📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Strategic Imperative of Vertical Expansion

In the high-stakes arena of modern logistics and warehousing, the relentless pressure to do more with less is a constant challenge. Warehouse managers, operations directors, and business owners are perpetually locked in a battle against a fixed constraint: the square footage of their facility.

When inventory peaks and available floor space evaporates, the conventional reflex is to consider expansion—a path fraught with prohibitive costs, debilitating operational downtime, and bureaucratic entanglements. However, a paradigm-shifting solution, one that is both elegantly simple and profoundly impactful, exists within the very fabric of the warehouse itself. The racking supported mezzanine stands as the definitive answer to the space-capacity conundrum. This engineered system represents a masterclass in efficiency, transforming unused vertical air space into high-density, highly functional storage and operational areas.

By fundamentally integrating with the core storage infrastructure, a racking supported mezzanine floor unlocks potential that traditional construction cannot touch. This exhaustive guide delves deep into the mechanics, advantages, and strategic implementation of these systems, demonstrating precisely how they empower businesses to maximize warehouse space radically enhance storage density, streamline material flow, and future-proof operations—all while completely avoiding the monumental costs and disruptions of new construction.

For any leader seeking a competitive edge through operational superiority, understanding the power of a racking supported mezzanine is the first critical step.

The Warehouse Capacity Crisis: A Choice Between Disruption and Intelligence

Growth is the ultimate objective of any successful business, but it often manifests as a logistical nightmare within the four walls of a warehouse. The point of peak capacity is not a hypothetical scenario; it is an inevitable eventuality that demands a strategic response. Historically, the playbook offered only two fundamentally flawed options.

The Archaic Burden of Traditional Construction and Relocation

The instinct to build a new addition or relocate to a larger facility is understandable but is increasingly recognized as a last resort due to its immense drawbacks. The financial burden alone is staggering, encompassing not just the raw construction costs but also architectural fees, civil engineering, and the skyrocketing price of materials. The timeline from conception to completion can span years, during which capital is locked away and leadership’s focus is diverted from core business activities. Operationally, the impact is even more severe.

Construction is inherently disruptive—a chaotic process of noise, dust, and safety hazards that forces workflows to be rerouted, compromises safety, and often brings productivity to a screeching halt. Furthermore, the labyrinth of zoning regulations, environmental assessments, and building permits presents a bureaucratic gauntlet that can delay projects indefinitely. Perhaps most critically, a concrete-and-steel extension is a permanent, inflexible fixture. It cannot adapt to future changes in technology, workflow, or business model, locking the company into a static footprint.

The Modern Paradigm: Capitalizing on Cubic Volume

The evolution of warehouse management thinking has shifted the focus from two-dimensional square footage to three-dimensional cubic volume. The average warehouse operates like a single-story operation inside a multi-story shell, leaving a vast reservoir of untapped potential hovering above the highest rack beam. This cubic air space, for which companies already pay through rent, utilities, and taxes, is the most valuable and underutilized asset in the facility.

The racking supported mezzanine is the engineered key that unlocks this potential. It facilitates a strategic pivot from outward expansion to upward optimization. By adding a second or even third tier within the existing envelope, businesses can effectively double their operational area without acquiring a single additional square foot of land or pouring a single yard of concrete. This approach is not merely an alternative; for the savvy operations leader, it is the obvious first choice.

Deconstructing the Powerhouse: What is a Racking Supported Mezzanine?

To appreciate the superiority of this solution, one must first understand its fundamental engineering principle. A racking supported mezzanine is a structurally independent elevated platform that derives its primary support from the integral framework of an existing or newly installed pallet racking system. This is a critical distinction from a free-standing mezzanine, which relies on its own dedicated support columns, or a structural mezzanine, which is tied into the building’s superstructure.

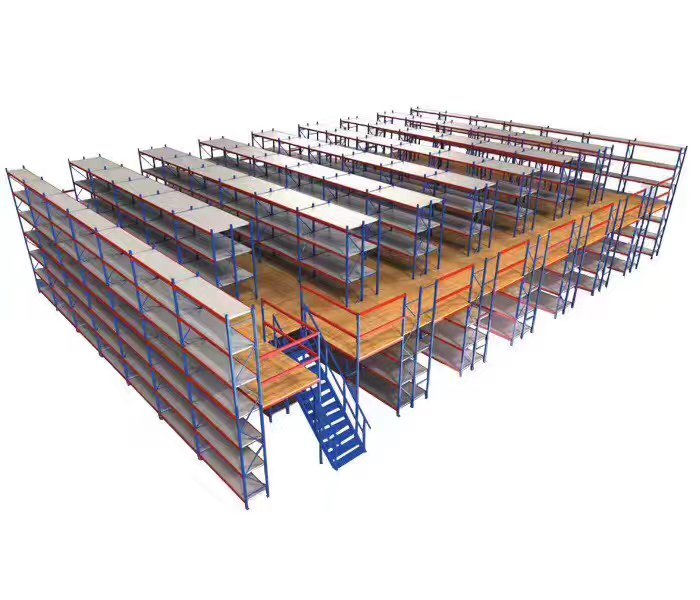

The system is a masterpiece of integrated design where the storage infrastructure and the building platform become one cohesive, interdependent unit. The decking—often comprised of robust steel bar grating, durable particle board, or sealed steel plates—forms the new working level. Simultaneously, the pallet racking beneath performs a dual role: it continues its primary function of storing palletized inventory while also assuming the critical structural responsibility of supporting the immense dead and live loads of the entire racking supported mezzanine floor above it.

This symbiotic relationship between storage and structure is what elevates a racking supported mezzanine from a simple product to a transformative warehousing solution, offering unparalleled efficiency for operations demanding maximum storage density.

Engineering Superiority: The Unmatched Advantages of a Rack-Supported Design

When evaluating mezzanine options, the choice between a free-standing and a rack-supported system is decisive. For pure warehousing and storage applications, the racking supported mezzanine delivers a suite of advantages that make it the superior choice for forward-thinking operations.

Unrivaled Space Efficiency and True Clear-Span Design

The most immediately apparent benefit is the complete elimination of internal support columns. Free-standing mezzanines require a network of their own columns, which inevitably protrude into valuable floor space. These obstructions create navigation hazards, disrupt optimized pick paths, and complicate warehouse layout planning. In stark contrast, a properly engineered racking supported mezzanine creates a pristine, clear-span environment beneath the platform.

This unobstructed space is nothing short of revolutionary for material flow. It allows for the seamless operation of forklifts, narrow-aisle reach trucks, and, most importantly, provides the open highways required for automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) to operate at peak efficiency without complex navigation programming around obstacles.

The Pinnacle of Storage Density and Footprint Optimization

By leveraging the existing racking for structural support, a racking supported mezzanine achieves a level of storage density that other systems cannot match. Every single square foot of the footprint is utilized with maximum efficiency. There are no wasted “dead zones” sacrificed for mezzanine support columns. The space below the racking supported mezzanine floor remains fully accessible for storage, while the platform above creates an entirely new storage or operational dimension. This double-utilization of the same footprint is the core economic driver behind investing in a racking supported mezzanine.

Holistic and Integrated Load Management Philosophy

The engineering of a racking supported mezzanine treats the entire system—racking, deck, and connections—as a single structural entity. Professional engineers calculate the combined loads, including the static dead load of the structure itself and the dynamic live loads from inventory, personnel, and material handling equipment. These forces are strategically distributed through the racking uprights and directly transferred to the concrete floor slab. This holistic approach often results in a more optimized and efficient use of materials, potentially allowing for higher overall load capacities compared to a system where the racking and mezzanine are designed independently of one another.

The Inherently Automation-Ready Platform

The future of warehousing is unequivocally automated. A racking supported mezzanine is not just compatible with this future; it is designed to accelerate its integration. The clear-span area below is a blank canvas for automation:

AGV and AMR Navigation: The absence of columns provides AGVs with unimpeded pathways, maximizing their uptime, efficiency, and safety.

Seamless Conveyor System Integration: Conveyors can be routed directly from the mezzanine level to packing stations, sortation systems, or other facility areas without the need for complex and costly designs to circumvent support columns.

Host for Automated Picking Technologies: The mezzanine level itself can be configured to support automated storage and retrieval systems (AS/RS), goods-to-person picking workstations, or robotic mobile fulfillment systems, creating a multi-tiered, high-throughput automation hub.

Beyond the Blueprint: Critical Considerations for a Successful Project

The deployment of a racking supported mezzanine is a significant capital project that demands meticulous planning, expert engineering, and precise execution. Overlooking these critical factors can compromise safety, functionality, and return on investment.

The Non-Negotiable: Professional Structural Engineering Analysis

This is the absolute bedrock of a safe and successful racking supported mezzanine installation. The involvement of a licensed professional engineer (PE) is not a recommendation; it is a mandatory requirement. Their analysis is comprehensive and includes:

Existing Floor Slab Capacity Analysis: The concrete slab must possess the compressive strength to handle the concentrated point loads transferred through the racking uprights. This often requires core sampling to verify the concrete’s psi rating and integrity.

Seismic and Wind Load Calculations: The entire structural design must comply with stringent local building codes, such as the International Building Code (IBC) and any regional amendments. The racking supported mezzanine must be engineered to withstand seismic events and other environmental forces specific to the geographic location.

Precise Load Calculations: The PE will calculate all applicable loads, including the dead load (structural weight), live load (inventory, personnel, equipment), and potential impact loads. Live loads for a storage-focused racking supported mezzanine floor typically start at 150 PSF but can be engineered to exceed 300+ PSF for heavy industrial applications.

Navigating the Maze: Building Codes and Permit Acquisition

A racking supported mezzanine is classified as a permanent structural modification. As such, it requires formal approval and a building permit from the local Authority Having Jurisdiction (AHJ). The permitting process can be complex, requiring detailed submission packages including engineered drawings, load calculations, and life safety plans. Partnering with a provider who manages this process end-to-end is crucial for avoiding delays and ensuring full compliance from the outset.

Life Safety Paramount: Fire Protection and Sprinkler Integration

The addition of a mezzanine level dramatically alters the building’s interior geometry and directly impacts its fire protection system. Building codes universally mandate that the sprinkler system be extended to provide adequate coverage both on the new racking supported mezzanine floor and in the space created beneath it. This involves designing a new sprinkler zone, potentially upgrading water supply lines, and ensuring all sprinkler heads are positioned for optimal coverage. This work must be designed by a certified fire protection engineer and installed by licensed professionals.

Material Flow Architecture: Planning for Access and Workflow

How personnel and product move to and from the new level is a fundamental operational decision that must be integrated into the initial design.

Forklift-Accessible Ramps: For facilities moving high volumes of palletized goods, a structurally reinforced ramp is the standard solution. The ramp’s incline, width, and landing areas must be designed for safety, efficiency, and compliance with OSHA standards.

Material Lifts and Vertical Reciprocating Conveyors (VRCs): For case picking, kitting operations, or transporting goods that are not on pallets, a material lift or VRC offers a highly efficient and space-conscious method of vertical transport.

Code-Compliant Stairways and Gates: Any racking supported mezzanine used for human occupancy must include OSHA-compliant stairways with handrails and safety gates to prevent falls from elevated work surfaces.

Transformative Applications: Unleashing the Potential of Your Space

The versatility of the racking supported mezzanine is one of its greatest strengths. It can be tailored to solve a diverse range of operational challenges across various industries.

<h3> High-Density Bulk Storage Megaplex</h3>

The most direct application is the creation of massive additional capacity for bulk storage. By building upward, a racking supported mezzanine can effectively double or triple the number of pallet positions within the same footprint, turning a constrained warehouse into a high-density storage megaplex without an inch of new construction.

<h3> Multi-Tiered Order Fulfillment and Picking Modules</h3>

Revolutionize order fulfillment by dedicating different levels to different velocity SKUs. The ground floor can be reserved for hyper-fast-moving products, while the racking supported mezzanine floor above houses medium-to-slow movers. This organizes the workflow, drastically reduces picker travel time and distance, and can increase order accuracy and throughput.

<h3> Overhead Mezzanine Office and Operational Command Centers</h3>

Reclaim valuable floor-level real estate by constructing secure, quiet, and elevated office spaces, quality control rooms, or supervisor platforms. A racking supported mezzanine used for this purpose provides management with a panoramic, bird’s-eye view of the entire operation, enhancing oversight and security without sacrificing productive space.

<h3> Flexible Work-in-Process (WIP) and Light Assembly Platforms</h3>

The mezzanine level can be isolated for specific functions like light assembly, kitting, custom packaging, or WIP storage. This effectively separates these value-added services from the main storage and distribution flows below, reducing congestion and improving specialized workflow management.

The Implementation Journey: A Phased and Partner-Driven Approach

The installation of a racking supported mezzanine is a significant project that benefits immensely from a structured, phased approach managed by experienced professionals. A best-practice process ensures a smooth transition from concept to operational reality.

In-Depth Consultation and Operational Needs Analysis: The process begins with a thorough discovery phase to understand unique operational pain points, growth projections, and specific workflow requirements.

Laser-Precision On-Site Survey and Assessment: Advanced laser measuring tools are used to capture every critical dimension of the facility, including ceiling height, column locations, and floor flatness, creating an accurate digital twin of the space.

3D Conceptual Design and Engineering Feasibility: Using state-of-the-art CAD software, designers create detailed 3D models of the proposed racking supported mezzanine, allowing stakeholders to visualize the final outcome and make informed decisions before fabrication begins.

Transparent Quotation and Project Scheduling: Clients receive a comprehensive, itemized quotation that leaves no room for hidden costs, accompanied by a clear and realistic project timeline outlining all phases from permit acquisition to final inspection.

End-to-End Permitting and Code Compliance Management: The provider assumes responsibility for preparing and submitting all necessary engineering documentation to the local building department, managing the permit application process to secure approval efficiently.

Precision Manufacturing and Quality Assurance: All components of the racking supported mezzanine are fabricated to exact specifications under strict quality control protocols in a controlled manufacturing environment.

Expert Installation with Minimal Operational Disruption: A certified and experienced installation team executes the project with a focus on safety, precision, and minimizing impact on ongoing warehouse activities, often working in phased sequences.

Final Inspection, Certification, and Knowledge Transfer: The provider coordinates the final building department inspection and upon approval, provides the client with all essential documentation, including engineering stamps, permits, and warranty information, for their records.

Conclusion: Building Your Future, Without Building a New Warehouse

The question facing warehouse operators today is no longer if they will need more space, but how they will acquire it in the most intelligent, strategic, and cost-effective manner possible. The decision to maximize warehouse space without construction by investing in a racking supported mezzanine is a definitive declaration of operational excellence. It is a choice that favors agility over permanence, efficiency over waste, and innovation over tradition.

This approach allows businesses to bypass the capital drain and monumental disruption of construction, instead choosing a path that delivers immediate capacity gains, enhanced workflow flexibility, and a robust platform for the integration of future automation technologies. In harnessing the unused cubic volume of their facilities, leaders can build a smarter, more responsive, and more competitive operation. The blueprint for the future of warehousing isn’t found on a new plot of land; it’s engineered overhead, within the powerful framework of a racking supported mezzanine.

Frequently Asked Questions (FAQs)

Q1: How does the cost of a racking supported mezzanine compare to building a new warehouse addition?

A: The cost differential is typically significant and favors the racking supported mezzanine. While exact figures vary, a traditional construction project involves costs for architecture, engineering, foundation work, materials, labor, and permits, often running into millions of dollars. A racking supported mezzanine project bypasses most of these, offering a solution that is generally a fraction of the cost per square foot of gained space. Furthermore, the dramatically shorter timeline means the return on investment is realized much quicker due to minimal operational downtime.

Q2: Can an existing pallet racking system be used to support a new mezzanine, or does it require new racking?

A: This is determined entirely by a professional structural analysis. While it is sometimes possible to reinforce existing racking to support a racking supported mezzanine, it is often more efficient and structurally sound to install new, purpose-built racking designed from the outset to handle the combined loads of storage and the mezzanine structure. The upright frames, beams, and footplates for a racking supported mezzanine are typically heavier-gauge and engineered to specific criteria that standard storage racking may not meet.

Q3: What are the different types of decking available for a racking supported mezzanine, and how do I choose?

A: The choice of decking is critical and depends on the application. The most common options are:

Steel Bar Grating: Offers excellent durability, fire resistance, and allows light and sprinkler water to pass through. Ideal for areas requiring ventilation and where debris falling through is not a concern.

Particle Board (OSB/MDF) over Steel Supports: Provides a solid, smooth surface that is easy to walk on and prevents small items from falling. Often topped with a durable sealant or epoxy coating.

Bolidt Flooring / Sealed Steel Plate: A premium, extremely durable and sealed surface, perfect for clean rooms, food-grade environments, or areas where a completely solid deck is required.

The choice hinges on the intended use, load requirements, fire code, and budget.

Q4: How does the installation process for a rack-supported mezzanine impact daily warehouse operations?

A: A key advantage of a racking supported mezzanine is the ability to plan a phased installation that minimizes disruption. Professional installers will sequence the work to occur in specific zones or aisles, allowing the rest of the warehouse to continue operating. While there will be some temporary disruption in the immediate work area—such as noise and the need to relocate inventory—a complete shutdown of operations is almost never necessary. Detailed pre-planning is essential to ensure a smooth process.

Q5: What kind of maintenance does a racking supported mezzanine require after installation?

A: Maintenance requirements are generally minimal but crucial for long-term safety and integrity. A regular inspection schedule should be established, consistent with the facility’s racking inspection program. This includes checking for:

Structural Integrity: Ensuring all bolts and connections remain tight.

Decking Condition: Looking for signs of wear, damage, or deflection.

Racking Uprights: Inspecting for any impacts from material handling equipment.

Safety Features: Ensuring guardrails, gates, and stairways remain secure and undamaged.

Maintenance is largely preventative and focuses on visual inspections and ensuring the structure remains in its original, engineered state.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com