📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Maximize Storage Efficiency: The Definitive Guide to Expert Racking Layout Optimization

In the high-stakes world of global supply chains, the warehouse has evolved from a passive storage depot into the dynamic, beating heart of commerce. Its rhythm dictates the pulse of the entire operation, influencing everything from cost-per-shipment to customer loyalty. For logistics managers, operations directors, and business owners across Southeast Asia, the Middle East, Latin America, and beyond, the challenge is universal: achieving more with the existing footprint.

The solution, increasingly recognized as a non-negotiable strategic imperative, is profound and systematic racking layout optimization. This discipline transcends the simple act of arranging steel beams. It represents a holistic, data-infused engineering philosophy aimed at orchestrating the entire storage environment into a seamless, high-velocity ecosystem. True racking layout optimization is the deliberate fusion of spatial physics, inventory intelligence, and human ergonomics, creating a facility where speed, accuracy, and cost-efficiency are engineered into its very DNA.

For companies leveraging AGVs, ASRS, and automated conveyor systems, this process is the critical foundation that determines whether their automation investment soars or stumbles. This comprehensive guide delves into the multifaceted world of expert racking layout optimization, providing a masterclass in transforming stagnant storage spaces into powerful engines of profitability and growth.

Decoding the Imperative: The Staggering Cost of Inefficient Racking Layouts

Many facilities operate with a racking system that is a relic of the past, a layout that has grown organically and reactively rather than strategically. The financial and operational penalties of such a suboptimal setup are immense, often hidden in plain sight within operational budgets. A deep understanding of these costs is the first step toward justifying a comprehensive racking layout optimization project.

The Labor Productivity Black Hole

In a poorly optimized warehouse, labor is the primary casualty. The most glaring inefficiency is excessive, non-value-added travel time. Pickers and forklift operators can spend up to 60% of their shift simply moving between locations. When a racking layout optimization initiative is ignored, fast-moving SKUs remain scattered, and pick paths resemble a tangled web rather than a streamlined route. This disorganization directly translates into longer order cycle times, higher labor costs per order, and physical worker fatigue that suppresses morale and increases turnover. Furthermore, congested aisles and ill-defined workflows create chronic bottlenecks, causing expensive mechanical handling equipment to sit idle, burning fuel and maintenance hours without moving product.

The Silent Profit Leak: Wasted Cubic Space and Premature Expansion

A warehouse can be full yet profoundly inefficient. The most common oversight is the failure to utilize the vertical cube. Standard selective pallet racking that stops at 16 feet in a 30-foot clear-height building is essentially wasting 14 feet of premium, rent-paying air. This underutilization is a direct subsidy to inefficiency, forcing companies to lease larger spaces or construct new facilities far earlier than necessary. Strategic racking layout optimization directly attacks this problem by implementing high-density storage solutions that aggressively use the full vertical and horizontal volume, often increasing storage capacity by 40% or more within the same four walls and deferring multi-million-dollar capital expenditures.

Accuracy and Safety: The Direct Correlation to Layout

A disorganized storage environment is a breeding ground for errors. A flawed racking layout, lacking clear signage, logical slotting, and consistent zoning, inevitably leads to mis-picks, lost inventory, and incorrect shipments. The downstream costs of these errors—returns, reverse logistics, customer credits, and reputational damage—can cripple profitability. From a safety perspective, the stakes are even higher. Aisles that are too narrow for specific forklifts, beams overloaded beyond their capacity, and chaotic traffic patterns significantly increase the risk of catastrophic accidents, product damage, and serious worker injury. A foundational principle of modern racking layout optimization is that a safe warehouse is inherently an efficient one; the two are inextricably linked.

The Architectural Pillars of a World-Class Racking Layout Optimization Strategy

Transforming a warehouse requires a move from ad-hoc adjustments to a principles-driven methodology. The following pillars form the architectural blueprint for any successful racking layout optimization project, ensuring the final design is robust, scalable, and precisely aligned with business objectives.

Pillar 1: Hyper-Granular, Data-Driven Inventory Slotting

The cornerstone of any meaningful racking layout optimization is a ruthless commitment to data. Guessing is not an option. The process begins with a deep forensic analysis of the company’s inventory profile, typically using 12 to 24 months of historical data from the WMS or ERP. This involves a sophisticated ABC analysis based on velocity (pick frequency), but it goes much further. True expert racking layout optimization cross-references velocity with:

-

Cube Size and Weight: The physical dimensions and mass dictate the appropriate storage medium and handling equipment.

-

Order Affinity: Identifying which SKUs are frequently ordered together (e.g., a specific phone model and its corresponding case) to enable batch or zone picking efficiencies.

-

Seasonality and Demand Volatility: Understanding how product flows change throughout the year to create a flexible, rather than rigid, layout.

The output of this analysis is a scientific slotting plan. ‘A’ items are positioned in the highly accessible “golden zone”—waist-to-eye level in the most ergonomic and travel-efficient locations. This single step in the racking layout optimization process often yields the most immediate and dramatic reduction in labor costs and pick times.

Pillar 2: Intentional Zoning for Unidirectional, Lean Material Flow

An optimized warehouse operates with the precision of a well-rehearsed symphony, where each section has a dedicated purpose. Zoning is the practice of dividing the facility into logical, functional areas that create a smooth, unidirectional flow of goods from receiving to shipping. A masterful racking layout optimization plan will define clear zones such as:

-

Rapid Receiving and Staging: Designed for swift unloading, decanting, and quality checks to get goods into the system faster.

-

High-Density Bulk Storage: Utilizing drive-in, push-back, or pallet flow racking for full-pallet quantities of medium-to-slow movers.

-

High-Velocity Forward Picking Areas: Featuring dynamic solutions like carton flow racks, bin shelving, or vertical lift modules (VLMs) for the fastest-moving SKUs.

-

Consolidation and Value-Add Areas: Dedicated spaces for kitting, custom packaging, and order consolidation before shipping.

The goal of this pillar of racking layout optimization is to eliminate all forms of waste in movement—backtracking, cross-traffic, and congestion—creating a lean, predictable, and highly efficient workflow.

Pillar 3: The Strategic Balance of Storage Density and Accessibility

At the core of racking layout optimization is the fundamental trade-off between how much you can store and how quickly you can access it. Different storage systems exist on a spectrum from high-density/low-accessibility to low-density/high-accessibility. An expert racking layout optimization strategy does not choose one system but artfully blends them to create a hybrid model that perfectly matches the inventory profile. This involves:

-

Selective Pallet Racking: For 100% accessibility to every SKU, ideal for the fast-moving, high-variety inventory that requires frequent, random access.

-

High-Density Dynamic Systems (Push-back, Pallet Flow): For sacrificing minimal accessibility to gain massive density benefits, perfect for medium-turnover items or batch-picked products.

-

Automated Systems (ASRS, VLM): For achieving ultimate density and speed for specific SKU types, though at a higher capital investment.

The art of racking layout optimization lies in placing the right product in the right type of storage at the right location within the flow.

The Toolbox: Advanced Storage Systems for Ultimate Racking Layout Optimization

The principles of racking layout optimization are brought to life through the intelligent application of advanced storage technologies. The modern warehouse is a tapestry of integrated systems, each selected for its specific performance characteristics.

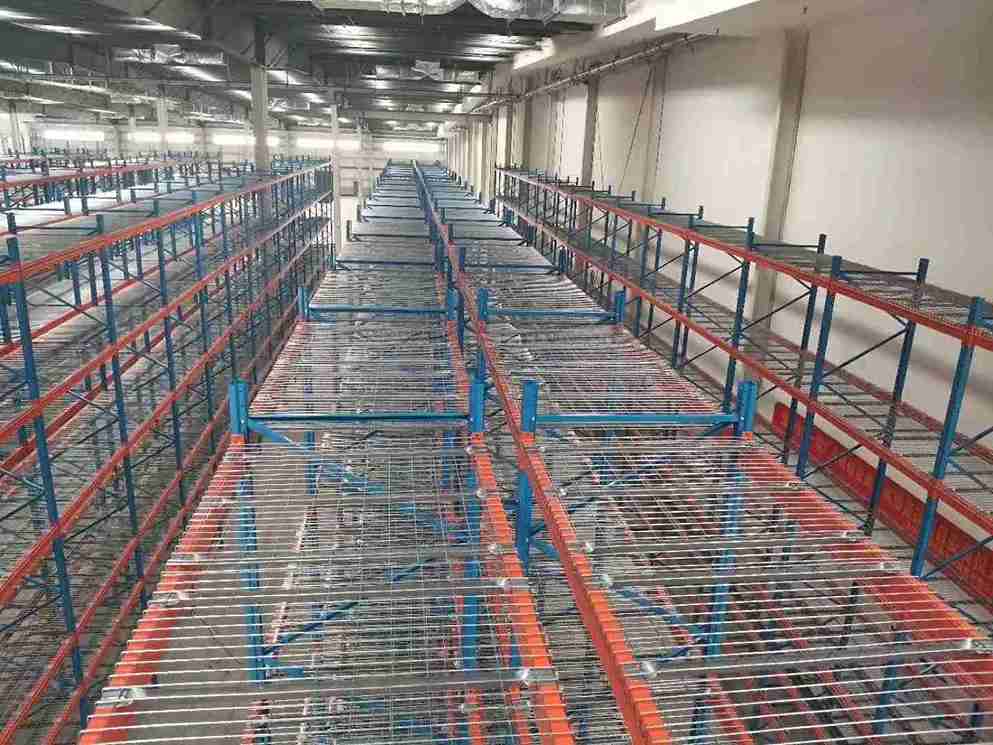

High-Density Dynamic Storage: Unlocking the True Potential of Your Footprint

When every square meter counts, high-density systems are the engine of racking layout optimization.

-

Push Back Racking: A system where pallets are stored multiple deep on inclined, nested carts. When a pallet is retrieved, the next one automatically rolls forward. This solution offers an excellent balance, providing 2-4 times the density of selective racking while still allowing for good selectivity, as each lane can hold a different SKU. It is a cornerstone of racking layout optimization for medium-turnover products.

-

Pallet Flow Racking: Utilizing gravity-fed lanes on a slight decline, this is the ultimate FIFO (First-In, First-Out) solution. It is indispensable in industries with expiration dates, such as food, beverage, and pharmaceuticals. The high-throughput nature of flow racks makes them a powerhouse in any racking layout optimization plan for high-volume, time-sensitive distribution.

-

Drive-In/Drive-Through Racking: This system maximizes density by eliminating aisles, allowing forklifts to drive directly into the rack structure. It is the highest-density pallet storage option but operates on a LIFO or FIFO basis. It is a specialized tool in the racking layout optimization toolbox, best for bulk storage of low-SKU-count, high-turnover products like raw materials or finished goods in cold storage.

The Automation Frontier: Racking Layout Optimization for Robotic and ASRS Integration

For facilities aiming at the pinnacle of efficiency, the racking layout optimization process must be designed from the ground up to accommodate automation.

-

Automated Storage and Retrieval Systems (ASRS): In an ASRS, the racking is an integral part of the machine itself. The racking layout optimization for an ASRS requires laser-sharp precision, with tolerances measured in millimeters to ensure the cranes can operate reliably at high speeds. The entire layout, including infeed and outfeed conveyor interfaces, is dictated by the software’s logic to ensure a continuous, unimpeded flow of goods.

-

Mobile Racking and Robotic Integration: For facilities using Autonomous Mobile Robots (AMRs) or AGVs, the racking layout optimization must account for their navigation needs. This includes designing aisles with consistent widths for safe robot passage, creating structured pick-face environments for human-robot collaboration, and ensuring the floor plan allows for efficient charging and staging. A failure to integrate these requirements during the racking layout optimization phase will severely limit the ROI of the automation investment.

The Blueprint for Transformation: A Phased Racking Layout Optimization Methodology

Achieving a superior warehouse environment requires a disciplined, phased approach. A world-class racking layout optimization project is a marathon, not a sprint, and its success hinges on meticulous execution at every stage.

Phase 1: Immersive Discovery and Holistic Data Auditing

The journey begins with a deep immersion into the client’s world. This phase involves more than just collecting spreadsheets; it includes on-the-ground time-motion studies, interviews with operators who possess tribal knowledge, and a thorough physical audit of the current facility. The goal is to build a complete picture of not just what should happen, but what actually happens day-to-day. This foundational step ensures the subsequent racking layout optimization is grounded in reality.

Phase 2: Advanced Simulation, Modeling, and Scenario Analysis

Using powerful simulation software, experts create a digital twin of the current warehouse. They then model multiple, distinct racking layout optimization scenarios. One model might prioritize maximum throughput for e-commerce fulfillment, while another might focus on maximizing storage density for a wholesale operation. These models are stress-tested using real historical order data, allowing for a data-driven comparison of potential ROI, bottleneck identification, and performance prediction long before any physical work begins.

Phase 3: Collaborative Design Engineering and Technical Finalization

The top-ranked racking layout optimization scenarios are presented to the client’s team in a collaborative workshop. This is where operational expertise meets engineering design. Feedback from floor managers and warehouse supervisors is incorporated to refine the final plan. The deliverable is a comprehensive package including detailed CAD drawings, 3D immersive renderings, a full bill of materials, and a phased implementation schedule.

Phase 4: Meticulous, Phased Implementation and Change Management

A key differentiator of professional racking layout optimization is its focus on minimizing operational disruption. Implementation is executed in carefully planned phases, often during off-peak hours or by temporarily relocating operations to a section of the warehouse. The project management covers everything from site preparation and racking installation to the integration of new software and hardware, ensuring a smooth transition.

Phase 5: Performance Validation, Training, and Continuous Improvement

The project’s success is quantitatively measured post-implementation. Key Performance Indicators (KPIs) such as order cycle time, picks per hour, and inventory accuracy are tracked against pre-optimization baselines. Comprehensive training ensures the staff can fully leverage the new system. This final phase of the racking layout optimization journey often includes a continuous improvement plan to make iterative adjustments and maintain peak performance.

Quantifying the Victory: The KPIs of a Successful Racking Layout Optimization

The impact of a professional racking layout optimization must be measurable. The following KPIs provide an undeniable report card on the project’s success:

-

Order Cycle Time Reduction: A direct measure of increased operational speed.

-

Picks per Labor/Hour Increase: A clear indicator of enhanced labor productivity.

-

Storage Capacity (Pallets per m²) Improvement: A tangible metric for space utilization gains.

-

Inventory Accuracy Attainment: Moving towards 99.9% accuracy, reducing shrink and errors.

-

Cost per Order Shipped Reduction: The ultimate financial metric proving the value of the racking layout optimization.

Conclusion: From Storage Liability to Logistical Asset

In the final analysis, racking layout optimization is the definitive strategic differentiator in modern logistics. It is a rigorous, multi-disciplinary process that systematically eradicates waste and injects velocity, accuracy, and intelligence into the warehouse environment. For businesses operating in the competitive landscapes of emerging global markets, the decision to invest in a profound racking layout optimization is the decision to stop treating the warehouse as a cost center and start leveraging it as a powerful, profit-driving asset. It is the essential foundation upon which automation, scalability, and market leadership are built. The journey toward a truly optimized operation begins with a commitment to excellence in racking layout optimization.

Frequently Asked Questions (FAQs)

1. How does the racking layout optimization process differ for a facility that is already partially automated?

The process becomes more complex and integrated. The racking layout optimization must be reverse-engineered from the capabilities and requirements of the existing automation. For example, the travel paths and pickup/drop-off points of an existing AGV fleet become fixed nodes that the new layout must connect optimally. The racking layout optimization focuses on enhancing the synergy between automated and manual zones, ensuring software and physical flow are perfectly aligned.

2. What are the critical structural and floor considerations often overlooked during racking layout optimization?

A superior racking layout optimization plan is useless if the building cannot support it. Key considerations include:

-

Floor Flatness Tolerance: Especially critical for narrow-aisle forklifts and ASRS, where even slight deviations can cause operational issues.

-

Column Grid Spacing: Existing columns can dictate aisle placement and module dimensions.

-

Seismic and Wind Load Requirements: Particularly important in certain geographic regions, these factors influence the structural engineering of the racking system itself.

-

Floor Load Capacity: Ensuring the slab can support the point loads of densely packed, heavy racking.

3. Can a successful racking layout optimization help with sustainability and green warehouse initiatives?

Absolutely. An effective racking layout optimization is a powerful sustainability tool. By maximizing storage density within an existing building, it defers the need for new construction and its associated embodied carbon. Furthermore, layouts that minimize travel distances directly reduce energy consumption, both from material handling equipment (less electricity/fuel) and from building services like lighting and HVAC (by making the space more efficient to condition).

4. For a multi-client 3PL warehouse, how does the racking layout optimization strategy change?

The racking layout optimization for a third-party logistics provider is uniquely challenging. It must prioritize flexibility and scalability above all. The layout often employs a modular pod-based design, allowing sections to be reconfigured for different clients. The slotting strategy is dynamic, constantly adapting to the changing inventory profiles of multiple clients. The racking layout optimization in a 3PL context is less about a single perfect state and more about creating an agile, reconfigurable system that can evolve with a fluid client base.

5. What is the role of the Warehouse Management System (WMS) in maintaining an optimized racking layout over time?

The WMS is the digital nervous system that brings a static racking layout optimization plan to life and keeps it relevant. A sophisticated WMS enforces the slotting rules, directs put-away to the correct locations, and creates intelligent pick paths based on the optimized layout. It provides the data necessary for continuous racking layout optimization, flagging when SKU velocities change and suggesting re-slotting to maintain peak performance. Without a capable WMS, even the best physical racking layout optimization will degrade over time.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com