📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Strategic Advantage of Push-Back Racking

In the relentless pursuit of warehouse efficiency, the conflict between maximizing storage density and maintaining selective access to inventory is a constant challenge. Traditional selective racking offers accessibility but wastes valuable air space. Drive-in systems offer density but sacrifice selectivity and can create significant operational bottlenecks. For operations requiring high-density storage for multiple SKUs with good selectivity, push-back racking system emerges as the premier, ROI-driven solution. This definitive guide delves into the engineering, financial, and operational nuances of push-back racking system.

The analysis will explore how its unique Last-In, First-Out (LIFO) design directly translates into tangible business outcomes: a dramatic reduction in your cost per pallet position, a significant increase in storage capacity within the same footprint, and a measurable acceleration in pallet put-away and retrieval cycles. By understanding the precise mechanics, cost-benefit analysis, and ideal application scenarios, logistics managers will be equipped to determine if a push-back racking system is the strategic key to unlocking a warehouse’s full potential and achieving a compelling return on investment.

The Warehouse Dilemma: Density vs. Selectivity

Every warehouse manager and logistics director faces a fundamental, space-constrained trade-off. On one end of the spectrum, selective pallet racking provides direct, immediate access to every single pallet. This is fantastic for throughput speed but terribly inefficient in its use of cubic space—it essentially leaves a goldmine of storage potential hovering above the aisles, unused. On the opposite end, drive-in racking maximizes density by turning entire rows into storage, eliminating the need for multiple aisles. However, it operates on a First-In, Last-Out (FILO) basis.

To retrieve a specific pallet, operators might have to move a dozen others. It’s slow, creates high risk of product damage and forklift abuse, and is only suitable for bulk storage of identical products. So, the dilemma is stark: should a operation choose accessibility or density? This is precisely where a push-back racking system shines, offering a sophisticated middle ground. It masterfully blends high-density storage with a high degree of selectivity, making this specific push-back racking system an ideal solution for multi-SKU environments with medium to high turnover rates. The value proposition of a push-back racking system lies in its ability to resolve this core conflict.

How Push-Back Racking Systems Work: A Mechanical Deep Dive

Understanding the elegant mechanics of a push-back racking system is key to appreciating its value proposition. Unlike static racking, a push-back racking system is a dynamic system where the storage structure itself facilitates movement. The fundamental principle behind every push-back racking system is gravity, allowing it to function without complex motors or energy consumption.

The Core Components: More Than Just Beams and Uprights

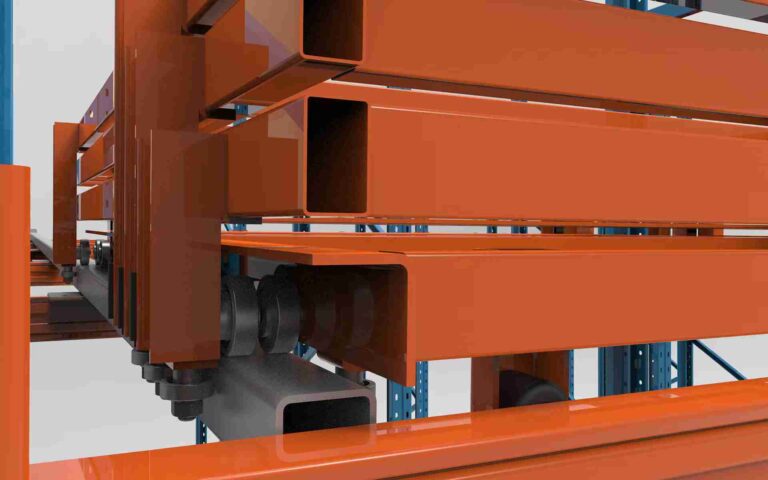

A typical bay in a push-back racking system consists of several integral parts that differentiate it from other storage solutions. Structural Upright Frames form the robust, vertical backbone of the push-back racking system, engineered to handle both significant static loads and the dynamic forces exerted during the loading process. Inclined Rails are installed on each level of the push-back racking system; these steeply angled rails are the heart of the gravity-fed design, enabling the smooth movement of pallets.

Nestable Carts are the wheeled carriages that sit on the inclined rails within the push-back racking system; each cart holds one pallet and is designed to nest compactly with others at the front of the bay. A Starter Pallet or skid is placed at the very back of the rail system to initiate the cart movement within that level of the push-back racking system.

The LIFO Operation in Action

The push-back racking system operates on a Last-In, First-Out (LIFO) principle, which is perfectly suited for storing products with high turnover or where batch sequencing is not critical. The loading process for a push-back racking system begins when a forklift operator places the first pallet onto the carts at the front of the bay. When the next pallet is loaded into the push-back racking system, the forklift gently pushes the first pallet back. The force of the new pallet pushes the nested carts, with their pallets, backward and upward along the inclined rails.

This process continues until the bay in the push-back racking system is full, with each level typically holding 2-5 pallets deep. The unloading process highlights the efficiency of the push-back racking system; the forklift simply removes the front pallet. Immediately, due to gravity, the next pallet on the nested carts behind it smoothly rolls down the inclined rails to the front “pick-up” position. This elegant, gravity-powered mechanism of the push-back racking system eliminates the need for complex automation or manual labor to manage the depth of the storage row.

Quantifying the ROI: A Detailed Cost-Benefit Analysis

Investing in any warehouse infrastructure demands a clear financial justification. The ROI of a push-back racking system is realized through both capital and operational savings, making the business case for a push-back racking system compelling for the right operation.

Capital Savings: Reducing Your Cost Per Pallet Position

The most immediate and calculable benefit of a push-back racking system is the drastic reduction in the cost per pallet position. By storing pallets 2 to 5 deep, a push-back racking system dramatically decreases the number of upright frames and floor anchors required per stored pallet. While the carts and rails represent an additional cost over selective racking, the net effect of implementing a push-back racking system is a significantly lower cost per pallet when factoring in the total storage capacity gained within the same square footage.

A company implementing a push-back racking system is essentially generating more storage capacity from its existing real estate or requiring a smaller building for the same volume, which has massive implications for property costs. The financial advantage of a push-back racking system is clear when analyzing the total storage volume achieved.

Operational Savings: Boosting Productivity and Safety

The financial benefits of a push-back racking system extend far beyond the initial hardware investment. Increased Forklift Productivity is a major gain; operators at a facility with a push-back racking system spend their time loading and unloading, not maneuvering in cramped aisles or relocating pallets to access others. Each trip to a bay in the push-back racking system results in multiple pallets being handled with minimal travel, potentially increasing operator productivity by 20% or more. Reduced Labor Costs are a direct result of the push-back racking system; higher throughput per operator hour means a warehouse can handle more volume with the same team or avoid costly overtime during peak periods.

Lower Energy Costs are realized because a push-back racking system narrows or eliminates aisles, reducing the lighting and climate control requirements for a significant portion of the warehouse floor. Minimized Product and Equipment Damage is a critical benefit; the controlled, guided movement of pallets within the push-back racking system drastically reduces the risk of forklifts striking uprights or pallets being knocked off beams.

This leads to lower damage rates for both inventory and material handling equipment, reducing maintenance and write-off costs. Enhanced Safety is a fundamental feature of a well-planned push-back racking system; with fewer and wider aisles required compared to a dense selective layout, traffic congestion is reduced. The systematic load/unload process also creates a more predictable workflow, reducing the chance of accidents.

Ideal Applications: Is Push-Back Racking Right For You?

A push-back racking system is a powerful tool, but it’s not a universal panacea. Its performance is maximized in specific scenarios. High-Density Needs with Good Selectivity make a push-back racking system perfect for warehouses where space is at an absolute premium, but faster access than drive-in can provide is still required. Multiple SKUs with Medium to High Turnover make a push-back racking system an excellent solution for batch picking or storing fast-moving consumer goods (FMCG), where products are restocked and shipped out in high volumes.

The LIFO system of a push-back racking system is ideal for this flow. Cold Storage Facilities greatly benefit from a push-back racking system; the high-density nature is exceptionally valuable in cold storage and freezer warehouses, where every cubic foot is incredibly expensive to cool. Minimizing space directly minimizes enormous energy costs, making the push-back racking system a strategic investment. Beverage and Food Distribution centers often find a push-back racking system ideal; these industries often have a large number of SKUs with high turnover, making a push-back racking system a perfect candidate for organizing products before they are moved to a forward picking area.

Less suitable applications for a push-back racking system include environments requiring strict FIFO (First-In, First-Out) inventory control (e.g., for perishable goods where date coding is critical) or for extremely slow-moving products where the capital investment may be harder to justify. A thorough analysis of SKU velocity and inventory rules is essential before choosing a push-back racking system.

Push-Back vs. Other High-Density Storage Solutions

To make an informed decision, it’s crucial to compare a push-back racking system to its alternatives. Each high-density solution has its place, and understanding the differences is key to selecting the right push-back racking system for a specific need.

Push-Back vs. Drive-In/Drive-Through Racking

The comparison between a push-back racking system and drive-in racking is a common one. Selectivity is a major differentiator; a push-back racking system offers far better selectivity. Operators can access any pallet at the front of its level without moving others. Drive-in requires moving multiple pallets to access a specific one deep in the lane. Speed is another factor; unloading is significantly faster with a push-back racking system as the next pallet is presented automatically by gravity.

Damage Risk is lower with a push-back racking system; the guided rails greatly reduce the risk of forklifts damaging the rack structure compared to the delicate maneuvering required deep inside a drive-in bay. However, FIFO Capability is a advantage for drive-through racking (with entry and exit on opposite ends), which can offer FIFO, a feature a standard push-back racking system cannot provide.

Push-Back vs. Pallet Flow Racking

Comparing a push-back racking system to pallet flow reveals different operational philosophies. Cost is a primary difference; pallet flow systems use wheels or rollers on a much steeper grade and require a complex braking system. This makes them generally more expensive than a push-back racking system. FIFO is a key advantage of flow systems; pallet flow is inherently a FIFO system, making it the superior choice for perishable inventory, whereas a push-back racking system is strictly LIFO. Maintenance requirements also differ; the mechanical components of a flow system can be more complex and require more specific maintenance than the simpler cart-and-rail design of a push-back racking system.

Push-Back vs. Mobile Pallet Racking

The choice between a push-back racking system and mobile racking depends on the priority between density and speed. Density is the winning point for mobile racking; it can achieve the absolute highest density by eliminating all but one aisle. However, it is slow—aisles must be opened and closed mechanically before access is possible. Access Speed is where a push-back racking system excels; it provides instantaneous access without any waiting for racks to move. Cost and Complexity are also higher for mobile systems; they are typically the most expensive option due to the required base rails, moving mechanisms, and safety systems, while a push-back racking system offers a more straightforward and often more cost-effective high-density solution.

Design and Implementation Considerations

Successfully deploying a push-back racking system requires careful planning and expert design. Cutting corners during this phase can undermine the entire investment in a push-back racking system.

Structural Integrity is the foremost consideration; the push-back racking system must be engineered for the specific loads and the dynamic forces exerted during the push-back operation. This includes considering the weight of the pallets, the carts, and the impact of the initial push. Professional engineering analysis is non-negotiable for a safe and effective push-back racking system.

Floor Condition and Flatness is a critical but often overlooked factor. The performance of the push-back racking system relies on the forklift operator being able to make a smooth, straight push. Uneven or poorly maintained floors can cause carts to bind or derail, leading to operational headaches and potential damage to the push-back racking system.

Forklift Operator Training is essential for a smooth operation. While simple, the loading technique for a push-back racking system is different from standard racking. Operators must be trained to approach the bay straight on and apply consistent, controlled force to push the entire nested row back smoothly. Proper training maximizes the efficiency and lifespan of the push-back racking system.

Professional Installation is the final key to success. Precision during the installation of a push-back racking system is non-negotiable. Rails must be aligned perfectly, and structures must be plumb and securely anchored to the floor to ensure smooth and reliable operation for years to come. An experienced installer familiar with the nuances of a push-back racking system is a invaluable partner.

Maximizing the Value of Your Push-Back System

To ensure a company gets the maximum return on its investment in a push-back racking system, adherence to industry best practices is essential.

Professional Consultation and Design is the first and most important step. Engaging with a seasoned storage solutions provider who can perform a detailed analysis of inventory profile, turnover rates, and workflow is crucial to designing a push-back racking system that is perfectly tailored to specific needs. A one-size-fits-all approach does not work for a push-back racking system.

Quality Matters immensely. Not all push-back racking system components are created equal. Investing in high-quality components—from the structural steel to the engineering of the carts and rails—is paramount. The durability and smooth operation of the push-back racking system over a 20+ year lifespan depend on the quality of its parts.

Warehouse Management System (WMS) Integration is a force multiplier. Ensuring the WMS can effectively manage the LIFO inventory within the push-back lanes of the push-back racking system is vital. Proper system integration provides accurate, real-time visibility into what is stored in each location, preventing errors and maximizing the efficiency of the push-back racking system.

Regular Maintenance Inspections protect the investment. Implementing a scheduled inspection routine to check for worn cart wheels, rail alignment, and structural integrity of the push-back racking system is a best practice. Preventive maintenance on a push-back racking system is far cheaper than emergency repairs or operational downtime.

The Future of High-Density Storage: Beyond Traditional Push-Back

The evolution of push-back racking system technology continues to align with broader trends in warehouse automation. The core principle of the gravity-assisted, high-density storage remains, but the execution is becoming smarter. We are now seeing the integration of hybrid systems that combine the density of a push-back racking system with the precision of automation. For example, some advanced push-back racking system designs can be paired with semi-automated forklifts or guided vehicles that are programmed to execute the perfect push movement every time, further optimizing speed and reducing the potential for human error.

This evolution ensures the push-back racking system remains a relevant and highly effective component in the broader automated storage and retrieval system (AS/RS) ecosystem. The future push-back racking system may include embedded sensors to provide real-time data on inventory levels within each lane, further bridging the gap between dense storage and digital visibility.

Conclusion: A Strategic Investment in Warehouse Efficiency

In the continuous effort to optimize logistics operations, the choice of storage infrastructure is foundational. For companies looking to break free from the false choice between density and selectivity, a well-designed push-back racking system presents a proven, high-ROI strategy. By delivering significant gains in storage capacity, forklift productivity, and operational safety, all while lowering the overall cost per pallet, a push-back racking system pays for itself many times over throughout its long service life. It is not merely a purchase of equipment; it is an investment in the future efficiency and scalability of an entire warehouse operation.

If an inventory profile aligns with its strengths, implementing a robust push-back racking system is one of the most impactful decisions a logistics manager can make to truly maximize storage and minimize costs. The push-back racking system stands as a testament to intelligent, gravity-powered design solving modern logistical challenges.

*

Frequently Asked Questions (FAQs)

1. What is the typical lifespan of a push-back racking system?

With proper installation, high-quality materials, and a consistent preventive maintenance program, a push-back racking system can have a functional lifespan of 20 to 25 years or more. The structural frames are incredibly durable, and wear parts like cart wheels can be replaced individually to extend the life of the system indefinitely.

2. Can push-back racking be reconfigured if our needs change?

Yes, one of the advantages of push-back systems is their modularity. While more complex to reconfigure than selective racking, it is entirely possible. Levels can be added or removed, and bays can be extended or shortened by a qualified professional. This flexibility allows your storage system to evolve alongside your business.

3. How does the weight capacity of a push-back system compare to selective racking?

The dynamic nature of the system means that weight capacities are carefully engineered for each specific configuration and depth. While individual beam capacities can be very high, the overall load on the upright frames is a critical design factor. Generally, you can expect high weight capacities comparable to heavy-duty selective racking, but this must be evaluated by an engineer based on your specific loads and layout.

4. Are there any specific forklift requirements for operating a push-back system?

You need a standard counterbalance forklift. The key requirements are adequate power to initiate the push of a fully loaded lane and, most importantly, a skilled operator who can approach the bay straight and apply force evenly. Using a forklift with excessive power without proper training can risk damaging the system.

5. How do we handle product recalls in a LIFO system?

This requires disciplined warehouse management. If a product in the middle of a lane needs to be recalled, you would need to unload all the pallets in front of it in that specific lane to gain access. This underscores the importance of slotting products with similar turnover and characteristics together and of having a WMS that provides precise location tracking to manage such situations efficiently.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com