📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Is Your Warehouse Built to Shake? The Definitive Guide to Seismic Safety for Pallet Racking

For logistics executives, warehouse managers, and facility engineers operating in active seismic zones across the globe, the specter of an earthquake is a persistent operational threat. The conversation around seismic safety for pallet racking has evolved from a niche compliance topic to a cornerstone of prudent risk management and business continuity planning. This comprehensive resource delves beyond basic guidelines, offering a deep, engineering-focused exploration of why achieving true seismic safety for pallet racking is non-negotiable for modern supply chain resilience.

The core premise is undeniable: standard storage racking, engineered for vertical load-bearing, possesses inherent vulnerabilities when subjected to the complex, multi-directional forces unleashed during seismic events. Neglecting this reality doesn’t merely risk equipment damage; it gambles with inventory worth millions, operational viability, and most critically, personnel safety. This guide articulates the path from vulnerability to verified security, framing a professional seismic safety for pallet racking assessment not as a cost, but as the most strategic investment in a facility’s future.

The Seismic Imperative: Why “Heavy-Duty” Does Not Mean “Earthquake-Proof”

A prevalent and dangerous misconception equates a racking system’s static load capacity with its dynamic seismic performance. A rack rated for 5,000 kg per level can catastrophically fail under a fraction of that weight when subjected to lateral accelerations. The physics of seismic loading fundamentally differ from standard operational loads. During an earthquake, the ground movement accelerates the building’s base, which in turn imparts inertial forces onto the racking structure and its stored loads. This creates a complex scenario of overturning moments, shear forces, and beam uplifts that standard designs simply ignore.

True seismic safety for pallet racking requires a paradigm shift in thinking—from viewing racking as passive storage furniture to treating it as an integral structural component of the building itself. It must be analyzed, designed, and maintained to handle these dynamic forces. The consequences of oversight are quantifiable and severe, extending far beyond the immediate zone of impact to disrupt entire supply chains.

Decoding the Mechanics: How Earthquakes Attack Storage Systems

Understanding the failure modes is crucial to appreciating the solutions. Seismic forces exploit specific weaknesses:

Progressive Collapse Initiated by Beam Disengagement: The most common failure point. Lateral movement induces uplift forces on beam end connectors. Standard connectors, often simple pins or tabs, can dislodge, dropping a beam. This creates an unstable chain reaction, potentially collapsing entire bays. A robust seismic safety for pallet racking strategy employs connectors engineered to resist this uplift, often through positive locking mechanisms or bolts.

Upright Frame Buckling and Distortion: The vertical upright frames, especially in the cross-aisle direction, act as columns under combined compression and bending. Insufficient or damaged horizontal and diagonal bracing leads to frame instability. Seismic safety for pallet racking mandates specific bracing patterns, member sizes, and connection details to ensure frames remain plumb and stable.

Anchorage Catastrophe: The only link between the racking and the building slab is its anchorage. Seismic events generate pull-out and shear forces that can overwhelm standard anchors. Achieving reliable seismic safety for pallet racking involves specifying high-capacity, certified seismic anchors, calculating their precise spacing and load capacity, and ensuring proper installation into competent concrete.

Load Projectile Hazard: Unrestrained pallets can slide or bounce off beams. This is not just inventory loss; these become deadly projectiles. Part of a holistic seismic safety for pallet racking protocol includes evaluating load security, potentially incorporating beam locks or netting for high-risk applications.

The Quantifiable Business Case: Beyond Compliance to Continuity

Investing in seismic safety for pallet racking is often viewed through the narrow lens of code compliance. While adherence to standards like the International Building Code (IBC), RMI (Rack Manufacturers Institute) Guidelines, or FEM 10.2.08 is essential, the broader business case is compelling.

Asset Preservation: A warehouse represents colossal capital: the racking system itself, the MHE (Material Handling Equipment), and the inventory it houses. A single event can wipe out this value. Seismic safety for pallet racking is the primary insurance policy for these physical assets.

Business Continuity Assurance: In today’s just-in-time logistics environment, downtime is revenue vaporized. A collapsed warehouse halts operations for months. Proactive seismic safety for pallet racking measures ensure that after an event, the facility can resume operations swiftly, maintaining customer commitments and market share.

Liability Mitigation: The highest cost of failure is human. A racking collapse can cause fatalities or life-altering injuries, leading to unprecedented legal liability, criminal charges for negligence, and irreparable reputational damage. Demonstrating due diligence through certified seismic safety for pallet racking is a powerful legal and ethical shield.

Insurance and Risk Financing: Insurers are increasingly sophisticated in assessing warehouse risks. A demonstrably seismically compliant facility, backed by a professional assessment, can lead to significantly lower premiums. Conversely, evidence of negligence can void coverage entirely.

The Gold Standard: Anatomy of a Professional Seismic Risk Assessment

A meaningful evaluation is not a casual walkthrough. It is a forensic, data-driven engineering process designed to diagnose vulnerabilities and prescribe actionable solutions. This is the critical first step toward genuine seismic safety for pallet racking.

Phase 1: Pre-Assessment Intelligence and Code Analysis

The work begins offsite. Specialists analyze the facility’s location against seismic hazard maps (like those from USGS or local geological surveys) to determine the precise Seismic Design Category (SDC). They review any available original racking layout drawings, structural building plans, and soil reports. This phase establishes the baseline design criteria against which the as-built condition will be measured, setting the stage for a targeted assessment of seismic safety for pallet racking.

Phase 2: The Forensic On-Site Engineering Audit

Equipped with tablets, laser measures, torque wrenches, and inspection tools, engineers conduct a millimeter-accurate audit:

As-Built Verification: Every bay is compared to original specs. Unauthorized modifications—added height, removed bracing, changed beam levels—are red-flagged.

Anchorage Audit: A statistically significant sample of anchors is tested for torque, pull-out resistance (where non-destructive methods allow), and corrosion. Installation errors are documented.

Damage Mapping: Each upright column is inspected for forklift impact damage. Even minor dents can reduce load and seismic capacity by over 50%. This mapping is crucial for an honest appraisal of seismic safety for pallet racking.

Load Audit: Actual unit load weights and centroids are recorded. Exceeding design weights or creating top-heavy configurations dramatically increases seismic overturning forces.

Connection and Bacing Inspection: Every beam connector, diagonal brace, and frame tie is checked for wear, deformation, missing locking pins, or improper installation.

Phase 3: Computational Analysis and Reporting

Data is fed into specialized structural analysis software. Engineers model the racking system, applying the site-specific seismic forces to the as-built, as-loaded configuration. The output is a Seismic Risk Assessment Report—a document of record that quantifies risk. It doesn’t just state problems; it calculates factors of safety, identifies the weakest links, and provides a prioritized, engineered roadmap to achieve full seismic safety for pallet racking.

The Solution Spectrum: From Targeted Retrofit to Designed-for-Seismic Systems

The assessment report dictates the remedy. Solutions are not one-size-fits-all but are engineered to address specific deficiencies.

H3: Seismic Retrofit and Reinforcement Engineering

For structurally sound but seismically deficient existing systems, retrofitting is a cost-effective path. This is precision engineering, not generic bracing. Solutions may include:

Supplemental Bracing Kits: Adding seismically rated horizontal struts or diagonal braces to existing frames to increase their lateral stiffness and strength.

Anchorage Upgrade Programs: Replacing underspecified anchors with certified, high-capacity seismic wedge anchors or epoxy-bonded rods, installed at calculated intervals.

Beam Lock Reinforcement: Installing secondary locking devices or replacing standard connectors with seismic-grade, moment-resisting connections.

Upright Column Repair and Reinforcement: Applying engineered steel repair sleeves or doubler plates to impacted uprights, restoring their original compressive and seismic capacity.

Designed-for-Seismic (DFS) New Installations

For new facilities or major expansions, the optimal approach is to specify racking designed from first principles for seismic performance. DFS systems embody seismic safety for pallet racking in every component:

Increased Section Moduli: Upright columns made from heavier-gauge, high-strength steel with optimized perforation patterns.

Proprietary Seismic Connections: Connectors designed to absorb energy through controlled deformation or featuring multiple, redundant locking points.

Optimized Bracing Architectures: Bracing patterns calculated to dissipate seismic energy efficiently, often using specialized member shapes and robust bolted connections.

Integrated Base Plate Designs: Larger, thicker base plates with multiple anchor holes to distribute loads and resist overturning moments.

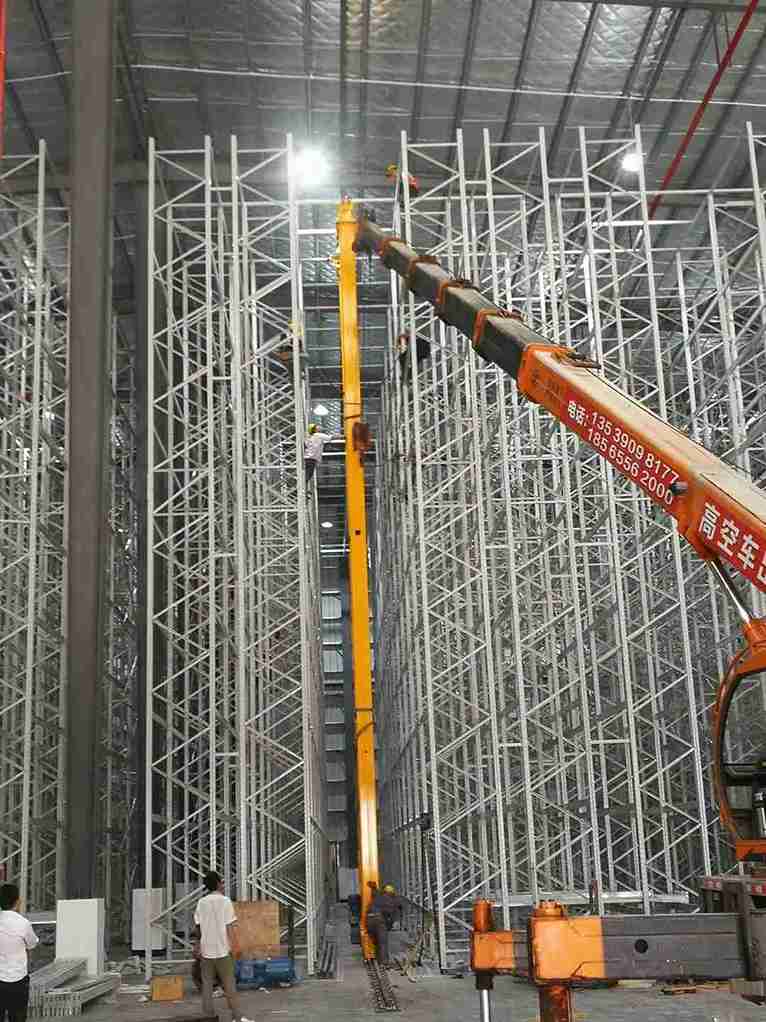

The Automation Intersection: Seismic Safety for Robotic and AS/RS Warehouses

The rise of automation adds a critical layer of complexity. An Automated Storage and Retrieval System (AS/RS) or a fleet of Autonomous Mobile Robots (AMRs) represents a massive investment that must be protected. Seismic safety for pallet racking in an automated context expands to encompass:

Dynamic Interaction Analysis: The movement of cranes (SRUs) or robots during an event creates additional forces. The structural analysis must account for these dynamic loads.

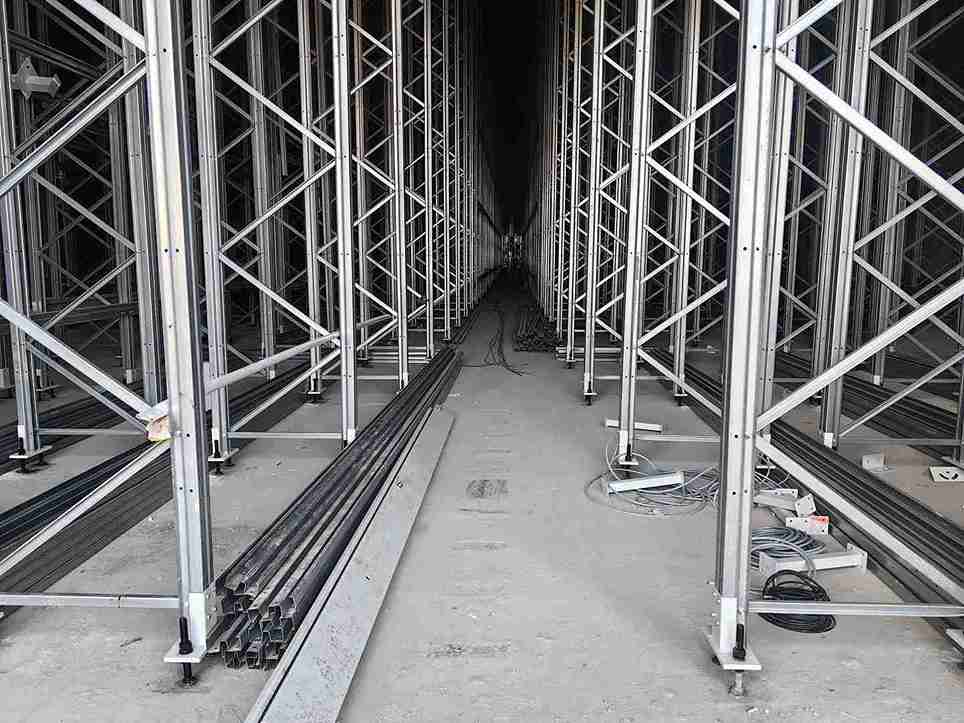

Runway Beam Integrity: The rails upon which cranes travel must be seismically braced and anchored to prevent misalignment, which would render the entire system inoperable.

System Shutdown Protocols: Integrating seismic sensors with the Warehouse Management System (WMS) and equipment controls to initiate a safe, orderly shutdown of automated equipment upon initial ground shaking, preventing collisions and reducing loads on the structure.

Post-Event Recalibration: Planning for the rapid geometric verification and recalibration of guide rails and positioning systems after a tremor to restore functionality.

Global Standards and Local Implementation: A Framework for Action

A key challenge in regions like Southeast Asia, the Middle East, and Latin America is the interplay between international best practices and local codes. A credible provider of seismic safety for pallet racking solutions must navigate this landscape.

International Benchmarks: Standards like the RMI Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks and the European FEM 10.2.08 provide rigorous, peer-reviewed methodologies for seismic design.

Local Code Adoption: Engineers must be fluent in how national and municipal building codes (e.g., Philippines’ NSCP, Chile’s NCh433) adopt or modify these benchmarks. True seismic safety for pallet racking is achieved when the solution is certified to meet the enforceable local jurisdiction requirements.

The Role of Professional Engineering (P.E.) Certification: In many regions, the final seismic design and stamp of approval must come from a locally licensed Professional Engineer. This adds a vital layer of legal accountability and is a hallmark of a mature seismic safety for pallet racking project.

Building a Culture of Seismic Vigilance: Beyond the Installation

Achieving seismic safety for pallet racking is not a one-time event but an ongoing discipline. The most expertly designed system can be compromised by poor operational practices.

Operational Protocols: Enforcing strict rules against exceeding posted load weights and heights. Implementing red zones for high-value or hazardous storage.

Forklift Damage Prevention and Management: A rigorous driver training program, combined with physical column guards and a mandatory reporting/repair protocol for any impact. A damaged upright is the Achilles’ heel of seismic safety for pallet racking.

Scheduled Re-Assessment: Recommissioning a seismic assessment every 3-5 years, or after any significant layout change, ensures the system’s integrity remains aligned with its operational use and evolving codes.

A Case Narrative: Transforming Risk into Resilience

Consider the case of a pharmaceutical distributor in a high-seismic risk Pacific Rim country. Their 10-year-old, high-bay racking warehouse had never been assessed. A preliminary offer of a Free Seismic Risk Assessment revealed several critical issues: impact damage on 15% of uprights, beam connectors that were not seismic-rated, and anchors that did not meet current code for the actual stored loads. The assessment report provided a phased plan.

Phase 1 involved immediate upright repairs and anchor upgrades in the most critical high-value storage zone.

Phase 2, executed during a planned inventory cycle, involved a full connector replacement across the facility. The project culminated in a certified engineering report submitted to their insurer, resulting in a 22% premium reduction. The client’s investment in seismic safety for pallet racking was amortized through insurance savings in under four years, while fundamentally de-risking their most valuable logistics asset.

The Path Forward: Initiating Your Seismic Resilience Journey

The question for executives is not if their region is seismic, but how prepared their operations are. The first step is knowledge, and that begins with a professional, engineering-led evaluation. Our firm extends a comprehensive Free Seismic Risk Assessment to qualified operations globally. This is not a sales tool but a diagnostic service, providing the clarity needed to make informed capital planning decisions. It represents a commitment to moving the topic of seismic safety for pallet racking from the peripheral budget line to the core of strategic operational risk management.

(Conclusion)

In the calculus of modern logistics, resilience is the ultimate currency. Earthquakes are a geological certainty in many of the world’s most dynamic economic regions. The structural vulnerability of standard pallet racking to seismic forces is an engineering certainty. Bridging this gap is not merely a technical exercise; it is a fundamental leadership responsibility.

A systematic, engineered approach to seismic safety for pallet racking protects human lives, safeguards capital assets, ensures contractual continuity, and fortifies the supply chain against disruption. It transforms a facility from a passive victim of circumstance to an active bastion of resilience. The journey begins with a single, decisive action: accepting the imperative to assess, understand, and fortify. The alternative—inaction—is a risk that no forward-thinking operation can afford to carry.

Frequently Asked Questions (FAQs)

1. We have a warehouse in a country with less stringent building codes. Is seismic safety still relevant?

Absolutely. Local building codes represent a minimum legal standard, not necessarily a best practice for operational resilience. Furthermore, many multinational corporations impose their own global safety standards on all facilities, regardless of location. Proactive seismic safety for pallet racking demonstrates world-class risk management, protects globally insured assets, and can be a competitive advantage when audited by major international clients.

2. How does the presence of mezzanines or multi-level pick modules affect seismic assessment?

These structures significantly increase complexity. They add mass high in the structure, altering the building’s dynamic response, and create a multi-degree-of-freedom system. A competent seismic safety for pallet racking assessment for such facilities must analyze the interaction between the main racking, the mezzanine structure, and the building floor. Often, this requires a more sophisticated, finite-element analysis model.

3. Can we perform a seismic assessment in-house with our maintenance team?

While regular visual inspections for damage are crucial, a formal seismic safety for pallet racking assessment requires specialized structural engineering knowledge, access to proprietary design software, and a deep understanding of dynamic load calculations. Misdiagnosis can lead to a false sense of security. This is a task for specialists, much like electrical or pressure vessel inspections.

4. What is the typical return on investment (ROI) for a seismic retrofit project?

ROI is measured in risk reduction, not direct revenue. The financial model includes avoided costs: potential inventory loss (a multi-million dollar figure for many warehouses), business interruption losses (revenue lost per day of downtime), reduced insurance premiums, avoided fines/litigation, and protection of brand equity. When framed this way, the ROI for achieving verified seismic safety for pallet racking is often compelling, with payback periods realized in the first avoided incident.

5. How do we manage the assessment and potential retrofit without disrupting ongoing 24/7 operations?

A seasoned provider will plan a phased approach. The assessment can be conducted during shifts using non-intrusive methods. Retrofit projects are meticulously sequenced, often bay-by-bay or in designated zones, using pre-fabricated kits to minimize on-site work time. Temporary shoring and relocation plans are developed for critical inventory. The goal is to enhance seismic safety for pallet racking with minimal impact on throughput, treating operational continuity as a parallel priority.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com