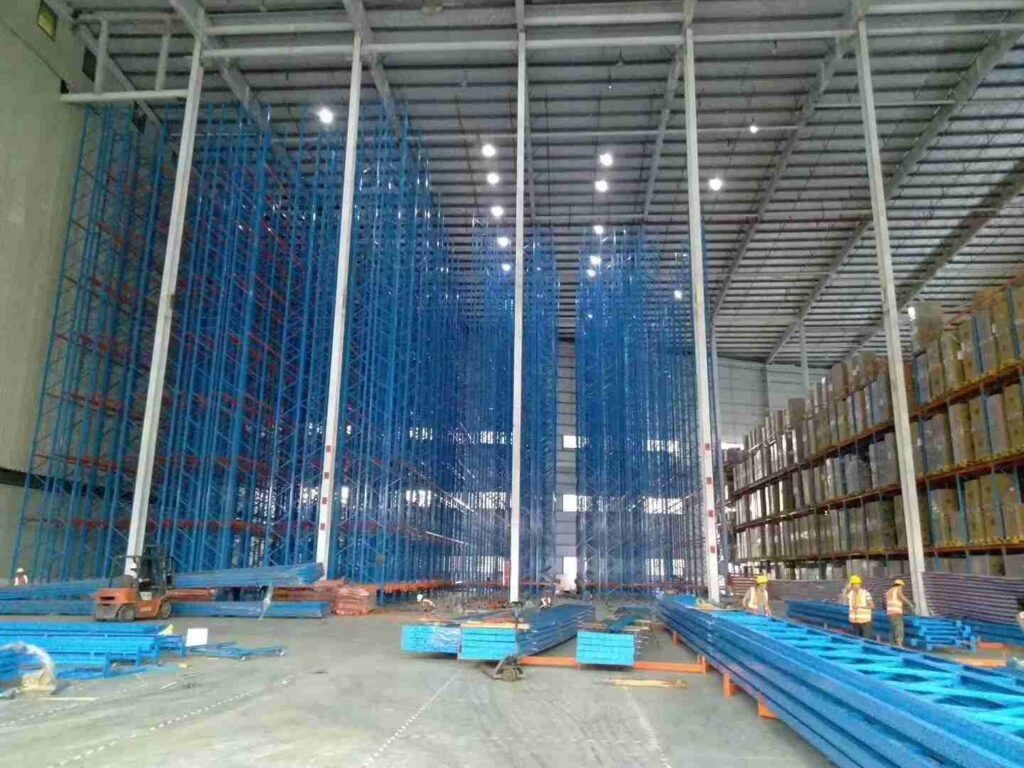

Laying the Groundwork for Future ASRS Implementation

Considering an Automated Storage and Retrieval System (ASRS) in the future? Planning ahead is everything. Designing and installing a pallet racking structure that is structurally ready for a later ASRS retrofit involves specifying heavier-duty components and ensuring precise column spacing. This foresight, while potentially adding 10-15% to the initial pallet racking installation cost, can save hundreds of thousands of dollars in future conversion costs, making it a shrewd strategic decision when evaluating the pallet racking installation cost.

Selecting the Right Partner: More Than Just a Supplier

Your choice of partner is the single most important factor in the success of your project and the accuracy of your pallet racking installation cost. Look for these critical attributes:

Proven In-Region Experience: A partner must have a portfolio of successful projects in your specific country, understanding local regulations and nuances that can affect the pallet racking installation cost.

In-House Engineering Capabilities: An integrated team of designers and engineers ensures accountability and seamless communication, leading to a more accurate and reliable pallet racking installation cost forecast.

Transparent and Detailed Quoting: The quote should be a clear, line-itemed document that educates you on the costs, not one that hides fees. Transparency in the pallet racking installation cost proposal is a hallmark of a trustworthy partner.

Commitment to Safety and Certification: Demand evidence of safety certifications for both the products and the installation crews. This due diligence is critical to ensuring the pallet racking installation cost does not become a precursor to future liabilities.

Conclusion: Investing in Intelligence, Not Just Steel

The journey to significantly reducing your pallet racking installation cost is a strategic one. It requires shifting the perspective from a simple procurement exercise to a comprehensive operational optimization project. By focusing on a holistic, engineered approach that prioritizes quality design, precision installation, and seamless integration, businesses do not merely install storage; they build a competitive advantage.

The framework detailed—encompassing deep analysis, digital prototyping, certified execution, and lifelong support—is a proven model that delivers quantifiable financial returns and operational resilience. The intelligent approach to the pallet racking installation cost is to see it not as an expense to be minimized, but as an investment to be optimized for a stronger, safer, and more profitable supply chain.

Frequently Asked Questions (FAQs)

1. How do you ensure spare parts availability and technical support for systems installed in remote industrial estates or special economic zones?

We maintain strategic inventories of high-wear parts (beam locks, safety pins, decking clips) and critical structural components (upright frames, connectors) at our regional service centers in Singapore, Dubai, and Bangkok. For projects in remote areas, we conduct a pre-emptive analysis and often recommend a small, on-site critical spares kit as part of the initial pallet racking installation cost proposal. Furthermore, we have established partnerships with local mechanical contractors in major industrial hubs who are trained to provide first-line support under our technical guidance, ensuring rapid response times.

2. We have an existing warehouse with mixed racking brands. Can you integrate a new system with the old, and how does this affect the installation cost?

Integration is often possible but requires a rigorous prior audit. Our engineers will assess the compatibility of upright profiles, beam connectors, and the load ratings of the existing system. We can frequently source adapters or manufacture custom connector plates to interface with legacy systems. However, this engineering service and any custom fabrication add complexity and are reflected in the project-specific pallet racking installation cost. In many cases, a hybrid approach is used: keeping sound, compatible sections while replacing non-compliant or worn sections, which can be a cost-effective strategy compared to a complete tear-down and replacement.

3. What are the typical payment terms associated with a major racking installation project, and do you offer progress-based invoicing?

Standard commercial terms for a large-scale pallet racking installation cost are progressive and tied to clear milestones. A common structure is: 30% upon order placement (for material procurement), 40% upon shipment of materials from the factory, 25% upon completion of installation, and a final 5% retention upon handover of all certifications and documentation. This aligns our cash flow with project progress and provides the client with financial control and visibility at each stage. We are also able to work with third-party project financing partners to structure lease or rental agreements if required.

4. Beyond seismic codes, are there other specific local regulations that can impact the design and cost?

Absolutely. Key regulations vary by country and can significantly influence the pallet racking installation cost. Examples include:

Fire Safety: UAE Civil Defence and Saudi SASO have specific requirements for clearance between rack tops and sprinkler heads, as well as potential need for in-rack sprinklers for high-bay storage.

Workplace Safety: Malaysia’s DOSH or Thailand’s Ministry of Labor may have regulations on safe working heights, mezzanine guardrail specifications, and load signage.

Environmental Regulations: Disposal of packaging materials and compliance with local waste management laws, especially for plastic wrapping and wooden crates, can be a logistical cost factor. A competent provider manages this compliance as part of the project scope.

5. For a business planning a new warehouse, at what point in the construction timeline should we engage a racking specialist to minimize total cost?

The ideal point is during the architectural and civil engineering design phase, before construction drawings are finalized. Early engagement allows the racking specialist to advise on optimal column grid spacing (e.g., recommending 12m x 24m over 10m x 20m for better racking density), floor flatness tolerances (critical for drive-in racking), door heights and locations, and electrical conduit placement for future automation. This collaboration can reduce the overall pallet racking installation cost by preventing costly change orders during construction and ensuring the building is perfectly suited for its primary function: efficient storage.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com