📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

In today’s fast-paced logistics and warehousing environment, the relentless pressure to do more with less space is a constant challenge. Push back racking systems have emerged as a revolutionary storage solution, masterfully balancing the critical demands of high-density storage and exceptional selectivity. This comprehensive guide delves deep into the mechanics, benefits, and strategic implementation of push back pallet racking. We are a leading manufacturer and integrator of advanced storage solutions, and we will demonstrate how investing in a high-quality push back system doesn’t just organize your warehouse—it transforms it.

By significantly increasing storage density without sacrificing access to your inventory, you unlock unprecedented levels of efficiency and cost-effectiveness. This article provides the expert insight you need to determine if this system is the right fit for your operation and how to procure a solution that delivers a rapid and substantial return on investment. We invite you to read on, explore the potential, and ultimately, get a free quote tailored precisely to your facility’s unique requirements.

Understanding the Core Mechanics of Push Back Racking

Let’s move beyond the basic definition and understand what makes a push back rack system tick. It’s a marvel of simple physics and elegant engineering designed for real-world warehouse operations.

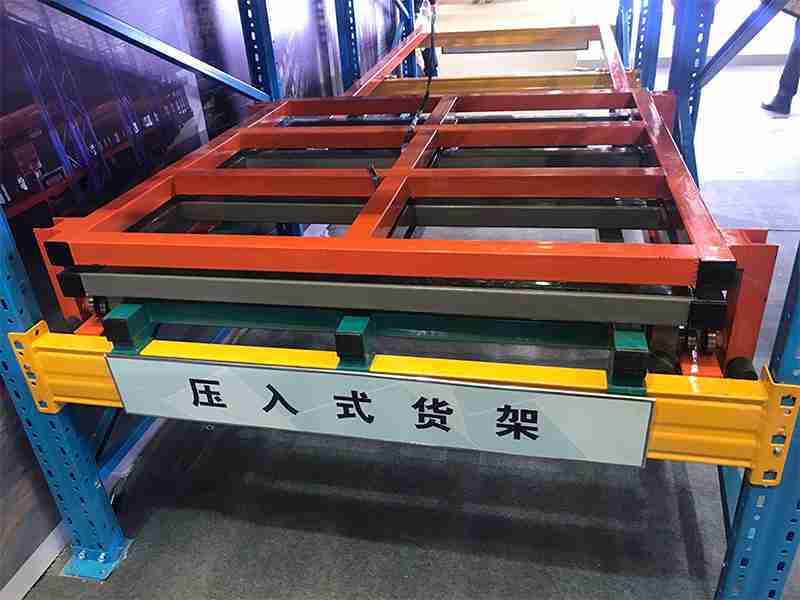

At its heart, a push back rack is a last-in, first-out (LIFO) storage system. Each bay consists of a series of inclined carts or rails that are nested at a slight angle, typically between 3 to 5 degrees. This gravity-assisted design is the key to its operation. Pallets are loaded from the front aisle onto the carts. When a new pallet is placed, it gently pushes the previously loaded pallet back one position along the rails. This process continues, with each new load pushing the existing loads further down the lane.

The magic happens during unloading. When the front-most pallet is removed by a forklift or an automated guided vehicle (AGV), the entire row of pallets behind it automatically shifts forward one position, brought gently into place by gravity. This dynamic movement means that, unlike drive-in racking, the forklift never enters the storage structure. The operator works solely from the safety and convenience of the front aisle, dramatically reducing the risk of product and rack damage and significantly speeding up load and unload times.

The system’s capacity and depth are configurable. Lanes can typically hold between 2 to 6 pallets deep, making it an ideal compromise between the ultra-high-density of pallet live storage (which is FIFO) and the simpler selectivity of selective pallet racking. For operations actively searching for a push back racking for sale, understanding this core LIFO principle is the first step in evaluating its suitability for their specific inventory challenges.

The Unbeatable Advantages: Why Push Back Racking is a Game-Changer

Why are so many distribution centers and manufacturing warehouses making the switch to push back systems? The advantages are tangible and directly impact your bottom line. Companies evaluating a push back racking for sale quickly realize it offers a unique value proposition that other systems struggle to match.

Exceptional Storage Density: This is the primary driver. By storing pallets multiple deep, you drastically reduce the number of aisles required compared to traditional selective racking. This means you can store more product in the same square footage or, conversely, require a smaller building to store the same amount of inventory, a major cost saving. The search for a push back racking for sale is often initiated by a need to solve a critical space crisis without the exorbitant cost of relocation.

High Selectivity and Accessibility: Unlike other high-density systems like drive-in or drive-through racking, push back offers excellent selectivity. Every single SKU stored in the system is accessible at all times without having to move other pallets. You aren’t forced to turn over an entire lane to access a single product. This is a critical advantage for warehouses with a large number of SKUs and a key reason why a push back racking for sale is a popular choice for diverse inventory profiles.

Operational Efficiency and Speed: The LIFO principle is perfectly suited for high-throughput environments where multiple pallets of the same SKU are received and shipped together. Loading and unloading are performed from a single, clear aisle, eliminating complex maneuvering and reducing cycle times. Operators can work faster and with less fatigue. This boost in productivity is a measurable ROI that justifies the investment in a quality push back racking for sale.

Enhanced Safety: The risk of accidents is considerably lower. Since the forklift operator never needs to enter the rack structure, the chances of colliding with upright frames or sprinkler heads are minimized. The design also promotes better visibility for the operator. For safety-conscious managers, this aspect is a major selling point for any push back racking for sale.

Reduced Product Damage: The smooth, controlled movement of the carts and the fact that forklifts don’t handle deep-stored pallets directly mean less opportunity for impact damage to both your inventory and your storage equipment. This protection of goods directly protects profit margins.

Space and Cost Efficiency: By maximizing your existing cube, you delay or avoid the enormous capital expense of relocating to a larger facility or adding onto your current building. You get more out of your current real estate investment. This long-term financial benefit is a core reason to consider a push back racking for sale as a strategic capital improvement.

Is Push Back Racking the Right Fit for Your Operation? A Strategic Evaluation

A push back racking for sale is powerful, but it’s not a universal panacea. Its effectiveness hinges on your specific inventory profile and operational flow. Here’s how to evaluate if it’s the right strategic choice for your warehouse. A thorough assessment is crucial before committing to any push back racking for sale purchase.

Ideal Use Cases:

High-Volume, Medium-Variety SKUs: It excels when you have a high quantity of a particular product but not so many that you need dedicated lanes for dozens of SKUs. Think of it as the perfect solution for 10-20 fast-moving SKUs. If this describes your inventory, a push back racking for sale is likely an excellent fit.

LIFO Inventory Management: If your product rotation follows a last-in, first-out flow (common in many industries like food and beverage, or where stock is not highly time-sensitive), it’s a natural fit. The inherent design of a push back racking for sale complements this workflow perfectly.

Seasonal Storage: For businesses with strong seasonal peaks, push back racking allows you to maximize space during your high-volume season without a permanent commitment to a dense system. A flexible push back racking for sale can be the ideal solution for managing these inventory fluctuations.

Build-to-Stock Manufacturing: Perfect for storing finished goods that are produced and shipped in large, predictable batches. The ability to store multiple pallets of the same product deep makes any push back racking for sale a valuable asset on the production floor.

Less Suitable For:

Strict FIFO Requirements: If your products have expiration dates or are highly time-sensitive (e.g., certain pharmaceuticals, fresh produce), the LIFO nature is a deal-breaker. In these cases, pallet live storage (flow rack) would be the appropriate high-density alternative. A push back racking for sale would be the wrong choice here.

Extremely High Variety, Low Volume: If you have thousands of SKUs and only one or two pallets of each, selective pallet racking remains the most efficient and accessible option. A push back racking for sale is designed for depth, not maximum SKU variety.

Extremely Heavy or Unusual Loads: While push back systems have high weight capacities, exceptionally heavy or non-standard pallet sizes may require a custom engineering review. Not every push back racking for sale is rated for ultra-heavy loads, so specifications must be carefully checked.

A thorough analysis of your SKU velocity (how fast items sell), cube (physical size), and inventory turnover ratio is essential before making a decision. This is where our free consultation and layout design service proves invaluable for anyone considering a push back racking for sale.

Critical Design and Engineering Considerations for Optimal Performance

You can’t just buy the first push back racking for sale you find online. Its performance and safety are a direct result of meticulous design and precision engineering. Here’s what industry experts factor into every system they quote for a push back racking for sale.

Structural Integrity and Load Capacity: Every component, from the heavy-duty structural upright frames to the specially engineered carts and rails, must be rated for your specific pallet weights. Engineers calculate the dynamic loads, not just the static ones, to ensure absolute safety and longevity. The integrity of the entire system offered in a push back racking for sale depends on the quality of these components.

The Incline Angle: The gravity-fed movement is governed by the angle of inclination. Too steep, and pallets may shift too violently. Too shallow, and they may not return to the front position reliably. Professional engineers calculate the perfect angle based on the weight of your loads and the coefficient of friction of the cart wheels. This is a detail often overlooked in low-quality push back racking for sale offerings.

Frame Depth and Lane Configuration: How deep should each lane be? This depends on your pallet size and the number of deep positions you require. A proper design ensures the frame perfectly accommodates your chosen lane depth without wasted space. This customization is a hallmark of a professional push back racking for sale provider.

Aisle Width: While push back requires fewer aisles, the remaining aisles must be wide enough for your material handling equipment to operate safely and efficiently. Designers factor in the turning radius of your forklifts or narrow aisle reach trucks to determine the optimal aisle width. This integration is a critical service that accompanies a professional push back racking for sale.

Integration with Other Systems: A push back system doesn’t exist in a vacuum. It must work in harmony with your bulk storage, your picking areas, and your automated conveyor systems. It should be designed as part of a holistic warehouse optimization strategy, not just as a standalone push back racking for sale.

Investing in a poorly designed system from a cut-rate push back racking for sale is a costly mistake. Three decades of experience ensure that a proper push back racking is not just a storage product, but a precision-engineered tool for growth.

The Quality Divide: Why Not All Push Back Systems Are Created Equal

The market is flooded with options for a push back racking for sale, but true quality—the kind that ensures safety, durability, and smooth operation for decades—is rare. Here’s what separates a superior push back racking for sale from a mediocre one.

Material Grade and Manufacturing: Leading manufacturers use only high-tensile strength steel that is roll-formed, not simply welded, for consistent strength and durability. The metallurgy matters; inferior steel can flex and fatigue over time, leading to premature failure. This is a key differentiator in a push back racking for sale.

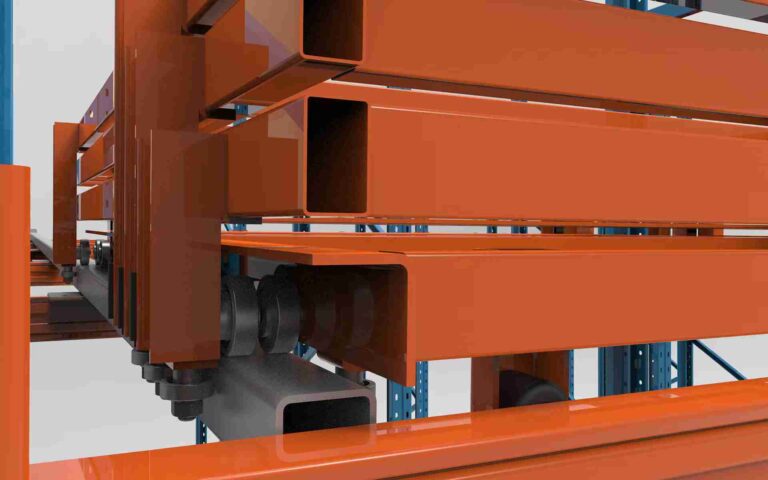

Cart and Wheel Engineering: This is the heart of the system. High-end carts feature reinforced designs with double-row, high-load bearing wheels made from industrial-grade polymers. These wheels are engineered for smooth, quiet rolling and exceptional resistance to wear and deformation, even under maximum load. Cheap systems often use simple, single-row wheels that can jam or fail. When evaluating a push back racking for sale, the cart design is the first place to look for quality.

Beam Design and Connectors: The beams must provide a perfectly level and secure track for the carts. Hot-rolled beams offer superior straightness and strength compared to cold-rolled alternatives. Safety-lock connectors ensure a rigid connection that won’t work loose from the constant vibration of pallet movement. The durability of these components defines the long-term value of a push back racking for sale.

Finish and Corrosion Resistance: A high-quality powder-coat finish is not just about aesthetics. It is a critical layer of protection against corrosion, scratches, and abrasion that can weaken metal over time. This is especially important in environments with any level of humidity or temperature fluctuation and is a sign of a premium push back racking for sale.

Safety Features: Look for integrated safety features like end-stop preventers that keep carts from being accidentally pushed out the back of the system, and guide rails that ensure pallets track correctly. These features are non-negotiable for a safe push back racking for sale.

Choosing a system based solely on the lowest price per pallet position is a false economy. The long-term operational costs, maintenance, and risk of downtime associated with a low-quality push back racking for sale will far outweigh the initial savings.

The Seamless Integration Process: From Concept to Operation

Implementing a new storage system from a push back racking for sale can be disruptive if not managed correctly. Leading providers have refined a seamless process that minimizes downtime and ensures a flawless installation.

Phase 1: In-Depth Consultation and Data Collection: It starts with a conversation. Experts learn about your business, your challenges, and your goals. They then conduct a detailed audit of your inventory, collecting data on SKU counts, pallet dimensions, weights, and turnover rates. This foundational step ensures the push back racking for sale is perfectly tailored.

Phase 2: Custom Layout Design and Engineering: Using advanced CAD and warehouse simulation software, engineers create a detailed 3D layout of your facility with the proposed push back system. This isn’t just a static image; it allows for the visualization of workflow, identification of potential bottlenecks, and optimization of the design before a single piece of steel is fabricated. This is the blueprint for your success and a critical value-add beyond a simple push back racking for sale.

Phase 3: Professional Installation: Certified installation teams are experts in their craft. They work efficiently and safely, following a precise project plan to install your new system from the push back racking for sale with minimal disruption to your ongoing operations. They handle all the details, from site preparation to final anchoring.

Phase 4: Comprehensive Training and Support: Reputable providers don’t just leave you with a new system. They provide thorough operational training for your forklift operators and warehouse managers, ensuring they understand how to use the system safely and to its full potential. This includes best practices for loading and unloading, maximizing the value of your push back racking for sale.

Phase 5: Ongoing Maintenance and Partnership: Many offer scheduled maintenance inspections to ensure your system from the push back racking for sale continues to perform like new for years to come. This establishes a long-term partnership in warehouse efficiency.

Push Back Racking in the Age of Automation: The Next Evolution

A modern push back racking for sale is not a relic of the past; it’s a key component of the automated warehouses of the future. Its simple, reliable mechanics make it ideally suited for integration with advanced material handling technologies.

AGV and AMR Integration: Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) can be programmed to interface perfectly with push back systems. The consistent, aisle-based operation is perfectly suited for robotic loading and unloading, creating a highly dense, lights-out storage zone. This automation-ready characteristic adds significant future value to any push back racking for sale.

Integration with Warehouse Management Systems (WMS): A modern WMS can perfectly manage the LIFO inventory within a push back system. It knows exactly which lane a pallet is in and its sequence, providing precise location data and ensuring accurate inventory rotation. This software integration is a key consideration for a high-tech push back racking for sale.

The Path to a Fully Automated Storage and Retrieval System (AS/RS): For companies looking to gradually automate, push back racking can be a strategic stepping stone. It introduces a higher level of density and system-based storage before making the larger investment into a fully automated AS/RS or vertical lift modules (VLMs). This scalability makes a push back racking for sale a smart, future-proof investment.

By choosing a push back system from a forward-thinking manufacturer, the push back racking for sale you purchase today is an investment that will continue to deliver value as your automation strategy evolves.

Calculating Your Return on Investment: The True Cost of Inefficiency

Justifying the capital expenditure for a push back racking for sale requires a clear financial model. The ROI on a high-quality push back racking system is compelling and multifaceted.

Real Estate Savings: This is often the largest saving. Calculate the cost per square foot of your warehouse space. By increasing storage density by 40-75% compared to selective racking, you are effectively “creating” new, valuable space without pouring a single concrete slab. The avoided cost of a facility expansion or move is a direct ROI that quickly offsets the cost of the push back racking for sale.

Labor Efficiency Gains: With faster load/unload cycles and reduced travel time between fewer aisles, your operators can do more in less time. This either reduces labor costs or allows you to handle increased throughput without adding more staff. The productivity gain is a continuous financial return on your push back racking for sale.

Reduced Product Damage: Assign a monetary value to the average cost of a damaged pallet. By virtually eliminating in-rack damage, the savings quickly add up, protecting your profit margins. This alone can justify the investment in a high-quality push back racking for sale.

Energy and Overhead Savings: A smaller, more efficient warehouse footprint means lower costs for lighting, heating, and cooling. These ongoing operational savings contribute to the payback period of your push back racking for sale.

Improved Inventory Accuracy and Turnover: Better organization leads to fewer lost pallets and more accurate inventory counts. Faster, more efficient operations can improve your overall inventory turnover ratio, freeing up working capital. This improved asset utilization is a powerful indirect benefit of the push back racking for sale.

Professional providers provide detailed ROI models with their quotes for a push back racking for sale, translating the engineering benefits into clear, hard financial language for your executive team.

Why Partner With a Expert for Your Push Back Racking Solution?

In a crowded market, choosing the right partner for your push back racking for sale is as important as choosing the right system. Here’s what sets industry leaders apart:

Direct Manufacturer Expertise: They are not just distributors; they are engineers and manufacturers. This gives them complete control over quality, cost, and lead times, and allows them to offer custom solutions without the markup of a middleman. This direct relationship ensures the push back racking for sale is built to exact specifications.

Holistic Warehouse Vision: They don’t just see racking. They see your entire operation. Their experts can advise on how the push back racking for sale integrates with your pallet racking, mezzanine floors, and conveyor systems to create a perfectly synchronized ecosystem.

Unmatched Project Management: From the initial call to the final bolt tightening, a dedicated project manager ensures everything stays on schedule and on budget. Transparent communication throughout the process of your push back racking for sale project is a hallmark of quality service.

Proven Track Record: Their systems are operating flawlessly in hundreds of facilities across the globe, from small cold storage operations to massive e-commerce fulfillment centers for Fortune 500 companies. This proven experience is crucial when selecting a supplier for your push back racking for sale.

The Guarantee of Quality: Their systems are backed by robust warranties and the peace of mind that comes from working with an industry leader committed to your long-term success. The warranty terms should be a key factor in your decision for a push back racking for sale.

Conclusion: Transform Your Warehouse Potential into Reality

The challenge of warehouse space is universal, but the solution is not one-size-fits-all. Push back racking systems represent a uniquely powerful compromise, offering a rare combination of high-density storage and excellent accessibility. They are a proven, reliable, and intelligent way to unleash the full potential of your existing facility, driving down costs and supercharging efficiency.

Understanding the intricacies of the system—from its LIFO mechanics to its critical quality differentiators—is the first step toward making an informed investment. This investment is not merely in steel and hardware; it is an investment in the future-proofing of your logistics operation, paving the way for higher throughput, greater safety, and seamless integration with automation technologies.

The journey to a more efficient warehouse begins with a conversation. The knowledge has been provided; the next step is action. Let experts translate your specific data and challenges into a customized layout design that proves the value on paper. Get your free, no-obligation quote and custom layout design today and take the first concrete step toward maximizing your storage density and operational efficiency with a tailored push back racking for sale solution.

Frequently Asked Questions (FAQs)

1. What is the typical lead time for manufacturing and installing a push back racking system?

Lead times can vary based on the project’s scale and complexity, as well as current manufacturing schedules. Typically, from the final sign-off on the design, manufacturing takes approximately 4-6 weeks. Installation is then scheduled and can take from a few days to a couple of weeks, depending on the system’s size. A detailed project timeline should be provided with every quote for a push back racking for sale.

2. Can push back racking be used in cold storage or freezer environments?

Absolutely. However, it requires specific engineering considerations. Special-grade steel and lubricants that remain functional at extremely low temperatures must be used to prevent brittleness and ensure the carts and wheels operate smoothly. The design must also account for the added weight of ice buildup on pallets. This is a key customization for a push back racking for sale intended for cold environments.

3. How do we handle maintenance or if a cart gets jammed or damaged?

Maintenance is generally minimal. The systems are designed for durability. In the rare event of a jam or damage, the carts are designed to be serviced from the aisleway. They can often be easily replaced by a trained technician without having to unload the entire lane, minimizing downtime. Inquire about maintenance packages and spare parts availability when considering a push back racking for sale.

4. Is push back racking compatible with any type of pallet?

While highly versatile, it works best with standard, well-constructed wooden or plastic pallets. Pallets must be in good condition, as damaged or misshapen pallets can cause jams. Non-standard pallets (e.g., slip sheets, very small pallets) require a special engineering review to ensure compatibility with the cart design and width. Discuss your pallet specs with your provider before finalizing your push back racking for sale.

5. How does the cost of push back racking compare to other high-density systems like drive-in or pallet flow?

Push back racking typically has a higher initial cost per pallet position than drive-in/drive-through racking due to its more complex components (carts, rails). However, it offers significant operational advantages like better selectivity and safety, which often provide a better long-term ROI. It is generally less expensive than a fully automated pallet flow (live storage) system, positioning a push back racking for sale as a cost-effective mid-point solution for LIFO applications.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com