📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Solving Warehouse Congestion? A Comprehensive Guide to High-Density Industrial Racking Systems

Warehouse congestion represents one of the most significant and costly operational challenges in modern logistics and supply chain management. It is a complex problem that silently erodes profitability, cripples productivity, and stifles scalability. For businesses facing exponential growth but constrained by a static physical footprint, the traditional answer of expanding the warehouse is often a capital-intensive and impractical solution.

The paradigm has shifted. The contemporary, strategic answer lies in a radical optimization of existing space through the implementation of advanced industrial racking systems. This exhaustive guide serves as a definitive resource on high-density storage, delving deep into the engineering principles, technological innovations, and strategic selection criteria that define modern industrial racking systems.

It is designed to provide logistics managers, operations directors, and business owners with the knowledge required to transform a congested, inefficient warehouse into a streamlined, high-throughput, and future-proof distribution center. The focus is unequivocally on industrial racking systems engineered for high-density storage, from sophisticated pallet flow racks to fully automated industrial racking systems integrated with robotic retrieval technology.

Quantifying the Crisis: The Multifaceted Cost of Warehouse Congestion

To fully appreciate the value proposition of high-density industrial racking systems, one must first move beyond a superficial understanding of congestion. It is not merely a nuisance; it is a systemic failure with quantifiable financial and operational repercussions.

The Direct Impact on Productivity and Labor Economics

In a congested facility, the travel time for order pickers and forklift operators can increase by over 50%. Operators are no longer engaged in value-added tasks but are instead navigating a labyrinth of inefficiently stored inventory. This leads directly to a lower number of orders picked per hour, increased labor costs per unit handled, and a reliance on costly overtime to meet daily shipping targets.

The design of conventional industrial racking systems often contributes to this problem, with wide aisles consuming valuable floor space that could be converted into productive storage. The cycle of inefficiency is self-perpetuating: congestion leads to slower operations, which requires more inventory on hand to buffer against delays, which in turn worsens the congestion.

Elevated Safety Risks and Infrastructure Damage

Safety is paramount, and a congested warehouse is an inherently hazardous environment. Narrow, cluttered aisles significantly elevate the risk of forklift collisions with the upright frames of industrial racking systems, building columns, and other infrastructure. A single impact can compromise the structural integrity of an entire bay of industrial racking systems, necessitating immediate repair and creating a potential collapse hazard. Furthermore, disorganized aisles obstruct emergency exits and can impede the effective coverage of sprinkler systems during a fire, violating safety codes and endangering personnel. Properly designed high-density industrial racking systems inherently promote safer working environments by creating defined pathways and reducing unnecessary traffic.

The Insidious Nature of Hidden and Indirect Costs

The financial drain extends far beyond visible labor inefficiencies. Poor space utilization means a company is paying to heat, cool, and light vast volumes of unproductive air. The real estate cost per pallet position becomes unjustifiably high. Moreover, a disorganized storage environment leads to a higher incidence of product damage from misplaced forklift forks and mishandling. Perhaps the most costly hidden expense is inventory shrinkage—pallets that are “lost” in the chaos of an unoptimized layout, leading to stock-outs, inaccurate inventory records, and write-offs. These combined hidden costs can silently erode profit margins by a staggering 10-15%, making the investment in optimized industrial racking systems a critical financial imperative.

The High-Density Paradigm: A Strategic Shift in Storage Philosophy

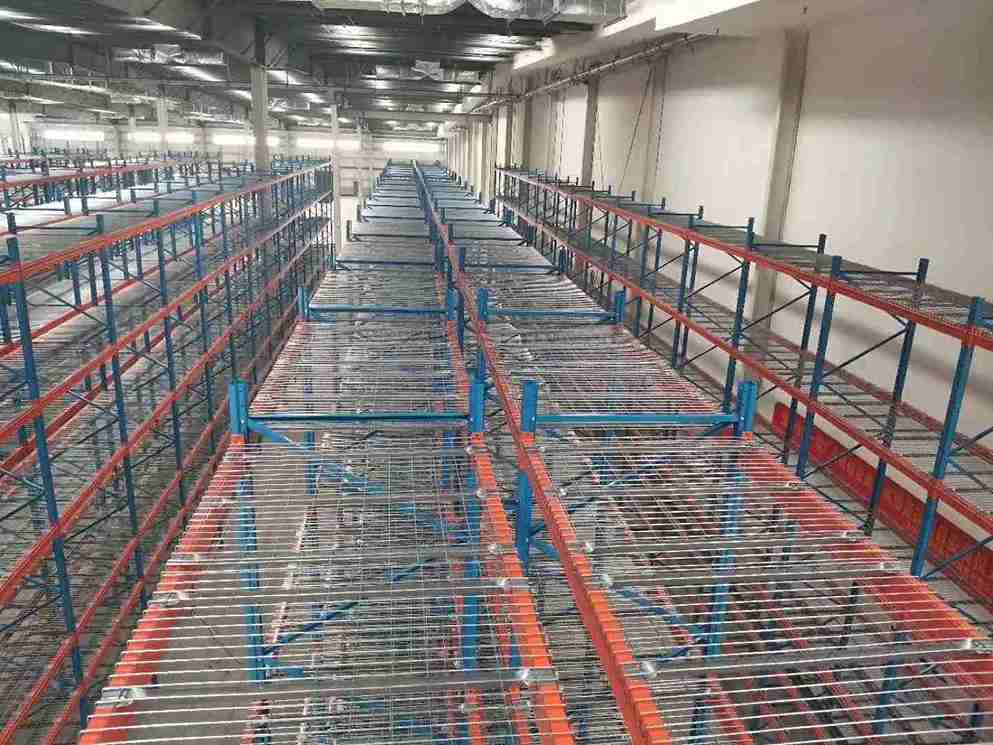

The core philosophy behind high-density storage is a fundamental re-imagining of the warehouse layout. It is about working smarter, not bigger. The goal is to store a greater volume of goods within the same, or even a reduced, footprint by leveraging engineering and technology. This involves a deliberate focus on two primary levers: the drastic reduction of non-productive aisle space and the full exploitation of the facility’s cubic volume from the floor to the ceiling joists.

Traditional industrial racking systems, with their wide aisles designed for counterbalance forklifts, often dedicate over 50% of the total floor space solely to access. High-density industrial racking systems challenge this outdated model, utilizing innovative designs to minimize or create aisles on-demand, thereby converting wasted travel space into high-value, revenue-generating storage.

The Foundational Principles of High-Density Industrial Racking Systems

Radical Aisle Reduction: This is the most impactful principle. By implementing industrial racking systems that allow for narrower aisles or that eliminate fixed aisles altogether, facilities can achieve a step-change in storage density.

Dynamic Storage and Live Inventory: Incorporating gravity-fed or automated retrieval mechanisms ensures disciplined inventory control, such as FIFO (First-In, First-Out), which is non-negotiable for perishable goods or items with strict expiry dates.

Aggressive Vertical Utilization: Most warehouses are volume-rich but floor-poor. High-density industrial racking systems are engineered to safely stack inventory to greater heights, actively leveraging the full clear height of the building, a resource that is often underutilized.

Seamless System Integration: The most advanced industrial racking systems are no longer passive storage structures; they are active, integrated components of the material handling ecosystem, working in concert with Automated Guided Vehicles (AGVs), automated conveyor systems, and sophisticated software.

An In-Depth Analysis of High-Density Industrial Racking System Technologies

The market offers a spectrum of high-density solutions, each with distinct advantages, operational characteristics, and ideal application scenarios. Selecting the correct type of industrial racking systems is a decision that must be driven by data and a clear understanding of operational requirements.

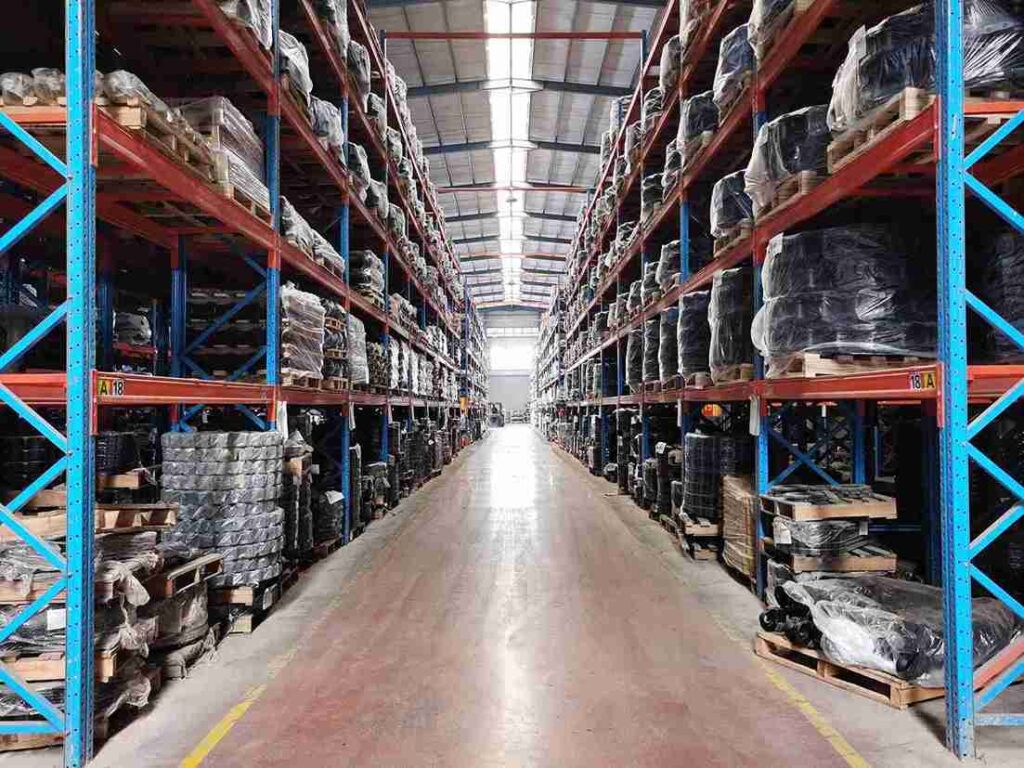

1. Narrow-Aisle & Very-Narrow-Aisle (VNA) Industrial Racking Systems

For many operations, transitioning to narrow-aisle industrial racking systems is the most logical first foray into high-density storage. By deploying specialized narrow-aisle reach trucks or order pickers, aisle widths can be reduced from a standard 11-12 feet down to 7-8 feet. For Very-Narrow-Aisle (VNA) applications, aisles can be as tight as 5-6 feet, which necessitates the use of guided vehicles like rail-guided or wire-guided turret trucks.

Ideal Application Profile: Operations with a vast number of SKUs that require selective, direct access to every single pallet location. It represents an optimal balance between enhanced density and unimpeded accessibility.

Primary Advantages: Can increase storage capacity by up to 40% compared to conventional wide-aisle industrial racking systems without a complete revolution in storage methodology. It offers a favorable return on investment.

Critical Considerations: Mandates investment in specialized Material Handling Equipment (MHE) and requires a exceptionally flat and stable concrete floor to ensure safe operation at height.

2. Drive-In & Drive-Through Industrial Racking Systems

These are depth-oriented industrial racking systems that function as LIFO (Last-In, First-Out) for drive-in and FIFO for drive-through configurations. They consist of a continuous rack structure where forklifts drive directly into the lanes to place or retrieve pallets from supporting rails. Drive-in racking has a single entrance/exit point, while drive-through racking features an entrance on one end and an exit on the other.

Ideal Application Profile: The storage of bulk quantities of a limited number of SKUs, such as in cold storage facilities, beverage distribution, or for holding seasonal product overflow.

Primary Advantages: Achieves exceptionally high density by storing pallets in depth, eliminating multiple parallel aisles. This design can achieve floor space utilization rates of up to 85%.

Critical Considerations: Throughput is slower than selective pallet industrial racking systems, and the potential for rack damage from forklift interaction is significantly higher. It is a poor choice for operations with high SKU diversity.

3. Pallet Flow Racking: The Dynamic Industrial Racking System

This is a high-density, live storage system that operates on the FIFO principle. Pallets are loaded onto an inclined track at the rear of the industrial racking systems. Using gravity, they glide smoothly on low-friction rollers or wheels to the front pick face. As a front pallet is removed, the next one automatically advances into the retrieval position.

Ideal Application Profile: Perfect for perishable goods, products with strict expiration dates, or high-throughput operations where flawless stock rotation is critical. It is widely used in the food and beverage, pharmaceutical, and fast-moving consumer goods (FMCG) sectors.

Primary Advantages: Maximizes space utilization while enforcing perfect, automated inventory rotation. Dramatically reduces labor because forklifts only interact with the load and unload points, never needing to enter the rack structure.

Critical Considerations: Carries a higher initial cost than static industrial racking systems. Requires meticulous load and SKU planning to ensure consistent, jam-free flow. The dynamics of the system must be precisely calculated based on pallet weight and dimensions.

4. Mobile Pallet Racking: The Industrial Racking System with Moveable Aisles

This innovative system transforms multiple static aisles into a single, moveable aisle. The entire rack structure is mounted on electrically driven carriages that move laterally on steel rails embedded in the floor. An aisle is opened only where and when it is needed, while all other aisles are condensed into a solid block of storage.

Ideal Application Profile: Ideal for archives, libraries, cold stores operating at sub-zero temperatures, and facilities with a very high number of SKUs but relatively low daily throughput.

Primary Advantages: Offers the highest storage density of any manually operated industrial racking systems, capable of doubling or even tripling storage capacity compared to static shelving by eliminating all but one aisle.

Critical Considerations: Access times are slower due to the need to open and close aisles. The system requires integrated safety features, such as pressure-sensitive safety floors, anti-tilt mechanisms, and aisle-end warning lights and alarms to ensure personnel safety.

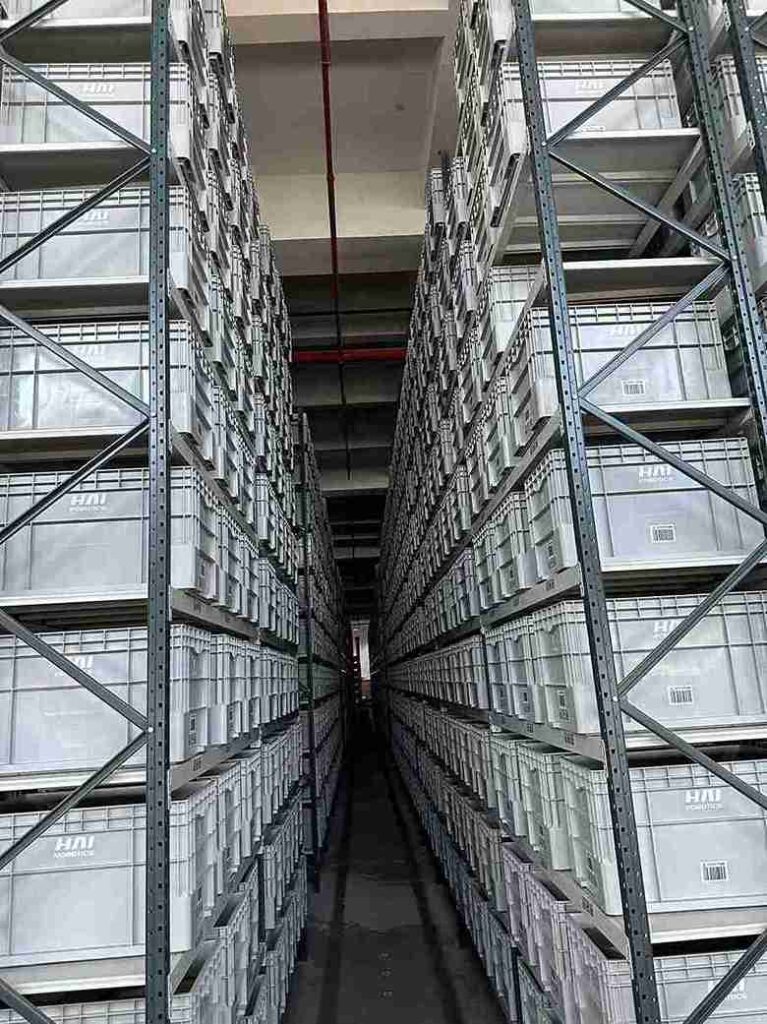

5. The Apex of Automation: AS/RS and Unit-Load Industrial Racking Systems

Automated Storage and Retrieval Systems (AS/RS) represent the ultimate synthesis of structural industrial racking systems and digital control technology. These systems consist of fixed-aisle, high-bay industrial racking systems serviced by fully automated, computer-controlled stacker cranes. These cranes operate within the aisle to store and retrieve unit loads with unparalleled speed, precision, and reliability, entirely without human intervention in the storage area.

Ideal Application Profile: High-volume, high-SKU-count environments where inventory accuracy, throughput speed, and space optimization are non-negotiable. They are the backbone of modern e-commerce fulfillment centers, manufacturing buffer storage, and large-scale distribution hubs.

Primary Advantages: Delivers unrivalled density, operational speed, and 99.99%+ inventory accuracy. These industrial racking systems can operate 24/7 in darkness, leading to substantial energy savings. They dramatically reduce labor costs and virtually eliminate product damage caused by human error.

Critical Considerations: Requires the highest capital investment and a significant commitment to software integration, including a robust Warehouse Management System (WMS) and Warehouse Control System (WCS). The planning and implementation phase is extensive and detailed.

Shuttle Rack Systems: The Adaptive and Scalable Industrial Racking System

Occupying a strategic middle ground between fully automated AS/RS and manual systems, shuttle technology has been a game-changer for high-density storage. A battery-powered, remotely controlled shuttle is deployed into a specific level of the industrial racking systems. It operates autonomously, traversing the rail depth to place and retrieve pallets or boxes. This technology can be integrated into various industrial racking systems frameworks, including drive-in, flow-through, and cantilever rack, and can range from a semi-automated to a fully automated solution.

Ideal Application Profile: An exceptionally versatile solution for both greenfield projects and the retrofitting of existing industrial racking systems. Excellent for high-density buffer storage in manufacturing, frozen food storage, and distribution centers seeking to incrementally automate.

Primary Advantages: Delivers high throughput, reduces labor dependency, enhances safety, and offers remarkable flexibility. It allows companies to adopt a “pay-as-you-grow” automation model, scaling their automation investment over time.

Critical Considerations: Demands a high degree of load uniformity (consistent pallet size and weight) for peak performance. The system’s efficiency is heavily dependent on the smooth functioning of the shuttle devices and their supporting software.

The Strategic Selection Framework: Choosing the Right Industrial Racking Systems

Investing in high-density industrial racking systems is a capital-intensive and strategic decision that will impact operations for years to come. The selection process must be methodical, data-driven, and devoid of a one-size-fits-all mentality.

Phase 1: A Granular Analysis of the Inventory Profile

The foundation of any successful project is a deep, data-led understanding of the inventory. This includes a complete SKU analysis, precise pallet dimensions and weights, inventory velocity (ABC analysis), and a clear understanding of product mix. How many pallets of each SKU are held on average and at peak? What are the FIFO/LIFO requirements? The answers to these questions will immediately narrow the field of suitable industrial racking systems.

Phase 2: Quantifying Throughput and Operational Tempo

Storage density is meaningless if it cripples the flow of goods. It is critical to quantify the operational tempo: the number of pallets received, put away, and shipped per shift, per day, and during peak periods. The system must be engineered not just for static storage, but for the dynamic velocity of goods moving in and out. A high-density industrial racking systems that cannot meet throughput demands is a failure.

Phase 3: A Rigorous Evaluation of Facility Constraints

The physical building dictates the art of the possible. What is the exact clear height? What is the condition and load-bearing capacity (PSF) of the concrete floor? Where are the columns, sprinkler heads, and other obstructions located? These tangible constraints will determine the maximum height, configuration, and ultimate feasibility of certain types of industrial racking systems.

Phase 4: A Clear-Eyed Total Cost of Ownership (TCO) Analysis

The decision must look far beyond the initial quote for the industrial racking systems. A comprehensive TCO analysis must include the cost of any required new MHE, professional installation, ongoing maintenance, energy consumption for lighting and automation, and the projected labor model over a 10-year horizon. An AS/RS, for example, may have a high upfront cost but a significantly lower TCO due to massive, sustained labor savings and operational gains.

Phase 5: Planning for Systems Integration and Future Scalability

The ideal industrial racking systems is not an island. It must integrate seamlessly with the existing or future Warehouse Management System (WMS), Warehouse Execution System (WES), and other automated material handling equipment like AGVs and conveyor systems. Furthermore, the design should be inherently scalable, allowing for future expansion or reconfiguration to accommodate business growth without requiring a complete and costly system overhaul.

The Supporting Cast: Critical Infrastructure for High-Density Industrial Racking Systems

A high-density industrial racking systems is the star of the show, but its performance is dependent on a capable supporting cast. Neglecting these elements can undermine the entire investment.

The Digital Brain: Warehouse Management System (WMS): In a high-density environment where thousands of pallets are stored in a compact space, a advanced WMS is not a luxury; it is an absolute necessity. It is the system of record that tracks every single pallet location, directs operators and automation, and ensures perfect inventory accuracy. Without a robust WMS, a high-density industrial racking systems quickly descends into chaos.

The Muscle: Material Handling Equipment (MHE): The industrial racking systems and the equipment are a symbiotic pair. From narrow-aisle forklifts and order pickers to AGVs and automated guided forklifts, the right MHE is the muscle that brings the static industrial racking systems to life, enabling it to achieve its designed throughput potential.

The Guardian: Comprehensive Safety Systems: High-density industrial racking systems, by their nature, concentrate value and risk. Enhanced safety is non-negotiable. This includes physical rack protection guards (column and end-of-aisle guards), clear signage, and for automated systems, comprehensive light curtains, safety fencing, and rigorous lock-out/tag-out (LOTO) procedures for maintenance personnel.

Conclusion: Engineering Flow and Unleashing Latent Capacity

Warehouse congestion is not an inevitability; it is a solvable engineering and operational challenge. The journey from a congested, costly facility to a lean, high-performance distribution center begins with the strategic adoption of high-density industrial racking systems. By embracing this paradigm shift and meticulously implementing the right system—whether it is a strategic narrow-aisle conversion, a dynamic pallet flow system, or a fully automated AS/RS—businesses can unlock massive latent capacity within their existing four walls.

This investment transcends the procurement of steel and software; it is an investment in operational excellence, workforce safety, and strategic scalability. It is the decisive step to stop merely managing chaos and to start engineering a predictable, efficient, and highly profitable flow of goods. The transformation begins with a professional, data-driven assessment and a clear vision for a superior operational future, all built upon the foundation of the right industrial racking systems.

Frequently Asked Questions (FAQs)

1. Can high-density industrial racking systems be retrofitted into my existing warehouse, or do I need a new building?

In the vast majority of cases, high-density industrial racking systems can be successfully retrofitted into an existing facility. Providers specialize in designing solutions that work around existing constraints such as column grids, specific ceiling heights, and door placements. Systems like mobile racking or modular shuttle systems are particularly well-suited for retrofits. A professional, on-site survey conducted by an engineer is the essential first step to determine precise feasibility and create a workable layout for the new industrial racking systems.

2. How do I know if my warehouse floor can support a high-density system, especially a heavy one like mobile racking or AS/RS?

This is a non-negotiable engineering consideration. High-density industrial racking systems, particularly mobile systems and high-bay AS/RS, concentrate immense loads onto the concrete slab. It is mandatory to engage a qualified structural engineer to conduct a comprehensive floor survey. This survey assesses the slab’s thickness, compressive strength (PSI), and flatness (Ff/Fl numbers). This due diligence is a standard part of the pre-design process for any reputable provider of heavy-duty industrial racking systems and is crucial for ensuring long-term safety and system integrity.

3. What is the typical lead time from design to full operational implementation for a complex system like an AS/RS?

Lead times vary dramatically based on the scale, complexity, and level of customization of the industrial racking systems. A basic narrow-aisle conversion might be completed in 8-12 weeks. A large-scale, fully integrated AS/RS project is a major capital project involving civil, electrical, mechanical, and software engineering disciplines. For such complex industrial racking systems, the timeline from initial concept and design to final commissioning and go-live can realistically range from 12 to 24 months. Reputable providers will furnish a detailed project timeline with clearly defined milestones and critical paths from the very outset.

4. How does a high-density system impact my fire safety and insurance requirements?

High-density industrial racking systems significantly alter the fire load and can negatively impact the effectiveness of standard ceiling-mounted sprinklers. The final design must strictly comply with local building codes and recognized standards like NFPA 13. This compliance often mandates the installation of in-rack sprinkler systems at various levels, increased water supply requirements, and the maintenance of specific horizontal and vertical flue spaces within the industrial racking systems.

It is imperative to work with providers who will collaborate directly with your insurance carrier and the local Authority Having Jurisdiction (AHJ) to ensure full compliance. A compliant design can often lead to reduced insurance premiums due to the enhanced safety and organization inherent in modern industrial racking systems.

5. We have a mix of palletized and non-palletized, odd-shaped goods. Are high-density solutions only for uniform pallets?

Absolutely not. While the most common applications involve uniform pallets, the high-density philosophy is universally applicable. For non-palletized, long, or odd-shaped items, specialized industrial racking systems provide the solution. High-density cantilever racking systems are ideal for lumber, piping, and sheet goods. High-rise mobile shelving systems can transform small parts storage. Furthermore, specialized AS/RS and shuttle systems are designed to handle totes, containers, and even individual items. The core principle remains constant across all these industrial racking systems: maximize the use of your cubic space by radically reducing wasted aisle space.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com