📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

For warehouse and operations managers facing relentless pressure to maximize space and streamline workflows, the question of storage investment is paramount. The inquiry into **push back racking system cost** is rarely just about the initial price tag; it is a fundamental question of value and long-term operational strategy. This comprehensive analysis moves beyond superficial price lists to deliver a granular, expert-driven breakdown of the variables that define a **push back racking system cost** and, more importantly, the substantial return on investment this technology delivers. We will dissect the multi-faceted components that constitute the final project price, from structural engineering and high-quality hardware to the critical value of professional installation and design.

Furthermore, this guide translates these capital expenditures into tangible business outcomes—calculating the undeniable value of dramatically increased storage density, significantly reduced labor expenses, enhanced inventory integrity, and improved workplace safety. By synthesizing deep industry expertise with practical financial modeling, this resource provides the framework to build a compelling, data-driven business case. The goal is to transform the conversation from a simple inquiry about **push back racking system cost** into a confident strategic decision, empowering you to determine if this solution is the key to unlocking your warehouse’s full potential and securing a durable competitive advantage.

## **Decoding the True Cost Structure of a Push Back Racking System Cost**

A professional quotation for a push back system is a complex document that reflects a symphony of engineering, material science, and logistical planning. To truly understand the **push back racking system cost**, one must appreciate that it is not a commodity purchase but a capital investment in a precision storage engine. A reputable provider doesn’t just sell racking; they engineer a solution tailored to your specific operational DNA, and the **push back racking system cost** reflects this bespoke approach. Understanding these cost components is the first step toward an accurate assessment and a successful implementation.

### **Core Hardware and Structural Components: The Foundation of Your Investment**

The physical system itself constitutes the most substantial portion of your capital outlay. The quality of materials and engineering here directly dictates system longevity, safety, and performance, making it a critical factor in the overall **push back racking system cost**.

Frame Capacity and Upright Design:** The heart of the system. Costs escalate directly with the required load capacity per level. A frame rated for 5,000 lbs per beam level is fundamentally different in steel gauge, column profile, and structural integrity from one rated for 12,000 lbs or more. The engineering behind the upright, including its bolt-hole patterns and the robustness of its footplate, are not just details; they are insurance policies against failure and are core to a justified **push back racking system cost.

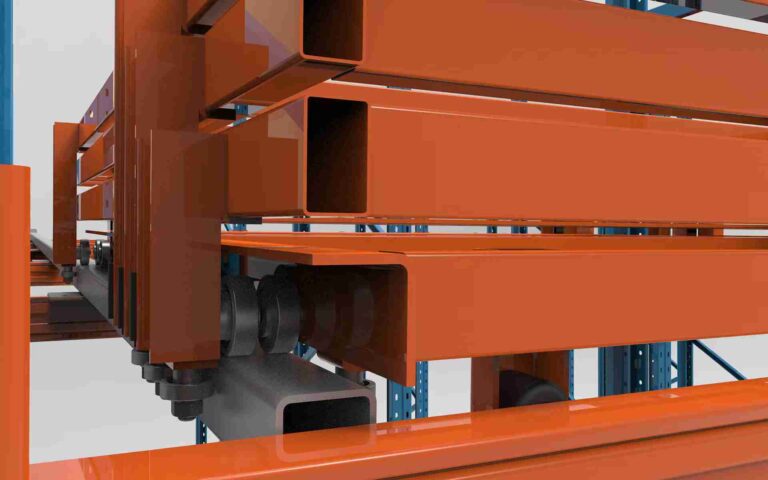

Beams and Roller Carriages:** The functional engine of the push back system. The **push back racking system cost** is heavily influenced by beam capacity, length, and, most critically, the quality of the roller carriage assembly. Precision-engineered carriages with commercial-grade bearings, hardened wheels, and a robust powder-coat finish ensure smooth, reliable operation and long service life, reducing maintenance costs and protecting your inventory—a value that far outweighs a minor upfront saving on inferior components.

Push Back Carts and Rails:** These are the moving parts that bear the direct load and are the defining elements of the system. The gauge and grade of steel used in the cart construction, the number of wheels per cart, and the precision of the guiding system are critical differentiators that impact the **push back racking system cost**.

Higher-quality carts minimize wobble, reduce friction, and ensure consistent performance, directly protecting your valuable inventory and forklift equipment from damage.

* **Structural Decking:** While not always required, many operations opt for steel or wire mesh decking to enhance safety and support non-palletized or smaller items. The type, gauge, and material of this decking add a variable component to the overall material **push back racking system cost**.

### **The Critical, Often Underestimated, Cost of Professional Installation**

A push back racking system is a precision assembly, not a simple kit. Its performance and safety are entirely dependent on correct installation. Therefore, the professional installation portion of the **push back racking system cost** is not a place to seek cuts; it is an investment in certainty and safety.

* **Labor Intensity and Expertise:** Push back systems are significantly more complex to install than selective pallet racking. They require a highly skilled, certified crew that understands precise leveling, laser alignment, and the intricate assembly of the cart and rail system. This level of expertise commands a premium that is a non-negotiable part of a realistic **push back racking system cost** projection.

Site Preparation and Operational Downtime:** Installation typically requires a clear warehouse floor. This often necessitates operational shutdowns or the temporary and costly relocation of inventory. The duration of the install, and thus its impact on the total **push back racking system cost**, is directly impacted by the size of the system, the accessibility of your facility, and the preparedness of the site.

* **Certification and Compliance:** Upon completion, a reputable installer will provide a structural engineering certification, ensuring the system meets all relevant safety standards (OSHA, RMI). This documentation is a critical deliverable and is factored into the **push back racking system cost**, providing legal and operational peace of mind.

### **Beyond the Hardware: The Soft Costs That Ensure Success**

The most accurate and comprehensive quotes for **push back racking system cost** encompass more than just materials and labor. They include the essential professional services that transform a collection of components into a high-performing operational asset.

* **Professional Warehouse Layout and Design Software:** This is where superior partners separate themselves. Using advanced software like AutoCAD or specialized warehouse simulation tools, systems engineers can create an optimized layout that maximizes your cube utilization, improves workflow, and integrates seamlessly with existing operations. This service, often included in a professional project bid, represents significant value and is a key part of the planning **push back racking system cost**.

Dedicated Project Management:** A single point of contact oversees the entire process—from finalizing design and coordinating manufacturing to scheduling the installation crew and ensuring timely delivery of all components. This coordination is invaluable for a smooth, on-budget, on-schedule project and is a vital line item in a fully realized **push back racking system cost** estimate.

* **Freight and Logistics:** Transporting multiple tons of steel and precision hardware from the manufacturing plant to your loading dock is a substantial and often volatile line item, influenced by fuel prices, geographic distance, and your facility’s accessibility for large freight vehicles. Any serious evaluation of **push back racking system cost** must include a detailed freight quote.

## **Quantifying the Return: How Push Back Racking Pays for Itself**

The **push back racking system cost** is a single data point in a much larger financial equation. The ROI is the narrative that justifies the investment. A push back system is not an expense; it is a capital investment in your operational efficiency with a measurable payback period. Here’s how it generates a compelling financial return that quickly offsets the initial **push back racking system cost**.

### **The Direct Financial Impact of Dramatically Increased Storage Density**

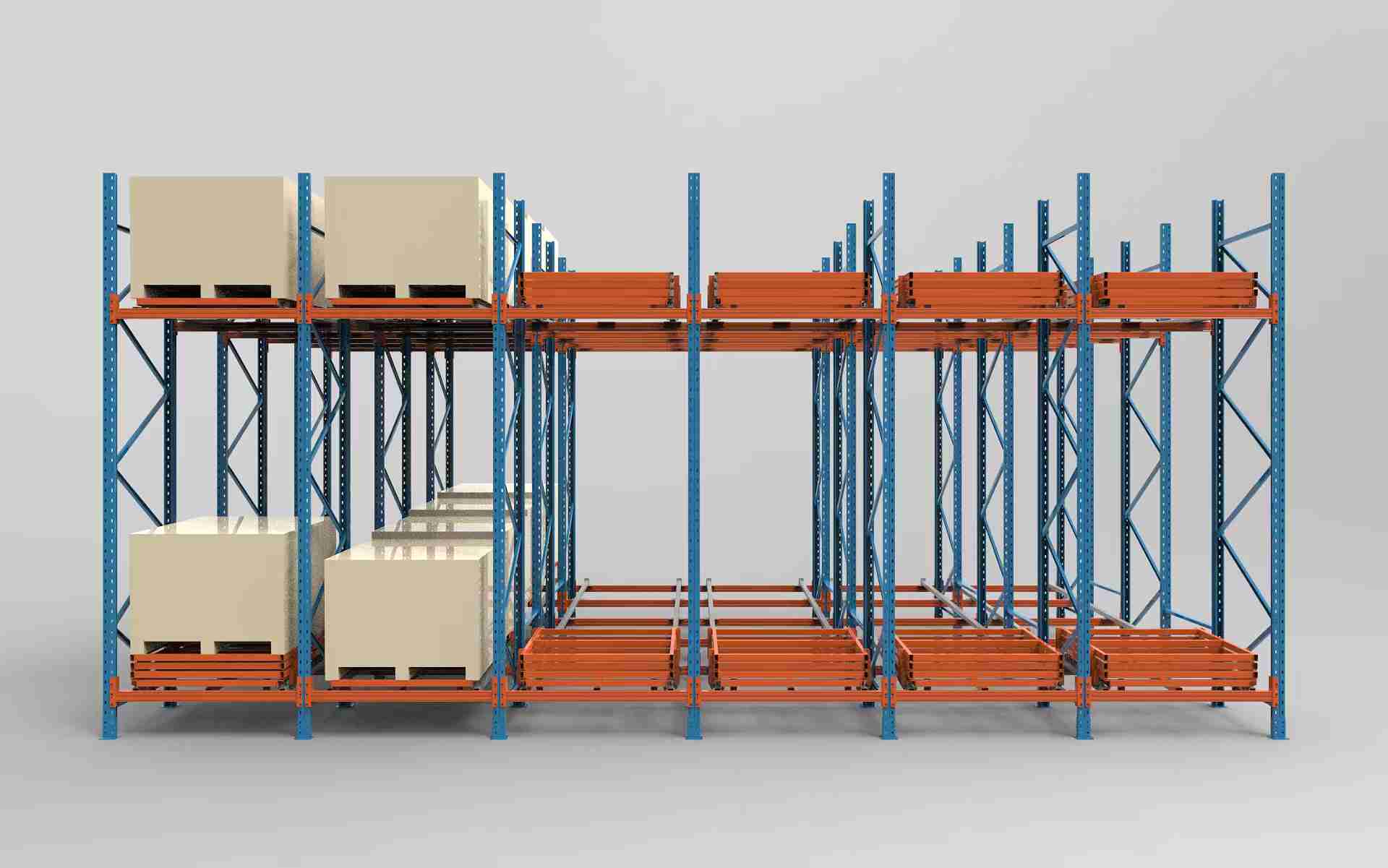

This is the most immediate and easily calculable benefit. By eliminating multiple aisles through its dynamic depth design, push back racking typically increases storage capacity by 50-75% compared to selective racking within the same building footprint. This density is the primary driver for justifying the **push back racking system cost**.

The “Avoided Cost” of Expansion:** For growing businesses, this massive gain in density can delay or even completely eliminate the need for a costly facility expansion or relocation. The ROI can be starkly calculated by comparing the total **push back racking system cost** to the annual lease or mortgage cost of the additional square footage you no longer need to rent. For instance, avoiding a 10,000 sq. ft. expansion at a conservative $7.50/sq. ft./year saves $75,000 annually. If your comprehensive **push back racking system cost** is $225,000, it achieves a full payback on this metric alone in just three years, after which it generates pure savings.

Utilizing Vertical Space:** These systems are engineered to build upward safely. By enabling deep-lane storage at significant height, you maximize the use of your cubic air space, which is often a massively underutilized asset. This vertical efficiency is a key multiplier in the value proposition against the **push back racking system cost**.

### **Labor Efficiency: Driving Down Your Largest Operational Expense**

Labor is consistently the single biggest ongoing cost in any warehouse. A push back system directly and aggressively reduces this expense through two primary mechanisms: the drastic reduction of non-value-added travel time and a significant increase in throughput per operator, directly counterbalancing the **push back racking system cost**.

* **Radical Reduction in Forklift Travel and Operator Fatigue:** With often 75% fewer aisles, forklift operators spend dramatically less time traveling to and from the picking face. This translates directly into more pallets moved per hour, less energy consumption (fuel or electricity), and reduced wear-and-tear on equipment. A less fatigued operator is also a safer, more focused, and more accurate operator, reducing costly errors. The annual savings from labor efficiency alone can be a substantial figure that quickly chips away at the **push back racking system cost**.

High-Throughput Operation with LIFO Inventory Management:** While a LIFO (Last-In, First-Out) flow isn’t ideal for all SKUs, it is perfectly suited for a vast range of applications like storing packaging materials, non-perishable ingredients, or products with long shelf lives. For these SKUs, push back allows for incredibly rapid loading and unloading from a single, consistent aisle position, streamlining operations and making the **push back racking system cost** a worthwhile investment in speed.

### **The Hidden Value of Improved Safety and Inventory Integrity**

While harder to quantify with absolute precision, the value of a safer and more secure warehouse is immense and contributes significantly to the long-term ROI, protecting your business from losses that are not factored into a simple **push back racking system cost**.

* **Elimination of Aisle Clutter and Congestion:** With no need to place pallets in the aisles for put-away or restocking, the warehouse floor remains clear of obstructions. This single factor drastically reduces the risk of forklift-to-forklift or forklift-to-infrastructure collisions, enhancing safety for all personnel.

Secure and Stable Load Storage:** The positive nesting of the carts and the guided, controlled movement of the pallets ensure loads are stored securely and retrieved smoothly. This engineering minimizes the risk of a pallet becoming dislodged and falling from height—a serious safety hazard and a potential catastrophe for inventory.

Reduced Product and Load Damage:** The smooth, rolling motion of the carts is inherently gentler on inventory than the repetitive maneuvering required to place and retrieve loads from deep within a selective racking bay. This preserves the value of your goods, reduces write-offs, and increases customer satisfaction. This protection of assets is an indirect but powerful financial return on the **push back racking system cost**.

## **Making the Strategic Decision: Is Push Back Racking Right For You?**

Push back is a powerful tool, but it’s not a universal panacea. Its ROI is highest for operations with specific characteristics. A deep understanding of your inventory profile is essential before committing to the **push back racking system cost**.

**Ideal Profile for Maximum ROI:**

* **High-SKU Count, High-Volume:** Operations with a large number of SKUs that require deep-lane storage (2-6 pallets deep) are perfect candidates. The system provides excellent density while maintaining good selectivity.

LIFO or Batch Inventory Management:** This is the ideal inventory flow for push back. Industries like food and beverage, manufacturing (storing raw materials), and certain bulk retail goods benefit enormously.

Facilities with Severe Space Constraints:** Where the cost of real estate is high, and every square foot must be optimized to its maximum potential. The **push back racking system cost** is quickly offset by the avoidance of costly expansion.

Operations Seeking a Balance:** It offers the perfect middle ground between the high density of drive-in racking and the full selectivity of pallet flow racking.

**Considerations and Alternatives:**

* **FIFO Requirement:** If you *must* have strict First-In, First-Out inventory rotation (e.g., for highly perishable goods), **pallet flow racking** (dynamic racking) is a more suitable, albeit often more expensive, alternative to consider alongside the **push back racking system cost**.

* **Ultra-High Density for Single SKUs:** For storing very high volumes of a single SKU, **drive-in racking** might offer greater density, albeit with significant trade-offs in selectivity, speed, and increased product damage risk.

* **Budget Constraints:** If capital is severely limited, **selective pallet racking** remains the most flexible and affordable entry point, though it forever sacrifices the density gains that justify the higher **push back racking system cost**.

## **Conclusion: An Investment in Competitive Advantage**

The dialogue around **push back racking system cost** must mature from a simple procurement question to a strategic financial analysis. The initial capital outlay, while substantial, is precisely that—an initial outlay. When viewed through the lens of total cost of ownership and annualized return on investment, the narrative shifts completely. This investment purchases critical capacity without the exorbitant cost of new construction, it funds efficiency through radically reduced labor overhead, and it builds operational resilience through a safer, more organized, and higher-throughput facility.

The paramount question for leadership is not merely “Can we afford this **push back racking system cost**?” but rather “Can we afford *not* to make this investment in our operational future and competitive edge?” By meticulously calculating the ROI based on your specific operational data, you transform this decision from a leap of faith into a calculated, justifiable, and powerful step toward securing a lasting advantage in the demanding world of logistics and supply chain management. The **push back racking system cost** is the price of entry, but the returns fund the future.

## **Frequently Asked Questions (FAQs)**

**1. How does the long-term maintenance cost of a push back system compare to selective racking over a 10-year period?**

While push back systems have moving parts (carts, wheels) that selective racking does not, high-quality systems are engineered for durability and minimal maintenance. Expect periodic visual inspections and cleaning of the carts and rails to remove debris. The maintenance cost is marginally higher than static racking but is dramatically offset by the savings in labor and space. Over a decade, the total cost of ownership, when factoring in the massive efficiency gains, is often lower than selective racking, making the initial **push back racking system cost** a wise long-term investment.

**2. Can push back racking be effectively integrated with our existing Warehouse Management System (WMS)?**

Absolutely. From a WMS perspective, a push back location is simply a unique storage address. A modern WMS can perfectly manage inventory within a push back system. The critical step is ensuring your WMS can be configured to handle the LIFO inventory logic automatically and that your warehouse staff is thoroughly trained on the specific put-away and retrieval processes required by the new layout. This integration is a software and training issue, not a hardware limitation of the **push back racking system cost**.

**3. What is a realistic lead time from order placement to final installation for a typical system?**

Lead times can vary based on global steel availability, manufacturer capacity, and project complexity. For a standard system, a realistic timeline is 10-16 weeks. This encompasses detailed engineering design, manufacturing of all custom components, shipping from the factory, and the scheduling of a certified installation crew. Larger, more complex projects may have longer timelines. Any credible provider will give you a detailed schedule upfront, which is a key part of planning for the **push back racking system cost**.

**4. Are there specific forklift requirements or modifications needed to operate a push back system?**

Yes, this is a crucial consideration. Operating a push back system requires a specialized forklift attachment called a “push-pull” attachment. This attachment clamps onto the pallet and uses a hydraulic plate to push the load off the forks onto the rails or pull it back onto the forks. If you don’t already have these attachments, they represent an additional capital cost beyond the **push back racking system cost**. Your existing forklifts must also have the correct capacity, mast height, and functionality to operate the attachment and service the highest storage levels safely.

**5. How does seismic engineering impact the design and cost for facilities in earthquake-prone zones?**

Seismic design is a critical engineering consideration that directly influences the **push back racking system cost**. In geographic zones with strict building codes (e.g., California, Japan, Chile), the structural design must account for seismic forces. This often requires heavier-gauge steel, additional bracing, and specific engineering analysis. Reputable manufacturers will design the system to meet or exceed the seismic requirements of your local building codes (IBC, CBC, etc.). This non-negotiable safety requirement is factored into the structural design and overall **push back racking system cost** from the outset.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com