📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Executive Summary: The Strategic Imperative of Intelligent Space

In the high-stakes arena of global e-commerce, the warehouse has undergone a profound transformation. It is no longer a passive storage depot but the dynamic, pulsating core of the entire customer fulfillment journey. Its performance, its agility, and its intelligence directly dictate market competitiveness. The most pervasive and costly challenge confronting e-commerce operators from Southeast Asia to Latin America is the radical disconnect between standard operational capacity and the crushing demands of peak seasons, flash sales, and unexpected viral growth.

Conventional responses—leasing temporary satellite facilities or embarking on costly new construction—are increasingly recognized as financially draining and operationally crippling stopgaps. These outdated approaches fundamentally fail to leverage the most underutilized asset within any existing facility: the vast, empty cubic air space hovering above the primary workflow. This is the strategic frontier where mezzanine racking for e-commerce ceases to be a simple storage product and emerges as a foundational, strategic operating system.

A truly scalable mezzanine racking for e-commerce solution is not a mere platform; it is a dynamic, three-dimensional framework for growth, engineered to adapt, integrate, and evolve. It represents the most logical and profitable methodology for future-proofing an e-commerce warehouse, ensuring that businesses do not merely cope with the next holiday surge or sales event, but that they harness it, converting logistical volatility into a definitive competitive advantage. This comprehensive analysis will delve into the engineering paradigms, configurational genius, and deep integration potential that establish modern mezzanine racking for e-commerce as the indispensable cornerstone of a resilient, scalable, and highly profitable fulfillment operation.

Beyond the Second Floor: Redefining Scalability in Mezzanine Racking

The traditional perception of mezzanine racking for e-commerce as a simple, static second-story platform is a dangerously antiquated notion. In the context of modern, high-velocity fulfillment, this view fails to capture the system’s true strategic potential. True scalability in mezzanine racking for e-commerce is a multi-faceted concept, encompassing not just physical expansion but also operational intelligence and technological adaptability. It is about constructing a responsive three-dimensional ecosystem that can be continuously reconfigured and enhanced to meet the fluid demands of omnichannel retail.

The Three Pillars of True Scalability for E-commerce

Leading providers of mezzanine racking for e-commerce define scalability through three interdependent, core pillars that guide their design philosophy:

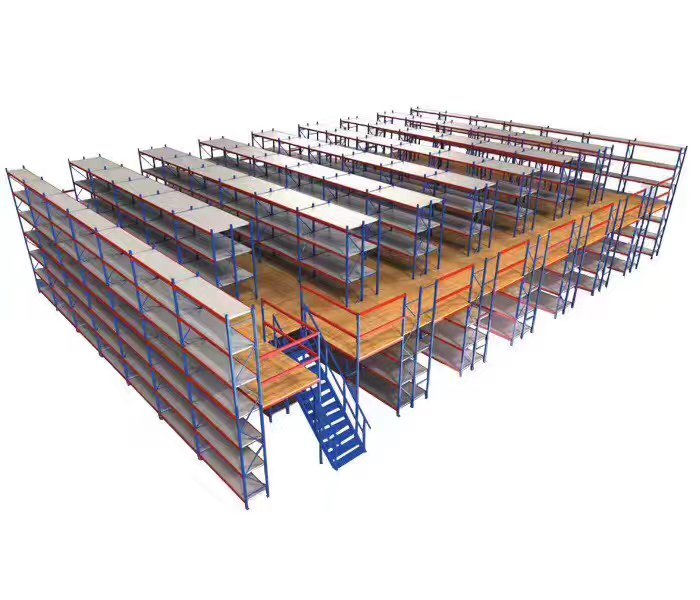

Vertical Scalability (Expanding the Cube): This is the most fundamental dimension of growth. It involves a deliberate and engineered exploitation of the vertical cube, often constructing two or even three operational tiers. This approach can effectively triple the usable storage and operational square footage without a single square meter of additional building footprint. The critical differentiator in advanced mezzanine racking for e-commerce is forward-looking engineering; a system conceived with future vertical expansion will feature primary columns, footings, and connections that are pre-certified to handle additional dynamic loads, making subsequent growth phases seamless, safe, and remarkably cost-effective.

Horizontal & Configurational Scalability (The Architecture of Adaptability): This dimension is where operational intelligence is physically embedded into the infrastructure. A scalable system of mezzanine racking for e-commerce is inherently modular and non-static. It is composed of interchangeable components that permit lateral expansion of the deck area as adjacent space is rationalized. It allows for the reconfiguration of pick modules, the rerouting of conveyor paths, and the repositioning of safety barriers to accommodate new workflows. This might involve altering the decking type from solid steel in bulk storage zones to open grating in areas requiring ventilation or sprinkler coverage, all within the same unified structure.

Operational & Technological Scalability (The Pathway to Automation): This is the ultimate differentiator between a basic storage solution and a future-proof fulfillment platform. A sophisticated mezzanine racking for e-commerce installation is designed from its inception with digital-physical integration in mind. This necessitates specifying load ratings that can support the constant movement of Automated Guided Vehicles (AGVs), designing clear vertical chases and reinforced points for automated conveyor systems, and ensuring the structural integrity to handle the unique dynamic forces exerted by goods-to-person picking stations and robotic retrieval systems. This pillar ensures that the mezzanine racking for e-commerce is not rendered obsolete by the next wave of automation but is, in fact, the ideal substrate for it.

The E-Commerce Peak Season Dilemma: Why Traditional Expansion Fails

The “peak season panic” is a universal experience in the e-commerce sector, a period where operational ambitions collide with physical infrastructure limitations. The conventional toolkit for addressing this surge is fundamentally broken, offering only two deeply flawed pathways that often exacerbate the very problems they seek to solve.

Leasing Additional Temporary Space: A Logistical and Financial Quagmire

The pursuit of a short-term lease for auxiliary storage space appears, on the surface, to be a pragmatic quick fix. In reality, it initiates a cascade of operational inefficiencies and hidden costs. Management complexity skyrockets as inventory must be synchronized across multiple locations, complicating receiving, put-away, and, most critically, order picking and consolidation. Labor costs inflate disproportionately due to the need for duplicated staffing, and the transportation expenses for shuttling inventory between sites can eviscerate the profit margins of the very sales surge the space was meant to support. This approach fragments the operation, making it slower and more expensive.

Building a New Warehouse: The Capital-Intensive Marathon

Commissioning a new greenfield distribution center is a strategic decision for long-term, predictable linear growth. It is entirely mismatched for the volatile, non-linear, and rapid-fire growth cycles that characterize successful e-commerce. The multi-year timeline from planning to operational readiness means that the business needs may have shifted dramatically by the time the facility opens, potentially leaving the organization with a fixed, and potentially sub-optimal, asset. This is not a solution for agility.

The Cubic Air Space Solution: Tapping the Internal Reservoir

The most underutilized and immediately accessible resource in any e-commerce warehouse is the vertical space above the existing operation. Industry analyses consistently show that many facilities utilize less than a quarter of their available clear height. This represents a massive, untapped reservoir of potential capacity. The implementation of mezzanine racking for e-commerce is the master key that unlocks this asset. It facilitates strategic expansion within the current footprint, centralizing management, streamlining workflows, and, most importantly, protecting and even enhancing profit margins during the most critical commercial periods of the year. This makes mezzanine racking for e-commerce a direct contributor to the bottom line.

Anatomy of a Future-Proof Mezzanine Racking System

A mezzanine designed for the demanding and unpredictable future of e-commerce is a masterpiece of industrial engineering. It is a system where every component is selected and integrated with longevity, strength, and adaptability as the primary objectives.

Structural Integrity: The Unseen Foundation of Trust

The structural frame is the silent, unwavering backbone of the entire operation. For critical mezzanine racking for e-commerce applications, off-the-shelf, generic components are insufficient. Reputable manufacturers utilize high-grade, hot-rolled steel for columns and beams, with designs that incorporate significant safety factors to account for unforeseen loads and impacts. The connection methodologies—whether employing high-strength bolts for future reconfigurability or controlled welding for maximum rigidity in specific zones—are executed to meet and often exceed stringent international building codes and seismic standards.

The objective is to create a platform that is not merely adequate for today’s requirements but is robust enough to confidently support the unknown demands of tomorrow’s technology and inventory profiles.

Decking Options: The Functional Skin of the Operation

The decking serves as the primary working surface, and its specification is a critical decision that directly impacts functionality, safety, and future flexibility. A one-size-fits-all approach is inadequate for sophisticated mezzanine racking for e-commerce.

Heavy-Duty Steel Plate: This is the premium choice for areas subjected to extreme point loads, such as palletized storage or the operation of heavy-duty unmanned pallet trucks. It provides an exceptionally durable and rigid surface that will not deflect under stress.

Bar Grating or Wire Mesh: This option is functionally superior for mezzanine levels that must allow for the passage of light, air, and, crucially, water from the facility’s fire sprinkler system to the level below. It also reduces the overall dead load on the structure.

Laminated Wood Products: While a lower-cost alternative for very light-duty applications or office spaces, it lacks the longevity, fire resistance, and load-bearing capacity required for intensive industrial mezzanine racking for e-commerce environments.

A hallmark of intelligent design is the use of multiple decking types across a single mezzanine level, tailoring the surface to the specific task performed in each zone, all within a cohesive structural whole.

Access & Safety: The Framework for Secure Workflow

The methodologies for moving both personnel and goods to and from the mezzanine level are fundamental elements of its scalability and daily safety. The placement of staircases, industrial-grade elevators, and vertical reciprocating conveyors (VRCs) is optimized using lean principles to minimize travel waste. Furthermore, integrated safety systems—including self-closing pallet gates, high-visibility handrails, and kick-plates—are not afterthoughts but are integral components of the initial design. A future-proof system will have pre-designated, structurally reinforced locations for adding secondary access points or upgrading a manual lift to a fully automated VRC as operational throughput escalates.

Synergy in Action: Integrating Mezzanines with Warehouse Automation

This is the pivotal juncture where a basic storage platform transforms into a high-velocity, integrated e-commerce fulfillment engine. The full potential of scalability is only realized when the physical structure of the mezzanine racking for e-commerce engages in a seamless dialogue with automated systems.

Creating a Multi-Level AGV & AMR Ecosystem

The era where Autonomous Mobile Robots (AMRs) and AGVs were confined to the ground floor is over. A strategically engineered system of mezzanine racking for e-commerce can incorporate gently sloped, reinforced ramps or dedicated automated lifts, enabling a unified fleet of robots to operate seamlessly across multiple tiers. This creates a highly dense, three-dimensional automated storage and retrieval system that offers remarkable flexibility compared to a monolithic ASRS. Robots can autonomously retrieve items from high-density storage on the upper level and deliver them directly to picking or packing stations, operating 24/7 with minimal human intervention and dramatically increasing throughput.

Conveyor System Integration: The Circulatory System of the Facility

Conveyors act as the circulatory system, moving products through the fulfillment process. A properly designed mezzanine racking for e-commerce structure is conceived with clear vertical chases, reinforced transfer points, and allocated space for the integration of spiral conveyors, vertical lifts, and declining belts. This engineering foresight enables a continuous, uninterrupted flow of goods from receiving, up to the mezzanine for high-density storage, and back down to sorting and shipping zones. This creates a powerful, streamlined workflow that drastically reduces manual handling, minimizes product damage, and slashes order cycle times.

Goods-to-Person (G2P) Picking Stations on Multiple Tiers

Perhaps the most significant efficiency gain in modern e-commerce fulfillment is delivered by goods-to-person picking technology. By deploying G2P stations on both the main floor and the mezzanine level, a business effectively doubles or even triples its picking capacity within the same foundational footprint. Inventory stored on the upper levels is brought automatically to an ergonomically optimized picking station on that same level. This paradigm eliminates all non-value-added travel time for associates, who can then fulfill orders at maximum, sustained rates of productivity. This configuration makes the mezzanine racking for e-commerce a direct catalyst for labor efficiency and order accuracy.

Strategic Configurations for Maximum E-commerce Impact

The spatial and operational configuration of the mezzanine racking for e-commerce is a strategic decision that yields vastly different outcomes. Here are several proven models that align with specific e-commerce challenges.

The High-Density Storage & Buffer Inventory Loft

This classic configuration dedicates the mezzanine level to the bulk storage of slower-moving SKUs, excess inventory, or seasonal products. This strategy is fundamental for effective mezzanine racking for e-commerce as it liberates the premium, ground-floor space for high-velocity picking, value-added services like kitting and customization, and returns processing. During peak seasons, this upper level transforms into a critical buffer zone, holding the surplus stock that prevents congestion and chaos on the primary fulfillment floor, making it an essential component of any mezzanine racking for e-commerce strategy.

The Multi-Tiered Pick Module Powerhouse

This is the ultimate configuration for high-volume, multi-SKU e-commerce operations. In this model, the mezzanine racking for e-commerce is not used for bulk storage but is dedicated entirely to the active fulfillment process. It features multiple levels of pick faces, with a “race-track” conveyor system running through its core. Pickers are stationed at fixed, ergonomic stations on the mezzanine, fulfilling orders for their designated zones and placing items onto the conveyor, which automatically routes them to a central consolidation and packout area. This configuration of mezzanine racking for e-commerce can increase pick rates by over 300% compared to traditional single-level walking-based layouts.

The In-House Returns Processing & Value-Add Center

E-commerce returns are a vast and costly operational challenge. Dedicating a defined section of the mezzanine racking for e-commerce to a centralized, dedicated returns processing center is a stroke of strategic genius. Returned items are immediately transported upstairs, where they are systematically inspected, sorted, triaged for restocking, repackaging, or liquidation. This containment strategy is a key benefit of mezzanine racking for e-commerce, as it prevents the disruptive, time-consuming, and messy process of returns from interfering with the clean, fast-paced, and optimized flow of outbound order fulfillment on the main level.

The Blueprint for Implementation: A Phased Approach to Scalability

Deploying a scalable mezzanine racking for e-commerce system is a strategic journey that aligns investment with business growth milestones. A phased, blueprint-driven approach mitigates risk and maximizes return on investment.

Phase 1: Comprehensive Site Assessment & Future-Proof Master Planning

This is the most critical phase, where the long-term vision is established. Expert engineers conduct a forensic-level site survey, analyzing floor load capacity, ceiling clearances, column grid patterns, and existing fire protection systems. Crucially, this phase involves collaborative modeling of not just current needs but projected 5-to-10-year growth trajectories. The output is a master plan—a detailed blueprint that outlines the entire lifecycle of the mezzanine racking for e-commerce, specifying how and when the system will scale in subsequent phases.

Phase 2: Core Structure Installation with Future-Proofing

This phase involves the installation of the primary structural frame, primary decking, and essential access points, all executed in strict accordance with the Phase 1 master plan. Even if the initial requirement is for a single level, the structure is engineered and erected to support future vertical expansion. Key connection points, column splices, and foundation supports are installed with future phases in mind, and their locations are meticulously documented for the next stage.

Phase 3: Operational Integration & Initial Workflow Optimization

With the core structure of the mezzanine racking for e-commerce in place, the initial workflow elements are integrated. This includes the installation of shelving, static racking, and basic material handling equipment. Concurrently, new operational processes are mapped and implemented to maximize the efficiency gains from the newly available multi-level space, training staff on the new workflows enabled by the mezzanine racking for e-commerce.

Phase 4: Strategic Scaling & Automation Enablement

As business growth or peak season demands escalate, the organization executes the next predefined phase of the master plan. This could involve adding the second tier, expanding the deck’s lateral footprint, or integrating the planned automation systems, such as conveyor spurs, AGV charging and routing stations on the mezzanine level, or goods-to-person workstations. Because the blueprint was established from the outset, this expansion is executed with surgical precision, minimizing cost, disruption, and downtime to the ongoing operations.

ROI Analysis: Calculating the Value of a Scalable Asset

Evaluating a scalable mezzanine racking for e-commerce system as a mere capital expense is a profound strategic error. It is, in fact, a high-yield investment with a clear and compelling financial return profile.

Dramatically Lower Cost per Square Foot/Meter: The capital outlay for adding operational space via a mezzanine racking for e-commerce system is typically a fraction of the cost associated with leasing new space, building an extension, or purchasing additional industrial property.

Direct Peak Season Profit Protection: By wholly eliminating the exorbitant costs of temporary leases and their associated logistical complexities, the mezzanine racking for e-commerce pays for itself by preserving and enhancing profit margins during the highest-volume, most profitable sales periods.

Quantifiable Labor Efficiency Gains: Configurations like multi-level pick modules directly reduce picker travel time, leading to a higher number of picks per hour and a lower labor cost per order shipped. These savings flow directly to the bottom line.

Tangible Asset Appreciation: Unlike a lease payment that vanishes, a permanently installed mezzanine racking for e-commerce system is a capital asset that appreciably enhances the functionality, capacity, and therefore the market value of the industrial property itself.

Conclusion: Engineering Unassailable Competitive Advantage

In the relentless, fast-paced global landscape of e-commerce, operational rigidity is a direct path to obsolescence. The capacity to scale efficiently and intelligently is not just an advantage; it is a fundamental prerequisite for survival and market leadership. A scalable mezzanine racking for e-commerce system is the physical embodiment of this essential adaptive capability. It is a dynamic, intelligent, and integrated platform that proactively transforms the warehouse from a static cost center into a responsive, profit-driving engine of growth.

It empowers organizations to master peak seasons, embrace automation on a logical and affordable timeline, and construct a logistics infrastructure that is not passively awaiting the future but is actively architecting it. The strategic space required to dominate your market is not in a distant, costly new building; it is an untapped reservoir, waiting directly above your current operations. The implementation of sophisticated mezzanine racking for e-commerce is the definitive strategy for unlocking this potential.

Frequently Asked Questions (FAQs)

1. What is the typical lead time for the design and installation of a scalable mezzanine system?

Lead times are project-specific, but a comprehensive, engineered mezzanine racking for e-commerce solution typically requires a 10 to 16-week timeline from the initial design engagement to final on-site installation. This period encompasses the critical stages of detailed engineering analysis, custom fabrication of components, and on-site assembly by certified technicians. For projects following a phased master plan, subsequent stages can be deployed significantly faster, as the foundational engineering and design are pre-approved and documented.

2. How do you ensure the mezzanine structure complies with our local building codes and safety regulations?

Reputable providers of mezzanine racking for e-commerce maintain engineering teams proficient in international building codes (IBC) and a vast library of local jurisdictional requirements across Southeast Asia, the Middle East, Africa, and Latin America. They assume full responsibility for producing professionally stamped and certified engineering drawings, calcs, and documentation required for local permit acquisition. Their designs inherently incorporate all mandated safety features, including definitive load ratings, compliant guardrail systems, and seamless integration with the facility’s existing fire protection scheme.

3. Can a mezzanine be installed in a warehouse with a relatively low ceiling height?

While the highest ROI is achieved in facilities with ample clear height, experienced engineers can design effective mezzanine racking for e-commerce solutions for warehouses with clear heights as low as 12 feet (approx. 3.6 meters). In these scenarios, the focus shifts from creating a full standing-height second story to constructing a raised platform or “mezzanine pod” for specific, space-intensive functions like secure pallet storage, office space, or equipment rooms, thereby still freeing up valuable ground-level space for core fulfillment activities.

4. What is the maintenance requirement for an industrial-grade mezzanine racking system?

The maintenance regimen for a high-quality mezzanine racking for e-commerce system is minimal but critically important for long-term integrity and safety. A scheduled bi-annual inspection is recommended to check for any loosened bolts or connectors, inspect the structural integrity for any signs of damage, and verify the condition of all decking and safety equipment. This preventative maintenance is analogous to the care required for pallet racking and other material handling assets. The robust steel construction is designed for decades of reliable service with this basic, proactive oversight.

5. We are considering automation in the next 2-3 years. What specific specifications should we insist on in our mezzanine now to prepare?

This is a forward-thinking and crucial question. To ensure your mezzanine racking for e-commerce is automation-ready, you must mandate three key engineering specifications during the initial design:

Enhanced Dynamic Load Rating: Insist on a load rating that accounts for the combined weight and dynamic impact of AGVs or AMRs and their loads, not just static storage. A minimum of 350 psf (or 1,700 kg/m²) is often recommended for zones designated for future automation.

Reinforced Column Pads and Foundations: Ensure the structural design includes reinforced foundations and column bases specifically engineered to handle the additional dynamic loads and potential vibrations from continuous robotic traffic.

Pre-Designed Integration Zones: The master plan must clearly outline pre-determined areas with reinforced connections, clear vertical chases, and unimpeded access for future conveyor penetration points, robotic lift stations, and automated safety gates. This foresight in planning mezzanine racking for e-commerce is what separates a basic project from a strategic investment.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com