📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Sustainable Racking Systems: The Strategic Blueprint for Slashing Costs and Building a Dominant, Eco-Conscious Warehouse

In the competitive landscape of global logistics, a silent revolution is reshaping the very foundations of warehouse management. The era of viewing storage as a static, cost-intensive necessity is over. Forward-thinking operations across Southeast Asia, the Middle East, Africa, and Latin America are now leveraging their storage infrastructure as a dynamic, profit-driving engine. At the core of this transformation are advanced sustainable racking systems.

These sophisticated structures represent a radical departure from conventional storage solutions. They form the intelligent, integrated backbone of a modern, eco-friendly warehouse, seamlessly syncing with Automated Guided Vehicles (AGVs), unmanned forklifts, and automated sortation systems. This synergy creates an operational ecosystem where efficiency and environmental responsibility are inextricably linked. The proven outcome? A dramatic reduction in operational expenditures, with a consistent and verifiable decrease in energy consumption by 30% or more, concurrently enhancing throughput, accuracy, and corporate sustainability credentials.

This definitive guide explores the engineering principles, strategic integration, and tangible return on investment that modern sustainable racking systems deliver, providing a clear roadmap for businesses aiming to future-proof their supply chain operations.

Deconstructing the Modern Sustainable Racking System: An Engineering Marvel Beyond Recycled Steel

The term sustainable racking systems often conjures an image of racking made from recycled materials. While the use of certified, high-recycled-content steel is a fundamental baseline, it is merely the first step in a comprehensive engineering philosophy. True sustainability in material handling is achieved through a holistic design approach that prioritizes lifelong efficiency, adaptability, and minimal total cost of ownership. These are not passive storage structures; they are active participants in an optimized workflow.

The most effective sustainable racking systems are conceived and engineered from the outset to be the perfect physical partner for smart automation, unlocking unprecedented levels of energy and spatial efficiency.

The Three Pillars of Intelligent Sustainable Racking Design

A superior sustainable racking system is built upon three interdependent design pillars that ensure long-term viability and performance:

Maximized Volumetric Efficiency: The most profound energy savings come from optimizing the warehouse cube. By storing more products within a smaller physical footprint, these systems directly reduce the spatial volume requiring climate control and artificial lighting. Advanced sustainable racking systems, such as high-density push-back racks and drive-in configurations, are precision-engineered to achieve storage densities that are often 75% higher than traditional selective pallet racking, fundamentally altering the energy dynamics of the facility.

Native Integration with Robotics and Automation: A rack that forces an AGV to take a longer route or an unmanned forklift to make unnecessary adjustments is a source of constant energy waste. The next generation of sustainable racking systems is designed with digital-twin technology, ensuring that every beam height, column spacing, and load bay is optimized for the most efficient travel paths and interaction points for automated material handling equipment. This native compatibility is what allows for the significant reduction in energy consumption per move.

Lifecycle Engineering for Durability and Reconfigurability: Sustainability is synonymous with longevity. A system requiring replacement in a decade due to corrosion or obsolescence is inherently wasteful. Leading providers engineer their sustainable racking systems with high-tensile steel and advanced coating technologies, such as epoxy-polyester powder coatings, to withstand harsh environments—from the humid climates of Vietnam to the saline coastal air of the UAE. Furthermore, modular design principles allow these sustainable racking systems to be easily reconfigured, expanded, or repurposed, protecting the client’s investment against future operational shifts.

The Mechanics of Efficiency: How Integrated Automation and Sustainable Racking Drive a 30% Energy Reduction

The pledge of a 30% reduction in energy costs is a calculated outcome of superior system design, not an aspirational goal. In a typical warehouse, the largest energy consumers are material handling equipment (e.g., forklifts), followed by lighting and HVAC systems. An integrated approach of sustainable racking systems and smart automation attacks these cost centers simultaneously.

Revolutionizing Material Handling: The AGV and Unmanned Forklift Synergy

Conventional, human-operated forklifts are inherently inefficient from an energy perspective. They idle frequently, follow suboptimal routes based on operator discretion, and require broad, consistent lighting for safety. The integration of sustainable racking systems with an automated fleet eliminates these inefficiencies at their source.

Algorithmically Optimized Travel Paths: These sustainable racking systems are implemented within a warehouse management system (WMS) that uses complex algorithms. The software controlling the AGV fleet calculates the most direct, collision-free path for every single storage and retrieval task. This precise coordination, inherent to a well-planned sustainable racking systems layout, ensures that automated vehicles travel the absolute minimum distance, directly conserving battery power.

Regenerative Braking Technology: Modern AGVs and unmanned forklifts designed for these environments often incorporate regenerative braking. This system captures kinetic energy during deceleration and converts it back into electrical energy, replenishing the battery. This technology, when deployed across an entire fleet operating within a high-density sustainable racking systems layout, can reduce external charging needs by up to 15%, compounding the energy savings.

Intelligent, Opportunistic Charging: Instead of operating on a rigid charging schedule, the fleet management system can instruct individual vehicles with lower charge levels to dock at wireless or contact charging stations during natural workflow lulls. This “opportunistic charging” smooths out the electrical demand curve, prevents peak load spikes, and enhances overall energy management within the facility housing the sustainable racking systems.

Taming Fixed Energy Drains: The “Dark Warehouse” and HVAC Advantage

A warehouse designed for people has fundamental, energy-intensive requirements. A warehouse built around sustainable racking systems and automation can circumvent these entirely.

The “Dark Warehouse” Model: AGVs and autonomous forklifts navigate using LiDAR, cameras, and inertial guidance systems that require minimal to no ambient light. This allows for the implementation of a “dark warehouse” where overhead lighting is only activated in specific, human-occupied zones. This single shift, enabled by the automated nature of operations within the sustainable racking systems, can slashing lighting energy consumption by 70% or more.

Dramatically Reduced HVAC Load: Human operators and combustion-engine machinery generate significant heat. A facility populated by a fleet of electric, high-efficiency AGVs produces substantially less ambient heat, thereby reducing the cooling load on the HVAC system. This is a critical advantage in the high-temperature regions of the Middle East and Africa, where air conditioning constitutes a massive portion of energy bills. The high-density nature of the sustainable racking systems also means a smaller volume of air needs to be conditioned.

The Product Ecosystem: A Detailed Look at Core Sustainable Racking and Automation Solutions

Achieving transformative results requires a synchronized suite of technologies. The following solutions represent the core components of a fully integrated, high-performance warehouse ecosystem centered on advanced sustainable racking systems.

High-Density Sustainable Racking System Configurations

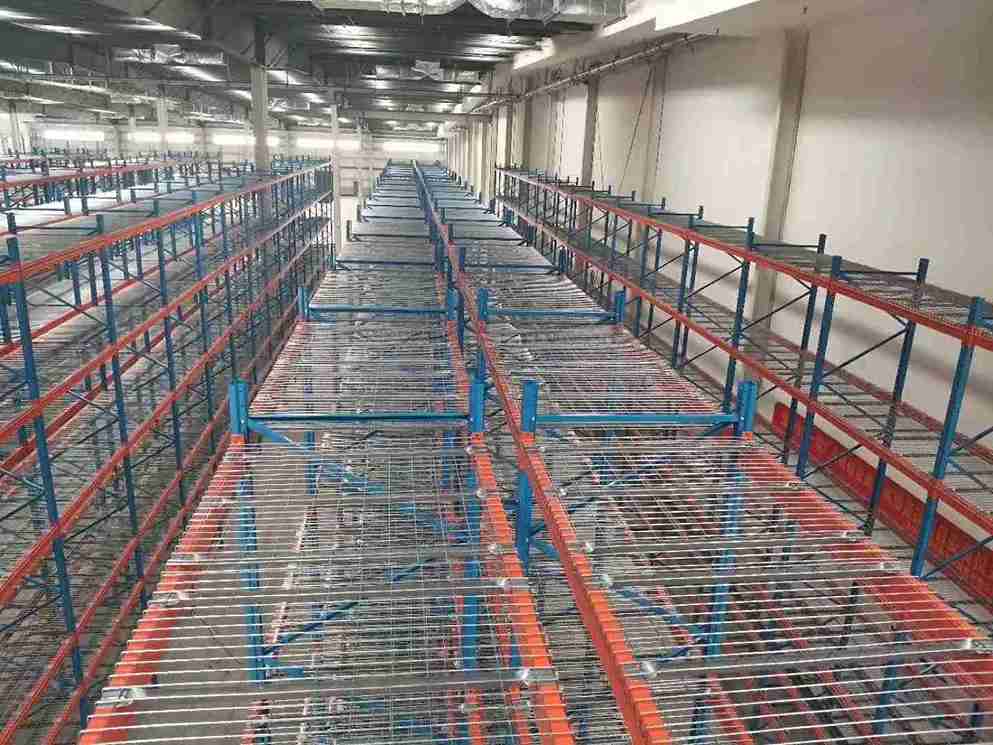

Push-Back Racking Systems: This pallet flow system is a cornerstone of modern sustainable racking systems. It stores pallets multiple deep on inclined rails, with each level functioning as an independent carriage. Ideal for operations with medium to high selectivity and high-density needs, this sustainable racking systems configuration can increase storage capacity by up to 75% compared to traditional selective racking, directly contributing to a smaller, more energy-efficient building footprint.

Drive-In/Drive-Through Racking: Engineered for high-volume, low-SKU-density storage, this sustainable racking systems design is particularly transformative for cold storage operations. By eliminating all but a few primary aisles, it drastically reduces the refrigerated air volume, leading to monumental energy savings in freezer and cooler applications. The structural integrity of these sustainable racking systems is critical to withstand the thermal stresses of a controlled environment.

Pallet Live Storage Systems: For very high-throughput operations, this sustainable racking systems solution uses gravity-fed roller tracks to create a dynamic, first-in-first-out (FIFO) inventory flow. The use of gravity to move pallets eliminates the need for powered conveyance in certain zones, contributing directly to the energy-reduction profile of the sustainable racking systems.

Automated Storage and Retrieval Systems (AS/RS): Representing the pinnacle of sustainable racking systems technology, AS/RS are ultra-high-density, fully integrated rack-supported structures. Robotic cranes or shuttles travel within the racking itself to store and retrieve goods. These systems operate in near-total darkness, use energy only during movement, and maximize cubic space utilization to levels unattainable by any other method, making them the ultimate expression of sustainable racking systems.

The Intelligent Material Handling Fleet: Precision Partners for Sustainable Racking

AGV (Automated Guided Vehicle) Pallets and Tow Tractors: The fleet of AGVs is not a generic off-the-shelf product; it is specifically calibrated for the narrow aisles and precise docking requirements of the installed sustainable racking systems. Their navigation software is mapped directly to the digital model of the racking layout, ensuring flawless physical and digital integration from the moment of commissioning.

Unmanned Forklifts (Autonomous Guided Forklifts): These machines handle the critical interface between the transport floor and the rack face. They are pre-programmed with the exact fork heights, tilt angles, and extension distances required for the specific beam levels and pallet types used within the sustainable racking systems, minimizing cycle times and the risk of energy-wasting errors or damaging impacts.

High-Efficiency Conveyor and Sortation Systems: The conveyance that feeds and receives from the sustainable racking systems is equally critical. Modern systems are equipped with variable frequency drives (VFDs) and high-efficiency motors that draw less power. They can be programmed to enter a low-power “sleep mode” or even shut down completely during periods of inactivity, a sophisticated feature often absent from standard conveyor systems.

Quantifiable Impact in the Field: A Deep-Dive Operational Case Study

A recent implementation for a major FMCG (Fast-Moving Consumer Goods) distributor in Indonesia serves as a powerful testament to the transformative power of integrated sustainable racking systems. The client operated a 12,000 square meter facility plagued by the high costs and inefficiencies of a legacy setup.

The Pre-Implementation Challenge: The warehouse utilized traditional selective pallet racking and a mixed fleet of 18 LPG and diesel forklifts. Soaring fuel costs, poor indoor air quality, excessive operational noise, and the mandatory 24/7 illumination of the entire facility were creating an unsustainable financial and operational burden.

The Deployed Integrated Solution:

Phase 1 – Racking Overhaul: The existing racking was systematically replaced with a custom-engineered high-density push-back racking system, increasing pallet positions by over 65% within the original footprint.

Phase 2 – Fleet Automation: A coordinated fleet of 22 electric AGV pallet trucks and 4 unmanned counterbalance forklifts was deployed, all managed by a central control system integrated with the client’s WMS.

Phase 3 – Facility Optimization: A “dark warehouse” protocol was implemented, with motion-activated, zone-specific LED lighting installed only in designated maintenance and picking areas.

The Documented Results (After 12 Months of Operation):

Energy Cost Reduction: A confirmed 34% overall reduction in energy costs, stemming from the elimination of fossil fuels, reduced electricity for charging, and a 72% drop in lighting costs.

Operational Throughput: Order fulfillment cycle times improved by 28%, enabling 24/7 operation without increasing headcount.

Space and Asset Utilization: The new sustainable racking systems freed up over 25% of the floor space, which was converted into a profitable cross-docking and value-added services area.

Sustainability Metrics: The project resulted in an annual reduction of approximately 110 tons of CO2 emissions, significantly boosting the company’s ESG (Environmental, Social, and Governance) reporting metrics.

The Geographic Imperative: Why Emerging Markets are Ideal for Sustainable Racking

The strategic argument for deploying advanced sustainable racking systems is particularly compelling in the target growth markets of Southeast Asia, Central Asia, the Middle East, Africa, and Latin America.

Southeast Asia & Africa: These rapidly industrializing regions often face volatile and rising energy prices, coupled with strains on public power infrastructure. Implementing a warehouse solution that drastically reduces dependency on the grid provides not only cost savings but also crucial operational resilience against brownouts and energy price hikes. The sustainable racking systems act as a buffer against economic uncertainty.

The Middle East: Nations like Saudi Arabia and the UAE are aggressively executing long-term visions (e.g., Saudi Vision 2030, UAE Net Zero 2050) that heavily prioritize economic diversification and sustainability. Adopting state-of-the-art sustainable racking systems aligns corporate strategy with national agendas, potentially unlocking government incentives and positioning companies as regional leaders in green logistics.

Latin America: Companies in countries like Brazil, Mexico, and Chile are increasingly aware of their environmental footprint, especially when exporting to markets with stringent sustainability standards. A warehouse powered by intelligent sustainable racking systems serves as a powerful market differentiator, enhancing brand reputation and meeting the demands of globally conscious supply chain partners.

A Phased Implementation Strategy: Minimizing Risk, Maximizing ROI on Sustainable Racking

Understanding that operational continuity is paramount, the deployment of a comprehensive sustainable racking systems solution is executed through a meticulous, phased methodology designed to de-risk the transition.

Phase 1: In-Depth Discovery and Digital Simulation: The process begins with a granular audit of current operations, inventory profiles, and growth projections. Using this data, a precise digital twin of the proposed sustainable racking systems and automation is created. This model simulates performance, providing a data-backed projection of ROI, throughput gains, and energy savings before any physical work begins.

Phase 2: Staged Racking Installation and Commissioning: The new sustainable racking systems are installed in strategic phases, often during off-peak hours or in designated sections of the warehouse, to allow the existing business to continue operating with minimal disruption. Each section is fully commissioned and validated before proceeding to the next.

Phase 3: Systematic Automation Integration: The AGV fleet and unmanned forklifts are deployed and their control systems are intricately woven into the client’s existing WMS and ERP systems. This ensures that the flow of information from the management software to the physical movement within the sustainable racking systems is seamless and error-free.

Phase 4: Continuous Optimization and Proactive Support: The relationship extends long after the system is live. Remote monitoring and data analytics are used to continuously fine-tune the performance of the sustainable racking systems and their automated partners, identifying further efficiency gains. Comprehensive support packages ensure maximum uptime and long-term system health.

The Comprehensive ROI: Justifying the Investment in Sustainable Racking Systems

The capital investment for a fully integrated warehouse with advanced sustainable racking systems is substantial. However, the return on investment is multi-layered, robust, and extends far beyond simple payback periods.

Direct and Tangible Cost Savings: This includes the guaranteed 30%+ energy savings, a significant reduction in labor costs associated with manual material handling, and lower long-term maintenance costs compared to traditional internal combustion engine equipment.

Indirect Financial Value: This encompasses a dramatic reduction in product damage caused by human error, near-perfect inventory accuracy (routinely exceeding 99.99%), a drastic improvement in workplace safety by removing personnel from high-traffic zones, and a reduction in insurance premiums.

Strategic and Intangible Value: This is perhaps the most critical for long-term dominance. It includes future-proofing the logistics operation against regulatory changes and energy volatility, substantially enhancing the corporate brand as an environmental leader, and ensuring compliance with the escalating demands from investors and partners for robust ESG frameworks. A warehouse powered by intelligent sustainable racking systems is a formidable strategic asset.

Conclusion: The Inevitable Ascendancy of the Sustainable, Automated Warehouse

The logistics industry stands at an inflection point. The paradigm of the warehouse as a simple, energy-intensive storage shed is obsolete. The distribution center of the future is a dynamic, intelligent, and highly profitable value center, and its foundational element is a masterfully engineered sustainable racking system. By fusing high-density, adaptable storage with a seamlessly integrated fleet of AGVs and unmanned forklifts, these systems do more than just save energy—they redefine operational excellence.

They build resilience, enhance brand equity, and create a competitive moat that is difficult to breach. The evidence from countless global implementations is unequivocal. The technology is mature, proven, and delivering measurable superior returns. The critical question for any logistics leader is no longer about the feasibility of upgrading to sustainable racking systems, but about the escalating opportunity cost of delay. The future of warehousing is efficient, automated, and undeniably sustainable, and that future is available for deployment today.

Frequently Asked Questions (FAQs)

1. How does the structural integrity and safety factor of sustainable racking systems compare to traditional racking, especially in seismic zones?

Professional engineers design sustainable racking systems with stringent adherence to international standards like FEM 10.2.03 and specific local seismic codes. The use of high-tensile steel and sophisticated structural analysis often results in a rack that is not only more efficient but also possesses a higher safety margin. In regions with seismic activity, specific bracing configurations and connection details are incorporated into the sustainable racking systems design to ensure stability and protect both the inventory and the automated equipment operating within it.

2. What is the typical lifespan of a sustainable racking system, and how does its performance degrade over time?

A properly specified and maintained sustainable racking systems has a design lifespan that typically exceeds 25 years. The key to maintaining performance is the quality of the steel and the protective coating. The advanced coatings used on high-quality sustainable racking systems are designed to resist chipping, corrosion, and UV degradation for decades. Performance does not degrade if the system is maintained according to the manufacturer’s guidelines, which include regular inspections for any accidental damage. The modularity of these sustainable racking systems also means individual components can be replaced without affecting the integrity of the whole structure.

3. Can these automated sustainable racking systems handle the variety of pallet types and non-standard load sizes common in our multi-client warehouse?

Absolutely. The flexibility of modern sustainable racking systems is one of their key strengths. During the design phase, the digital twin models account for the full range of pallet types (CHEP, EUR, GMA), sizes, and load dimensions. The AGVs and unmanned forklifts can be equipped with customizable fork attachments and sophisticated vision systems to safely handle this variety. The sustainable racking systems themselves can be configured with adjustable beams and bespoke decking solutions to accommodate non-standard loads, ensuring that automation does not come at the cost of flexibility.

4. What is the cybersecurity posture of the software that controls these integrated sustainable racking systems and the AGV fleet?

Cybersecurity is a critical component of any modern automated warehouse. Reputable providers implement a multi-layered security strategy for the control software of their sustainable racking systems and automation. This includes encrypted data transmission (both wired and wireless), secure user authentication protocols, regular security patch updates, and network segmentation to isolate the operational technology (OT) network from the general corporate IT network. This ensures the physical operation of the sustainable racking systems is protected from external threats.

5. We have existing racking. Is a “hybrid” approach possible, where we integrate automation with some of our current structures and supplement with new sustainable racking systems?

A hybrid approach is often a very effective and cost-conscious strategy. A professional audit can determine which sections of existing racking are suitable for integration with new automation. In many cases, AGVs can be programmed to operate within older racking sections. However, to achieve the full energy and density benefits, new sustainable racking systems are typically deployed in the highest-activity zones or where density gains are most crucial. This phased investment allows companies to progressively modernize their facility, leveraging their existing assets while strategically upgrading to advanced sustainable racking systems for maximum impact.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com