📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Maximizing Warehouse Space in Southeast Asia: A 50%+ Storage Boost with Very Narrow Aisle Pallet Racking Systems

Introduction: The Spatial Imperative in Southeast Asia’s Logistics Boom

The landscape of Southeast Asia’s industrial and logistics sectors is undergoing a transformation of unprecedented scale. Nations like Vietnam, Indonesia, Thailand, and the Philippines are not only becoming global manufacturing pivots but also witnessing an explosive growth in domestic consumption and e-commerce. This surge places immense, unrelenting pressure on a critical and often static asset: the warehouse.

For operations managers, logistics directors, and business owners across the region, the equation is deceptively simple yet operationally complex. Demand for storage is skyrocketing, while the availability of affordable, well-located industrial land is constricting just as rapidly. Constructing new greenfield facilities is a capital-intensive and time-consuming endeavor, often impractical in urban-adjacent logistics hubs where space is at a supreme premium.

This pressing challenge births a singular, strategic question: how can a business radically increase its storage capacity without expanding its physical footprint? The answer, validated across continents and industries, lies not in horizontal expansion but in the intelligent, volumetric optimization of existing space. This is the definitive domain of the Very Narrow Aisle Pallet Racking system. Far more than a simple storage product, a properly engineered Very Narrow Aisle Pallet Racking solution represents a comprehensive re-engineering of warehouse density logistics.

It is a paradigm shift from selective racking’s accessibility-focused model to a density-optimized architecture. When integrated with the appropriate guided handling technology, implementing a Very Narrow Aisle Pallet Racking system is the most reliable method to achieve a 50% or greater increase in pallet positions within the same building envelope. For Southeast Asian businesses aiming to scale operations efficiently, mastering and deploying this technology is not merely an option; it is a competitive necessity.

This analysis moves beyond superficial overviews to provide a granular, expert-level examination of the Very Narrow Aisle Pallet Racking ecosystem. It will dissect the engineering principles that enable such remarkable density gains, demystify the symbiotic relationship between the racking structure and specialized equipment like turret trucks and AGVs, and present a rigorous financial framework for evaluating the investment. The goal is to furnish decision-makers with the depth of knowledge required to champion this transformation within their organizations, transforming spatial constraints into a formidable logistical advantage.

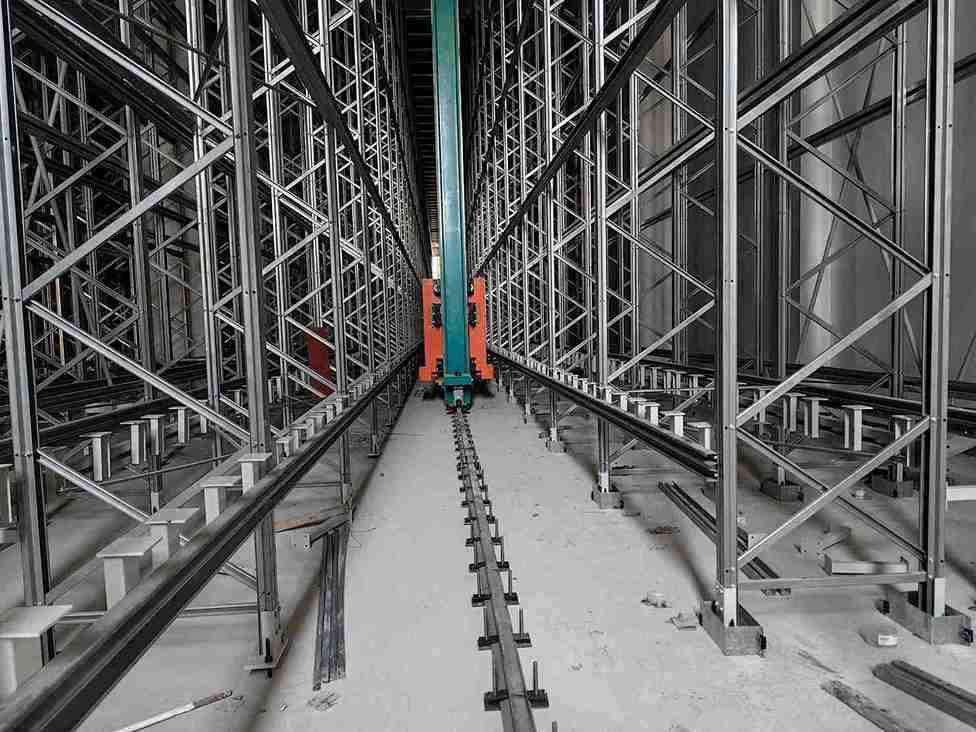

Very narrow aisle pallet racking system maximizing vertical storage

Part 1: The Density Calculus – Understanding the Physics of Space Reclamation

H2: The Cost of Empty Air: Quantifying the Waste in Conventional Layouts

To appreciate the transformative impact of Very Narrow Aisle Pallet Racking, one must first understand the inherent inefficiency of traditional warehouse designs. Conventional selective pallet racking, serviced by counterbalance or reach forklifts, requires aisle widths typically between 3.2 and 3.5 meters. This dimension is dictated by the need for forklifts to maneuver, turn, and position loads without colliding with the racking.

In a standard layout, these travel aisles can consume 45% to 50% of the total warehouse floor area. This is essentially expensive, covered real estate dedicated not to storing revenue-generating inventory, but to facilitating movement. Every square meter of aisle is a square meter not holding stock. In the context of Southeast Asia’s rising land and construction costs, this waste translates directly to eroded profitability and capped growth potential.

H3: The Vertical Frontier: Exploiting the Cubic Capacity

Warehouse capacity is a function of both floor space and height. Many existing warehouses, especially older facilities, underutilize their vertical clearance. Standard reach trucks are often limited to heights of 10-12 meters due to stability concerns. A core engineering advantage of Very Narrow Aisle Pallet Racking is its design for stability at greater elevations.

These systems are routinely engineered for heights of 15, 18, or even beyond 20 meters. By pairing narrower aisles with increased stacking height, the capacity gain is multiplicative. It’s a shift from a two-dimensional floor plan to a three-dimensional storage cube optimization. The Very Narrow Aisle Pallet Racking structure, with its reinforced uprights and integrated bracing, is specifically designed to handle the increased moment forces and load dynamics at these elevated heights safely.

H4: The Numerical Proof: A Comparative Scenario

Consider a hypothetical warehouse in Jakarta, measuring 100 meters in length and 60 meters in width, with a clear internal height of 14 meters. Under a conventional selective racking plan with 3.5m aisles and 11m high racking, the facility might accommodate approximately 6,000 pallet positions.

Now, implement a Very Narrow Aisle Pallet Racking system with 1.6m aisles, extending storage to 13.5 meters. The immediate effect of narrower aisles increases the floor area available for racking footprints. Concurrently, the additional vertical levels add more positions per rack footprint. The combined result can comfortably surpass 9,000 pallet positions—a 50%+ increase in the same building. This is not theoretical improvement; it is the standard outcome of applying the Very Narrow Aisle Pallet Racking methodology. This reclaimed air space, previously a cost center, is converted directly into productive asset capacity.

Part 2: The Anatomy of a Very Narrow Aisle System – More Than Just Racking

H2: The Structural Core: Engineered for Precision and Resilience

A critical misconception is viewing Very Narrow Aisle Pallet Racking as merely standard racking installed closer together. This is a fundamental and potentially catastrophic error. The racking structure in a VNA application is a high-precision engineered system with distinct, non-negotiable characteristics:

Superior Material Specifications: The upright frames and load beams are fabricated from high-tensile steel, often with thicker gauges and larger column profiles. This provides the necessary load-bearing capacity and rigidity for tall, dense configurations. The static and dynamic load calculations for a Very Narrow Aisle Pallet Racking system are far more rigorous, accounting for seismic forces (crucial in parts of Southeast Asia), impact loads, and the precise weight distribution from guided vehicles.

Precision Tolerances and Installation: The operational success of the entire system hinges on maintaining a consistent aisle width. Tolerances are typically within +/-10mm across the entire aisle length. Achieving this requires laser-guided installation techniques and a floor that meets strict flatness standards. The integrity of the Very Narrow Aisle Pallet Racking installation is the foundation upon which all equipment reliability and safety are built.

Enhanced Safety and Protection Features: Given the close proximity of moving equipment, the racking design incorporates dedicated protective elements. These include robust column guards, heavy-duty footguards, and often specially designed upright profiles that can withstand incidental contact far better than standard racking. Protecting the integrity of the Very Narrow Aisle Pallet Racking investment is a primary design consideration.

H3: The Guided Vehicle Symbiosis: Turret Trucks and AGVs

The racking structure defines the potential storage volume, but it is the handling equipment that unlocks it. The choice between manned and automated solutions defines the operational character of the Very Narrow Aisle Pallet Racking system.

Man-Up Turret Trucks: The operator ascends to the load level within the aisle, providing direct visual control for precise placement and retrieval. These vehicles run on guide rails or optical wire guidance, eliminating steering drift and enabling the ultra-narrow aisle. They offer excellent flexibility for warehouses with a high variety of SKUs, complex picking patterns, or lower throughput volumes that don’t justify full automation. The turret truck and the Very Narrow Aisle Pallet Racking form a cohesive, high-performance manual unit.

Very Narrow Aisle AGVs (Automated Guided Vehicles): This represents the zenith of density and operational efficiency. An Automated Very Narrow Aisle Pallet Racking system, served by driverless fork AGVs, operates on pre-programmed or dynamically optimized routes. It maximizes utilization by working 24/7, reduces labor costs and associated risks, and can operate in low-light or cooler environments (reducing energy costs for lighting and climate control). For new facilities or major retrofits with high, predictable volumes, the combination of Very Narrow Aisle Pallet Racking with AGVs delivers the highest long-term ROI and positions the warehouse at the forefront of Industry 4.0 logistics.

H4: The Command Center: Warehouse Management Software Integration

A high-density storage system without intelligent coordination is a gridlock waiting to happen. The Warehouse Management System (WMS) is the central nervous system of a modern Very Narrow Aisle Pallet Racking operation. Its role extends far beyond basic inventory tracking:

Dynamic Location Management: The WMS intelligently assigns incoming pallets to optimal locations within the Very Narrow Aisle Pallet Racking grid based on SKU dimensions, weight, turnover velocity, and expiry dates.

Travel Optimization: It sequences retrieval tasks to minimize the travel distance for turret trucks or AGVs, dramatically increasing effective throughput.

System Orchestration: In automated setups, the WMS directly communicates with the AGV fleet management software, translating storage and retrieval commands into precise machine instructions.

Inventory Integrity: By enforcing strict putaway and picking rules via RF or onboard terminals, the WMS ensures the perfect alignment between the physical stock in the Very Narrow Aisle Pallet Racking and the digital database, achieving near-100% inventory accuracy.

Part 3: Tailoring the VNA Solution for Southeast Asia’s Unique Operating Environment

H2: Confronting Climatic and Infrastructural Realities

A successful implementation of Very Narrow Aisle Pallet Racking in Southeast Asia requires solutions engineered for the region’s specific challenges, not simply importing off-the-shelf European or American designs.

Corrosion Resistance in Humid Climates: The constant high humidity mandates superior corrosion protection. A Very Narrow Aisle Pallet Racking system destined for this region should specify hot-dip galvanizing with a minimum coating mass of Z600 (600 grams per square meter), significantly heavier than the Z275 common in temperate zones. For highly corrosive environments like coastal areas or cold storage, even higher specifications or powder-coating over galvanization may be required.

Seismic Engineering: The Pacific Ring of Fire necessitates rigorous seismic design for warehouses in Indonesia, the Philippines, and parts of Thailand. The structural design of the Very Narrow Aisle Pallet Racking must be calculated by qualified engineers using local seismic zone coefficients. This influences everything from base plate size and anchoring depth to the frequency and design of horizontal and vertical bracing.

Power and Flooring Considerations: In areas with less stable electrical grids, the design for AGV systems or electric turret trucks must incorporate robust battery management, fast-charging stations, and potential backup systems. Furthermore, the precision required for Very Narrow Aisle Pallet Racking operations demands exceptionally flat floors, often requiring professional grinding or topping as a prerequisite to installation—a critical factor in retrofit projects.

H3: Configuring for Dominant Regional Industries

The optimal Very Narrow Aisle Pallet Racking configuration is intensely application-specific.

For Food, Beverage, and Cold Storage: In these sectors, the cost per cubic meter of storage space is exceptionally high. Very Narrow Aisle Pallet Racking maximizes the value of this expensive environment. Designs must account for thermal contraction/expansion and use compatible materials. Automated systems (Very Narrow Aisle Pallet Racking with AGVs) are highly advantageous as they minimize the time storage doors are open, conserve energy, and allow operation in very cold temperatures unsuitable for personnel.

For Third-Party Logistics (3PL) Providers: Flexibility and accuracy are paramount. A 3PL’s Very Narrow Aisle Pallet Racking system must handle a vast array of pallet types and SKUs for multiple clients. Man-up turret trucks often provide the necessary adaptability. The WMS must be capable of sophisticated multi-client inventory segregation, batch tracking, and streamlined cycle counting within the dense Very Narrow Aisle Pallet Racking array.

For Manufacturing and Bulk Raw Materials: These applications often involve heavy, uniform loads. The Very Narrow Aisle Pallet Racking design focuses on high beam load capacities and durable construction. Throughput might be lower, so the financial justification centers overwhelmingly on the real estate savings achieved by consolidating vast bulk storage into a fraction of the former floor area.

Part 4: The Investment Rationale – A Comprehensive Total Cost of Ownership (TCO) Analysis

H2: Understanding the Full Capital Outlay

The initial capital expenditure (CAPEX) for a Very Narrow Aisle Pallet Racking system is undeniably higher than for a conventional racking and forklift solution. An accurate budget must encompass:

The fully engineered and fabricated Very Narrow Aisle Pallet Racking structure, including all safety features.

The guided handling equipment (turret trucks or AGV fleet).

Guidance infrastructure (rails, wires, navigation targets).

Professional installation, certification, and commissioning.

WMS software integration, licensing, and customization.

Any necessary civil works (floor remediation, power infrastructure for charging).

H3: The Compelling Operational Savings (OPEX)

The true economic justification emerges when evaluating ongoing operational savings against the alternative of building anew:

Real Estate Avoidance: This is the most significant saving. It eliminates the need to purchase/lease additional land and construct a new building, a saving that can run into millions of dollars.

Labor Productivity and Optimization: Operators in man-up turret trucks cover less distance per pick/place cycle. AGVs reduce direct labor costs, eliminate shift limitations, and mitigate risks associated with manual high-bay operation.

Energy and Maintenance Efficiency: A denser storage footprint means less cubic volume to light, cool, or dehumidify. AGVs can operate in darkness. Higher-quality racking and guided vehicles typically experience lower damage rates, reducing maintenance and product loss.

Inventory and Accuracy Gains: The WMS-directed nature of operations within a Very Narrow Aisle Pallet Racking system drastically reduces mis-picks and lost stock, optimizing inventory turns and working capital.

H4: Building a Conservative ROI Model

A credible feasibility study models two scenarios over a 7-10 year horizon. Scenario A (Expansion): Costs of land acquisition, construction, and outfitting a new conventional warehouse, plus its ongoing OPEX. Scenario B (Retrofit): The full CAPEX and OPEX of the Very Narrow Aisle Pallet Racking solution within the existing facility.

The analysis factors in local real estate appreciation rates, construction cost inflation, financing costs, and projected labor wage increases. In the vast majority of cases for facilities over 5,000 sqm in high-cost logistics corridors, the Very Narrow Aisle Pallet Racking retrofit demonstrates a payback period of 2.5 to 4 years based on avoided costs alone. Post-payback, the system generates continuous positive cash flow through superior operational efficiency, a fact that makes the Very Narrow Aisle Pallet Racking investment a compelling strategic asset.

Part 5: From Concept to Reality – A Phased, Risk-Mitigated Implementation Pathway

H2: Phase 1: In-Depth Feasibility and Digital Simulation

The journey begins with data, not design. A comprehensive audit captures SKU profiles, pallet data, daily throughput flows, and growth projections. Advanced simulation software then creates a digital twin of the proposed Very Narrow Aisle Pallet Racking operation. This virtual environment can stress-test the design under peak season volumes, simulate different equipment fleet sizes, and identify potential bottlenecks before any physical commitment is made. This phase de-risks the project and optimizes the configuration for the specific business case.

H3: Phase 2: Detailed Engineering and Project Management

Following design freeze, detailed engineering drawings are produced for the Very Narrow Aisle Pallet Racking structure, including seismic calculations and foundation plans. A dedicated project manager oversees the entire timeline: site preparation, coordination of local contractors for civil works, the arrival and precision installation of the racking by certified crews, installation of guidance systems, and the commissioning of both hardware and software. This single-point accountability is crucial for keeping complex projects on schedule and budget.

H4: Phase 3: Go-Live, Training, and Continuous Optimization

Commissioning is followed by a structured go-live with parallel support. Comprehensive training is provided for operators, maintenance staff, and WMS users. The relationship, however, does not end at handover. Performance data is monitored, and the WMS settings are fine-tuned to adapt to seasonal patterns or changing product mixes. The modular nature of Very Narrow Aisle Pallet Racking allows for future reconfiguration—aisles can be adjusted, sections added—ensuring the investment remains aligned with business evolution for decades.

Part 6: The Strategic Horizon: VNA as the Foundation for the Autonomous Warehouse

H2: The Evolutionary Path to Full Automation

Implementing a Very Narrow Aisle Pallet Racking system integrated with a modern WMS is the most logical and scalable first major step towards warehouse automation. The infrastructure put in place—the high-precision storage grid, the digitized inventory mapping, the robust data backbone—is the essential prerequisite for more advanced automation. Transitioning from manned turret trucks to an AGV fleet becomes a phased, manageable upgrade rather than a disruptive overhaul. This makes the Very Narrow Aisle Pallet Racking system a future-proof investment.

H3: Integration within a Broader Automated Ecosystem

The Very Narrow Aisle Pallet Racking zone is designed to be a synergistic component within a larger automated material handling flow. It seamlessly interfaces with:

Automated Storage/Retrieval Systems (AS/RS) for small-parts storage.

Conveyor and Sortation Systems that transport goods from the dense Very Narrow Aisle Pallet Racking bulk storage to packing stations and dispatch.

Automated Monorail or Shuttle Systems for high-speed horizontal movement across the facility.

This holistic approach, with Very Narrow Aisle Pallet Racking serving as the high-density engine for unit loads, creates a resilient, scalable, and data-driven logistics operation capable of meeting the demanding service-level agreements of modern commerce.

Conclusion: Securing Competitive Advantage through Volumetric Mastery

For logistics and supply chain leaders across Southeast Asia’s dynamic economies, spatial constraints represent a defining challenge of this era. The path forward is clear: continued reliance on low-density storage layouts is a direct concession of competitive ground. Building anew is a slow and capital-heavy response. The strategic, agile, and financially superior path is the intelligent retrofit of existing facilities through Very Narrow Aisle Pallet Racking technology.

This is an investment that transcends equipment procurement. It is a commitment to operational excellence, a leveraging of engineering ingenuity to convert untapped cubic air into a strategic asset. The promised 50%+ increase in storage capacity is a consistently achievable outcome when the Very Narrow Aisle Pallet Racking system is holistically designed, precision-engineered for local conditions, and seamlessly integrated into warehouse workflows.

In the relentless pursuit of efficiency and scalability that characterizes Southeast Asia’s growth story, those who master the volumetric potential of their warehouses—who look upward and inward with the power of Very Narrow Aisle Pallet Racking—will not just solve a space problem; they will build an enduring foundation for market leadership.

Frequently Asked Questions (FAQs)

1. How do we handle maintenance or repairs deep within a Very Narrow Aisle Pallet Racking system if an AGV or pallet becomes stuck?

Robust systems are designed with redundancy and recovery protocols. AGV fleets have built-in diagnostics and can often be remotely instructed to perform recovery maneuvers. For physical blockages, the design of the Very Narrow Aisle Pallet Racking system includes specific “rescue aisles” or slightly wider cross-aisles at intervals, allowing a service turret truck or manual equipment to access any blocked location. Safety procedures and tools for safely recovering loads from within the Very Narrow Aisle Pallet Racking are a standard part of operator training and system design.

2. Can a Very Narrow Aisle Pallet Racking system be installed in an existing warehouse with uneven or marginally compliant floors?

This is a common scenario in retrofits. A detailed floor flatness survey is the first step. While Very Narrow Aisle Pallet Racking demands high flatness (e.g., ±3mm/3m), solutions exist for suboptimal floors. These can include selective floor grinding, the use of precision shims under the Very Narrow Aisle Pallet Racking base plates during installation, or, in some cases, specifying a guidance system (like rail guidance) that can accommodate minor floor variations better than wire guidance. The feasibility and cost of floor remediation are key factors in the initial site assessment.

3. What is the lead time for a complete Very Narrow Aisle Pallet Racking solution, and how disruptive is installation to ongoing operations?

Total lead time typically ranges from 16 to 30 weeks from order to commissioning, depending on system complexity and equipment sourcing. A well-planned phased installation minimizes disruption. Often, the project is executed in zones: one section of the warehouse is cleared and converted to Very Narrow Aisle Pallet Racking, while operations continue in another. Inventory is gradually transferred into the new high-density system, allowing business continuity. Detailed phasing plans are a core component of professional project management for Very Narrow Aisle Pallet Racking deployments.

4. How does the performance of a Very Narrow Aisle Pallet Racking system with turret trucks compare to an AS/RS (Automated Storage and Retrieval System) for pallet handling?

Both are high-density solutions, but with different profiles. A Very Narrow Aisle Pallet Racking system with trucks offers greater flexibility for handling non-standard pallets and mixed SKU environments, often at a lower initial cost per pallet position. It requires operators. An ASRS (like a unit-load crane system) offers the highest possible throughput speed and density in a fully automated, enclosed structure, but with less flexibility and higher CAPEX. The choice depends on throughput requirements, SKU profile, labor strategy, and budget. A Very Narrow Aisle Pallet Racking system often represents the optimal balance of density, flexibility, and cost for the majority of pallet storage applications.

5. Are there specific fire safety regulations that affect the design of high-bay Very Narrow Aisle Pallet Racking warehouses?

Absolutely. High-bay storage facilities are subject to stringent fire protection codes. The design of the Very Narrow Aisle Pallet Racking layout must collaborate with fire safety engineers. Key considerations include the need for in-rack sprinkler heads at various levels within the Very Narrow Aisle Pallet Racking structure to overcome ceiling-level sprinkler obstructions, adequate flue spaces between back-to-back racking to allow heat and water penetration, and compliance with local regulations on storage height versus sprinkler design. These requirements are integral to the early design phase of any Very Narrow Aisle Pallet Racking project.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com