📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Introduction: Why Push Back Racking Systems Are Revolutionizing Warehousing

In an era where warehouse space is at a premium, push back racking systems have emerged as a game-changing solution for businesses looking to maximize storage density without sacrificing operational efficiency. Unlike traditional selective pallet racking, push back racking systems allow multiple pallets to be stored in a single lane, dramatically reducing aisle space while maintaining quick access to inventory.

This in-depth guide explores every aspect of push back racking systems, from their mechanics and benefits to real-world applications and cost considerations. Warehouse managers, logistics professionals, and business owners will discover why push back racking systems are becoming the preferred choice for high-density storage—and how they can be implemented for maximum efficiency.

How Push Back Racking Systems Work: A Deep Dive into the Mechanics

The Science Behind Push Back Racking Systems

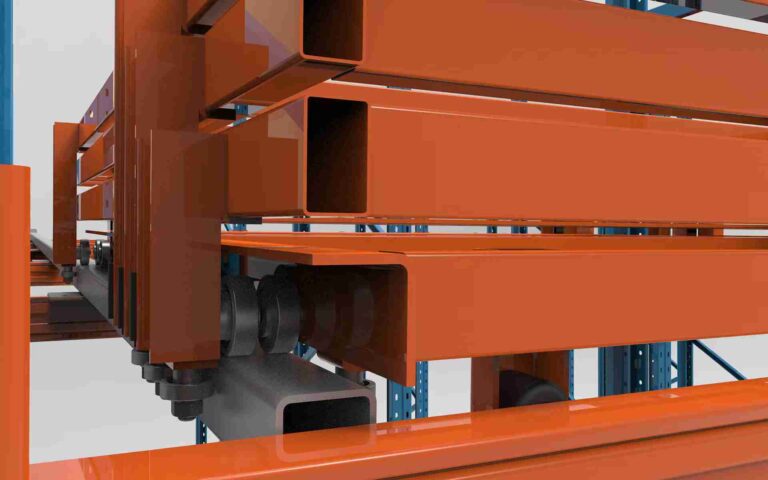

Push back racking systems operate on a Last-In, First-Out (LIFO) principle, making them ideal for businesses that manage inventory with similar expiration dates or production cycles. The system consists of wheeled carts that glide along inclined rails, allowing pallets to be stored 2-5 deep per lane.

- Cart & Rail Mechanism: Each lane is equipped with multiple carts that move smoothly on inclined rails, ensuring seamless pallet movement.

- Loading Process: When a new pallet is loaded, it pushes the existing pallets backward, creating a dynamic storage lane.

- Retrieval Process: As pallets are removed, the remaining ones automatically roll forward, eliminating the need for forklifts to enter the lane.

This innovative design makes push back racking systems one of the most efficient high-density storage solutions available.

Key Benefits of Push Back Racking Systems

1. Unmatched Storage Density

Push back racking systems can store up to 5 pallets deep per lane, significantly increasing storage capacity compared to selective racking.

2. Optimized Space Utilization

By utilizing depth instead of width, warehouses can store more inventory in the same footprint, reducing the need for costly expansions.

3. Faster Loading & Retrieval Times

Since pallets automatically reposition after each pick, forklift operators spend less time navigating aisles, leading to higher productivity.

4. Enhanced Inventory Control

The LIFO access method makes push back racking systems perfect for industries like food & beverage, pharmaceuticals, and retail, where batch management is crucial.

5. Lower Risk of Damage & Maintenance Costs

Unlike drive-in racking, push back racking systems eliminate the need for forklifts to enter storage lanes, reducing the risk of collisions and rack damage.

Ideal Applications for Push Back Racking Systems

Top Industries That Benefit from Push Back Racking Systems

- Food & Beverage: Ideal for managing perishable goods with expiration dates.

- Pharmaceuticals & Healthcare: Ensures efficient batch rotation for medicines and medical supplies.

- Retail & E-Commerce: Maximizes storage for high-turnover SKUs.

- Manufacturing & Automotive: Perfect for storing raw materials and components.

When to Choose Push Back Racking Systems Over Alternatives

- When space optimization is a top priority.

- When quick access to multiple SKUs is required.

- When pallet quantities per SKU are moderate (not extremely high or low).

Push Back Racking Systems vs. Other High-Density Storage Solutions

Push Back Racking Systems vs. Drive-In Racking

| Feature | Push Back Racking Systems | Drive-In Racking |

|---|---|---|

| Access Method | LIFO | LIFO/FIFO |

| Forklift Entry Required? | No | Yes |

| Storage Depth | 2-5 pallets deep | 5+ pallets deep |

| Damage Risk | Lower | Higher |

Push Back Racking Systems vs. Pallet Flow Racking

- Pallet flow racking uses gravity rollers for FIFO access, while push back racking systems operate on a LIFO basis.

- Flow racking is better for high-volume single-SKU storage, whereas push back racking systems excel in multi-SKU environments.

Design & Configuration Tips for Push Back Racking Systems

1. Optimal Lane Depth for Maximum Efficiency

- 2-5 pallet depths are the most common configurations.

- Deeper lanes increase storage but may reduce accessibility.

2. Load Capacity & Structural Integrity

- Standard push back racking systems support 1,500–3,000 lbs per pallet.

- Heavy-duty options are available for industrial and automotive applications.

3. Aisle Width & Forklift Compatibility

- Requires narrower aisles than selective racking.

- Works seamlessly with standard forklifts, eliminating the need for specialized equipment.

Installation & Maintenance Best Practices for Push Back Racking Systems

Proper Installation Guidelines

- Ensure level flooring to prevent cart misalignment.

- Follow manufacturer specifications for rail spacing and beam heights.

Maintenance Tips to Extend Lifespan

- Regularly inspect carts and rails for wear and tear.

- Lubricate rails periodically to ensure smooth pallet movement.

Cost Analysis: Are Push Back Racking Systems Worth the Investment?

Initial Costs vs. Long-Term Savings

- Higher upfront cost than selective racking, but lower than fully automated systems.

- ROI is achieved through space savings and reduced labor costs.

Factors That Influence Pricing

- Number of lanes and storage depth.

- Material quality (standard steel vs. reinforced designs).

Future Trends: How Push Back Racking Systems Are Evolving

Integration with Warehouse Automation

- Automated guided vehicles (AGVs) can now work in tandem with push back racking systems.

- RFID and IoT tracking enhance inventory visibility.

Sustainability & Eco-Friendly Innovations

- Recycled materials are being used in rack construction.

- Energy-efficient warehouse designs are incorporating push back racking systems to reduce carbon footprints.

Conclusion: Why Push Back Racking Systems Are the Future of Warehousing

Push back racking systems represent the perfect balance between high-density storage and operational efficiency. By minimizing aisle space, speeding up load retrieval, and improving inventory management, they are an ideal solution for modern warehouses.

Whether managing perishable goods, retail inventory, or industrial components, push back racking systems deliver unmatched efficiency and cost savings. For businesses looking to optimize storage without compromising accessibility, push back racking systems should be the top consideration.

Frequently Asked Questions (FAQs)

1. Can push back racking systems be used for FIFO inventory management?

No, push back racking systems operate on a LIFO basis. For FIFO, pallet flow racking is a better choice.

2. What is the maximum weight capacity for push back racking systems?

Most push back racking systems support 1,500–3,000 lbs per pallet, with heavy-duty options available.

3. How much space can push back racking systems save compared to selective racking?

They can reduce aisle space by up to 50%, depending on configuration.

4. Are push back racking systems compatible with automated forklifts?

Yes, AGVs and semi-automated forklifts can efficiently operate with push back racking systems.

5. What is the typical lifespan of push back racking systems?

With proper maintenance, push back racking systems can last 15–20 years or more.