📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The relentless, humming cold of a warehouse is more than just a temperature setting; it’s a formidable business challenge. For decision-makers in logistics, supply chain, and operations, the cold chain represents a constant balancing act between preserving product integrity and managing astronomical costs. The traditional model of wide aisles and forklifts scurrying through freezing fog is increasingly revealed as a relic—an expensive, inefficient, and risky way to operate. The central question facing the industry is no longer about incremental improvements but about fundamental transformation. This is where the strategic implementation of shuttle racking for cold chain logistics transitions from a competitive advantage to an operational necessity.

The concept of shuttle racking for cold chain logistics is often misunderstood as simply replacing a forklift with a robot. In reality, it represents a holistic re-engineering of the storage paradigm. It is a high-density, automated storage and retrieval system (ASRS) specifically engineered to thrive where conventional systems falter: in the sub-zero environments critical for food, pharmaceuticals, and other temperature-sensitive goods.

This article serves as an exhaustive exploration of how shuttle racking for cold chain logistics serves as the cornerstone for building a truly resilient, efficient, and future-proof cold chain warehouse. We will dissect the engineering marvels that allow these systems to operate flawlessly at -25°C, the intelligent software that transforms inventory management from a reactive task into a predictive science, and the compelling financial calculus that positions this technology not as a capital expense, but as a strategic investment with a rapid and substantial return. For any organization serious about dominating the cold chain landscape, understanding the nuances of shuttle racking for cold chain logistics is the first step toward unlocking unprecedented levels of performance and profitability.

H2: The Shuttle Racking For Cold Chain Logistics Imperative: Why Legacy Systems Are No Longer Sustainable

The pressures on cold chain operations are converging into a perfect storm. Skyrocketing energy costs, a volatile labor market, and escalating customer demands for speed and traceability are pushing traditional warehousing methods to their breaking point. The limitations of selective pallet racking and manual operations are no longer mere inconveniences; they are significant threats to profitability and viability.

H3: The Space and Energy Drain: Cooling Empty Air is Burning Cash

In a conventional freezer or cooler, the layout is a study in inefficiency. To accommodate the turning radius of forklifts, aisles can be 10 to 12 feet wide. This design means that between 50% and 60% of the immensely expensive refrigerated cube is dedicated not to product, but to empty space. The refrigeration system works tirelessly, and expensively, to cool this void. Every kilowatt-hour spent maintaining -20°C in an aisle is a direct and wasteful drain on the bottom line.

The business case for shuttle racking for cold chain logistics begins with this simple truth: it eliminates the vast majority of these aisles, creating a dense, continuous storage block. By drastically reducing the volume of air that requires refrigeration, facilities implementing shuttle racking for cold chain logistics routinely report energy savings of 30% to 50%, a transformative reduction in a primary operational cost.

H3: The Human Equation: Labor Challenges in a Hostile Environment

Recruiting and retaining personnel to work in deep-freeze environments is a persistent and growing challenge. Productivity naturally declines in the cold, safety risks associated with heavy equipment in congested spaces are amplified, and employee turnover is high. This creates a scenario of constant retraining and operational inconsistency. The beauty of a well-executed shuttle racking for cold chain logistics system is its ability to redefine the human role.

It removes staff from the harsh environment of the storage aisles, redeploying them to more ergonomic, climate-controlled workstations for order consolidation and quality control. This not only enhances employee well-being and retention but also unlocks new levels of operational consistency that are simply unattainable with a manual workforce.

H3: Accuracy and Traceability: The Silent Profit Killers

Manual processes are inherently prone to error. In a vast, cold warehouse, a mis-picked pallet or an incorrect lot number can have catastrophic consequences, leading to spoiled goods, recalled shipments, and devastated customer relationships. Furthermore, achieving perfect FIFO (First-In, First-Out) or FEFO (First-Expired, First-Out) control is a monumental challenge with paper-based or rudimentary digital systems. This is a core strength of shuttle racking for cold chain logistics.

The integrated Warehouse Management System (WMS) exercises absolute control over every pallet movement. It knows the exact location, batch number, and expiration date of every single item, ensuring flawless inventory rotation and providing an immutable digital trail that is indispensable for compliance in sectors like pharmaceuticals and high-value foods.

H2: Deconstructing the System: What Exactly is Shuttle Racking for Cold Chain Logistics?

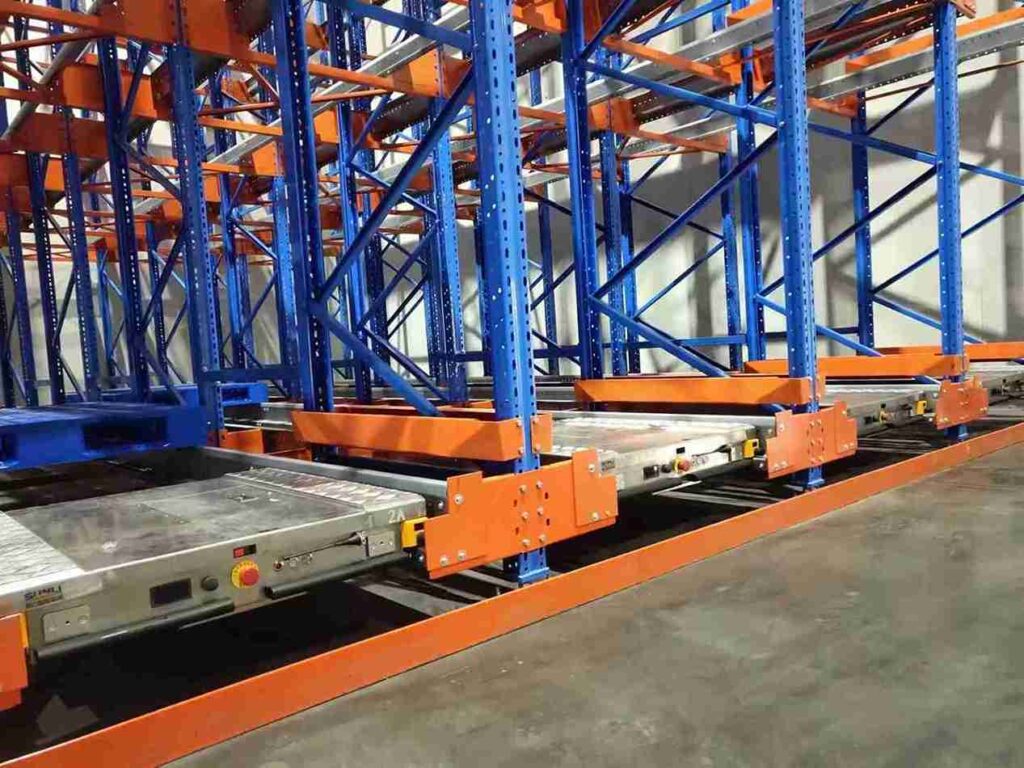

To appreciate the transformative power of this technology, one must look beyond the captivating sight of a shuttle darting through a rack. A comprehensive shuttle racking for cold chain logistics solution is a symphony of precision hardware and sophisticated software, each component engineered for reliability and performance.

H3: The Shuttle Vehicle: The Arctic Workhorse

The shuttle itself is a marvel of engineering tailored for harsh environments. Unlike standard models, units designed for shuttle racking for cold chain logistics feature cold-tolerant lithium-ion batteries housed in thermally protected compartments to prevent rapid charge depletion. Their motors, gears, and rollers are lubricated with special oils that remain fluid at extreme temperatures, and their structural components are made from materials resistant to brittleness. These shuttles are not just automated; they are fortified for the cold, ensuring reliable operation day in and day out.

H3: The Racking Structure: The Backbone of Density

The racking is far more than a passive support structure. It is the shuttle’s dedicated highway, engineered for immense loads and precision. The design of the racking for shuttle racking for cold chain logistics is critical for achieving maximum density and stability. It forms a solid, continuous block of storage, often several pallets deep and multiple levels high, transforming the warehouse footprint from a sprawling space into a compact, high-capacity storage engine.

H3: The Lift Module: The Vertical Conveyor

The lift module, or pallet elevator, is the critical link that elevates the system from semi-automation to full automation. It stands at the front of the racking system, seamlessly receiving pallets from the inbound conveyor or AGV and then vertically traversing to the correct level. There, it hands off the pallet to the awaiting shuttle, which then stores it in the pre-determined location. This automated handoff is what creates the high-throughput capability of a true shuttle racking for cold chain logistics ASRS.

H3: The Warehouse Management System (WMS): The Intelligent Brain

If the hardware is the body, the WMS is the central nervous system. This is where the true intelligence of shuttle racking for cold chain logistics resides. Advanced algorithms within the WMS do not merely react to commands; they optimize continuously. The system intelligently assigns storage locations based on a multitude of factors: product turnover (ABC classification), expiration dates, product compatibility, and future order forecasts. This dynamic slotting ensures that the fastest-moving goods are positioned for the quickest retrieval, dramatically reducing cycle times. The WMS is the key to unlocking the full potential of shuttle racking for cold chain logistics, transforming it from a storage solution into a dynamic fulfillment engine.

H2: Engineered for the Extreme: The Cold-Chain Specific Design Philosophy

Deploying automation in a freezer requires more than just specifying “cold-chain capable” equipment. It demands a holistic design philosophy that anticipates the unique challenges of the environment. Success in shuttle racking for cold chain logistics is found in these critical details.

H3: Battling the Elements: Condensation, Frost, and Thermal Shock

One of the greatest operational challenges is managing the intrusion of warm, moist air. Every time a warehouse door opens, humidity rushes in, condensing and freezing on every cold surface. For shuttle racking for cold chain logistics, this can lead to frost buildup on guide rails and sensors, potentially disrupting operations. Mitigation strategies are integral to the design. These can include the use of airlock chambers for pallet intake, specialized coatings on equipment to reduce frost adhesion, and strategic placement of air curtains to minimize air exchange. The goal is to create a stable micro-environment for the equipment within the larger cold space.

H3: Reliability and Redundancy: Designing for Uptime

In a cold chain, system downtime is not an option. A failure can jeopardize millions of dollars in inventory. Therefore, reliability is the paramount design criterion for any shuttle racking for cold chain logistics project. This involves using components with proven performance histories in low-temperature applications. Furthermore, systems can be designed with built-in redundancies, such as the ability for a single shuttle to service multiple lanes or the availability of quick-swap backup shuttle units, ensuring that a single point of failure does not halt the entire operation.

H2: The Compelling Value Proposition: Quantifying the Benefits of Shuttle Racking for Cold Chain Logistics

The decision to invest in automation must be justified by a clear and demonstrable return. The benefits of implementing shuttle racking for cold chain logistics are profound and touch every aspect of the operation.

H3: Unprecedented Storage Density and Footprint Reduction

The most immediately apparent benefit is the dramatic increase in storage capacity. By consolidating storage into a dense block, facilities can typically increase pallet positions by 80% to 100% within the same building envelope. For businesses facing physical expansion constraints or exorbitant real estate costs, this density offered by shuttle racking for cold chain logistics is a game-changer, effectively postponing or eliminating the need for new construction.

H3: Transformative Energy Efficiency

As previously mentioned, the energy savings are substantial. The reduced air volume to be cooled is a fundamental thermodynamic advantage. However, the benefits compound further. The automated nature of shuttle racking for cold chain logistics means warehouse doors can remain closed for longer periods, and the heat generated by internal combustion forklifts is eliminated. This leads to a more stable thermal environment and significantly lower energy consumption, making the operation both greener and more cost-effective.

H3: Throughput, Accuracy, and Scalability

Automation brings a level of speed and precision that manual labor cannot match. Systems for shuttle racking for cold chain logistics can operate 24/7, unaffected by shifts, breaks, or ambient conditions. Throughput rates become predictable and scalable. During peak seasons, the system simply operates for more hours, eliminating the frantic search for temporary qualified labor. The integration of the WMS ensures virtually perfect inventory accuracy, often exceeding 99.99%, which in turn eliminates the costs associated with shipping errors, lost inventory, and order discrepancies.

H2: The Financial Calculus: Building the Business Case for Shuttle Racking for Cold Chain Logistics

Justifying the capital outlay for an automated system requires a rigorous financial analysis that looks beyond the initial price tag. The true value of shuttle racking for cold chain logistics is captured in its Total Cost of Ownership (TCO).

H3: Analyzing Total Cost of Ownership (TCO)

A comprehensive TCO analysis contrasts the capital expenditure (CapEx) against the dramatic reductions in operational expenditure (OpEx). Key factors to model include:

Labor Cost Reductions: Savings from a smaller forklift fleet, lower labor hours, and reduced costs associated with recruitment, training, and turnover.

Energy Cost Savings: Projected reductions in refrigeration costs based on the increased density.

Product Loss Reduction: Financial value of eliminating spoilage due to improved FIFO/FEFO control.

Insurance Premiums: Potential reductions due to enhanced safety and security.

Increased Revenue Capacity: The ability to handle more volume within the same facility.

When these factors are quantified, the payback period for a shuttle racking for cold chain logistics system is frequently calculated to be between two and five years. After the payback period, the annual OpEx savings contribute directly to the bottom line, year after year.

H2: Is Shuttle Racking for Cold Chain Logistics the Right Fit for Your Operation?

While powerful, this technology is not a universal panacea. It delivers maximum value under specific operational profiles. A thorough feasibility study is essential. Operations that are ideal candidates for shuttle racking for cold chain logistics typically exhibit one or more of the following characteristics: high product volume with moderate SKU count, strict inventory rotation requirements (FIFO/FEFO), high-value goods where security and traceability are critical, and severe constraints on space, energy, or labor availability.

H2: The Implementation Journey: A Phased and Partnership-Based Approach

A successful deployment of shuttle racking for cold chain logistics is not a simple transaction; it is a collaborative partnership. Leading providers follow a meticulous process to ensure success, from initial concept to long-term operation. This journey typically involves an in-depth consultation and data analysis phase, where every aspect of the current operation is mapped and understood.

This is followed by a detailed design and 3D simulation phase, creating a digital twin of the proposed system to validate performance before installation. The physical installation is then carefully planned and executed in phases to minimize disruption to ongoing operations. Finally, comprehensive training and ongoing support ensure that the client’s team is fully empowered to operate and maintain the system for its entire lifecycle.

H2: The Integrated Future: Shuttle Racking as the Heart of a Touchless Cold Chain

The ultimate expression of modern logistics is the fully automated, “touchless” warehouse. In this context, a shuttle racking for cold chain logistics system acts as the high-density heart of a larger automated ecosystem. It can be seamlessly integrated with other technologies such as Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) for horizontal transport, conveyor systems for case picking and sortation, and robotic palletizers. This creates a continuous flow of goods from receiving to shipping, with minimal human intervention, maximizing efficiency, accuracy, and product safety.

H2: Conclusion: Securing a Competitive Advantage in the Cold Chain

The cold chain industry is at an inflection point. The companies that will lead in the coming decade are those making strategic investments today to build more resilient, efficient, and intelligent operations. The question of whether to adopt shuttle racking for cold chain logistics is, fundamentally, a question about future readiness. Legacy systems represent a growing liability, while an automated high-density system represents an asset that drives value daily.

By embracing the power of shuttle racking for cold chain logistics, businesses are not just upgrading their equipment; they are future-proofing their operations, protecting their profitability, and positioning themselves to meet the demands of the market for years to come. The journey toward a future-proof cold chain begins with a strategic evaluation of how shuttle racking for cold chain logistics can transform your specific operation.

H2: Frequently Asked Questions (FAQs)

Q1: How does the system handle a power outage? Is there a risk of pallets being stuck inside?

This is a critical design consideration for any shuttle racking for cold chain logistics installation. The systems are equipped with multiple layers of redundancy. Each shuttle has a reserve battery capacity sufficient to complete its current cycle and return to the pickup and deposit (P&D) point at the front of the aisle. Furthermore, the overall control system and lift modules are typically connected to the facility’s backup generator system. This ensures that in the event of a power failure, the system can execute a controlled shutdown or continue limited operations, safeguarding both the inventory and the equipment.

Q2: What are the ongoing maintenance requirements, and how is downtime managed?

Preventive maintenance is streamlined and predictive. Modern shuttle racking for cold chain logistics systems are equipped with remote monitoring and diagnostic tools that track component health and usage, allowing maintenance to be scheduled proactively before a failure occurs. For critical components, having a spare shuttle on-site is a common practice to enable quick swaps and minimize downtime. Maintenance contracts with providers ensure access to specialized parts and technical expertise, guaranteeing high system availability.

Q3: Can the system accommodate different pallet types and sizes (e.g., Euro, CHEP, plastic) within the same installation?

Yes, flexibility is a key feature. A shuttle racking for cold chain logistics system can be configured to handle a mix of pallet sizes and types. This is achieved through adjustable guide rails within the racking lanes and configurable settings on the shuttles and lifts. The Warehouse Management System (WMS) is programmed with the dimensions of each pallet type, ensuring it is only assigned to a storage location that can accommodate it safely and efficiently.

Q4: We have limited capital. Can we start with a basic version and automate later?

Absolutely. A phased approach is a very common and sensible strategy. Many providers offer a semi-automated entry point for shuttle racking for cold chain logistics. This involves the high-density racking and the shuttles, but the shuttles are moved between lanes manually using a forklift. This provides the immediate benefit of high density without the full cost of the lift module and top-tier software. This semi-automated system can be seamlessly upgraded to a fully automated shuttle racking for cold chain logistics ASRS in the future, protecting the initial investment and allowing for scalable growth.

Q5: What kind of data and operational insights can we expect from the system’s software?

The software suite for a shuttle racking for cold chain logistics system is a powerful business intelligence platform. It moves far beyond simple inventory tracking. You gain access to real-time dashboards showing system throughput, shuttle utilization rates, inventory dwell times, and perfect order performance. You can generate detailed reports on energy consumption per pallet stored, forecast capacity constraints, and analyze picking efficiency. This data-driven insight is invaluable for continuous operational improvement and strategic planning.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com