📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The True Engine of Your Automated System

When engineering the blueprint for an automated warehouse, the spotlight invariably falls on the sophisticated technology: the silent, orchestrated dance of AGVs (Automated Guided Vehicles), the artificial intelligence driving AMRs (Autonomous Mobile Robots), and the towering, robotic efficiency of automated storage and retrieval systems (AS/RS).

However, an often-underestimated component forms the very physical and operational foundation upon which this entire automated ecosystem operates: the engineered steel pallet. For logistics directors and automation engineers, selecting the right steel pallet is a strategic decision that transcends basic procurement; it is a critical exercise in systems integration and risk mitigation. The most forward-thinking steel pallet manufacturers understand that their role is not merely to supply a product but to deliver a guaranteed-performance component.

This in-depth guide moves beyond the quote to explore why standard, off-the-shelf pallets represent a single point of failure in automated environments and how partnering with expert steel pallet manufacturers to invest in precision-engineered steel pallets is paramount for maximizing system uptime, ensuring operational safety, and achieving the full return on investment promised by automation technology.

We will delve into the specific design criteria, the rigorous testing protocols, and the seamless integration required for true AGV/AMR compatibility, positioning the humble pallet not as a commodity cost, but as a core enabling technology that determines the success or failure of a multi-million dollar automation project.

Why Your Automated Warehouse Can’t Afford “Standard” Pallets

The transition from a traditional, manual warehouse to a fully automated one represents a quantum shift in operational philosophy, demanding a corresponding evolution in every component, especially the pallet. In a manual facility, a slightly warped wood pallet or a unit with a loose board is a manageable nuisance, often corrected in real-time by the innate adaptability and problem-solving skills of a human forklift operator. In an automated world, this flexibility vanishes, replaced by strict programming and digital commands.

AGVs, AMRs, and automated forklifts interact with pallets based on precise, pre-defined parameters. They operate on a binary principle of success or failure, expecting perfect, unvarying consistency. A dimensional variance of even a few millimeters can trigger a cascade of systemic failures that cripple throughput. Reputable steel pallet manufacturers stress these critical risks:

Failed Picks and Retrievals: This is the most frequent and disruptive issue. An AGV’s forks, programmed to a specific height and angle, might miss the pallet’s entry openings due to warping, incorrect spacing, or deck deflection, halting the workflow entirely and necessitating costly human intervention.

Catastrophic System Jams: Within automated conveyor systems and high-speed sortation systems, an out-of-spec pallet can catch on a guide rail, jam against a sensor, or misalign on a transfer point, shutting down an entire line within seconds. The cost of this unplanned downtime can escalate into thousands of dollars per minute in lost productivity and recovery efforts.

Increased Product Damage: Instability caused by a poor-quality or fatigued pallet leads to gradual or sudden load shifts. In a high-speed, largely unattended environment, this can result in massive product damage before any personnel are even aware of an issue, directly impacting the bottom line.

Direct Equipment Damage: This represents the most severe financial risk. A collapsed wood pallet can be dragged into a conveyor mechanism, shearing pins, damaging motors, and destroying guide rails. An AMR attempting to lift an unstable or failed load can drop it catastrophically, damaging both the valuable product and the expensive robot itself. The “savings” realized from choosing a cheaper, standard pallet are instantly and utterly erased by a single hour of such unplanned downtime. This fundamental reality is why leading steel pallet manufacturers position their engineered steel pallets not as an optional upgrade but as a non-negotiable necessity for protecting the integrity of a multi-million dollar automation investment.

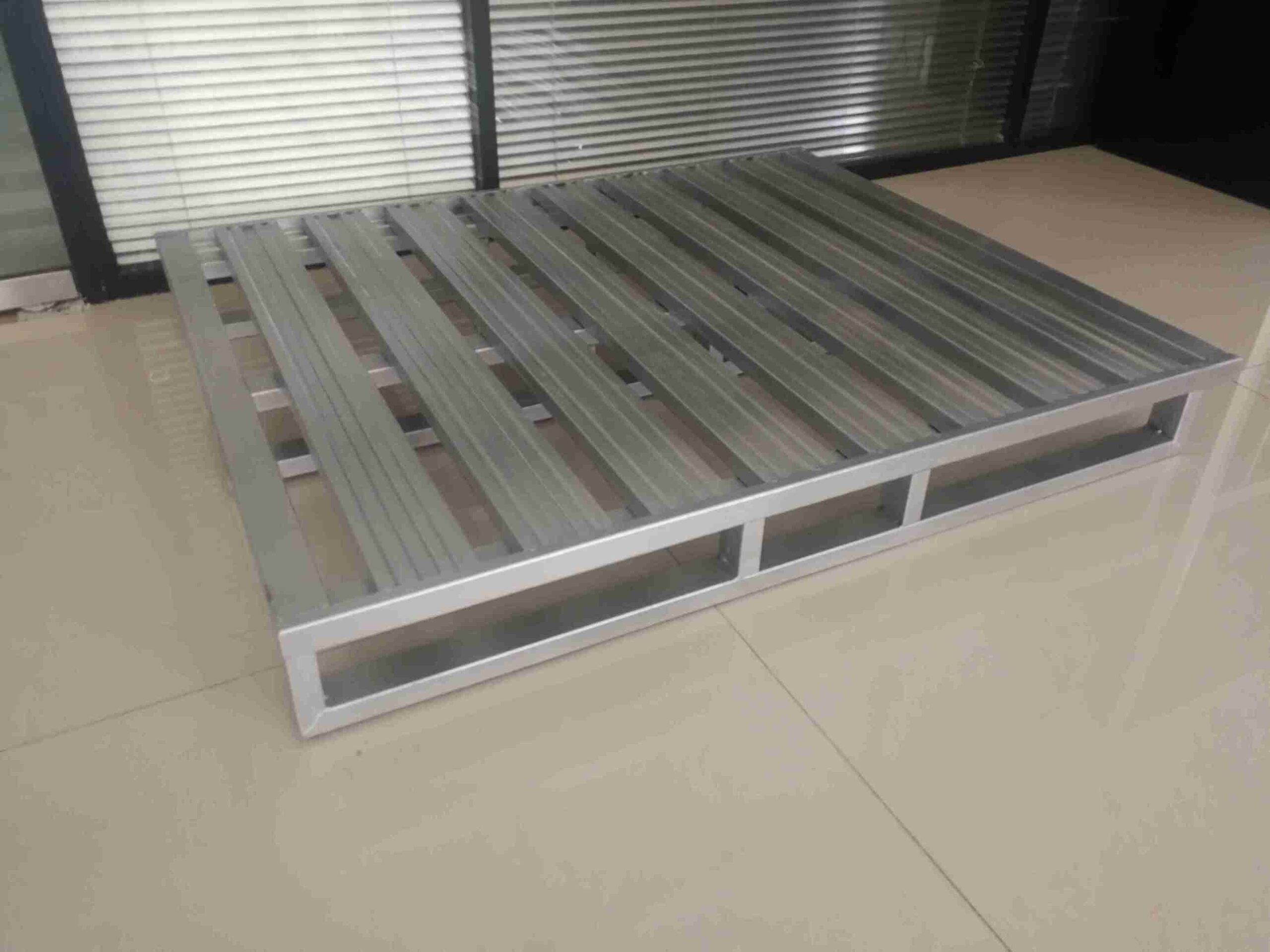

The Anatomy of an Engineered Steel Pallet: More Than Just Metal

An engineered steel pallet from a quality-focused manufacturer is a far cry from simply welding a few pieces of standard steel together. It is a product of meticulous design philosophy, advanced manufacturing processes, and rigorous validation protocols. Every single aspect, from the raw material to the final coat of paint, is optimized for peak performance, durability, and seamless integration. The best steel pallet manufacturers operate more like aerospace engineering firms than traditional warehouse suppliers.

Core Design Features for Automation

Uncompromising Dimensional Precision and Consistency: This is the absolute non-negotiable foundation. Unlike wood, which swells and warps with humidity, or plastic, which can creep and deform over time under heavy loads, engineered steel pallets are manufactured to exacting tolerances (often within ±0.5mm). This guarantees that every single interaction with robots, conveyors, and racking is predictable and flawless, batch after batch, year after year.

Optimized Fork Openings (Fork Pockets): The design of the entry chamfers, the internal height, and the clearance within the fork pockets are critical engineering feats. They are specifically engineered to guide the forks of AGVs and automated forklifts in smoothly, even when the robotic approach is not perfectly aligned, effectively compensating for minor systemic positioning variances and ensuring a successful lift cycle every time.

Superior Strength-to-Weight Ratio: Steel pallets offer immense structural strength while maintaining a manageable and consistent weight. This is crucial for the energy efficiency of AMRs and AGVs, which operate on battery power and have strict weight limits for their payloads. A lighter yet stronger pallet allows these robots to transport more product per trip and per charge, directly increasing overall system efficiency and reducing the number of required fleet units.

Closed-Deck Design: For the vast majority of automated systems, a smooth, rigid, closed-deck surface is mandatory. It provides a stable, uniform base for products and is an essential requirement for reliable operation on roller conveyors, sortation systems, and shuttle systems. It also prevents debris, packaging materials, and liquids from falling into the sensitive mechanical parts of the automation equipment, reducing maintenance needs.

Integrated Features for Robotics: This is where the true engineering expertise of advanced steel pallet manufacturers shines. Pallets can be custom-designed with a host of integrated features:

Protected RFID Tag Mounting Points: Precise, recessed, and shielded locations to securely mount RFID tags for seamless inventory tracking throughout the facility without any risk of damage during contact with other pallets or equipment.

Visual Target Mounting Surfaces: Specific, flat, and neutral-colored surfaces designed for the application of fiducial markers or high-contrast barcodes that vision-guided robots use to instantly identify, locate, and orient the pallet.

Standardized Lifting Lugs: For systems that use overhead cranes or grippers instead of traditional fork-based lifts, integrated lugs provide a secure and predictable grab point.

Material and Fabrication Excellence

Top-tier steel pallet manufacturers begin with the raw material. They typically use high-tensile, low-carbon steel for an optimal balance of strength, durability, and formability. The fabrication process is a testament to modern manufacturing, involving precision laser cutting or punching for perfect componentry, robotic welding for unwavering consistency and strength, and a multi-stage finishing process. This process typically includes phosphating for superior corrosion resistance and a durable, chemical-resistant powder-coated finish that is easy to clean—a key requirement for regulated industries like food and beverage, pharmaceuticals, and chemicals.

AGV and AMR Compatibility: The Nuts and Bolts of Integration

The term “compatible” is often used loosely in marketing materials. For serious steel pallet manufacturers, it means the pallet has been specifically designed, prototyped, and tested to interface perfectly with the exact mechanisms and software of modern automated guided vehicles and mobile robots. This requires deep technical collaboration.

Precision Interface with Fork-Based AGVs

These robots mimic traditional forklifts but with far less margin for error and no capacity for improvisation. The leading steel pallet manufacturers design their products with the following in mind:

Precise Fork Pocket Height and Clearance: Matched meticulously to the fork height and thickness of common AGV models to ensure a clean lift without dragging or jamming.

Adequate Ground Clearance: Ensures the AGV’s forks can slide underneath effortlessly without the pallet’s base structure contacting the floor, even on slightly uneven surfaces.

Reinforced Lead Boards and Chamfers: The first point of contact is heavily reinforced and features pronounced chamfers to guide the forks in, effectively absorbing the repeated, sometimes imperfect, impacts from an automated approach and preventing deformation over thousands of cycles.

Seamless Interface with Conveyor-Based AMRs

Many modern AMRs, like those from Locus Robotics or 6 River Systems, do not use forks. Instead, they employ a powered conveyor deck to pull the loaded pallet onto themselves. For these systems, the pallet’s base must be perfectly smooth, flat, and may require a specific friction coefficient or even integrated low-friction pads to facilitate easy, consistent movement onto the robot’s deck without requiring excessive power or causing jerky motion.

Unshakeable Interface with AS/RS and Unit Load Cranes

In a unit-load AS/RS, a high-speed stacker crane retrieves a whole pallet from deep within a dense racking system. The pallet must possess incredible structural integrity and minimal deflection to handle the significant dynamic forces of high-speed acceleration, transverse movement, and deceleration while fully loaded, often dozens of feet in the air. Any flexing or weakness can cause the load to shift dangerously, risking a catastrophic drop. The most respected steel pallet manufacturers subject their products to rigorous testing that simulates these exact dynamic load scenarios, ensuring absolute stability and safety.

The Critical Role in Automated Storage and Retrieval Systems (AS/RS)

An AS/RS represents the pinnacle of storage density, speed, and inventory control. The pallets used within it are the fundamental unit of storage; their performance directly dictates the performance, safety, and longevity of the entire system. This is where the value proposition of specialized steel pallet manufacturers becomes most apparent.

Perfect Racking Compatibility: The pallet must be designed from the ground up to work seamlessly with the specific type of racking—whether it’s standard roll-formed, structural boltless, or drive-in racking. The pallet’s support points must align perfectly with the rack beams to prevent bending, ensure even weight distribution, and avoid point loading that could damage both the rack and the pallet itself.

Rigorous Dynamic Load Testing: An AS/RS pallet isn’t just holding a static load. It’s subjected to significant G-forces as the crane accelerates, moves at high speed, and comes to a rapid stop. Ordinary pallets can fail under these conditions. Steel pallet manufacturers focused on automation engineer and test their pallets to handle these dynamic forces, ensuring load stability and system safety at all times.

Maximized System Throughput: The unwavering consistency and supreme durability of engineered steel pallets mean precisely zero time is lost due to pallet-related failures, jams, or inspections. This reliability ensures the AS/RS achieves its designed throughput and availability metrics, which is essential for maximizing the return on the substantial automation investment.

Testing and Validation: Proving Performance Beyond Doubt

Distinguished steel pallet manufacturers differentiate themselves not just through design but through a culture of validation. They don’t just manufacture pallets; they prove their performance under the most extreme conditions. Their quality assurance process is designed to simulate a decade of brutal warehouse abuse in a matter of days, providing customers with empirical data and peace of mind.

Dimensional Integrity Checks: Every production batch is sampled using coordinate measuring machines (CMM) to verify that all critical dimensions remain within the tiny tolerances promised.

Comprehensive Load Testing: They perform both static and dynamic load tests that far exceed standard international requirements (e.g., ISO 8611). This includes testing for uniform distributed load, concentrated point load (simulating a poorly placed heavy item), and fork impact resistance.

Accelerated Life Cycle Testing: They simulate the entire automation cycle—fork insertion, lifting, transportation, placement on racking, and retrieval—tens of thousands of times on test rigs to identify and eliminate any potential for metal fatigue, weld failure, or cosmetic degradation.

Real-World Compatibility Testing: The most reputable steel pallet manufacturers often work directly with leading AGV and AMR manufacturers (like Dematic, Daifuku, Toyota, etc.) to test their pallets on the actual equipment, ensuring flawless interaction and often resulting in formal compatibility certifications.

Total Cost of Ownership (TCO): The Real Metric for Investment

It is an undeniable fact that the initial purchase price of a high-quality engineered steel pallet from dedicated steel pallet manufacturers is higher than that of a wood, plastic, or low-grade steel alternative. However, the true and compelling business case is made when logistics and financial analysts look beyond the price tag and analyze the Total Cost of Ownership (TCO) over a 5, 10, or 15-year horizon. This analysis consistently reveals the superior economics of quality.

Exceptional Longevity: A high-quality steel pallet from a reputable manufacturer lasts 10-15+ years, even in the most demanding and punishing environments. Over the same period, a company will purchase and dispose of wood pallets dozens of times, incurring not just unit costs but also handling, repair, and disposal costs.

Near-Total Elimination of Downtime: This is the most significant financial factor. The cost of unplanned downtime in an automated facility is astronomical, affecting shipping schedules, labor productivity, and customer satisfaction. Engineered steel pallets are designed to prevent the jams, crashes, and interruptions caused by inferior pallets, safeguarding continuous operation.

Dramatically Reduced Product Loss: Superior stability and strength mean no load shifts and no damaged goods. This protects revenue and eliminates the hidden costs associated with processing damaged inventory and dealing with customer complaints.

Negligible Maintenance: Wood pallets require a constant, labor-intensive cycle of repair, sorting, and disposal. Steel pallets are virtually maintenance-free. They may require occasional cleaning in specific environments, but they will not splinter, break, or require nail repairs.

Enhanced Hygiene and Safety: They are impervious to pests, moisture, and bacteria, making them ideal for food, pharmaceutical, and chemical industries. They do not splinter or have protruding nails, creating a safer environment for any personnel working near the automation cells.

When all of these operational and financial factors are considered objectively, engineered steel pallets from professional steel pallet manufacturers consistently demonstrate a significantly lower TCO and a higher return on investment, making them the most intelligent and economical choice for automated warehouses.

Selecting the Right Manufacturing Partner: It’s an Engineering Collaboration

Choosing a supplier for engineered steel pallets is fundamentally different from buying a commodity like office supplies. You are not just purchasing a product; you are engaging an engineering partner whose component is critical to your operation’s success. The right steel pallet manufacturers will act as an extension of your team. They will:

Conduct a Deep Needs Analysis: They will ask detailed, technical questions about your automation equipment (make and model of AGVs/AMRs), racking specifications (make, model, beam heights), load characteristics (weight, dimensions, center of gravity), and environmental conditions (temperature, humidity, chemicals).

Provide True Customization: Offer genuine engineering support to customize pallets for your unique application, whether it’s adding special features like RFID mounts, adjusting leg heights for specific clearances, or designing for an unusual load shape.

Supply Robust Validation Data: Provide certified test reports from independent labs or their own extensive facilities, proving the pallets meet the promised specifications for load capacity, durability, and dimensional stability.

Offer a Traceable, Consistent Product: Have rigorous, documented quality control processes (often ISO 9001 certified) ensuring that every single pallet that leaves their facility is identical to the prototype you approved, guaranteeing performance and eliminating variability.

Conclusion: The Foundation of Flawless Automation

In the sophisticated symphony of an automated warehouse, every component, from the warehouse management software to the smallest sensor, must perform in perfect harmony to achieve peak efficiency. The engineered steel pallet is the silent, unwavering percussion section—keeping the time, providing the stable rhythm, and forming the reliable base upon which the entire melody of automation is built. Ignoring its profound importance in favor of a lower upfront cost is arguably the single most consequential error a company can make when implementing AGVs, AMRs, or AS/RS.

It is a false economy of the highest order. By investing in precision-engineered steel pallets from steel pallet manufacturers that truly understand systems integration and the brutal demands of automation, you are doing much more than buying a pallet. You are investing in the fundamental reliability, efficiency, and safety of your entire automated operation. You are ensuring that your substantial technology investment delivers on its promise of transformative productivity, moving your business decisively beyond the quote and into a new era of operational excellence, resilience, and competitive advantage. The right steel pallet manufacturers are not vendors; they are partners in engineering success.

Frequently Asked Questions (FAQs)

1. How do steel pallets from specialized manufacturers impact the battery life of our AMR fleet?

Due to their excellent strength-to-weight ratio, well-designed engineered steel pallets are often lighter than their load-capacity equivalents in other materials. A lighter payload means the AMR uses significantly less energy to accelerate, decelerate, and move. This directly extends battery life per charge, increasing the number of cycles an AMR can complete in a single shift and potentially reducing the size of the required fleet or the number of battery swap stations. This energy efficiency is a key consideration for steel pallet manufacturers serving the automation market.

2. Can engineered steel pallets be safely and effectively used in cold storage or freezer environments?

Absolutely. In fact, they are exceptionally well-suited for these harsh environments and are a preferred choice for cold chain logistics. Unlike wood, which can become brittle, absorb moisture, and harbor bacteria, or plastic, which can become brittle and crack at very low temperatures, steel pallets maintain their structural integrity and dimensional stability. The specific powder coat finish applied by quality steel pallet manufacturers can be formulated to resist moisture, condensation, and chemical corrosion commonly found in cold storage facilities, preventing rust and ensuring a long service life.

3. We have a mixed fleet of traditional forklifts and new AGVs. Will pallets from your manufacturers work with both?

Yes, universal compatibility is a fundamental design principle for any serious steel pallet manufacturers serving this transitionary market. A properly engineered steel pallet is built to ISO or other relevant standards to be universally compatible. It will have standardized fork pockets that work perfectly for both human-operated forklifts and AGVs. This allows for a smooth and flexible transition period as you phase in automation without needing to manage two separate pallet pools, thereby simplifying operations and reducing costs.

4. What is the typical lead time for custom-engineered steel pallets compared to standard options?

The lead time for a first order of custom pallets is naturally longer, typically ranging from 4-8 weeks for most steel pallet manufacturers. This timeframe is necessary for the design finalization, prototyping, sample testing, and validation cycle to ensure the pallets meet your exact technical specifications and performance requirements. Subsequent repeat orders for the same custom pallet design have a much shorter lead time, often similar to standard products, as the tooling, programming, and processes are already in place and validated.

5. How do leading steel pallet manufacturers handle end-of-life for their products? Are they recyclable?

This is a significant sustainability and environmental advantage that reputable steel pallet manufacturers proudly highlight. At the end of their exceptionally long service life (which can often be 15+ years), steel pallets are 100% recyclable. They are simply collected and melted down in a furnace, and the high-quality material is used to create new steel products, creating a genuine circular economy with no downcycling. There is virtually no waste sent to landfills, unlike with broken wood, composite, or plastic pallets. Furthermore, many manufacturers already produce their pallets from a high percentage of recycled steel at the outset, minimizing the environmental footprint from the very beginning.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com