📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

H1: Heavy Duty Racking Systems: The Ultimate Guide to Maximizing Warehouse Storage & Long-Term Savings

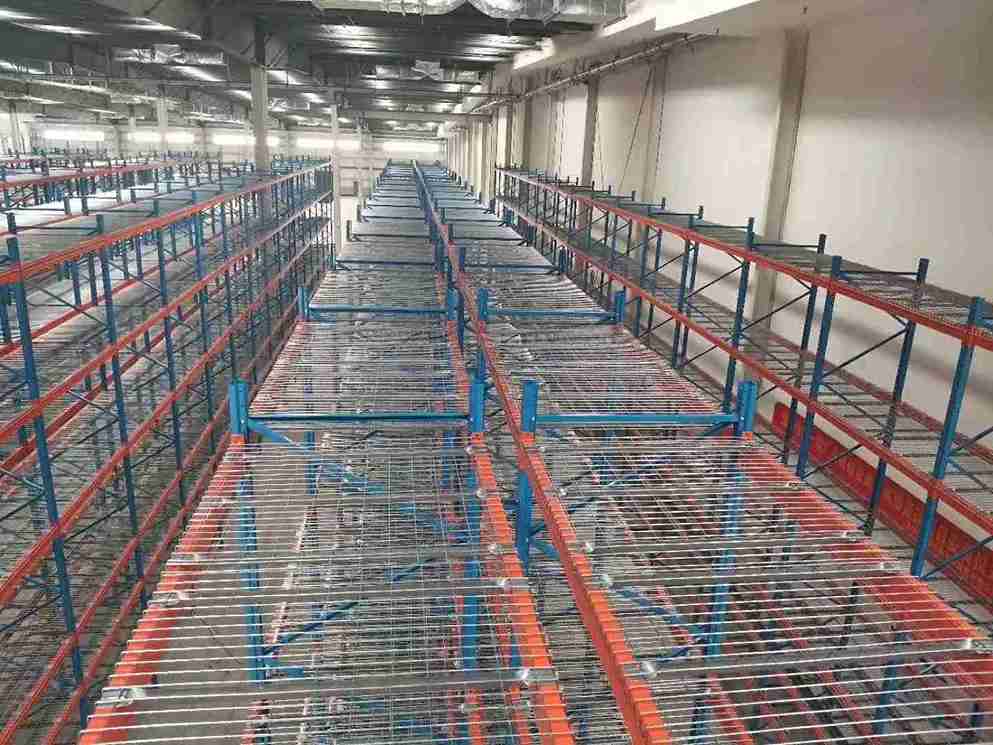

For industrial warehouse managers and logistics operators across Southeast Asia, Latin America, and emerging markets, the relentless pressure to optimize space and reduce costs defines daily operations. The single most critical investment confronting these professionals is the selection of a storage infrastructure that can withstand immense weight, adapt to fluctuating inventory, and deliver a rapid return on investment. The cornerstone of this infrastructure is the industrial-grade heavy duty racking system.

These are not mere storage shelves; they are engineered ecosystems of steel and precision, designed to transform chaotic storage areas into models of efficiency and safety. This definitive resource explores how professionally engineered heavy duty racking systems serve as the foundational pillar for achieving unparalleled storage density, operational resilience, and significant long-term financial savings. For any organization managing substantial palletized loads, understanding the nuances of these systems is the first step toward building a world-class logistics operation.

H2: The Engineering Backbone of Modern Warehousing: Defining Heavy Duty Racking Systems

What exactly separates a standard storage rack from a true industrial heavy duty racking system? The distinction lies in its fundamental purpose and construction. A heavy duty racking system is a structural framework meticulously calculated to support palletized goods with unit weights that can easily exceed 2,500 kilograms. These systems are the undisputed workhorses of industries such as manufacturing, bulk distribution, and cold storage, where failure is not an option. The design philosophy behind every superior heavy duty racking system prioritizes load integrity, operational safety, and spatial efficiency over mere cost, making it a strategic capital expenditure rather than a simple purchase.

H3: Deconstructing the Anatomy of a Heavy Duty Racking System

The legendary durability of a well-built heavy duty racking system is a direct result of its component-level engineering. Each part is optimized for strength and longevity.

Upright Frames: These vertical columns form the literal spine of the entire structure. In a high-capacity heavy duty racking system, uprights are fabricated from high-tensile steel, with roll-formed profiles often reaching depths of 120mm or more. The specific gauge, or thickness, of the steel is scientifically determined based on the required load capacity and the seismic activity of the region—a critical factor for warehouses in geologically active zones like parts of Central Asia or South America.

Load Beams: These horizontal members are the shoulders of the operation, bearing the direct weight of the stored pallets. Beams in a premium heavy duty racking system feature a torsion-resistant box design. Their load-bearing capacity is a function of their vertical step, length, and material thickness. For operations utilizing automated guided vehicles (AGVs) or forklifts, reinforced end connectors are essential to withstand the repeated minor impacts of pallet placement.

Beam Connectors and Safety Locks: The connection point between the beam and upright is a potential failure point in poorly designed systems. In a robust heavy duty racking system, this connection is secured with patented safety locks that engage automatically, preventing accidental dislodgement. This is a non-negotiable safety feature that protects both inventory and personn

Bracing and Footplates: These components provide critical lateral stability, ensuring the heavy duty racking system can resist the dynamic forces of forklift traffic and seismic events. Large, welded footplates, secured to the concrete slab with high-grade anchor bolts, distribute the immense vertical loads safely into the building’s foundation.

H2: The Compelling Financial Logic: How Heavy Duty Racking Systems Generate Substantial ROI

The decision to invest in a high-quality heavy duty racking system should be framed as a strategic financial move. The initial investment is systematically offset by a multitude of operational savings and efficiency gains that compound over the system’s decades-long lifespan.

H3: Cubic Space Maximization: The Alternative to Costly Expansion

The most immediate and quantifiable saving from a heavy duty racking system is the vertical utilization of air space. By building upwards with a racking system engineered for heights of 15 meters or more, warehouses can dramatically increase storage density without expanding their physical footprint. In markets where industrial real estate is at a premium, such as Bangkok, Dubai, or Mexico City, this capability is transformative. The ability to store more within the same four walls directly lowers the cost per pallet position, a fundamental Key Performance Indicator (KPI) for any logistics operation. A well-planned heavy duty racking system turns previously wasted vertical space into a high-density storage asset.

H3: Driving Down Operational Costs Through Enhanced Workflow

An intelligently configured heavy duty racking system is a catalyst for operational efficiency. It creates a logical, organized environment that minimizes non-value-added travel time for both manual order pickers and automated equipment. The strategic layout of a heavy duty racking system facilitates:

Accelerated Order Fulfillment: Clear aisles and defined pick paths allow workers to locate and retrieve items faster, slashing cycle times.

Reduced MHE Operating Costs: With less distance to travel for each pallet move, forklifts consume less energy, and their components experience less wear and tear.

Optimized Labor Productivity: Employees spend less time searching and more time on productive tasks, effectively increasing throughput without increasing headcount.

For facilities leveraging automation, the precision and consistency of a professionally installed heavy duty racking system are paramount. The performance of AGVs and automated forklifts is entirely dependent on the predictable, accurate environment that these systems provide.

H3: Mitigating Loss: Product Damage and Inventory Shrinkage

An unreliable storage solution is a significant source of financial loss. Beams that deflect under load or unstable frames can lead to pallet collapse, resulting in damaged goods and lost inventory. A properly engineered heavy duty racking system is designed for minimal deflection, ensuring pallets remain stable and secure. Furthermore, the systematic organization inherent to a heavy duty racking system drastically improves inventory control. It reduces misplacements and simplifies cycle counting, leading to superior inventory accuracy and a healthier bottom line.

H2: The Art of Customization: Engineering Heavy Duty Racking Systems for Unique Challenges

The term “custom” is often used as a marketing buzzword, but in the context of industrial storage, it is an engineering imperative. Off-the-shelf solutions cannot address the unique variables of each warehouse. A truly custom heavy duty racking system is designed from first principles to meet a facility’s specific operational profile, inventory characteristics, and growth projections.

H3: The Foundational Site Assessment: Blueprinting for Success

The design process for a reliable heavy duty racking system begins with a comprehensive site assessment conducted by experienced engineers. This due diligence is critical for safety and performance. The assessment includes:

Floor Flatness and Load-Bearing Analysis: The concrete slab is meticulously measured for flatness, and core samples may be taken to verify its compressive strength. An uneven foundation can compromise the integrity of even the strongest heavy duty racking system.

Dimensional Mapping: Every structural column, sprinkler head, light fixture, and utility line is mapped in 3D space to ensure the new heavy duty racking system layout maximizes every cubic meter of available space.

MHE Compatibility Analysis: The specifications of the warehouse’s material handling equipment—be it narrow-aisle reach trucks, counterbalance forklifts, or turret trucks—directly determine the required aisle widths and racking clearances.

Inventory Profiling: A deep analysis of SKU velocity, pallet dimensions, and weight distribution informs the final layout, creating an optimal mix of bulk storage, pick faces, and reserve locations within the heavy duty racking system.

H3: Advanced Configurations for Extreme Demands

Beyond standard selective pallet racking, the versatility of a custom <b>heavy duty racking system</b> allows for the integration of high-density storage technologies.

Push-Back Racking Systems: This high-density configuration uses a series of nested carts on inclined rails within the heavy duty racking system structure, allowing pallets to be stored several deep while remaining accessible from a single aisle. It is an ideal solution for storing multiple SKUs with high depth in a Last-In, First-Out (LIFO) sequence.

Drive-In/Drive-Through Racking: This design transforms the heavy duty racking system into a structure that forklifts can drive into, effectively eliminating multiple aisles to achieve exceptional storage density. It is perfectly suited for cold storage applications or for storing large quantities of a single SKU, following either FIFO or LIFO principles.

Rack-Supported Buildings: In this scenario, the heavy duty racking system itself becomes the primary structural support for the building’s roof and walls. This integrated approach is often the most cost-effective solution for new, large-scale distribution centers, as it eliminates the need for separate building columns.

H2: The Automation-Ready Foundation: Heavy Duty Racking Systems in the Smart Warehouse

In the era of Industry 4.0, a heavy duty racking system is no longer a passive storage structure. It is an active, integral component of the automated warehouse ecosystem. The precision and robustness of the racking directly determine the success and reliability of automated technologies.

H3: The Critical Interface with AGVs and Robotic Forklifts

When deploying AGVs or unmanned forklifts, the racking interface is a mission-critical element. These autonomous systems rely on a perfectly predictable and consistent physical environment. A heavy duty racking system designed for automation is installed with laser-guided precision to ensure:

Perfect Pallet Pickup and Placement: Consistently aligned bays and levels are essential for the robotic arms or forks to engage pallets reliably without error.

Adequate Operational Clearance: Calculated tolerances are built into the heavy duty racking system to account for minor sensor drift or navigation inaccuracies in the automated equipment.

Integrated Impact Protection: Reinforced upright guards and other protective devices are strategically placed to absorb incidental contact, safeguarding both the racking structure and the high-value automation assets.

H3: Enabling Seamless Conveyor and Sortation System Integration

A logically planned heavy duty racking system layout is the genesis of an efficient material flow. By creating distinct zones based on product velocity and coupling them with an automated conveyor system, warehouses can establish a highly efficient “goods-to-person” order fulfillment model. The heavy duty racking system acts as the bulk reservoir that feeds the conveyor, which then transports items to ergonomic picking stations or automated sortation systems, dramatically reducing manual labor and accelerating order throughput.

H2: Material Integrity and Manufacturing Excellence: What Separates Superior Heavy Duty Racking Systems

The promise of “heavy duty” is meaningless without superior materials and manufacturing rigor. The quality of the raw steel and the precision of the fabrication process are what differentiate a capital-grade asset from a commodity product.

H4: The Science of High-Tensile Steel and Precision Roll-Forming

Leading manufacturers of heavy duty racking systems specify certified, high-tensile steel. This material offers a superior strength-to-weight ratio, allowing upright frames to support colossal loads without adding unnecessary bulk and weight. The roll-forming process, where coils of steel are shaped into precise upright and beam profiles, is conducted with extreme accuracy. This ensures that every component of the heavy duty racking system fits together perfectly during installation, a prerequisite for achieving the designed structural integrity.

H4: Advanced Corrosion Protection for Demanding Environments

A standard paint finish is wholly inadequate for warehouses in humid coastal regions, chemical storage facilities, or temperature-controlled cold storage. The protective finish on a premium heavy duty racking system is a multi-stage engineering process in itself. It typically involves a phosphate cleaning stage, a cathodic electrocoating primer for complete coverage, and a final application of a thermosetting epoxy-polyester powder coat, cured at high temperatures. This results in a finish that is exceptionally resistant to chipping, scratching, and corrosion, ensuring the long-term viability of the heavy duty racking system in challenging conditions.

H2: A Culture of Safety: Global Standards and Proactive Risk Management in Heavy Duty Racking Systems

Safety is not a feature; it is the foundational principle governing the design, installation, and maintenance of any heavy duty racking system. Reputable providers engineer their systems to comply with rigorous international standards, such as those from the Rack Manufacturers Institute (RMI) and the European Federation of Materials Handling (FEM).

H3: The Non-Negotiable Need for Professional Load Calculation and Seismic Analysis

Every component within a heavy duty racking system must be specified based on rigorous structural calculations. This engineering discipline is especially critical in seismically active regions. Professional engineers perform detailed seismic analyses to ensure the proposed heavy duty racking system can withstand the lateral forces prescribed by local building codes. This provides warehouse owners with documented proof of safety for their insurers and regulatory bodies, and, most importantly, protects their workforce.

H3: Implementing a Proactive Inspection and Maintenance Regime

A heavy duty racking system is a dynamic asset that is subject to wear and potential impact. A proactive approach to maintenance is essential. This includes:

Scheduled Professional Inspections: Quarterly or bi-annual inspections by certified technicians can identify minor damage or wear before it escalates into a major safety hazard or structural failure.

Rack Protection Systems: The strategic installation of column guards, aisle-end protectors, and pallet stop bars is a low-cost, high-impact method of preserving the integrity of the heavy duty racking system.

Comprehensive Operator Training: Ensuring that forklift operators are trained to handle loads safely around the heavy duty racking system is one of the most effective ways to prevent damage.

H2: The Future-Proof Warehouse: Smart Heavy Duty Racking Systems and IoT Integration

The next evolutionary step for the industrial heavy duty racking system is its transformation into a data-generating component of the smart warehouse. The integration of sensor technology is turning passive storage into an intelligent logistics hub.

H3: Sensor-Embedded Racking for Real-Time Asset Management

Innovative providers are now embedding IoT sensors directly into the components of a heavy duty racking system. These sensors can provide a continuous stream of valuable data, monitoring:

Real-Time Load Monitoring: Sensors on beams can verify that a pallet’s weight does not exceed the rated capacity, preventing dangerous overloads.

Instant Impact Detection: Accelerometers can detect and immediately report the force and location of a forklift impact, triggering a mandatory safety inspection.

Inventory Visibility: Ultrasonic or infrared sensors can confirm the presence or absence of a pallet in a specific location, providing real-time stock visibility and automating inventory reconciliation.

H3: Digital Twins and Lifecycle Management Software

For large-scale, complex facilities, creating a “digital twin” — a virtual, dynamic replica of the physical heavy duty racking system — is becoming a best practice. This digital model allows logistics managers to simulate layout changes, test the impact of new product introductions, and plan maintenance activities in a risk-free virtual environment. This software becomes the central system of record for the entire lifecycle of the storage infrastructure.

H2: Selecting a Strategic Partner: The Most Critical Decision in Your Heavy Duty Racking System Project

Choosing a supplier for a heavy duty racking system is a long-term strategic partnership, not a simple transactional purchase. The provider must demonstrate proven engineering expertise, a global portfolio of successful projects, and an unwavering commitment to safety and service.

A world-class partner offers a true, single-source solution: from initial consultation and detailed design to precision manufacturing, certified installation, and ongoing support and maintenance. Prospective clients should request detailed case studies from projects within their industry and geographic region. Inquiries should be made into the provider’s internal quality control protocols and the comprehensiveness of their warranties on both materials and installation workmanship. The right partner will act as an extension of your team, dedicated to ensuring your heavy duty racking system delivers on its promise of safety, efficiency, and savings for decades to come.

Conclusion

In the high-stakes environment of modern industrial logistics, the storage infrastructure is the fundamental element that dictates operational capacity, safety, and profitability. A professionally engineered, custom heavy duty racking system is a transformative capital asset that delivers demonstrable, long-term value through maximized spatial efficiency, enhanced workflow productivity, and unparalleled structural durability. It is the essential, robust foundation upon which successful and scalable warehouses are built.

By collaborating with an expert partner who possesses deep knowledge of structural engineering, material science, and logistics workflows, an organization is not merely purchasing racking; it is making a strategic investment in the future resilience, growth, and competitive advantage of its entire supply chain.

Frequently Asked Questions (FAQs)

1. What is the typical lead time for a custom heavy duty racking system project from design to installation?

Lead times are project-dependent but generally range from 10 to 18 weeks for a complete turnkey solution. This timeline encompasses the detailed engineering phase, material procurement and manufacturing, international shipping (if applicable), and the on-site installation. For projects involving complex automation integration or a rack-supported building, the timeline is longer and is detailed in a comprehensive project plan provided before commencement.

2. Can a new heavy duty racking system be integrated with our existing, older racking?

While technically possible in some cases, it is a practice generally discouraged by engineering professionals. Mixing systems from different manufacturers and eras poses significant risks to structural integrity. Differences in engineering standards, steel quality, beam connector designs, and even minor dimensional tolerances can create weak points. A professional assessment can determine feasibility, but a phased replacement of the old system is often the safer and more cost-effective long-term strategy.

3. How does the installation process for a large-scale heavy duty racking system work within a live, operational warehouse?

Expert providers are adept at phased installations in live environments. The process involves meticulous planning with the client’s logistics team to create an installation sequence that minimizes disruption. This typically involves working in designated zones, often during off-peak hours or weekends, to ensure that the majority of warehouse operations can continue unimpeded while the new heavy duty racking system is constructed around them.

4. Beyond standard pallet racking, what are the weight capacity limits of your most robust heavy duty racking systems?

While standard selective heavy duty racking systems are routinely engineered for capacities of 3,000 kg per pallet position, specialized structural racking solutions are available for extreme loads. These systems, often used in heavy machinery, metal fabrication, or automotive parts storage, can be designed to support shelf loads of 10,000 kg or more, utilizing built-up structural steel members instead of roll-formed profiles.

5. Do you provide full structural certification for the installed heavy duty racking system for our insurance and compliance records?

Absolutely. A reputable provider will supply a comprehensive engineering package upon project completion. This dossier includes all structural calculations, load capacity certificates for each component, and “as-built” drawings that reflect the final installed configuration. This documentation is vital for insurance compliance, meeting local regulatory requirements, and serves as the benchmark for all future safety inspections and maintenance of the heavy duty racking system.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com