📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Maximize Storage & Minimize Cost: Durable Pallet Racking Systems for SMEs

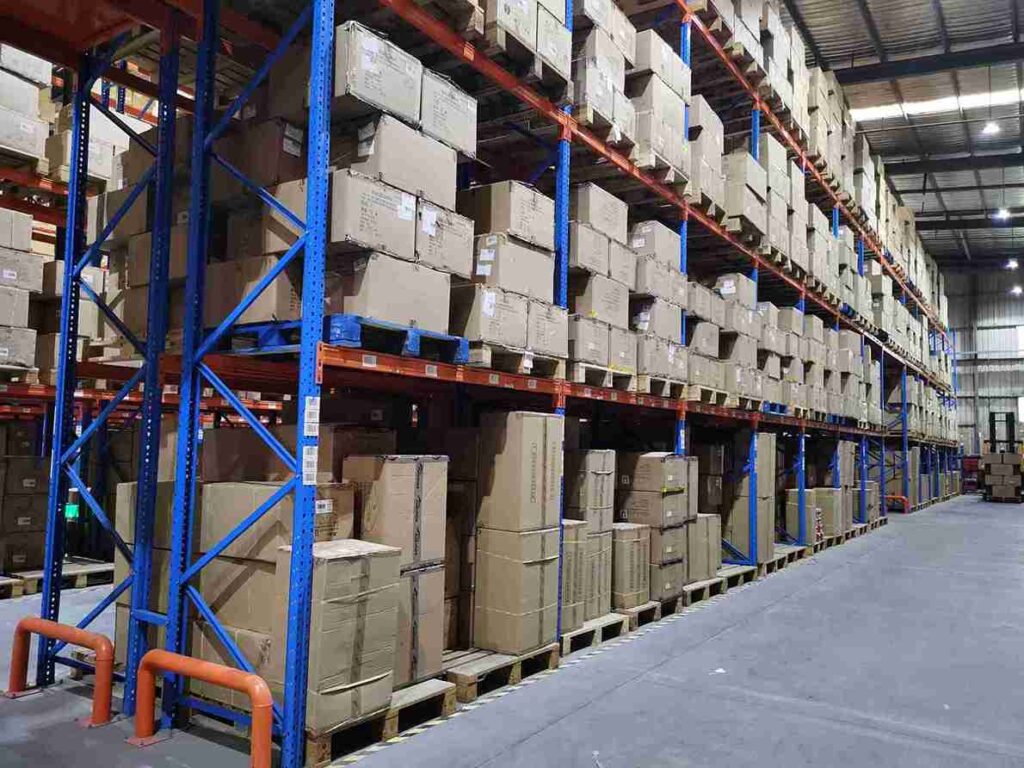

For small and medium-sized enterprises (SMEs) navigating the complexities of growth, the warehouse often becomes the epicenter of both challenge and opportunity. The pressing need to maximize storage capacity perpetually clashes with the imperative to minimize operational costs. This balancing act transcends mere logistics—it represents a strategic decision that can define a business’s trajectory. At the heart of an efficient, scalable, and cost-effective warehouse operation lies a solution that is both foundational and transformative: the durable pallet racking system.

Far from being a simple storage apparatus, a professionally engineered pallet racking system serves as a capital investment that directly enhances the bottom line by unlocking vertical space, streamlining inventory management, and ensuring workplace safety. For SMEs operating in emerging markets across Southeast Asia, Latin America, Africa, and beyond—where resources are carefully allocated and every square foot counts—selecting the right pallet racking system is a critical business decision.

This comprehensive guide delves into the engineering, economic, and strategic considerations of industrial pallet racking systems, offering SMEs the expert knowledge required to make an informed choice—one that bolsters operational efficiency, supports sustainable growth, and delivers a rapid return on investment. From selective pallet racking systems to high-density solutions, this analysis covers the full spectrum of options, evaluates the true cost of ownership, and outlines a practical framework for implementation tailored to the unique demands of the SME sector.

The Strategic Imperative: Why Your SME’s Warehouse Is Your Greatest Asset—or Liability

In today’s competitive business environment, the warehouse is frequently the most underestimated asset for small and medium-sized enterprises. Too often, it is viewed as a cost center—a static space for storing goods. This perspective represents a critical strategic misstep. In reality, the warehouse functions as a dynamic engine of the supply chain. An optimized warehouse, centered around a high-performance pallet racking system, directly influences order fulfillment speed, inventory accuracy, labor productivity, and—ultimately—customer satisfaction.

For growing businesses, inefficiencies in storage—such as wasted vertical space, difficult-to-access inventory, or disorganized layouts—compound rapidly. These inefficiencies translate into increased labor hours, higher risks of product damage and inventory errors, and an inability to scale operations without incurring exorbitant costs for additional space. By strategically investing in a durable pallet racking system, business owners are not merely purchasing metal beams; they are investing in a framework that systematizes operations, reduces the cost per pallet position, and creates predictable, efficient workflows.

This strategic approach transforms the warehouse from a static liability into a proactive, profit-driving asset. The right pallet racking system serves as the backbone of this transformation, enabling SMEs to achieve new levels of operational excellence.

The Anatomy of a Durable Pallet Racking System

Understanding the components and engineering principles behind a pallet racking system is essential for appreciating its long-term value and durability. These systems represent sophisticated structural solutions, not simple assemblies of metal components.

Core Components and Their Engineering Specifications

A standard selective pallet racking system—the most versatile and widely implemented type—comprises three primary elements, each critical to the system’s overall integrity and performance:

Upright Frames: These vertical columns form the structural backbone of the pallet racking system. Typically manufactured from high-tensile steel, they feature precisely engineered holes or teardrop-shaped slots for beam connections. The design, gauge thickness, and depth of the upright frames directly determine the system’s load-bearing capacity and resistance to seismic activity or impact forces. Industry-leading pallet racking systems incorporate uprights with robust column sections to ensure maximum stability under dynamic operating conditions.

Beams: These horizontal members, fabricated from roll-formed steel, connect to the uprights and provide direct support for palletized loads. Beams incorporate safety locks that securely engage with the upright frames, preventing accidental dislodgement during warehouse operations. The load capacity of beams depends on their steel grade and structural profile. For heavy-duty pallet racking systems, engineers often recommend stepped-beam designs or reinforced box beams to enhance strength and durability.

Wire Mesh Decking or Pallet Supports: While not always mandatory, decking significantly enhances safety and operational efficiency in a pallet racking system. It provides a stable surface for pallets, prevents goods from falling through the structure, and can serve as secondary fire protection. Welded wire mesh decking represents the optimal choice for most pallet racking systems due to its exceptional durability and compatibility with sprinkler system requirements.

The Science of Load Capacity and Safety Factor

When engineering a pallet racking system, professionals consider far more than the listed capacity. They calculate the applied load, which includes the combined weight of the pallet structure, the stored products, and any additional packaging materials. Furthermore, a substantial safety factor is integrated into all structural calculations.

This safety margin accounts for dynamic loads (such as forklift impacts), potential overloading scenarios, and the gradual material fatigue that occurs over the system’s operational lifespan. A truly durable pallet racking system is engineered to never operate near its theoretical limits, thereby ensuring extended service life and uncompromised operational safety.

A Deep Dive into Pallet Racking Types for SMEs

Selecting the appropriate type of pallet racking system represents a pivotal decision for warehouse optimization. The optimal choice depends on multiple factors: inventory profile, SKU count, throughput requirements, and the crucial balance between storage density and accessibility.

Selective Pallet Racking: The Gold Standard for Accessibility

Selective pallet racking systems remain the most versatile and widely implemented storage solutions globally, and for compelling reasons. They provide direct, immediate access to every single pallet location, making them ideal for diverse operational requirements.

Operational Methodology: This configuration utilizes a simple, modular design where each pallet occupies an individual bay, accessible directly from the aisle.

Ideal Applications: These pallet racking systems perfectly serve SMEs managing numerous SKUs where all products require constant accessibility. They excel in first-in, first-out (FIFO) inventory management environments and demonstrate exceptional compatibility with various forklift types.

Advantages: 100% stock accessibility, straightforward reconfiguration and expansion capabilities, favorable initial cost per bay, and superior performance for manual picking operations.

Limitations: Lower storage density compared to specialized systems, necessitating wider aisles for forklift maneuvering.

High-Density Storage Solutions: When Space Becomes Premium

When warehouse footprint remains fixed while inventory volumes grow, high-density pallet racking systems become transformative solutions for maximizing cube utilization.

Drive-In & Drive-Through Racking Systems

These innovative pallet racking systems transform conventional aisles into storage lanes, with forklifts physically driving into the rack structure to place and retrieve pallets.

Operational Methodology: Pallets rest on rails that extend deep into the rack structure, enabling multiple pallets to be stored in a single lane in depth sequence.

Ideal Applications: Perfect for cold storage facilities or operations storing large quantities of limited SKUs with lower rotation rates. Drive-through pallet racking systems permit access from both ends, facilitating FIFO inventory management.

Advantages: Exceptional storage density optimization, ideal for bulk storage applications.

Limitations: Reduced accessibility (typically operating on last-in, first-out principles for drive-in configurations), requires specialized forklift operator training, and offers slower throughput rates.

Push-Back Racking Systems

These innovative pallet racking systems strike an optimal balance between storage density and selectivity, offering multiple-deep storage while maintaining good accessibility.

Operational Methodology: Pallets rest on nested carts mounted on slightly inclined rails. When loading a new pallet, it pushes existing pallets backward along the rail system. During unloading, the subsequent pallet automatically advances to the pick face.

Ideal Applications: These pallet racking systems serve SMEs requiring enhanced density over selective configurations while maintaining better selectivity than drive-in systems. They excel in batch-picking environments.

Advantages: Superior density compared to selective pallet racking systems (typically accommodating 2-5 pallets deep), operates on LIFO principles while maintaining an active, dynamic pick face.

Limitations: Higher cost per position than selective pallet racking systems, slightly reduced weight capacity per level due to the cart mechanism.

The Strategic Role of Mezzanine Floors in Storage Maximization

While not strictly a pallet racking system, structural mezzanine floors represent the ultimate solution for capitalizing on unused vertical space. By installing a second or even third level within existing warehouse facilities, businesses effectively double or triple their available floor area without expanding their building’s footprint. These additional levels can support light-duty pallet racking systems, office spaces, packing stations, or slow-moving inventory archives. For SMEs operating facilities with high ceilings, mezzanine integration with pallet racking systems often represents the most effective method to dramatically maximize storage capacity.

The True Cost of Ownership: Minimizing Expenses Beyond Initial Investment

The most consequential mistake an SME can make involves selecting a pallet racking system based solely on the lowest initial purchase price. The genuine cost of ownership encompasses a far more comprehensive financial perspective that extends throughout the system’s operational lifespan.

Initial Investment Versus Long-Term Value Proposition

A lower-cost, inferior-quality pallet racking system might conserve capital initially but inevitably generates higher costs throughout its lifecycle. These hidden expenses typically include:

Frequent Repairs and Component Replacements: Inferior steel quality and substandard manufacturing processes lead to bent beams, damaged uprights, and premature system failure.

Safety Incident Risks: A racking collapse can cause catastrophic product loss, significant facility damage, and—most importantly—serious personnel injuries. The resulting financial and reputational damage can prove devastating to SMEs.

Operational Inefficiency Costs: A poorly designed pallet racking system creates wasted time in picking and put-away operations, increased energy consumption from extended forklift travel, and reduced overall throughput.

Investing in a durable pallet racking system from a reputable supplier means allocating resources toward superior materials, precise engineering, and certified manufacturing processes. This strategic investment delivers continuous returns for 20, 30, or more years through uninterrupted operation, minimal maintenance requirements, and sustained operational efficiency.

Calculating the ROI of a Durable Pallet Racking System

The return on investment for a high-quality pallet racking system is both tangible and measurable through several key performance indicators:

Cost per Pallet Position: By maximizing vertical space utilization, businesses dramatically reduce their storage cost per pallet. Rather than leasing additional space, they utilize existing infrastructure more intelligently through optimized pallet racking systems.

Labor Productivity Metrics: An organized, accessible warehouse layout utilizing efficient pallet racking systems reduces travel and search time for forklift operators, enabling more moves per hour and lowering labor costs.

Inventory Damage Reduction: A stable, professionally designed pallet racking system significantly decreases product damage risks from falling loads or forklift impacts, directly preserving profit margins.

The Implementation Blueprint: From Assessment to Operation

A successful pallet racking system project requires meticulous planning and execution. Following a structured implementation process ensures optimal results and maximum return on investment.

Phase 1: Comprehensive Warehouse and Inventory Analysis

Before commencing design work, professionals conduct thorough operational analysis including:

Detailed Inventory Profiling: Documenting pallet dimensions, weights, and total SKU counts to inform pallet racking system design parameters.

Throughput Analysis: Determining inventory turnover rates using ABC analysis to optimally position fast-moving items within the pallet racking system layout.

Facility Condition Assessment: Measuring clear ceiling heights, column locations, floor conditions, and door placements to optimize pallet racking system configuration.

Equipment Compatibility Audit: Reviewing existing or planned forklift specifications to determine minimum aisle width requirements for the pallet racking system.

Phase 2: Customized Layout and Engineering Design

Using advanced warehouse design software, engineers create detailed 2D and 3D layouts of the proposed pallet racking system. These models function as data-rich simulations that optimize:

Aisle Configuration Strategies: Balancing storage density with accessibility requirements within the pallet racking system.

Picking and Replenishment Pathways: Creating efficient workflow patterns through strategic pallet racking system placement.

Precise Load Calculations: Ensuring every component within the pallet racking system handles specific loads with appropriate safety margins.

Phase 3: Professional Installation and Safety Integration

A perfect design proves worthless without flawless execution. Professional installation teams ensure the pallet racking system is assembled to exact engineering specifications through:

Precision Anchoring Procedures: Securing upright frames to concrete floors to resist seismic and impact forces on the pallet racking system.

Plumb and Level Alignment: Ensuring entire structures maintain perfect vertical and horizontal alignment for even load distribution throughout the pallet racking system.

Comprehensive Safety Integration: Installing column guards, aisle-end protectors, and pallet safety nets as required for complete pallet racking system protection.

Phase 4: Operator Training and Maintenance Protocol Development

The human element remains critical to pallet racking system safety and efficiency. Comprehensive training for forklift operators establishes safe practices within the new storage environment. Additionally, proactive maintenance protocols—including regular visual inspections and periodic professional audits—ensure long-term integrity and safety of the pallet racking system investment.

Why Emerging Markets Demand Superior Pallet Racking Systems

SMEs operating in Southeast Asia, the Middle East, Latin America, and Africa face unique challenges that make a durable pallet racking system an essential operational component rather than a luxury.

Supply Chain Volatility Considerations: Longer lead times for replacement parts make system downtime particularly costly in these regions. The inherent durability and reliability of well-engineered pallet racking systems become paramount under these conditions.

Diverse Environmental Challenges: From Southeast Asia’s high humidity to the Middle East’s dusty environments, pallet racking systems require appropriate protective finishes (such as advanced powder coating) to resist corrosion and maintain structural integrity.

Accelerated Growth Trajectories: SMEs in emerging markets frequently experience rapid expansion. Modular, scalable pallet racking systems enable seamless operational growth without requiring costly, disruptive complete system replacements.

Beyond Basic Storage: Integrating Pallet Racking with Automation

For forward-thinking SMEs, the pallet racking system serves as the foundational layer for future automation integration. While operations may initially utilize manual forklifts, selecting a pallet racking system compatible with emerging technologies represents a prudent long-term strategy.

AGV (Automated Guided Vehicle) Compatibility: Modern selective pallet racking systems can be engineered with consistent, precise dimensions that seamlessly integrate with AGV systems when operations scale.

WMS (Warehouse Management System) Preparation: A well-organized pallet racking system layout, featuring clearly defined location schemes, provides the essential foundation for successful WMS implementation, further optimizing inventory control and picking efficiency.

Conclusion

In the relentless pursuit of growth and operational excellence, the strategic implementation of a durable pallet racking system represents one of the most impactful decisions an SME can undertake. These systems form the cornerstone of modern, responsive, and cost-effective warehouse operations. The dual mandate to maximize storage while minimizing costs transforms from a paradoxical challenge into an achievable reality through intelligent engineering and thoughtful design.

By looking beyond initial price considerations to focus on long-term value, safety, and scalability of storage infrastructure, business owners invest directly in the operational excellence that will fuel their enterprises for decades. The right pallet racking system—professionally designed, engineered, and installed—transforms warehouses from static cost centers into dynamic, profit-driving engines capable of meeting both local market demands and global competition.

Frequently Asked Questions (FAQs)

1. What is the typical lead time for the supply and installation of a pallet racking system for an average SME warehouse?

Lead times vary based on project complexity and system customization, but for standard selective pallet racking systems, businesses can typically expect a 4-8 week timeline from final design approval. This comprehensive timeframe includes manufacturing, shipping, and professional installation of the pallet racking system. Reputable suppliers provide detailed project schedules before commitment.

2. Can pallet racking systems be easily reconfigured or relocated if our warehouse needs change?

Absolutely. The modular design of selective pallet racking systems provides inherent flexibility. Beams can be quickly unclipped and repositioned on upright frames to adjust shelf heights. Furthermore, entire pallet racking systems can be disassembled and relocated to new facilities, protecting capital investments and providing exceptional adaptability for growing businesses.

3. How do we determine the correct load capacity needed for our pallet racking system?

This critical engineering determination occurs during initial consultation phases. Professionals require dimensions and weights of your heaviest loaded pallets. The pallet racking system design then specifies load capacities per level that exceed these weights, incorporating significant safety factors according to international standards (RMI or FEM) to account for dynamic impacts and operational variances.

4. What kind of ongoing maintenance is required for a pallet racking system?

A two-tiered maintenance approach is recommended for pallet racking systems. Internal teams should conduct regular visual inspections, checking for damage signs like dents, bends, or missing safety locks. Additionally, annual professional inspections by qualified engineers assess overall structural integrity, anchor tightness, and alignment, ensuring pallet racking systems remain in optimal, safe condition.

5. Are your pallet racking systems compliant with international safety standards, and do you provide certification?

Yes, reputable suppliers design, manufacture, and install pallet racking systems according to major international standards (RMI/FEM). Upon installation completion, comprehensive certification packages for the pallet racking system include load capacity certificates and engineering drawings, providing complete compliance documentation and peace of mind regarding local safety regulations.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com