📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Strategic Imperative: Mastering Sustainable Logistics with Advanced Green Warehouse Solutions

In the complex landscape of modern global supply chains, a profound transformation is underway. The traditional warehouse, once a static cost center characterized by sprawling footprints and energy-intensive operations, is being reimagined. The future—and indeed, the present—belongs to the intelligently automated, environmentally conscious facility. At the heart of this revolution are integrated Green warehouse solutions that seamlessly blend operational excellence with ecological responsibility. These are not mere incremental upgrades; they represent a fundamental redesign of logistics infrastructure for resilience, profitability, and sustainability.

The most powerful and effective of these Green warehouse solutions involve the synergistic integration of Automated Guided Vehicles (AGVs) and Automated Storage and Retrieval Systems (AS/RS). This powerful combination moves beyond simplistic automation to create a dynamic, self-optimizing ecosystem. For business leaders across Southeast Asia, the Middle East, Africa, and Latin America, investing in these sophisticated Green warehouse solutions is no longer a luxury but a strategic necessity.

It is the most reliable path to future-proofing operations against volatile energy costs, tightening environmental regulations, and intensifying consumer demand for corporate sustainability. This comprehensive exploration delves into how these technologies form the core of next-generation Green warehouse solutions, delivering unparalleled efficiency and a definitive competitive edge.

Redefining Efficiency: The Core Principles of Modern Green Warehouse Solutions

To fully appreciate the impact of AGVs and AS/RS, one must first understand the multi-faceted nature of true Green warehouse solutions. A genuinely sustainable facility is an interconnected system where environmental stewardship and operational performance are two sides of the same coin. It is an operational philosophy built upon several foundational pillars that these advanced technologies directly address.

Radical Energy and Resource Efficiency: Superior Green warehouse solutions prioritize a drastic reduction in energy consumption. This is achieved by transitioning from fossil-fuel-dependent machinery to all-electric, high-efficiency automation that operates on-demand, significantly slashing both carbon emissions and utility expenses.

Optimal Spatial Utilization and Footprint Reduction: The most environmentally friendly building is the one that never gets built. Leading Green warehouse solutions focus on maximizing the cubic volume of existing facilities through high-density storage, thereby avoiding the massive embodied carbon footprint and capital outlay associated with new construction.

System-Wide Waste Elimination: True Green warehouse solutions are designed for minimal waste. This extends beyond packaging to include the elimination of unnecessary material movement, the near-total eradication of product damage through precision handling, and the optimization of inventory to reduce obsolescence.

Data-Driven Intelligence and Adaptive Control: Intelligent Green warehouse solutions are governed by a smart central nervous system. Advanced software not only directs equipment but also continuously analyzes energy usage, predicts maintenance to preempt downtime, and adapts workflows in real-time for peak performance with minimal resource expenditure.

The Technological Synergy: How AGVs and AS/RS Form the Backbone of Advanced Green Warehouse Solutions

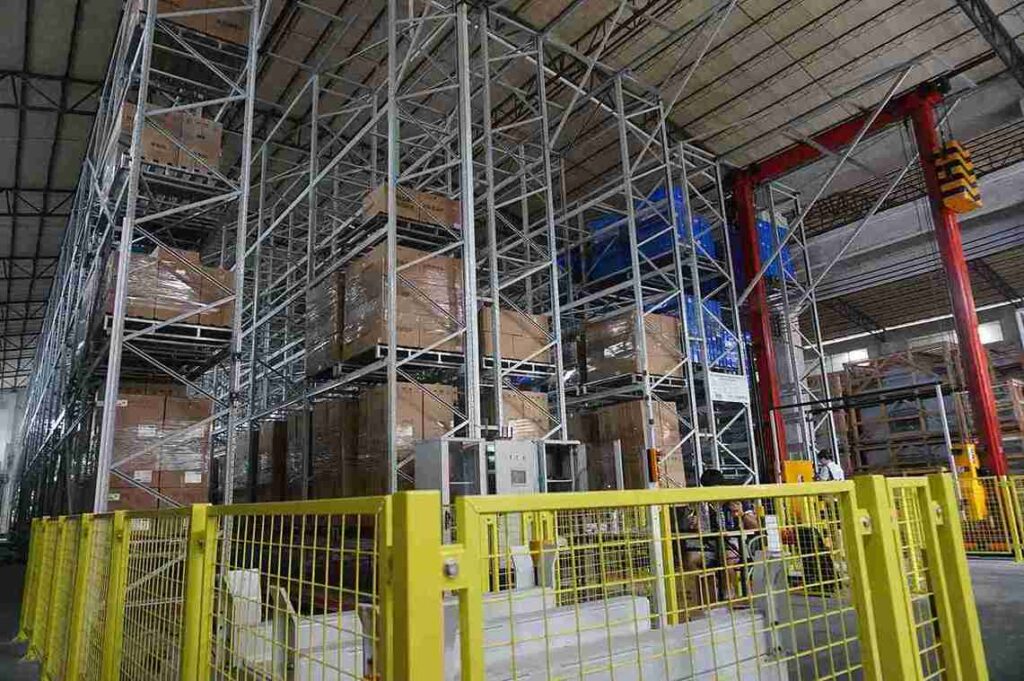

The unparalleled effectiveness of modern Green warehouse solutions stems from the powerful, synergistic partnership between AS/RS and AGVs. An AS/RS—encompassing unit-load cranes, pallet shuttles, and mini-load systems—acts as the ultra-efficient, high-density core of these Green warehouse solutions. It consolidates vast inventories into a minimal footprint. Simultaneously, AGVs—including nimble Autonomous Mobile Robots (AMRs) and robust unmanned forklifts—serve as the flexible, intelligent logistics network within these Green warehouse solutions.

They connect the high-density storage heart to manufacturing, staging, and shipping areas. Together, they create a closed-loop system of material flow that is inherently more efficient and sustainable than any manual or siloed automated process.

AS/RS: The High-Density, Low-Impact Engine of Green Warehouse Solutions

The Automated Storage and Retrieval System is the cornerstone of spatial and energy efficiency in any comprehensive Green warehouse solutions portfolio. Its design principles are intrinsically linked to sustainability outcomes.

Revolutionizing Space Utilization to Minimize Environmental Impact

Conventional warehouses are a study in horizontal inefficiency, consuming vast land areas and requiring immense energy for climate control. The AS/RS components within advanced Green warehouse solutions fundamentally shatter this paradigm. By building vertically, often to clear heights of over 30 meters, these systems can increase storage density by 400% or more within the same building envelope. This approach is a hallmark of sophisticated Green warehouse solutions, directly combating urban sprawl and preserving land resources.

The sustainability dividend is immense: retrofitting an existing facility with a high-density AS/RS as part of a Green warehouse solutions strategy avoids the embodied carbon of constructing a new, larger facility. Furthermore, a compact, dense storage block is exponentially more efficient to light and climate-control, yielding continuous energy savings for decades.

Intelligent Energy Management and Regenerative Technology

The latest AS/RS technologies integrated into top-tier Green warehouse solutions are engineered for minimal energy waste. Unlike constantly running conveyor belts, an AS/RS crane operates on a strict on-demand basis, springing into action only when a task is received. This alone represents a significant leap in efficiency. However, the most advanced Green warehouse solutions incorporate regenerative drive technology into their AS/RS.

This sophisticated system captures the potential energy generated when a crane lowers a heavy load, converting it back into electricity that is fed into the facility’s power grid. Over thousands of cycles daily, this recaptured energy substantially reduces the net power consumption of the storage system, making these Green warehouse solutions a benchmark for industrial energy innovation.

The Agile Connectors: AGVs and Unmanned Forklifts in Dynamic Green Warehouse Solutions

While the AS/RS provides the high-density core, the fleet of AGVs, AMRs, and unmanned forklifts provides the dynamic, flexible mobility that defines fully integrated Green warehouse solutions. They systematically address and eliminate the inefficiencies of traditional internal combustion engine (ICE) forklifts.

Electrifying Operations and Phasing Out Fossil Fuels

The transition to all-electric material handling is a non-negotiable principle of effective Green warehouse solutions. A single ICE forklift can emit pollutants equivalent to dozens of cars, contributing to poor indoor air quality and a significant carbon footprint. The AGV fleets deployed in modern Green warehouse solutions are 100% electric. They utilize smart charging protocols and advanced battery management systems to optimize energy use and ensure operational availability. By replacing a fleet of ICE vehicles with these silent, clean AGVs, businesses instantly eradicate a major source of on-site emissions, a critical objective for any credible Green warehouse solutions program.

Optimizing Material Flow and Eradicating Empty Miles

The operational intelligence of Green warehouse solutions is perhaps most visible in the routing efficiency of their AGV fleets. Governed by a central Warehouse Execution System (WES), these vehicles are dispatched along mathematically optimal paths. The software orchestrates the entire fleet to avoid congestion and, crucially, ensures that robots are almost never traveling without a load. After completing a delivery, an AGV is immediately assigned a new task, often picking up goods from a nearby workstation. This systematic elimination of “empty miles,” a core feature of intelligent Green warehouse solutions, represents a direct and substantial reduction in energy consumption and a corresponding boost to overall facility throughput.

The Power of Integration: Synergistic Workflows in Unified Green Warehouse Solutions

The most significant performance and sustainability gains are realized when AGVs and AS/RS are not operated as isolated islands of automation but are deeply integrated into a unified workflow. This synergy is the defining characteristic of world-class Green warehouse solutions.

Imagine a perfectly choreographed process: An inbound pallet arrives and is transported by an unmanned forklift AGV to the AS/RS induction point. The AS/RS crane, having received its command from the WES, stores the pallet in a location optimized for its turnover rate. Later, when an order is placed, the system triggers the retrieval of the pallet, which is placed at a designated hand-off point. Instantly, an AMR is tasked to meet the pallet and transport it directly to the shipping lane.

This end-to-end process, a hallmark of fully integrated Green warehouse solutions, requires no manual material handling, operates entirely on electricity, and executes with a level of speed and accuracy that crushes traditional models in both performance and sustainability metrics.

The Command Center: The Warehouse Execution System (WES) in Green Warehouse Solutions

This seamless, high-efficiency operation is impossible without a sophisticated Warehouse Execution System (WES). In the architecture of advanced Green warehouse solutions, the WES acts as the intelligent command center. It sits above the Warehouse Management System (WMS) and directly controls and coordinates all automation assets. It makes real-time, compute-intensive decisions: “Which AGV has sufficient charge and is closest to the task? Which AS/RS crane can complete this retrieval fastest? How can workload be balanced across the system to prevent energy-wasting bottlenecks?” This intelligent, dynamic dispatching is what unlocks the full, promised ROI of integrated Green warehouse solutions, ensuring that the entire system operates as a single, highly efficient organism.

The Compelling Business Case: Quantifying the ROI of Advanced Green Warehouse Solutions

For any strategic investment, the financial and operational returns must be clear and compelling. The business case for implementing these Green warehouse solutions is robust, impacting both the bottom line and the top line.

Substantial Reduction in Operational Expenditure: Companies implementing comprehensive Green warehouse solutions consistently report a 30-50% reduction in energy costs. This is achieved through the shift to all-electric vehicles, high-density storage that reduces lighting and HVAC needs, and regenerative energy systems.

Labor Optimization and Workforce Upliftment: These Green warehouse solutions directly address chronic labor shortages and high turnover rates. They allow companies to redeploy their human capital from repetitive, physically demanding tasks to higher-value roles in system supervision, data analysis, and exception management, leading to improved employee satisfaction and operational innovation.

Unmatched Throughput and Accuracy Gains: Facilities powered by integrated Green warehouse solutions routinely achieve a doubling or more of their order fulfillment rates while reaching unprecedented accuracy levels of 99.99% or higher. This translates into faster order-to-delivery cycles and the virtual elimination of costly errors, enhancing customer satisfaction and brand reputation.

Capital Expenditure Avoidance and Real Estate Savings: By achieving three to four times the storage density within an existing building, these Green warehouse solutions delay or completely eliminate the need for costly facility expansions. This represents a multi-million-dollar capital saving, a crucial factor for businesses in high-growth emerging markets.

Global Implementation: Tailoring Green Warehouse Solutions for Diverse Markets

The application of these advanced Green warehouse solutions is not monolithic; it requires careful adaptation to regional logistics landscapes. The provider’s expertise lies in customizing these systems to meet specific local challenges.

Southeast Asia’s E-commerce and Electronics Sector: For the booming e-commerce and electronics sectors in Vietnam, Indonesia, and the Philippines, Green warehouse solutions often feature mini-load AS/RS for high-SKU counts combined with swarms of agile AMRs for dynamic order picking and sorting. This configuration creates a high-velocity, high-density fulfillment hub perfectly suited for the region’s rapid market growth.

The Middle East’s Mega-Distribution and Cold Chain Logistics: In the UAE, Saudi Arabia, and Qatar, where massive distribution centers serve vast regional markets, Green warehouse solutions are critical for temperature-controlled environments. Unit-load AS/RS and pallet shuttle systems provide deep-storage capacity for palletized goods, while fleets of unmanned forklifts reliably manage high-volume transport in freezing conditions, ensuring product integrity while minimizing energy use in challenging climates.

Latin America’s Manufacturing and Agri-Export Hubs: In manufacturing powerhouses like Mexico and Brazil, and in the agri-export sectors of Chile and Peru, Green warehouse solutions integrate AGVs directly into production and packaging lines. These robots feed raw materials and transport finished goods to and from high-density AS/RS, creating a seamless, just-in-time logistics loop that minimizes inventory holding costs and accelerates export processes.

A Strategic Roadmap: Phased Implementation of Scalable Green Warehouse Solutions

Recognizing that a full-scale transformation is a significant undertaking, leading providers of Green warehouse solutions advocate for a phased, consultative implementation strategy. This approach mitigates risk and allows for a clear, staged realization of ROI.

Comprehensive Consultation and Data-Driven Design: The process begins with an in-depth analysis of current operations, SKU data, order profiles, and growth projections. Sophisticated simulation modeling is used to design the optimal configuration of Green warehouse solutions for the client’s specific needs.

Modular and Phased Integration: A company can start its journey by deploying a fleet of AMRs to optimize its picking operations, demonstrating quick wins and building internal comfort with automation. Subsequently, a modular AS/RS can be integrated for fast-moving goods, with both systems unified under a powerful WES. This phased approach is a hallmark of practical and scalable Green warehouse solutions.

Lifecycle Partnership and Continuous Optimization: The relationship does not end at go-live. Premier providers of Green warehouse solutions offer ongoing support, remote monitoring, and regular software updates that continuously enhance system performance, energy efficiency, and adaptability, protecting the client’s long-term investment.

Conclusion: The Inevitable Ascendancy of Intelligent Green Warehouse Solutions

The trajectory of global logistics is unequivocal. The convergence of economic pressure, environmental necessity, and technological possibility has made the adoption of sophisticated Green warehouse solutions an imperative for any business seeking long-term leadership. The synergistic integration of AGV and AS/RS technologies represents the pinnacle of this evolution, offering a proven pathway to unprecedented levels of operational efficiency, resilience, and sustainability.

These are not mere installations of machinery; they are the implementation of a smarter, more responsible way to manage the flow of goods. For forward-thinking decision-makers across emerging global markets, the question is no longer about whether to invest in Green warehouse solutions, but how quickly they can partner with an expert to embark on this transformative journey and secure a definitive competitive advantage for the future.

Frequently Asked Questions (FAQs) on Green Warehouse Solutions

1. How scalable are these Green warehouse solutions to accommodate our company’s rapid growth forecast?

Scalability is a fundamental design principle of modern Green warehouse solutions. A well-architected system is inherently modular. For instance, an initial AS/RS installation can be designed with additional vertical storage frames and cranes that can be added later. Similarly, an AGV fleet can start with a dozen units and be seamlessly expanded to fifty or a hundred, with the WES effortlessly managing the larger fleet. This modularity ensures that your Green warehouse solutions investment grows in lockstep with your business, avoiding premature obsolescence.

2. What is the typical payback period for a comprehensive investment in integrated Green warehouse solutions?

While the payback period is highly specific to the scale of operation and existing cost structures, businesses implementing these advanced Green warehouse solutions typically see a full return on investment within 2 to 4 years. This calculation factors in hard savings from reduced labor, lower energy costs, decreased product damage, and avoided real estate expenses. The continuous operational advantages and competitive edge provided by these Green warehouse solutions deliver substantial value long after the payback period is complete.

3. Can these Green warehouse solutions be retrofitted into our existing warehouse building, or do we need a new facility?

A significant advantage of today’s Green warehouse solutions is their adaptability. Most systems, particularly AS/RS and AGV fleets, are engineered for retrofitting into existing buildings. A detailed structural analysis is conducted to ensure the building can support the loads and heights. Retrofitting is often a more sustainable and cost-effective approach, aligning perfectly with the core philosophy of Green warehouse solutions by maximizing the use of existing infrastructure.

4. How do these systems handle peak season surges, such as during major sales or holiday periods?

The inherent flexibility of Green warehouse solutions makes them exceptionally well-suited for demand volatility. The software (WES) is designed to handle fluctuating order volumes. During peak seasons, the system can operate at maximum capacity, 24/7 if necessary, without the challenges of finding and training temporary manual labor. The AGV fleet and AS/RS work continuously, ensuring that surge capacity is built into the operation, a critical capability that manual warehouses consistently struggle with.

5. What kind of staff training and organizational changes are required to manage these advanced Green warehouse solutions?

Implementing Green warehouse solutions necessitates a strategic shift in workforce skills. The provider’s responsibility includes comprehensive training programs for a client’s staff. This training covers system monitoring, exception handling, routine maintenance, and data analysis. The organizational change involves moving personnel from manual, physical roles to technology-oriented, supervisory positions. This “upskilling” is a key benefit, leading to a more engaged, stable, and highly skilled workforce that is capable of managing the sophisticated Green warehouse solutions of tomorrow.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com