📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Hidden Tax of Your Warehouse: Is Inefficient Racking Path Planning Draining Your Profits?

In the relentless pursuit of supply chain excellence, warehouse managers and logistics directors across Southeast Asia, the Middle East, Latin America, and beyond face a constant, gnawing challenge. It’s the challenge of unmet potential. They have invested in towering, robust racking. They have commissioned fleets of automated guided vehicles (AGVs) and state-of-the-art forklifts. Yet, the promised land of peak efficiency remains frustratingly out of reach. The culprit, more often than not, is not the quality of the hardware but the intelligence of the software that guides it. The critical failure point is inadequate racking path planning in warehouses.

This concept, racking path planning in warehouses, is the sophisticated discipline of designing and managing the travel routes for all material handling equipment within a storage facility. It is the digital central nervous system that connects physical storage infrastructure to operational workflow. When executed poorly, racking path planning in warehouses creates a silent, persistent drain on productivity, safety, and profitability. It is a hidden tax levied daily on the operation.

This article delves deep into the multifaceted impact of flawed racking path planning in warehouses, articulates the core principles of an optimized system, and presents a clear pathway for businesses to transform this critical function from a liability into their most powerful competitive advantage. The ultimate goal is to equip decision-makers with the knowledge to see beyond the steel and silicon, to understand the profound importance of the pathways in between.

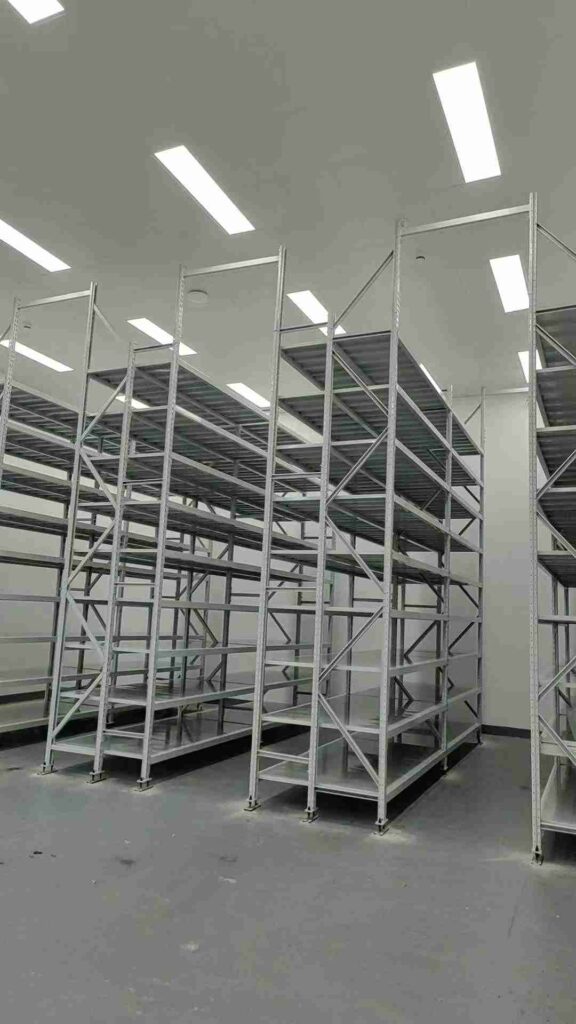

Inefficient racking path planning in warehouses before optimization

The High Price of Chaos: A Granular Look at the Impacts of Poor Racking Path Planning

To truly appreciate the value of superior racking path planning in warehouses, one must first understand the exorbitant cost of getting it wrong. These costs are rarely isolated to a single department; they ripple throughout the entire organization, eroding margins and stifling growth.

Skyrocketing Operational Expenditure: The Direct Hit to the Bottom Line

Every single decision related to racking path planning in warehouses has a direct and calculable financial consequence. Inefficient routes force both manual and automated equipment to travel greater distances to complete the same tasks. For human-operated forklifts, this translates into more labor hours required for each shift. Operators spend more time driving and less time on value-added activities like loading or complex order picking. The cost of this wasted time compounds exponentially over weeks and months.

For automated systems, the financial implications of poor racking path planning in warehouses are even more acute. A fleet of AGVs operating on suboptimal, static paths will experience constant congestion and deadlocks. These intelligent machines are reduced to performing like a disorganized swarm, wasting precious battery life on avoidable detours and idle waiting. The result is that the organization fails to realize the full return on its automation investment.

The throughput per vehicle plummets, often necessitating the purchase of additional AGVs to meet demand—a capital expense that could have been avoided with intelligent racking path planning in warehouses. The equation is simple: longer, poorly planned paths mean higher operational costs per unit handled.

Accelerated Asset Depreciation: The Silent Budget Erosion

The physical toll of chaotic movement is a frequently overlooked consequence of flawed racking path planning in warehouses. Material handling equipment is a significant capital investment, and its lifespan is directly tied to its usage patterns. Equipment navigating a facility with poor racking path planning in warehouses is subjected to a punishing regimen of excessive starts, stops, sharp turns, and emergency maneuvers.

Manual forklifts suffer from accelerated wear on brakes, tires, transmission systems, and mast components. The maintenance schedules shorten, repair costs escalate, and the total operational lifespan of the vehicle is significantly reduced. For AGVs, the strain on drive motors, guidance sensors (whether laser, vision, or wire), and control systems is immense. The constant stress of navigating a poorly planned environment leads to more frequent component failures and unplanned downtime.

This silent budget erosion, a direct result of inadequate racking path planning in warehouses, can double the total cost of ownership of the equipment over its lifetime. A smooth, well-planned path is not just about speed; it is about preserving the integrity of your physical assets.

Compromised Safety and Unacceptable Risk Exposure

There is no greater priority than the safety of personnel and the integrity of inventory. A warehouse environment where racking path planning in warehouses is an afterthought is inherently unsafe. Narrow aisles, blind intersections, and unregulated traffic flows create a high-stress, high-risk environment. The close-quarters interaction between manual forklifts, pedestrian workers, and automated AGVs becomes a recipe for disaster.

Collisions, product damage from impacts with racking, and—most severely—worker injuries are the tragic outcomes of a neglected pathway strategy. In many of the target markets, from the industrial hubs of Saudi Arabia to the growing logistics corridors of Mexico, regulatory bodies are increasingly focusing on warehouse safety standards. A demonstrably safe operation, underpinned by a professional approach to racking path planning in warehouses, is not just an ethical imperative; it is a strategic one that mitigates legal and reputational risk. Effective racking path planning in warehouses incorporates designated travel lanes, clear right-of-way rules, speed control zones, and safe stopping distances, creating a predictable and secure ecosystem for all occupants.

Strangulation of Storage Density and Scalability

A common and costly mistake in warehouse design is to prioritize pure storage density at the expense of flow. A manager might select a high-density racking system like narrow aisle racking or drive-in racking to maximize pallet positions but fail to integrate the corresponding path planning strategy. The result is a system that looks efficient on paper but is crippled in practice.

For instance, if the racking path planning in warehouses for a narrow aisle system does not account for the precise turning radius and guidance requirements of the specialized forklifts or AGVs, the aisles must be widened, negating the density advantage. Similarly, in drive-in racking, the internal pathways are part of the racking structure itself. Without a meticulous sequencing plan for the racking path planning in warehouses within these lanes, forklifts can become trapped, leading to massive inefficiencies and product damage.

Therefore, the ultimate storage density achievable is not a function of the racking alone; it is a direct output of the synergy between the racking and the sophistication of the racking path planning in warehouses. Poor planning locks a business into a rigid, un-scalable layout that cannot adapt to future growth.

The Anatomy of Excellence: Foundational Principles of Intelligent Racking Path Planning

Moving from a state of chaotic cost to one of optimized flow requires a foundational understanding of what constitutes intelligent racking path planning in warehouses. It is a multi-disciplinary science that sits at the intersection of industrial engineering, data analytics, and logistics management.

The Critical Evolution: From Static to Dynamic Pathing Systems

The single most significant advancement in the field of racking path planning in warehouses has been the shift from static to dynamic pathing models. This evolution separates legacy systems from modern, high-performance warehouses.

Static Pathing: This traditional approach to racking path planning in warehouses relies on fixed, unchangeable routes, akin to train tracks on a map. While simple to implement, it is brutally inflexible. It cannot adapt to real-world variables such as a temporary obstacle blocking an aisle, a spike in order priority, or simple traffic congestion. A static system for racking path planning in warehouses is the primary cause of the “AGV traffic jams” that plague many automated facilities. It treats the warehouse as a static environment, which it never is.

Dynamic Pathing: This is the modern standard for world-class racking path planning in warehouses. It employs powerful, real-time algorithms that allow each AGV to calculate its own optimal route based on a live feed of warehouse conditions. This system for racking path planning in warehouses considers the current location and destination of every other vehicle, active pick stations, battery levels, and predefined priorities. It creates a fluid, adaptive, and self-optimizing network. Dynamic racking path planning in warehouses is what transforms a collection of individual vehicles into a cohesive, intelligent swarm, capable of collectively achieving maximum throughput.

The Inseparable Trinity: Racking, Equipment, and Pathway Integration

The most successful projects in racking path planning in warehouses are those where the storage system, the material handling equipment, and the pathway network are designed as a single, integrated unit from the very first blueprint. They are three interlocking components of one system.

The Dictates of Racking on Pathways: The type of racking installed fundamentally shapes the racking path planning in warehouses. Selective pallet racking demands wider aisles and pathways suitable for the turning radius of counterbalance forklifts. A narrow aisle racking system demands exceptionally precise racking path planning in warehouses, often relying on wire or rail guidance to ensure flawless vehicle operation within tight confines. The design of racking path planning in warehouses for a push back racking or pallet flow system must account for the dynamics of load entry and exit at the lane faces.

The Capabilities of Equipment: The racking path planning in warehouses must be tailored to the specific capabilities of the equipment. The path planning for a laser-guided AGV differs from that of a vision-based one. The requirements for a forklift with a rotating fork head for very narrow aisles are unique. The entire strategy for racking path planning in warehouses must be built around the operational envelope of the chosen vehicles. One cannot simply purchase AGVs as an afterthought and expect them to navigate a racking layout designed for manual forklifts efficiently.

This holistic approach to racking path planning in warehouses ensures that there are no compatibility gaps, no wasted space, and no compromised performance. The pathway is the critical interface that ensures the racking and equipment speak the same language.

The Brain of the Operation: The Role of WMS, WES, and Real-Time Data

Advanced racking path planning in warehouses is not possible without a constant stream of rich, operational data. The pathways are the arteries, but the software is the brain.

Warehouse Management System (WMS): The WMS provides the strategic commands—the “what.” It defines which SKU needs to be picked, from which location, and for which order. It is the source of truth for inventory and order priorities.

Warehouse Execution System (WES): The WES is the tactical commander that brings advanced racking path planning in warehouses to life. It takes the orders from the WMS and makes real-time decisions on the “how.”

It performs the complex racking path planning in warehouses calculus: Which AGV is closest and has sufficient battery? What is the most efficient route considering current traffic? Should it batch multiple tasks for one vehicle to minimize travel? By integrating the racking path planning in warehouses directly into a powerful WES, the warehouse moves from a reactive to a predictive state. The system doesn’t just respond to commands; it orchestrates the entire flow of the facility, making thousands of micro-optimizations to the racking path planning in warehouses every second to achieve a macro-level goal of supreme efficiency.

A Framework for Transformation: A Systematic Approach to Optimizing Racking Path Planning

Recognizing the need for superior racking path planning in warehouses is the first step. The journey to achieving it requires a structured, methodical approach that moves from diagnosis to design to implementation.

The Indispensable First Step: A Comprehensive Warehouse Efficiency Audit

Before any solutions can be proposed, a precise and unbiased diagnosis is essential. A professional Warehouse Efficiency Audit focused specifically on racking path planning in warehouses is not a superficial walk-through; it is a forensic-level analysis conducted by seasoned engineers. This audit delves into the core of the operation:

Precision Spatial Mapping: Utilizing 3D laser scanning technology to create a millimeter-accurate digital twin of the entire facility. This model captures the exact placement of every racking bay, column, door, and piece of infrastructure, providing the definitive canvas for all racking path planning in warehouses analysis.

Quantitative Flow Analysis: Employing time-motion studies and data logging to measure the real-world performance of the current racking path planning in warehouses. This process identifies specific congestion points, quantifies travel versus task time, and reveals the hidden bottlenecks in the material flow.

Systems and Process Interrogation: Reviewing the capabilities of the current WMS/WES and evaluating the workflow processes. The audit assesses how well the software supports or hinders effective racking path planning in warehouses and identifies gaps in process logic that contribute to inefficiency.

The output of this audit is a definitive, data-backed report that answers the critical question: “To what extent is our current racking path planning in warehouses costing us money, and where are the specific opportunities for improvement?” It provides the objective foundation for all subsequent investment decisions.

Strategic Design and Simulation: Engineering the Optimal Solution

With the audit data in hand, the design phase begins. This is where the future state of the warehouse’s racking path planning in warehouses is engineered. Modern design relies heavily on simulation, a powerful tool that allows engineers to test and validate countless scenarios without disrupting the live operation.

Define Key Performance Indicators (KPIs): The process starts by aligning on the business objectives. Is the goal to maximize throughput (picks/hour), minimize order cycle time, reduce labor costs, or achieve a specific storage density? The KPIs guide all aspects of the racking path planning in warehouses design.

Create and Validate Digital Models: Engineers build a virtual model of the warehouse, incorporating proposed changes to the racking layout and equipment fleet. Different scenarios for racking path planning in warehouses are programmed into the simulation—testing dynamic versus static routing, different vehicle fleet sizes, and various racking configurations (e.g., selective vs. narrow aisle).

Stress-Test with Virtual Operations: The model runs through thousands of simulated order cycles, replicating weeks or months of operation in a matter of hours. This virtual stress-test reveals how the proposed racking path planning in warehouses strategy will perform under peak demand, during equipment failures, and as inventory profiles change. It allows for the optimization of the racking path planning in warehouses algorithms in a risk-free environment, ensuring the final design is robust and reliable.

This rigorous, data-driven approach to racking path planning in warehouses de-risks the capital investment and provides a high degree of confidence that the new system will deliver the promised operational and financial returns.

Evidence in Action: Global Case Studies in Racking Path Planning Optimization

The theoretical benefits of superior racking path planning in warehouses are compelling, but the most convincing evidence comes from real-world applications. The following case studies illustrate the transformative impact of a professionally executed racking path planning in warehouses strategy.

Case Study 1: E-Commerce Fulfillment Center in Southeast Asia

A major e-commerce player in Indonesia commissioned a new, state-of-the-art fulfillment center equipped with narrow aisle racking and a large fleet of AGVs. Despite the modern hardware, the facility struggled to meet its next-day delivery targets during sales peaks. The core issue was the racking path planning in warehouses. The AGVs operated on a static pathing system, causing predictable and severe congestion at high-activity zones like the picking stations and battery swap areas. Our audit quantified a 45% inefficiency in travel paths and a 70% increase in AGV idle time during peak hours.

The solution was a complete overhaul of the racking path planning in warehouses, implementing a dynamic, real-time system fully integrated with a new Warehouse Execution System (WES). The new racking path planning in warehouses algorithm allowed AGVs to reroute on the fly, batch tasks intelligently, and avoid congestion. The results were transformative: a 32% increase in orders picked per hour, an 85% reduction in AGV congestion delays, and the consistent achievement of next-day delivery service level agreements (SLAs). This case underscores that without intelligent racking path planning in warehouses, even the most advanced automation hardware cannot deliver its full potential.

Case Study 2: Food and Beverage Cold Storage in the Middle East

A large beverage distributor in the United Arab Emirates operated a sprawling cold storage facility utilizing drive-in racking to maximize storage density for a high-volume, low-SKU-count product range. The operation relied on manual forklifts, which suffered from excessively long cycle times and a troubling rate of product damage caused by difficult maneuvering deep within the racking lanes. The problem was a fundamental flaw in the racking path planning in warehouses for the drive-in system.

There was no coordinated strategy for sequencing the entry and exit of forklifts, leading to inefficiencies and risky operations. The solution involved a hybrid approach to racking path planning in warehouses. We designed and implemented a semi-automated pallet shuttle system to operate inside the deep lanes of the drive-in racking. This changed the role of the forklifts; they now only needed to transport pallets to and from the face of the rack, where the shuttle would take over.

This dramatically simplified the racking path planning in warehouses for the forklifts, reducing their travel paths and eliminating complex in-rack maneuvering. The outcome was a 40% reduction in forklift cycle time, a 100% elimination of in-rack product damage, and a 15% increase in overall storage throughput due to the faster, more predictable operation. This case demonstrates how innovative racking path planning in warehouses can solve even the most stubborn operational challenges in specialized environments.

Your Strategic Questions on Racking Path Planning, Answered

Q1: For a new greenfield warehouse project, what is the ideal timeline for integrating racking path planning?

A: The integration of racking path planning in warehouses must begin during the very earliest conceptual design phases, concurrent with the initial architectural and structural planning. The fundamental layout of the building, including column spacing, door placement, and ceiling height, will either enable or constrain effective racking path planning in warehouses. It is a foundational element, not a finishing touch. The detailed strategy for racking path planning in warehouses should be fully developed before finalizing purchase orders for both racking and material handling equipment.

Q2: Is it possible to achieve significant improvements in racking path planning without a complete, costly overhaul of our existing infrastructure?

A: Yes, absolutely. While a greenfield project allows for a perfect, integrated design, most businesses operate in brownfield sites. In these cases, a professional audit can identify high-impact, low-cost opportunities for optimizing the racking path planning in warehouses. This can include retraining operators on optimized travel routes, reprogramming AGV pathing algorithms for dynamic behavior, adjusting WMS slotting logic to minimize travel distances, and implementing simple traffic management protocols. Significant gains in efficiency from improved racking path planning in warehouses are often achievable through strategic retrofitting and software upgrades.

Q3: How does the approach to racking path planning differ when managing a mixed fleet of AGVs and traditional forklifts?

A: Managing a mixed fleet adds a layer of complexity to racking path planning in warehouses but is a common and manageable scenario. The strategy must account for the different behaviors and capabilities of each vehicle type. AGVs follow precise, software-defined paths, while human forklift operators have more autonomy. The racking path planning in warehouses system for a mixed environment often involves creating designated zones or travel lanes for AGVs to ensure predictable movement, while using the WES to communicate tasks and priorities to both man and machine. The key is to create a unified racking path planning in warehouses strategy that establishes clear rules of interaction to ensure safety and efficiency for all.

Q4: Beyond congestion, what is a less obvious but critical metric that indicates poor racking path planning?

A: One of the most telling, yet often overlooked, metrics is the ratio of empty travel to loaded travel for your material handling equipment. In a warehouse with poor racking path planning in warehouses, vehicles spend a disproportionate amount of time moving without a load—traveling back to a home base, repositioning after a drop-off, or taking long, circuitous routes to their next assignment. Excellent racking path planning in warehouses, often powered by a WES, focuses on task sequencing and interleaving to dramatically reduce empty travel, which is the purest form of waste in a logistics operation.

Q5: In the context of Industry 4.0, what is the future of racking path planning in warehouses?

A: The future of racking path planning in warehouses is moving towards fully autonomous, predictive, and self-healing systems. This involves the use of AI and machine learning algorithms that do not just react to current conditions but predict future states. The system could forecast congestion based on the order queue and proactively reroute vehicles. It could perform predictive maintenance on AGVs by analyzing pathing data to detect motor strain.

Furthermore, the concept of racking path planning in warehouses will expand to include seamless coordination with other automated systems, like robotic picking arms and automated conveyor networks, creating a truly lights-out, fully optimized fulfillment ecosystem where the racking path planning in warehouses is the central orchestrator of a completely integrated digital-physical system.

Conclusion: Transforming Your Warehouse from a Cost Center to a Profit Driver

The evidence is overwhelming and clear. The discipline of racking path planning in warehouses is not a minor technical consideration; it is a strategic business function with a direct and profound impact on profitability, scalability, and competitiveness. Inefficient racking path planning in warehouses acts as a relentless, hidden tax, siphoning resources from the organization through higher labor and maintenance costs, reduced asset lifespan, safety incidents, and constrained storage capacity. It is the invisible barrier that prevents businesses from realizing the full return on their investments in racking and automation.

The path to liberation from this cycle is through a deliberate, engineering-led approach. It begins with a clear-eyed diagnostic audit to quantify the problem, proceeds through a sophisticated design and simulation phase to engineer the optimal solution, and culminates in a precise implementation that integrates racking, equipment, and pathways into a single, high-performance system.

For businesses operating in the dynamic and competitive markets of Southeast Asia, the Middle East, Africa, and Latin America, mastering racking path planning in warehouses is no longer a luxury—it is a fundamental requirement for survival and growth. The question for any logistics leader is no longer if they should address their racking path planning in warehouses, but how quickly they can begin the process of transforming their largest operational cost center into their most powerful engine of efficiency and profit.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com